Double-P type radiant tube and manufacture method thereof

A manufacturing method and technology of radiant tubes, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve the problems of low heat energy utilization rate, high cost, and heavy radiant tube weight, so as to improve heat transfer efficiency, save construction costs, save The effect of heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the shape, structure and characteristics of the present invention, preferred embodiments will be listed below and described in detail with reference to the accompanying drawings.

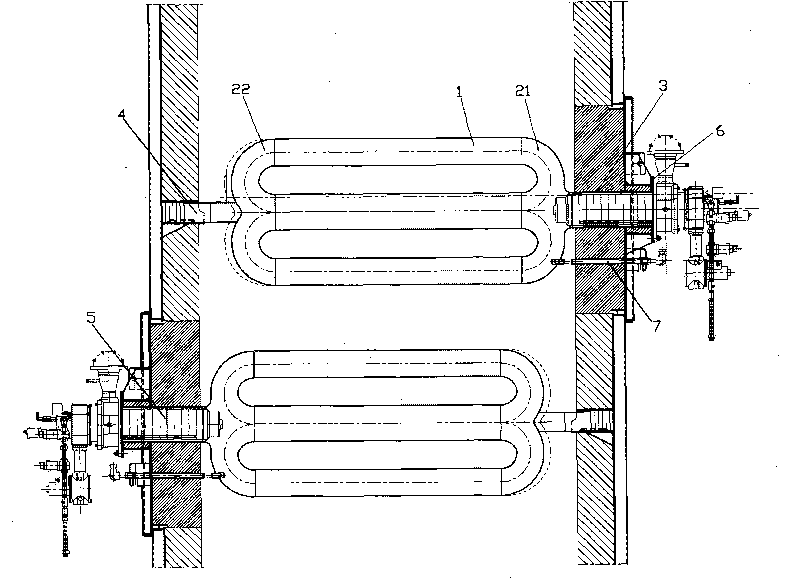

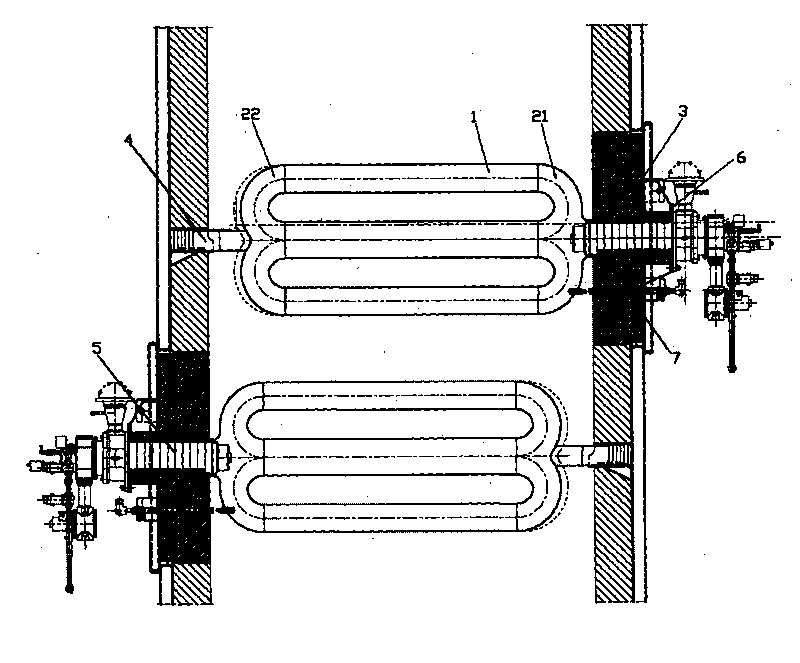

[0031] The double P-type radiant tube of the present invention is installed in the heat treatment furnace, and the two ends are fixed on the furnace wall of the heat treatment furnace. The inner side of the furnace wall is made of insulation cotton made of ceramic fiber blanket and other materials to play the role of fire prevention and heat preservation. The outer side of the furnace wall is a furnace shell made of steel plate, which can fix and support the furnace body. figure 1 It is a structural schematic diagram of the double P-type radiant tube of the present invention, as shown in the figure, it mainly includes three straight tubes 1 arranged in parallel, and two curved tubes 21 and 22 are welded symmetrically at both ends of the straight tube 1 . As shown...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com