Molten pool temperature detection system and method for selective laser melting 3D printer

A 3D printer and laser melting technology, applied in the direction of spectrometry/spectrophotometry/monochromator, thermometers with physical/chemical changes, thermometers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

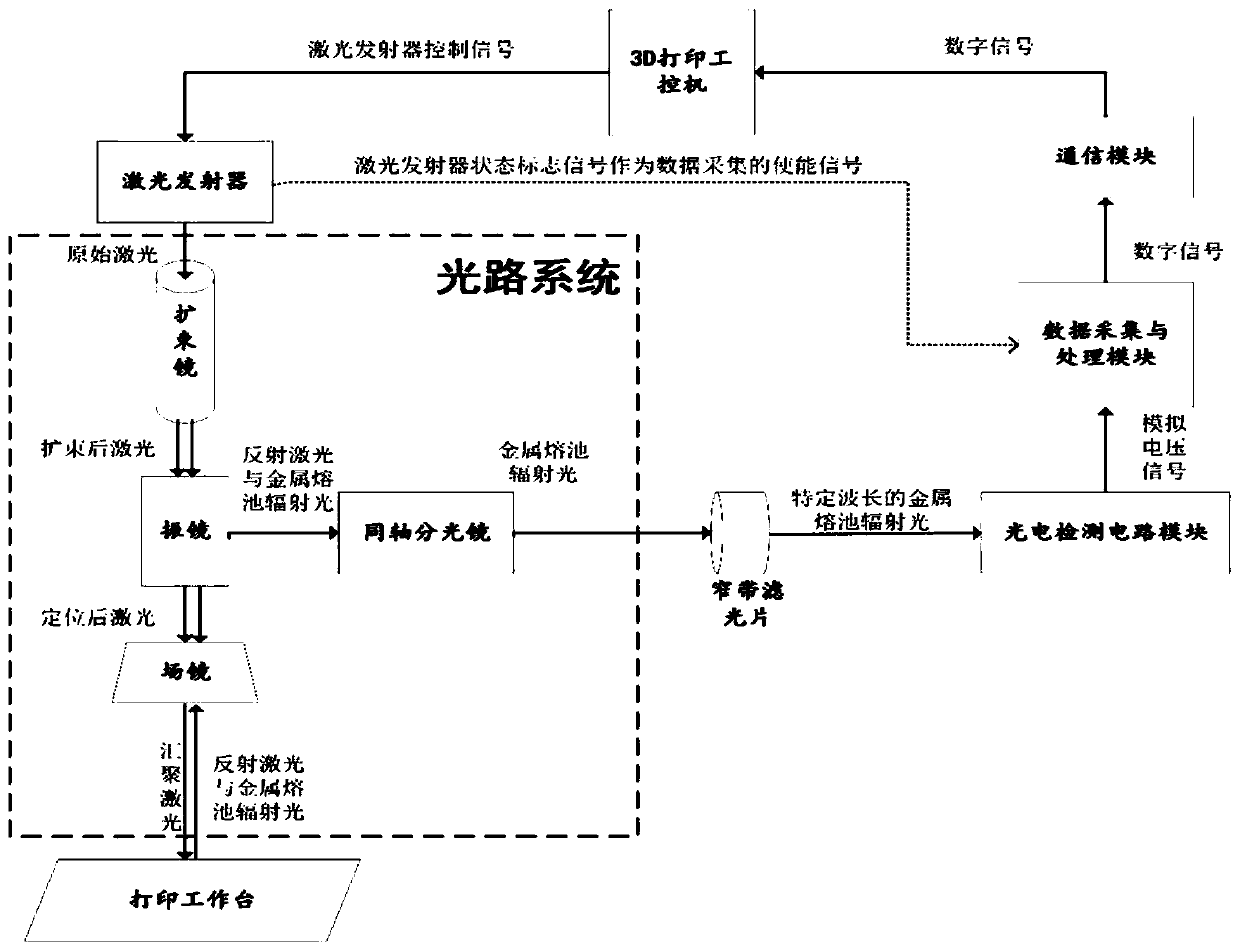

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] The detection of the melt pool temperature in the present invention is realized by locking the characteristic spectrum of the workpiece material to be processed. The principle is: when the metal material powder under high-energy laser irradiation absorbs energy from the incident laser and the temperature continues to rise, the ground state electrons of the metal atoms receive light. Energy and thermal energy are excited to jump to the high-energy orbit of the outer layer of the atom, but this excited state electron (also called Joule electron) is unstable, and after about 10 -8 [s] will return to the inner orbit with a lower energy level in the future, and finally return to the ground state to reach a new stable state. Accompanied by a series of energy level transitions of Joule electrons, metal materials release characteristic spectra of specific wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com