Gas laser device

一种气体激光、排气装置的技术,应用在激光器、激光器零部件、电气元件等方向,能够解决激光加工作业效率恶化、花费时间等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

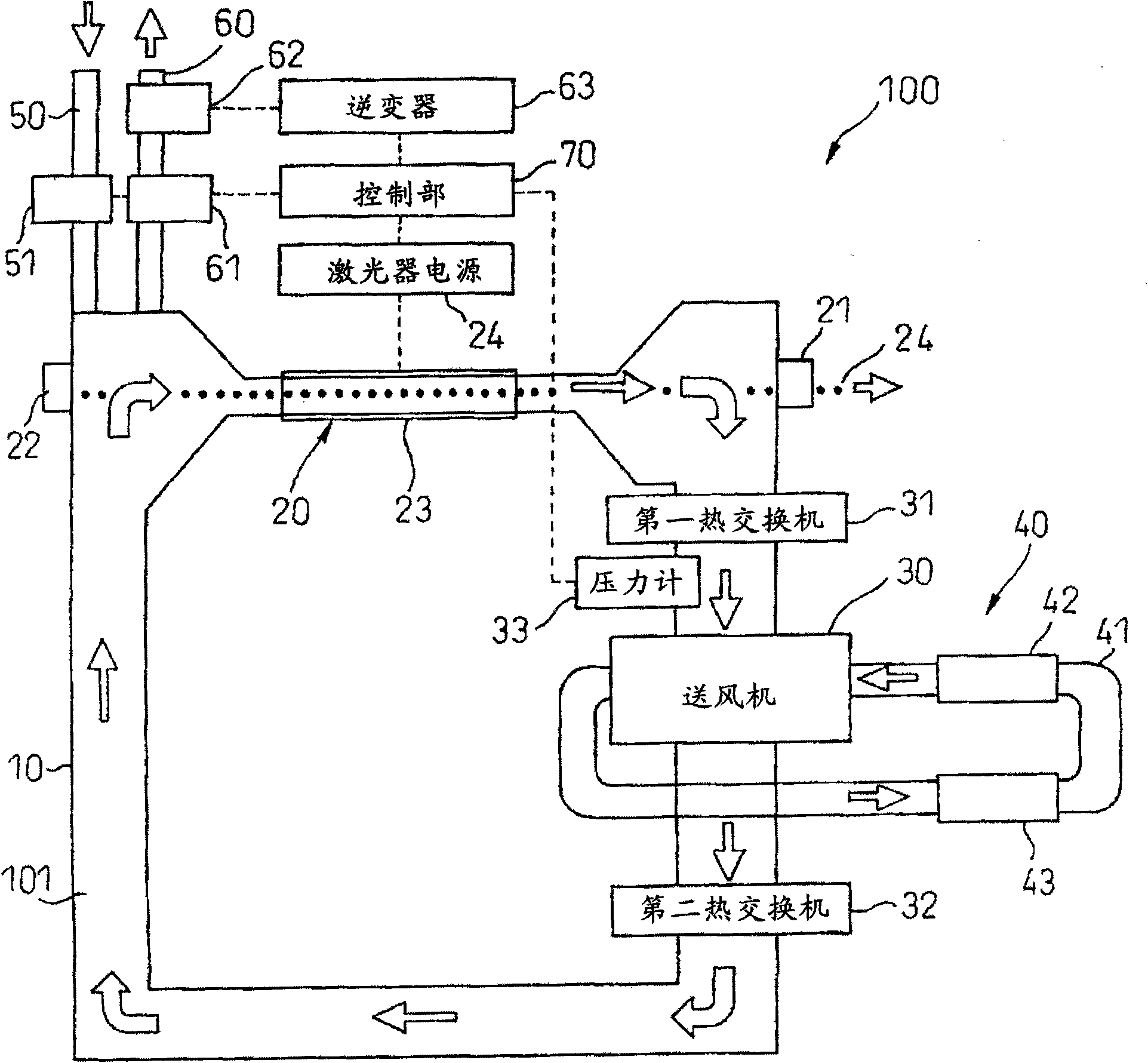

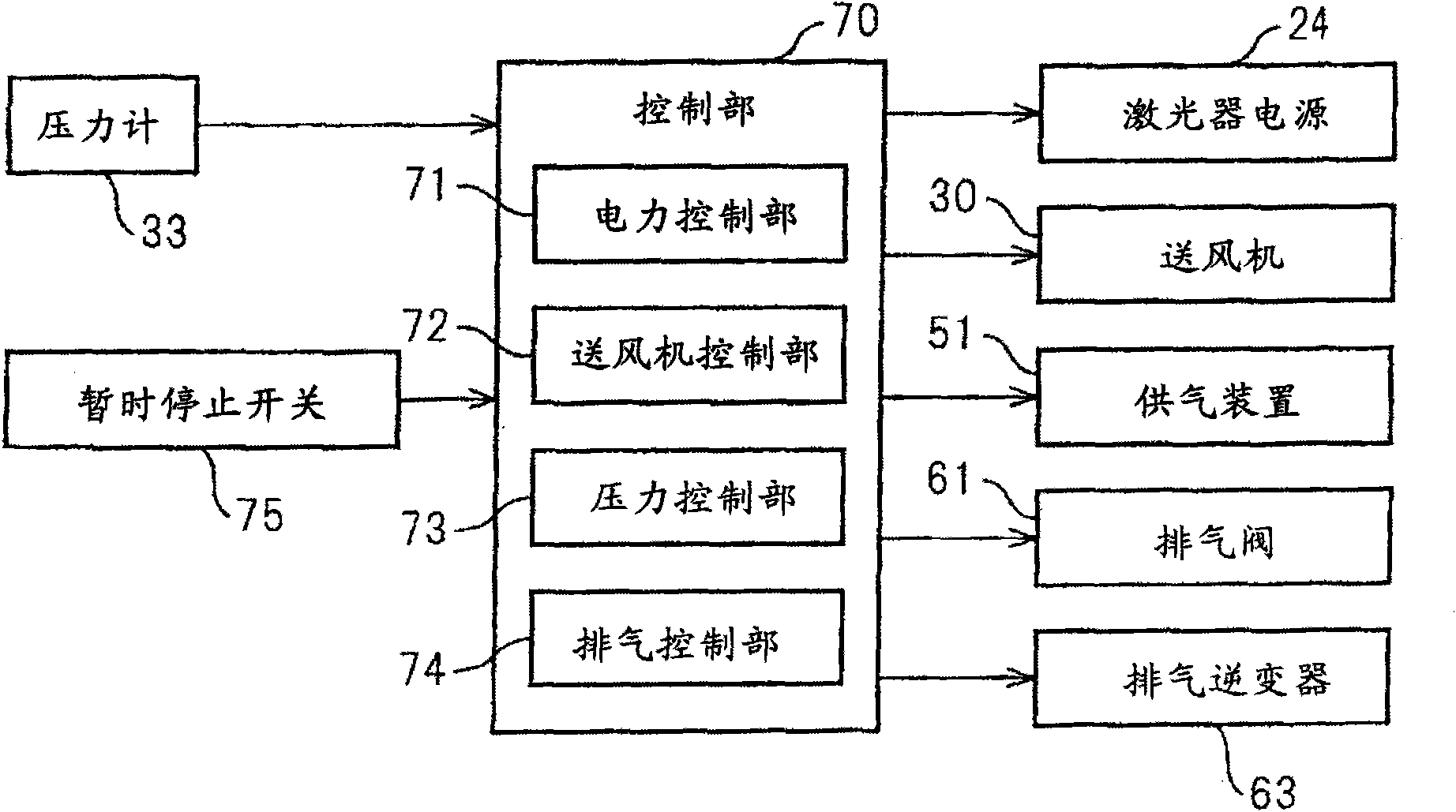

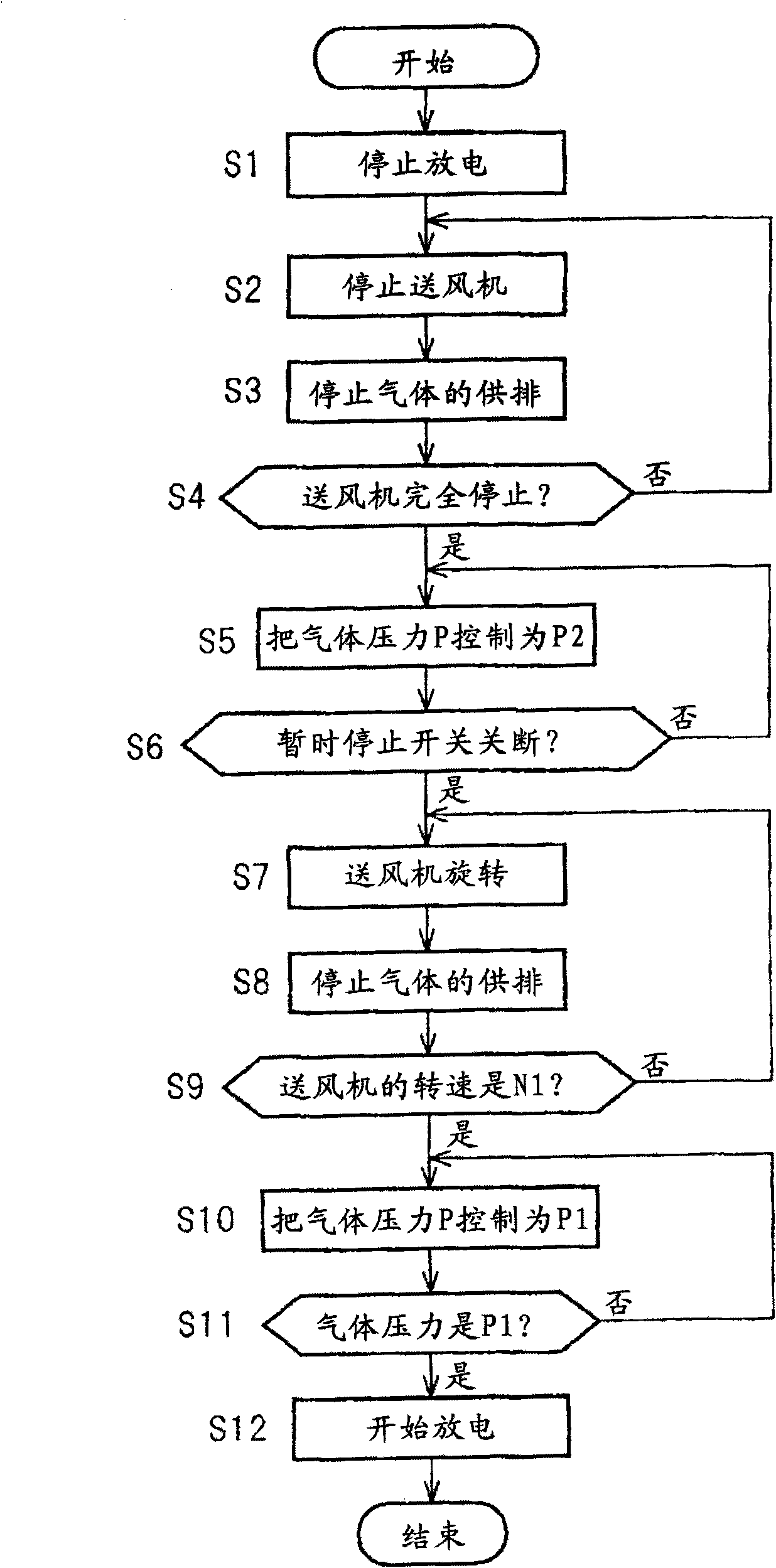

[0014] Refer below Figure 1 ~ Figure 6B Embodiments of the present invention will be described. figure 1 It is a figure which schematically shows the structure of the gas laser apparatus 100 which concerns on embodiment of this invention. This gas laser device 100 has a laser gas container 10 forming a gas flow path 101 through which laser gas circulates, and a laser oscillator 20 and a blower 30 arranged on the gas flow path 101 . The gas laser device 100 of this embodiment can be used in a wide range of fields such as processing, medical treatment, and measurement.

[0015] The laser gas container 10 seals a predetermined laser gas in a state isolated from the atmosphere. As the laser gas, a medium gas for laser oscillation containing a laser medium such as carbon dioxide gas, nitrogen gas, or argon gas can be used.

[0016] The laser oscillator 20 has an output mirror 21 , a back mirror 22 , and a discharge tube 23 arranged between the output mirror 21 and the back mirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com