Still kettle quick accumulated residual steam accumulated energy circulating device and method

A technology of circulation device and energy storage device, which is applied to direct contact heat exchangers, fixed conduit components, lighting and heating equipment, etc., can solve the problems of the influence of the green body quality, the large volume of the autoclave, and the waste of heat resources. Achieve the effect of high heat recovery and utilization efficiency, short steam exhaust time, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

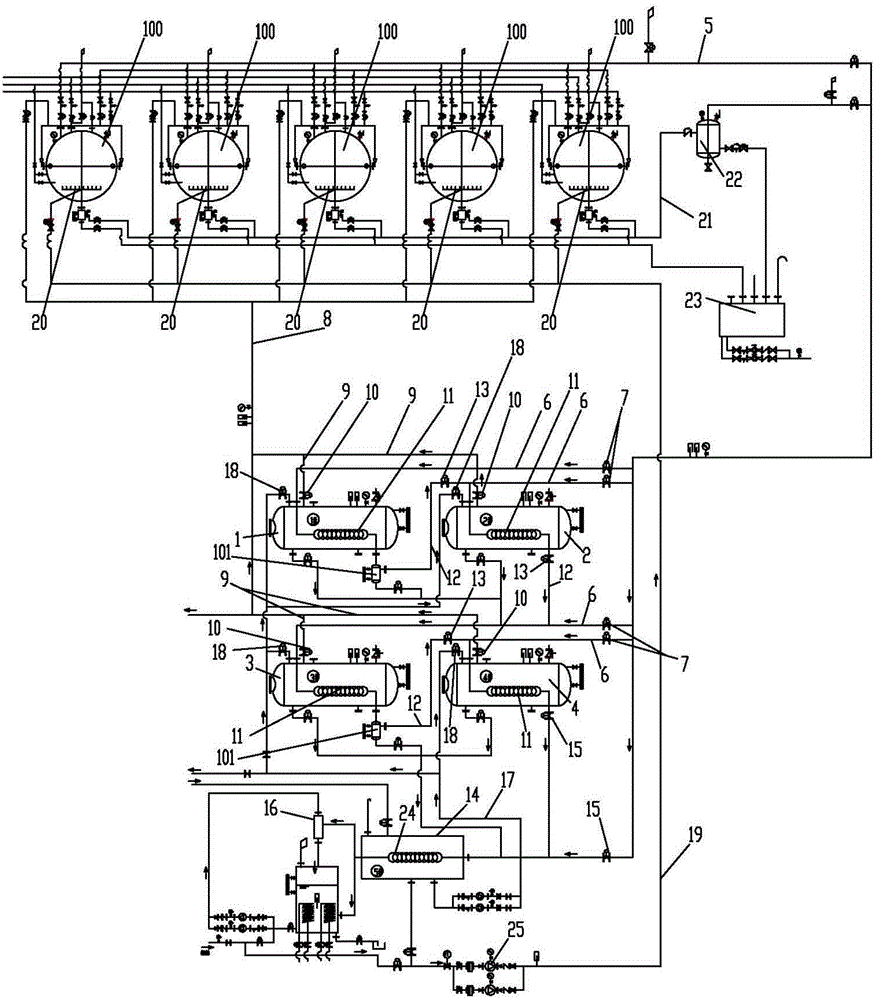

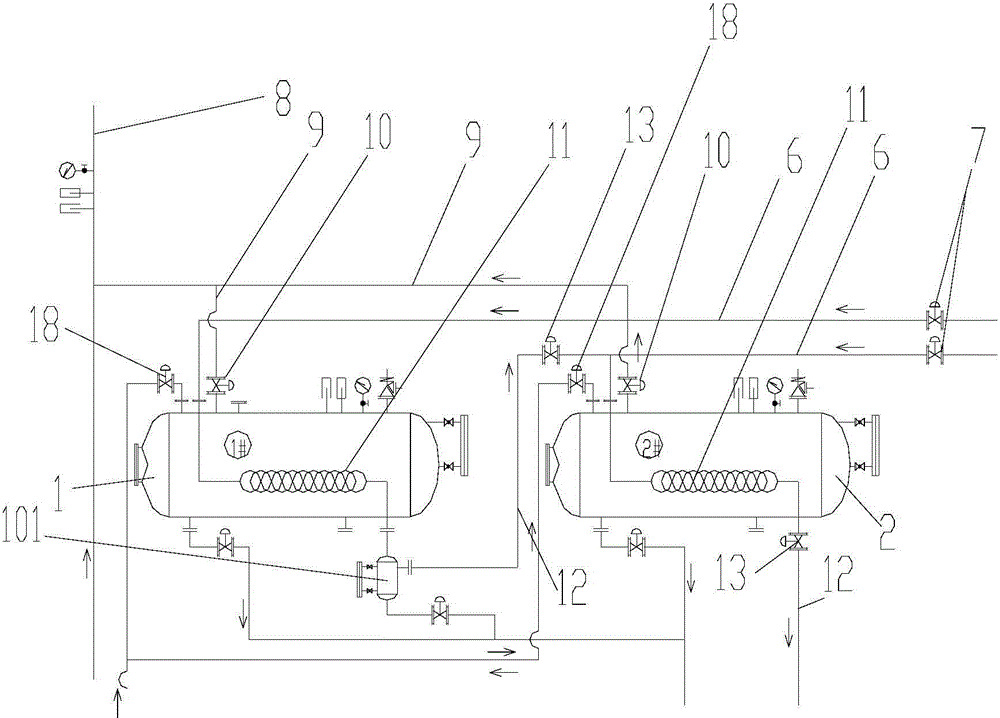

[0051] see figure 1 , the autoclave rapid accumulation type residual vapor energy storage circulation device includes an energy storage device communicated with the autoclave 100, and the energy storage device includes a first-stage energy storage container 1 and a second-stage energy storage container 2; in this implementation Also include the third stage energy storage container 3 and the fourth stage energy storage container 4 in the example, the quantity of energy storage container can be set according to need; The first stage energy storage container 1, the second stage energy storage container 2, the third stage The steam inlet ends of the energy storage container 3 and the fourth-stage energy storage container 4 are respectively communicated with the exhaust ends of a plurality of autoclaves 100 through exhaust pipes, and the first-stage energy storage container 1, the second-stage energy storage container 2, The steam outlet ends of the third-stage energy storage conta...

Embodiment 2

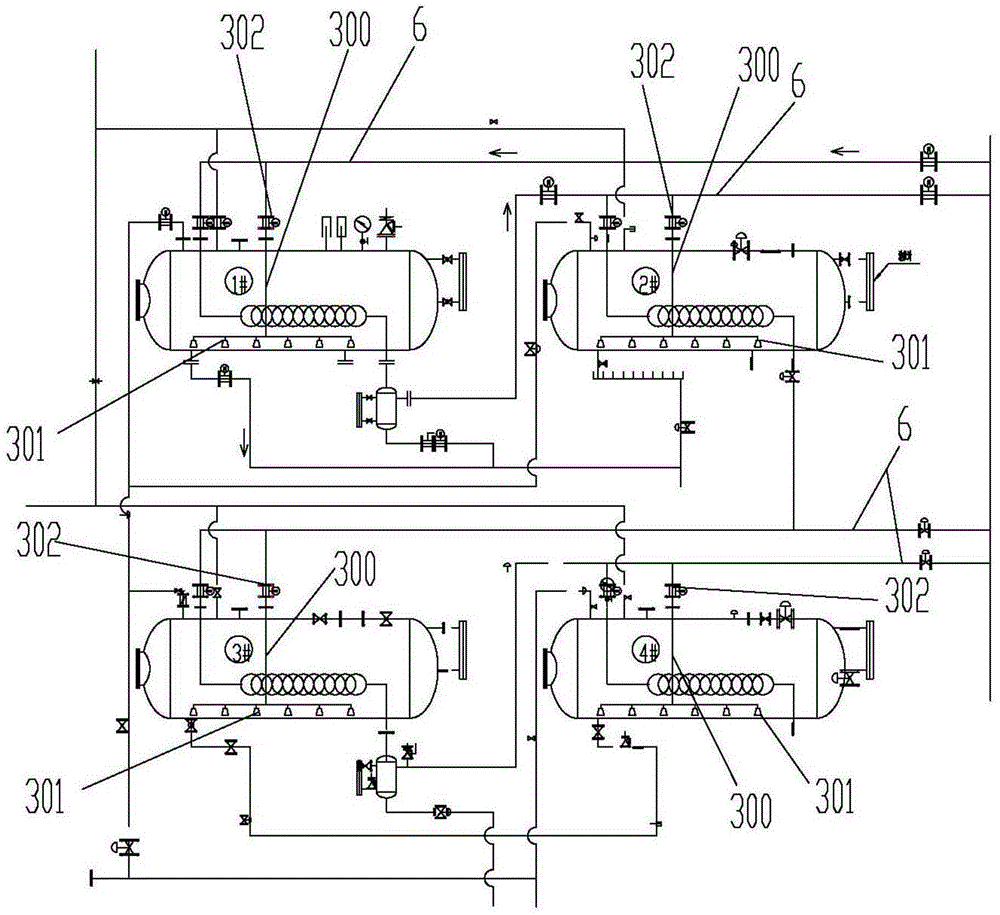

[0060] In the first-stage energy storage container, the second-stage energy storage container, the third-stage energy storage container, and the fourth-stage energy storage container, there is also a steam direct charging structure, which includes steam distribution pipes in each stage of energy storage container 300, a plurality of steam nozzles 301 are communicated on the steam distribution pipe, and one end of the steam distribution pipe extends through the energy storage container to the outside to communicate with the exhaust branch pipe 6 of each stage of energy storage container and is provided with a control valve 302; the advantage of this is The steam discharged from the autoclave can directly enter each energy storage container through the steam distribution pipe and the steam nozzle, and the steam is directly recovered.

Embodiment 3

[0062] Heating devices can also be respectively arranged in the first-stage energy storage container, the second-stage energy storage container, the third-stage energy storage container, and the fourth-stage energy storage container, and the heating device heats the liquid medium in the energy storage container, To generate steam, the heating device here can coexist with the above-mentioned flow pipe heating method, and can also be used to replace the flow pipe heating method; if this heating device is used to replace the flow pipe heating method, the energy storage container of the next stage The series pipeline of the energy storage container needs to be communicated with the steam outlet of the upper stage energy storage container. The heating device here can be realized by electric heating, steam heating and the like.

[0063] The above three embodiments of the autoclave rapid accumulation type residual vapor energy storage circulation device can be implemented separately,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com