Method for shaping plastics material

A plastic material and plastic technology, applied in applications, home appliances, and other home appliances, can solve the problems of low thermal efficiency of infrared panel heaters and longer heating time of plastic materials, and achieve the effect of improving heating efficiency and improving heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Next, embodiments of the present invention are described in detail by referring to the drawings.

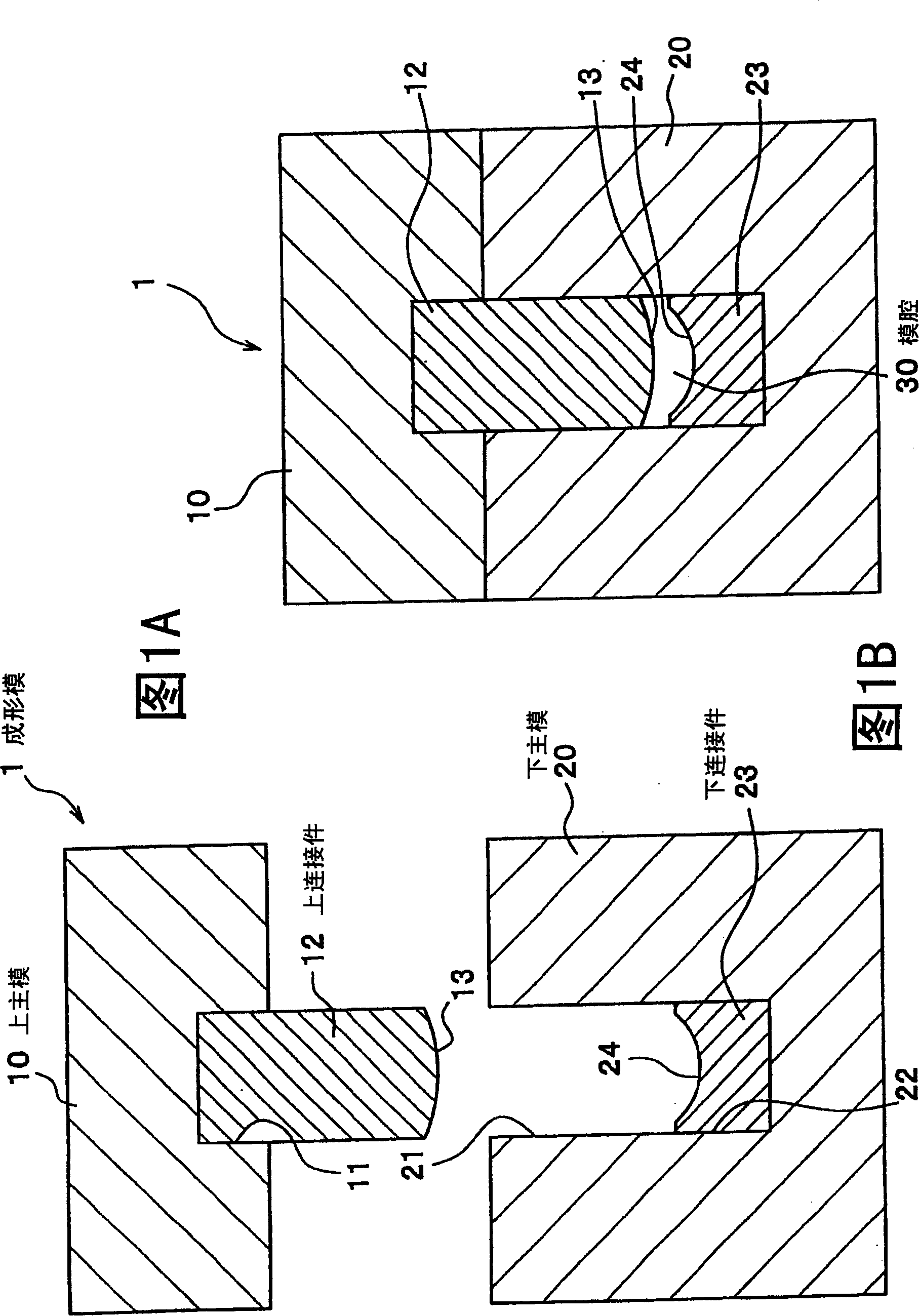

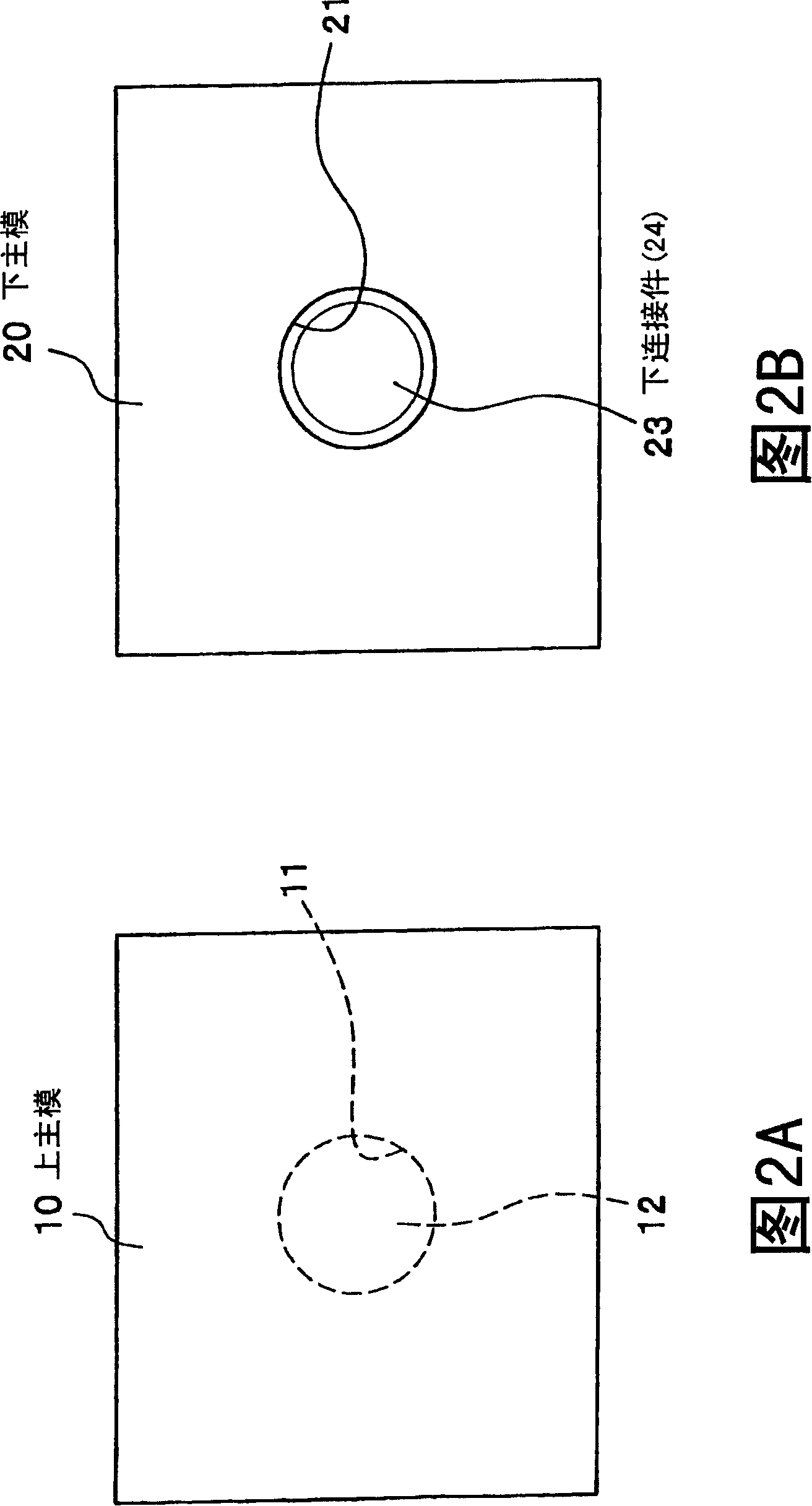

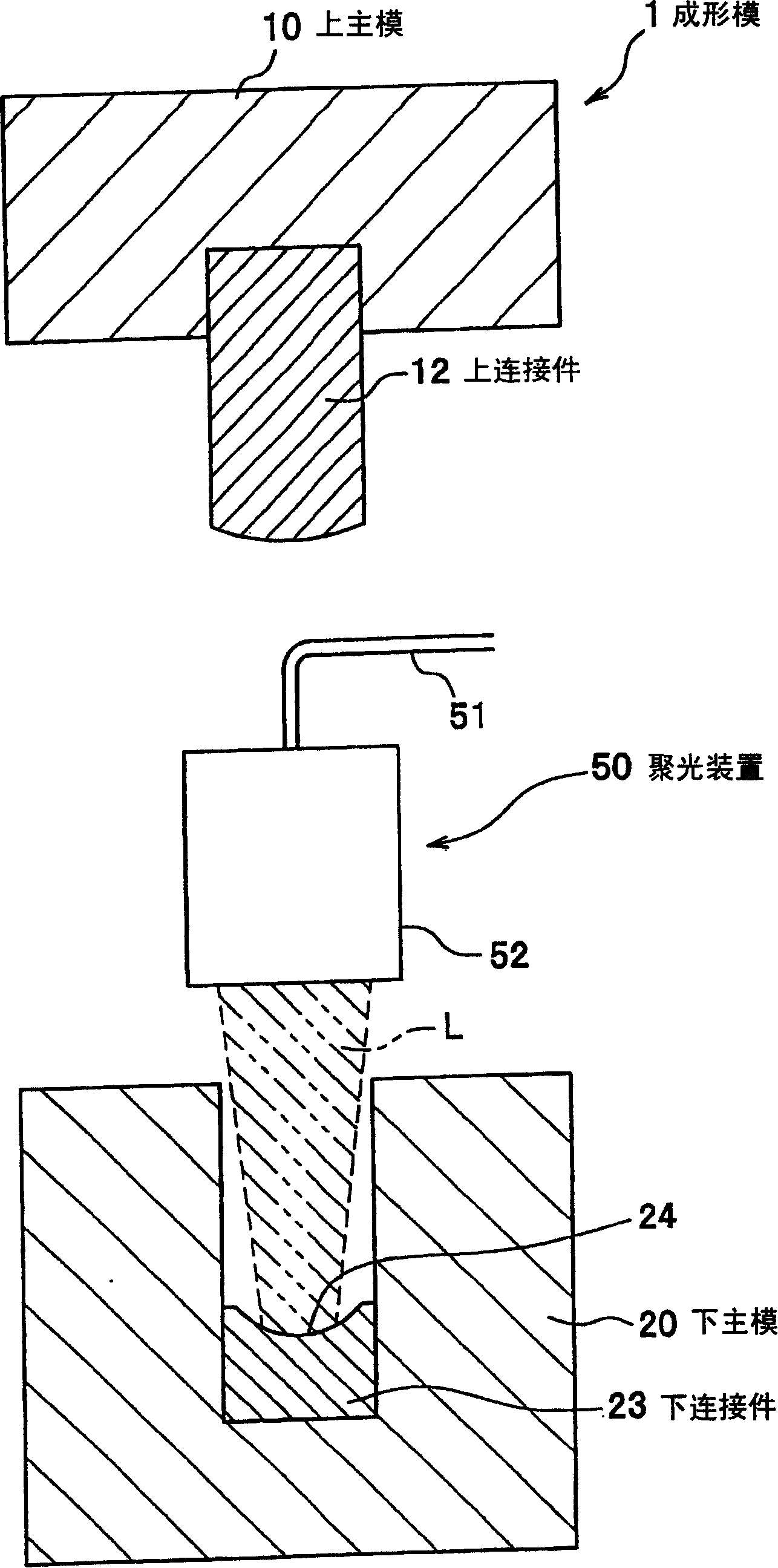

[0044]1A and 1B are views showing a forming die used in the forming method of the plastic material of the present embodiment. FIG. 1A is a side sectional view showing separate main forms, and FIG. 1B is a side sectional view showing the main forms joined together. 2A and 2B show views of a forming die used in the forming method of the plastic material of the present embodiment. FIG. 2A is a plan view showing an upper main mold, and FIG. 2B is a plan view showing a lower main mold. image 3 is a side sectional view showing a molding die used in the molding method of the plastic material of this embodiment, in which light concentrating means are provided between main dies.

[0045] In this embodiment, an example of a method for manufacturing a plastic lens using compression molding of a plastic material will be used to explain the present invention.

[0046] (Structure of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com