Open type hot runner injection mold device

An open hot runner injection molding technology, applied in the field of preform injection molds, can solve the problems of loose hot runner, long hot runner, glue leakage, etc., achieve improved sealing effect, precise temperature control, and solve the effect of whitening and drawing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

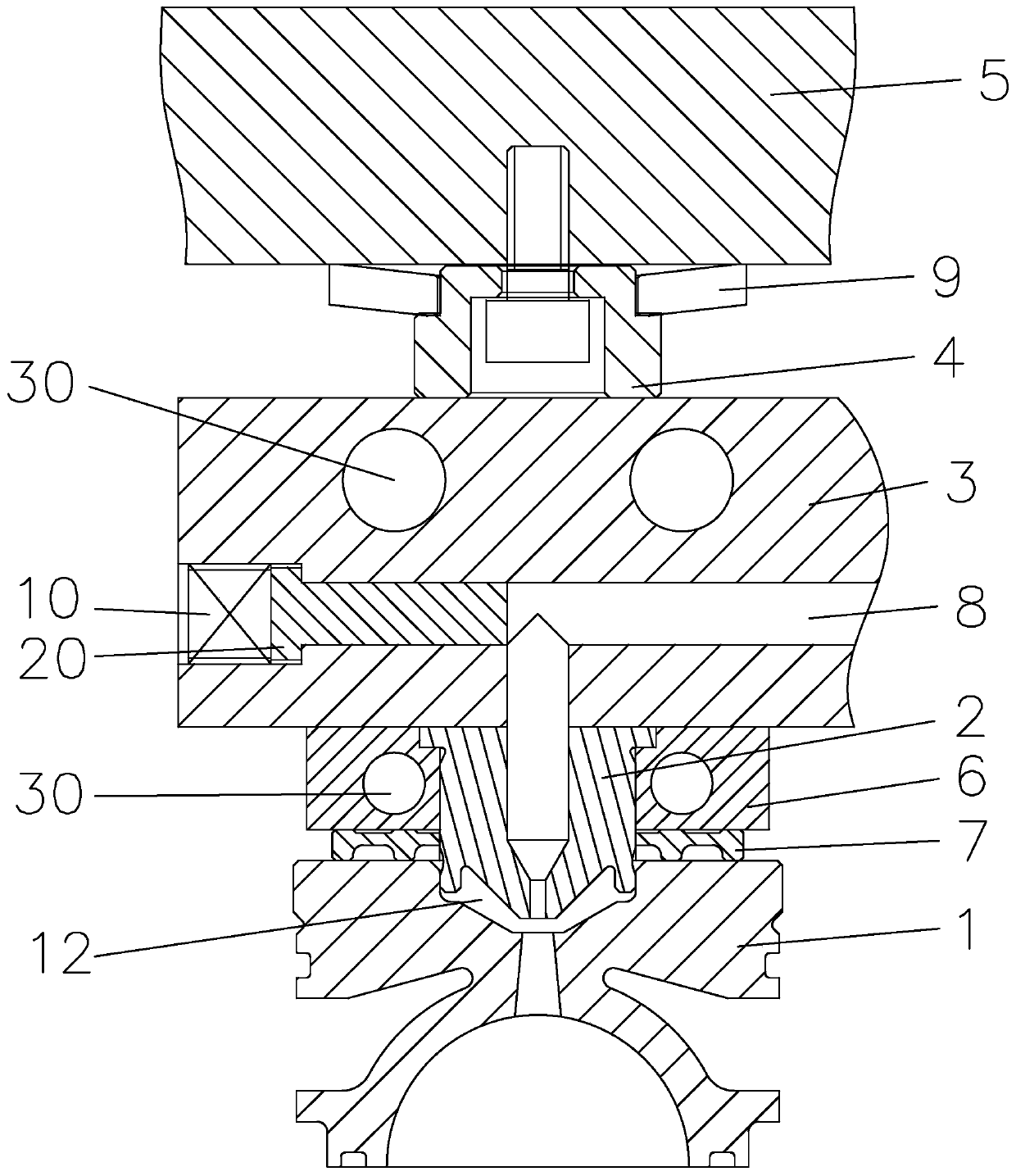

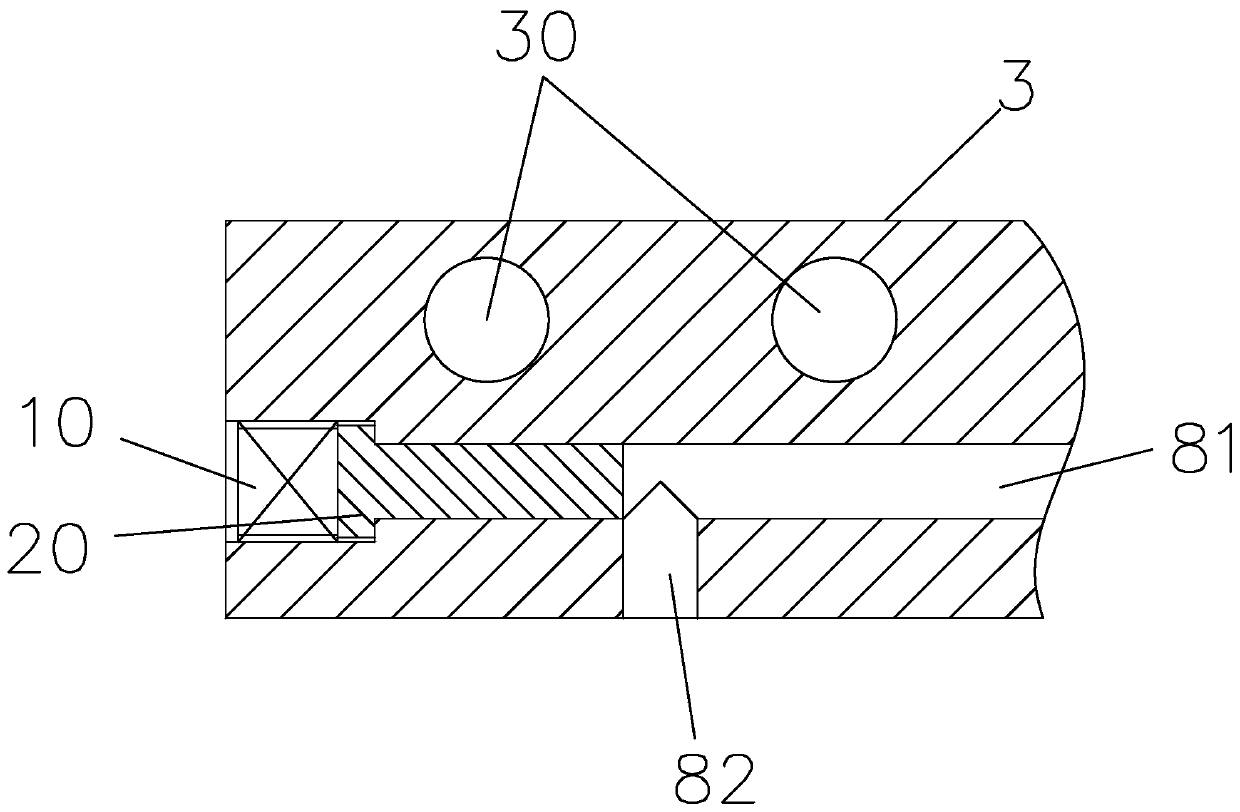

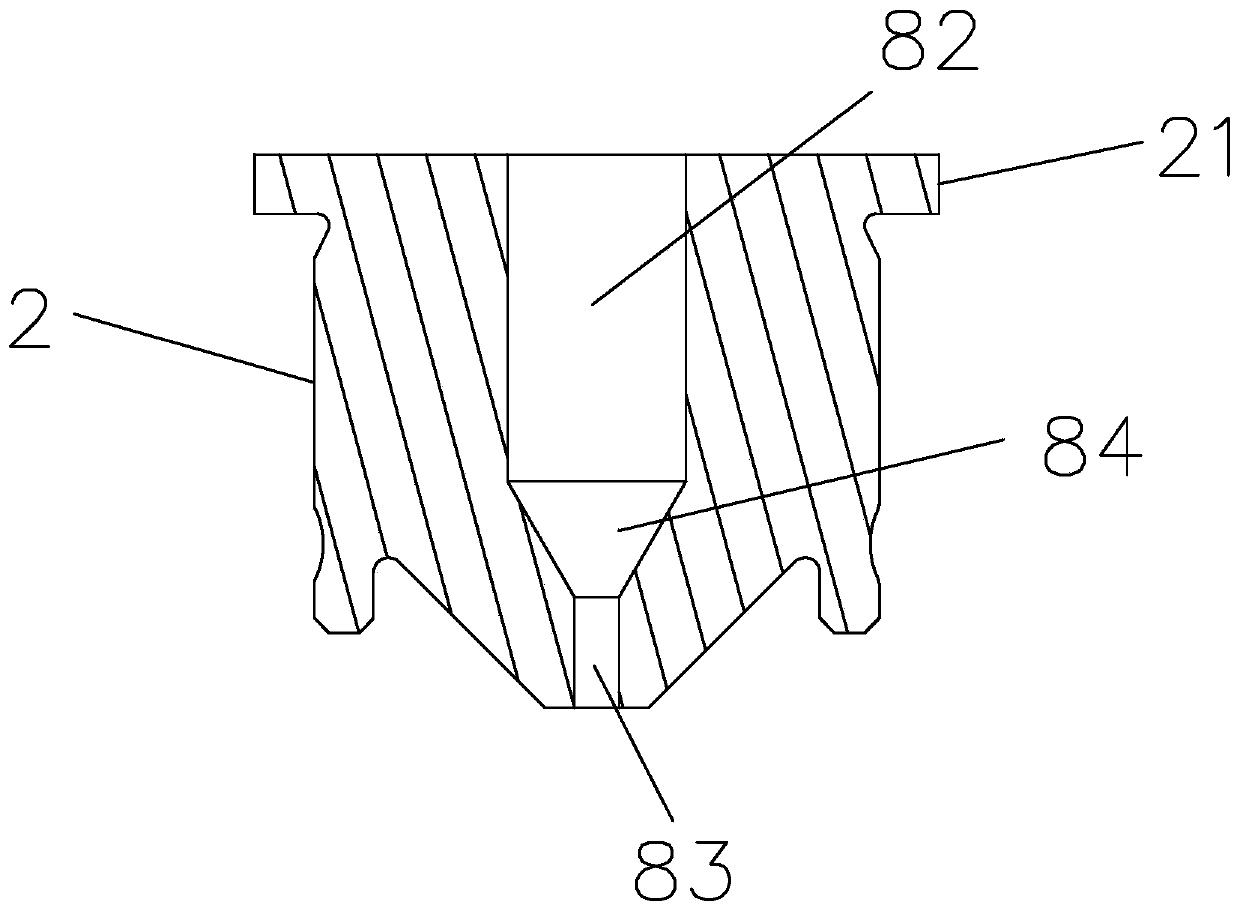

[0034] This embodiment discloses an open hot runner injection mold device. The mold cavity 1, nozzle 2, hot runner plate 3, support ring 4 and back plate 5 are installed sequentially from bottom to top. There is a heating plate 6 and a heat insulating gasket 7, the heating plate 6 and the heat insulating gasket 7 are sleeved on the outer wall of the nozzle 2, the mold cavity 1 is separated from the heating plate 6 by the heat insulating gasket 7, and the heat flow A hot runner 8 is provided inside the channel plate 3 and the nozzle 2, and the hot runner 8 passes through the hot runner plate 3 and the nozzle 2 to connect to the mold cavity 1 in turn, and the outer side of the support ring 4 is sleeved with a spring washer 9 , one end of the spring washer 9 is connected to the support ring 4 , and the other end is connected to the back plate 5 . The hot runner 8 includes a main channel 81, a runner 82 and a gate 83, the main channel 81 is arranged on the hot runner plate 3, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com