Multiphase reaction process using microchannel technology

A multiphase reaction and microchannel technology, applied in chemical methods, organic chemical methods, chemical instruments and methods for reacting liquids and gaseous media, to achieve effective mixing of reactants, precise temperature control, and effective mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

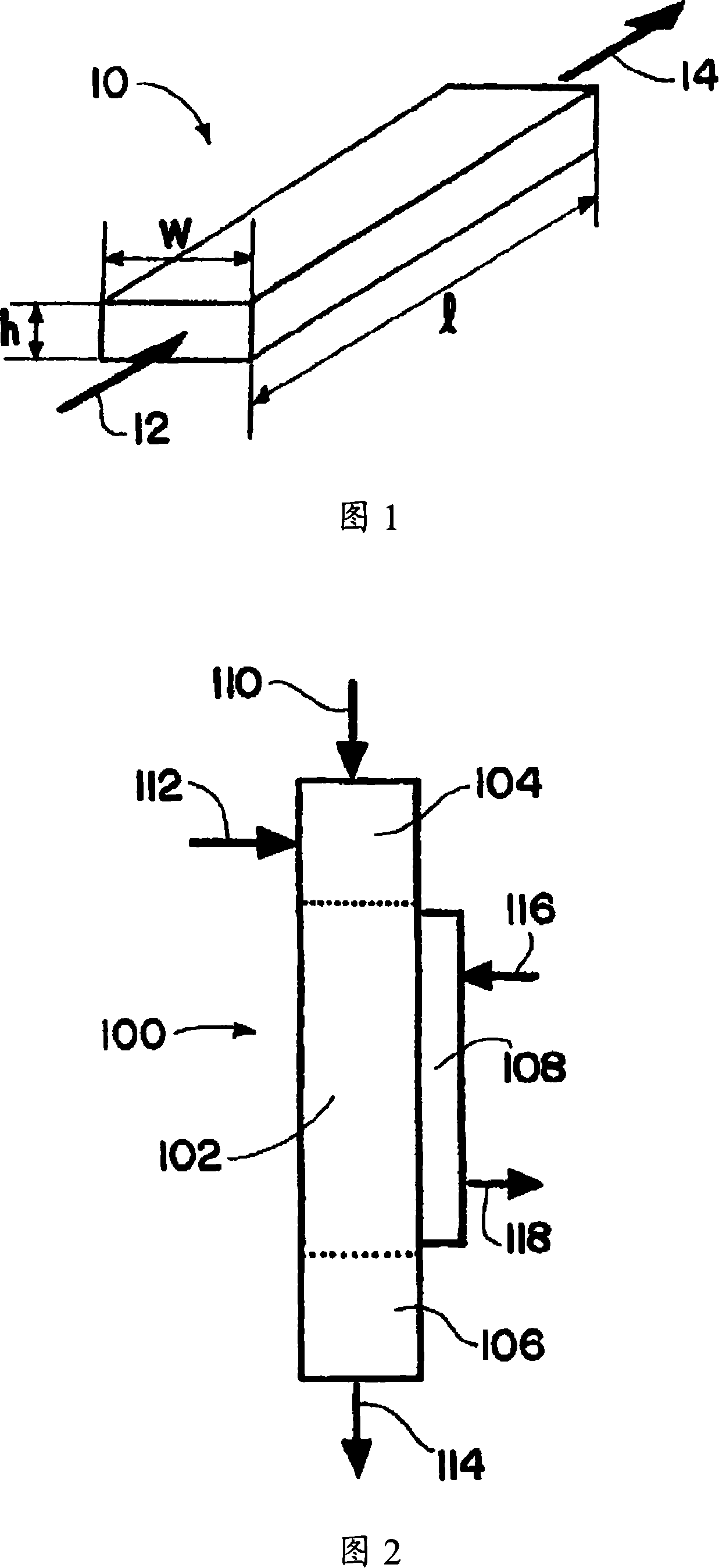

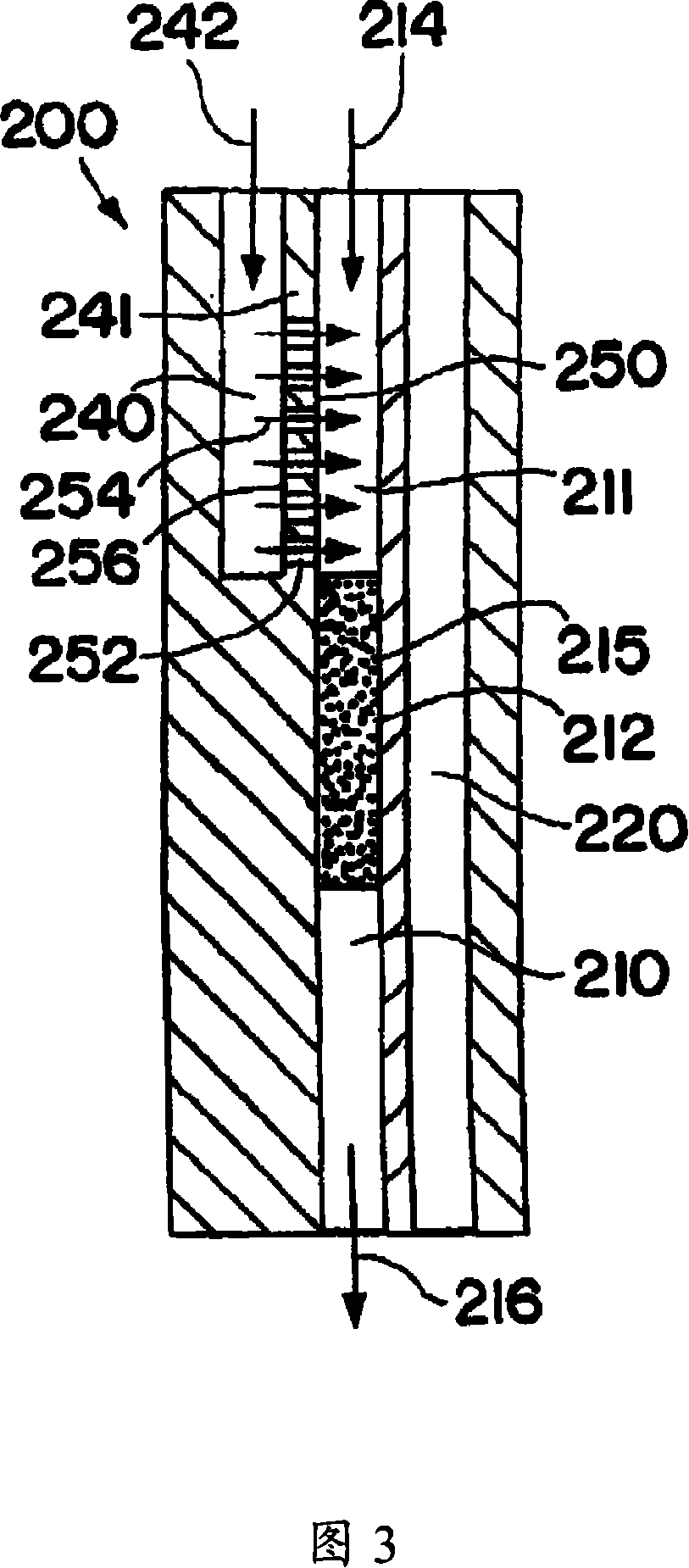

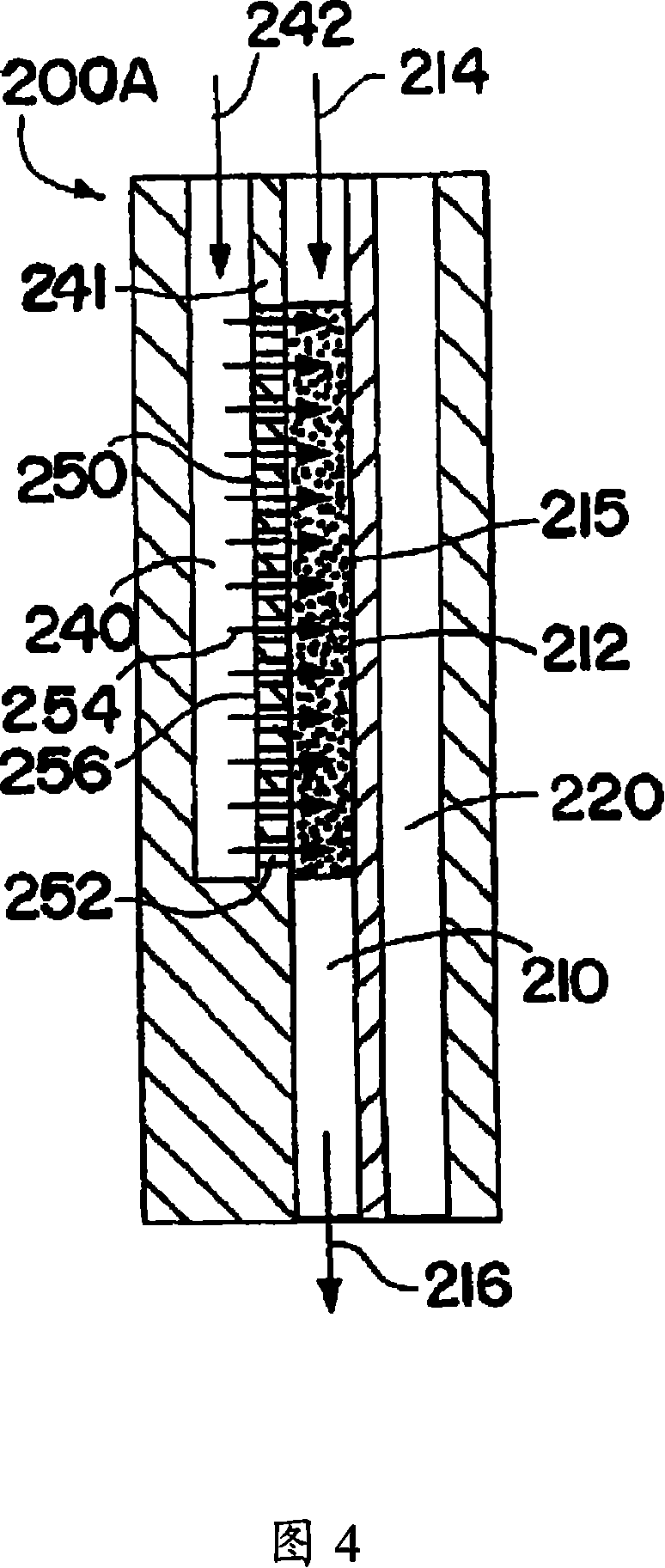

[0232] A microchannel reactor comprising an acrylic process microchannel with a rectangular cross-section and internal dimensions of 0.040 x 1.25 x 3 inches (1.02 x 31.75 x 76.2 mm) was fabricated. There is an apertured region in one sidewall of the process microchannel. The apertured region has a nominal pore or pore diameter size of 0.1 microns and dimensions of 0.010 x 1 x 1.5 inches (0.254 x 25.4 x 38.1 mm). The perforated area was constructed of stainless steel 316L and was supplied by Mott Company of Farmington, CT under catalog number 1110-12-12-018-01-A. The perforated area is connected with a gas distribution gas filling system and pipelines to allow gas to flow through the perforated area into the process microchannel. Palladium black and the catalyst in the form of nano-sized particles were dispersed on the inner walls of the process microchannels using carbon black as a dispersion / binder. The process microchannels are connected with tubing to allow liquid to flow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com