A direct buried heat preservation and anticorrosion expansion joint

An expansion joint, directly buried technology, applied in the field of directly buried thermal insulation and anti-corrosion expansion joints, can solve the problem of reducing the safety quality and operating life of corrugated expansion joints, limiting the use range of directly buried corrugated expansion joints, and reducing the thermal efficiency of directly buried heating pipes. and other problems, to achieve the effects of small internal stress, improved service life and reduced heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

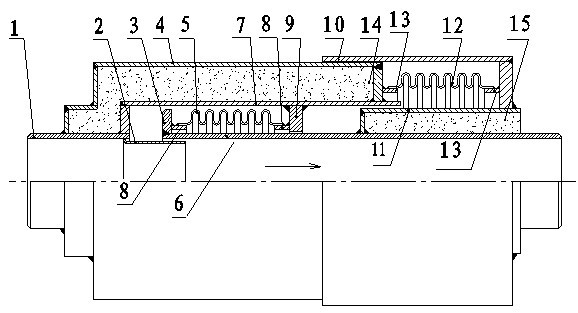

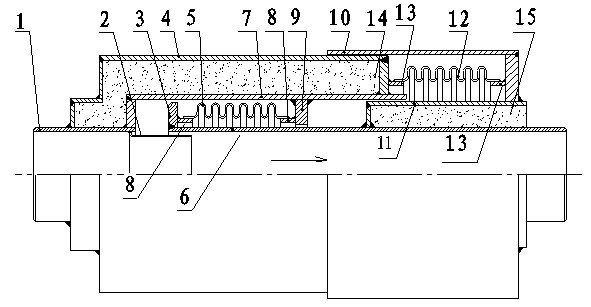

[0011] see figure 1 , the present invention includes an end pipe 1, a guide tube 2, a through pipe 6, a working bellows 5, an anti-corrosion bellows 12, a pressure-bearing isolation cover 7, a first protective cover 4, a second protective cover 10, a guide isolation cover 11, Work takeover 8, anticorrosion takeover 13, etc. Among them, the components that complete the medium conveying function include the end pipe 1, the guide tube 2, the through pipe 6, etc.; the components that complete the displacement compensation function include the working bellows 5, the working connection 8, the anti-corrosion bellows 12, the guide isolation cover 11, the anti-corrosion Bellows 12, anti-corrosion connecting pipe 13, etc.; components that complete the heat preservation function include the first heat-insulation material layer 14 and a second heat-insulation material layer 15; components that complete the anti-corrosion function include the first protective cover 4 and the second protect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com