Coating roller of roller coater

A technology of coating roller and roller coater, which is applied to the device for coating liquid on the surface, coating and other directions, can solve the problems of uneven surface temperature of coating roller, difficult heat dissipation of heating elements, and easy damage of heating elements, etc. The effect of fast heat conduction, quality improvement and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

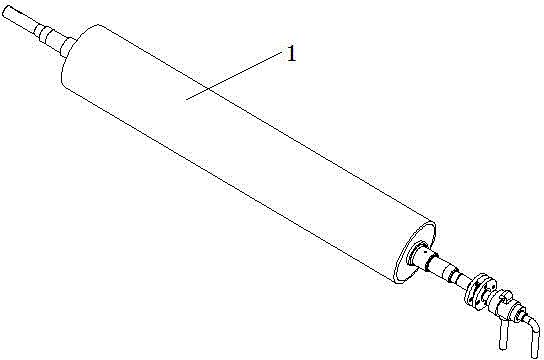

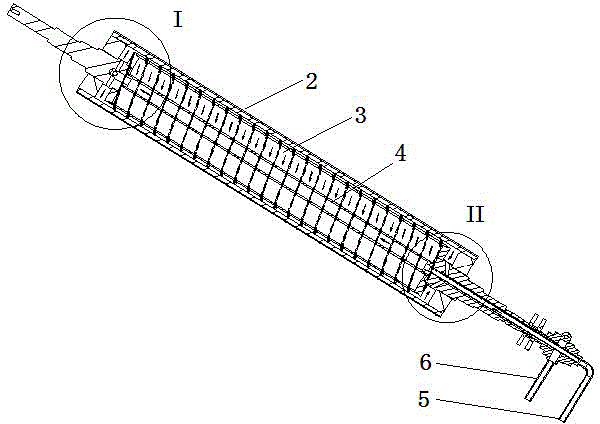

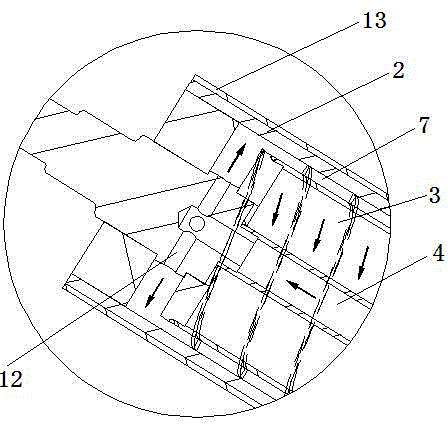

[0022] Example: as attached figure 1 , with figure 2 , with image 3 And attached Figure 4 As shown, a coating roller for a roll coater includes a roll body 1, the roll body includes a roll shell 2 and a roll core 3, the roll shell and the roll core are nested with each other, the center of the roll core is penetrated to form a central passage 4, and the roll core The outer surface is provided with a double helix thread, the outer surface of the roller core cooperates with the inner surface of the roller shell to form a double helical channel 7, and one end of the roller body is provided with an inlet pipe 8 and an outlet pipe 9, and the inlet pipe and the outlet pipe are concentric Pipe, the input pipe is the input channel 10, the output channel 11 is formed between the introduction pipe and the output pipe, the input channel is connected to the central channel, the output channel is connected to the double helix channel, and the other end of the roller body is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com