Grain drying process and drying equipment

A technology of grain drying and drying equipment, which is applied in the direction of grain drying, drying solid materials, and dry cargo handling, etc. It can solve the problems of high cost and high height of the dryer, and achieve the effects of improving quality, reducing burnt rate, and reducing height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

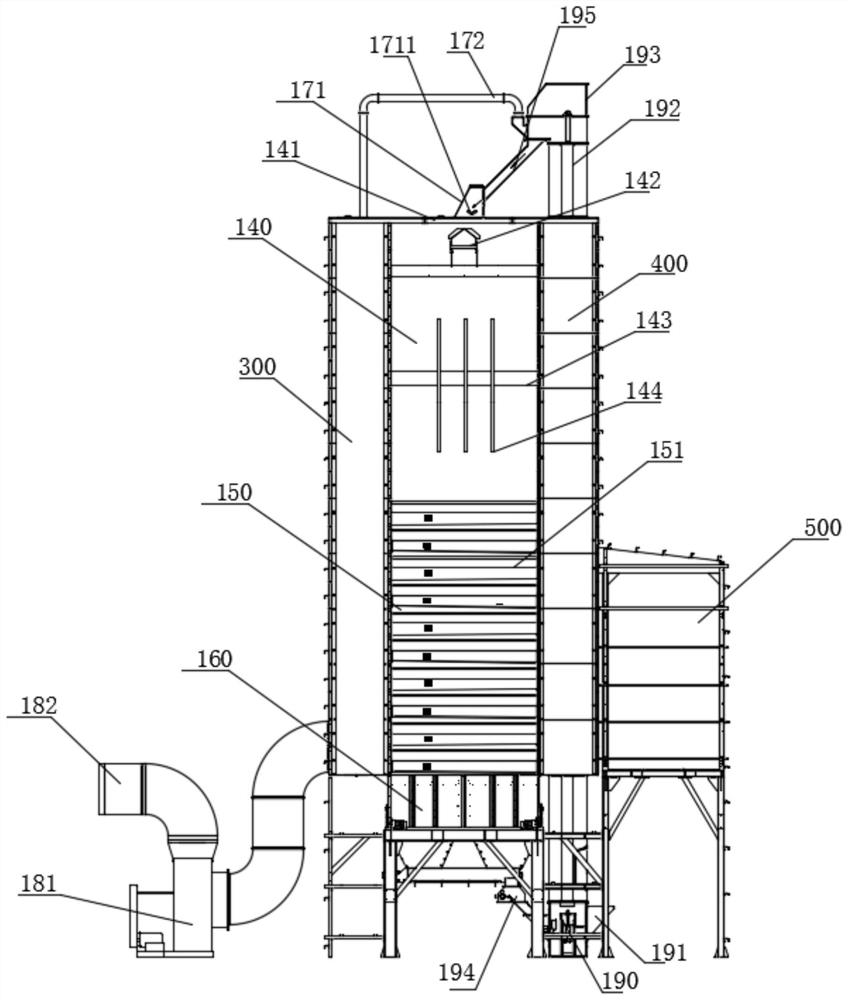

[0029] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

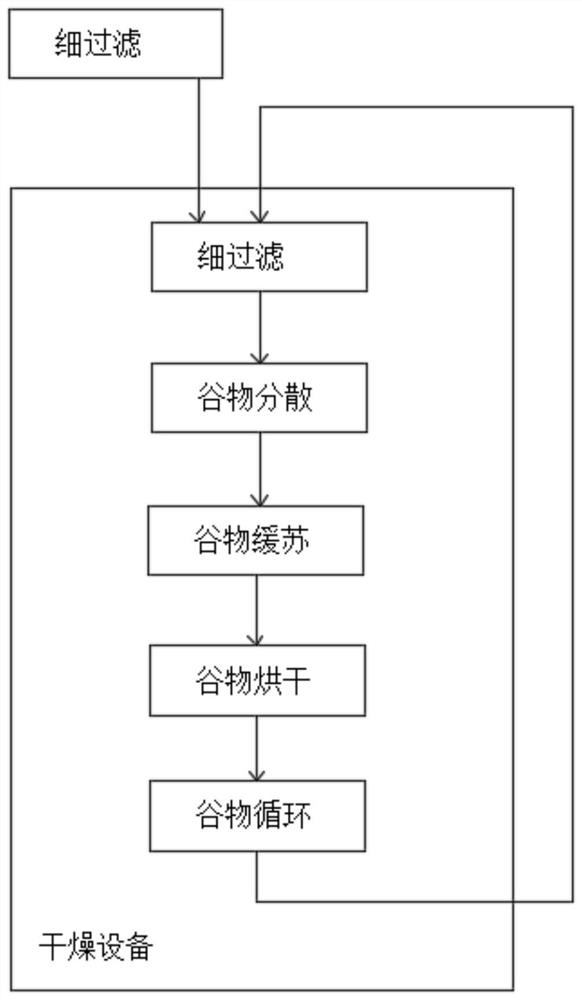

[0030] refer to figure 1 Shown, the present invention provides a kind of grain drying process, comprises the following steps:

[0031] Preliminary filtration, using a screening and impurity removal device to remove heavy gravel impurities in the grain;

[0032] Fine filtration, the grain enters the drying equipment to remove dust and broken shell impurities;

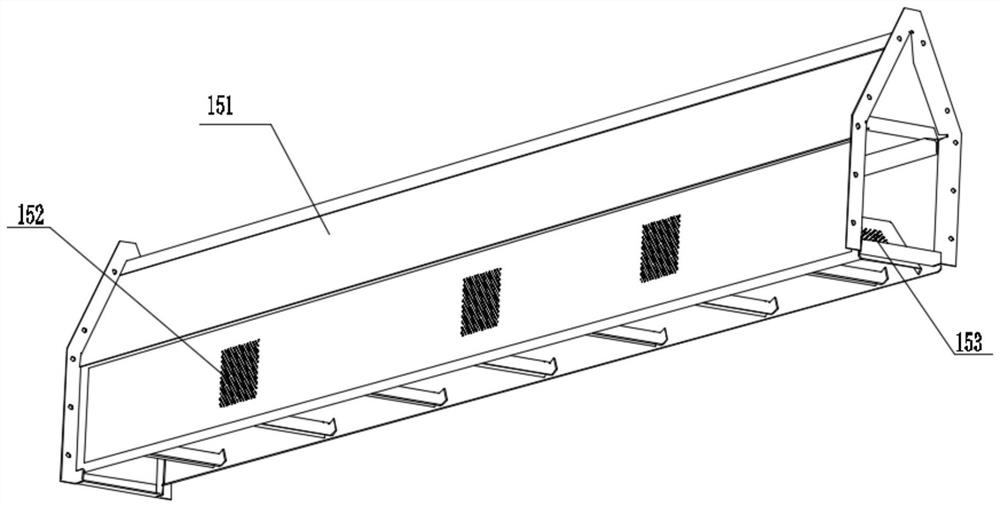

[0033] Grain dispersal, the grain passes through the inside of the drying equipment to disperse the grain evenly and prevent it from forming a grain mass;

[0034] Grain slowing, the slowing process is carried out on the grains, and the slowing process keeps the grains in a non-ventilated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com