Drum-type tea processing equipment

A kind of processing equipment, drum-type technology, applied in the field of drum-type tea processing equipment, can solve the problems of difficult transportation and installation, large waste of resources, environmental pollution, etc., and achieve the effects of strong process adjustment ability, uniform internal and external temperature, and reduced bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

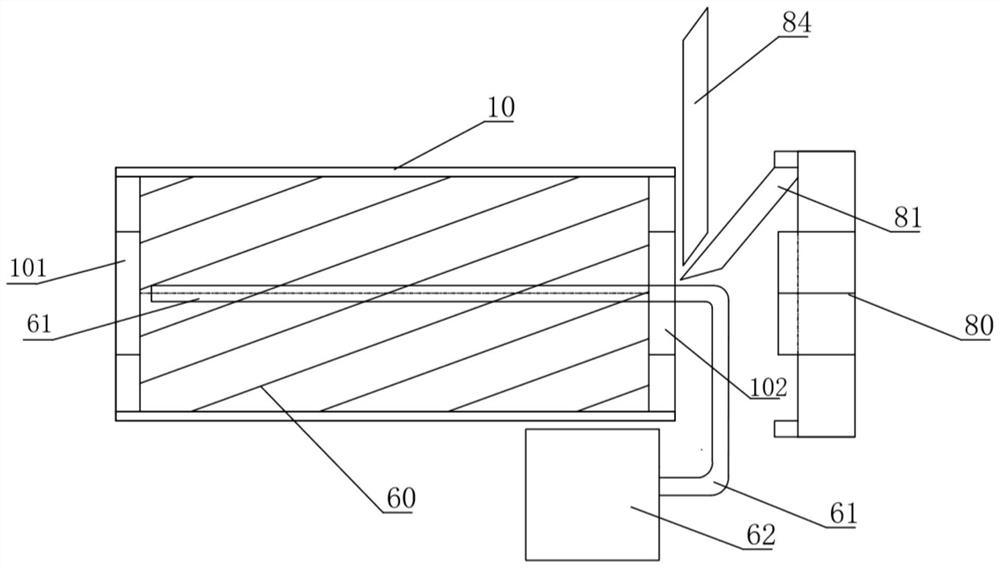

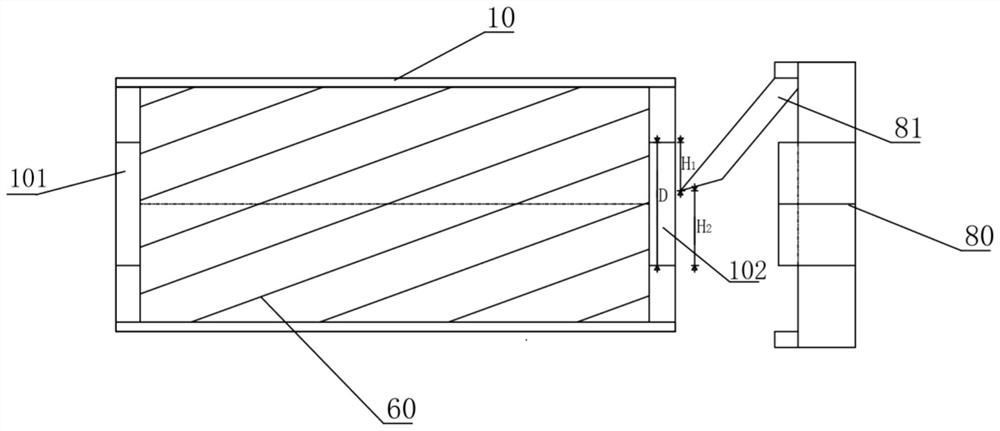

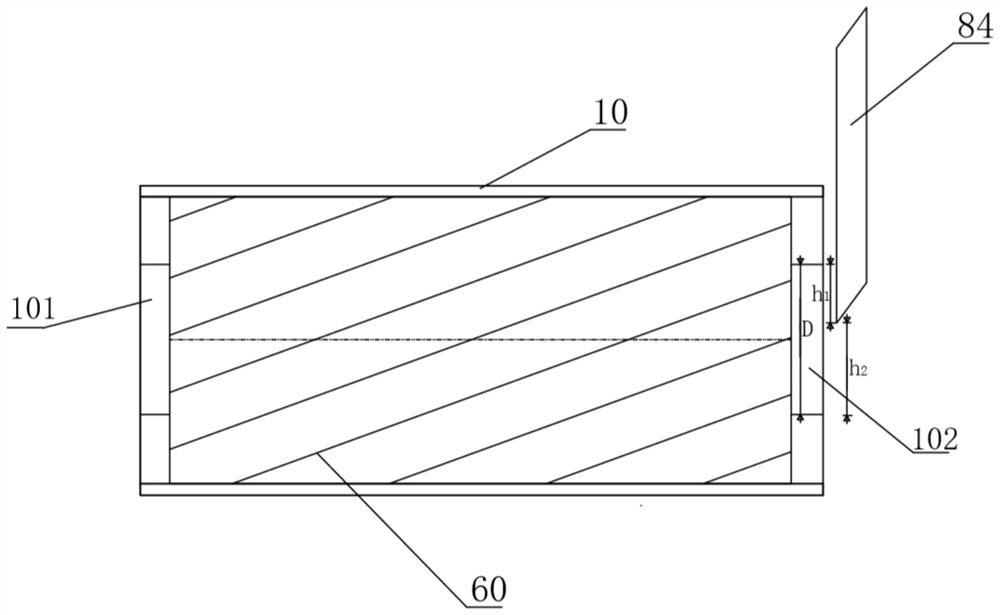

[0057] Such as Figure 1-9 Shown: the present invention provides a specific embodiment of a drum-type tea processing equipment, including a drum 10, the outer wall of the drum 10 is wrapped with a heat insulating layer and an insulating layer from the inside to the outside, and the insulating layer on the outer wall of the drum 10 A stepped intermittent electromagnetic induction heating system for intermittently heating the drum 10 is also installed on the outer surface, and 6 to 8 vane guides 60 are installed at equal intervals on the inner wall of the drum 10 . The feed port 101 extends continuously to the discharge port 102 of the drum 10;

[0058] The guide vanes 60 have a spiral structure, and each guide vane 60 forms an included angle of 15°-19° with the axial direction of the drum 10;

[0059] The adjustment range of the installation inclination angle of the drum 10 is -5°~+8°, specifically: when the drum 10 is in a state of high front and low rear, a maximum inclinati...

Embodiment 2

[0091] Such as Figure 1-9 Shown: the present invention provides a specific embodiment of a novel high-efficiency and energy-saving drum-type tea processing equipment,

[0092] Including the drum 10, the outer wall of the drum 10 is wrapped with a heat insulation layer and a thermal insulation layer in turn from the inside to the outside, and a stepped intermittent electric heater for intermittently heating the drum 10 is also installed on the outer side of the thermal insulation layer on the outer wall of the drum 10. Magnetic induction heating system, and an air intake and dehumidification system for inputting hot air into the drum 10 to discharge moisture; the stepped intermittent electromagnetic induction heating system can stably control the temperature inside the drum 10 at 250°C to 280°C;

[0093] On the inner wall of the drum 10, 6 to 8 guide vane plates 60 are equidistantly installed, and these guide vane plates 60 extend continuously from the feed inlet 101 of the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com