Laser heating auxiliary arc striking micro-explosion processing method and device for engineering ceramic material

A technology of engineering ceramics and laser heating, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as unsatisfactory effects, improve quality and processing efficiency, improve processing quality, and reduce damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0039] A laser heating-assisted micro-explosion processing method for gas pressure sintered silicon nitride engineering ceramics, comprising the following steps:

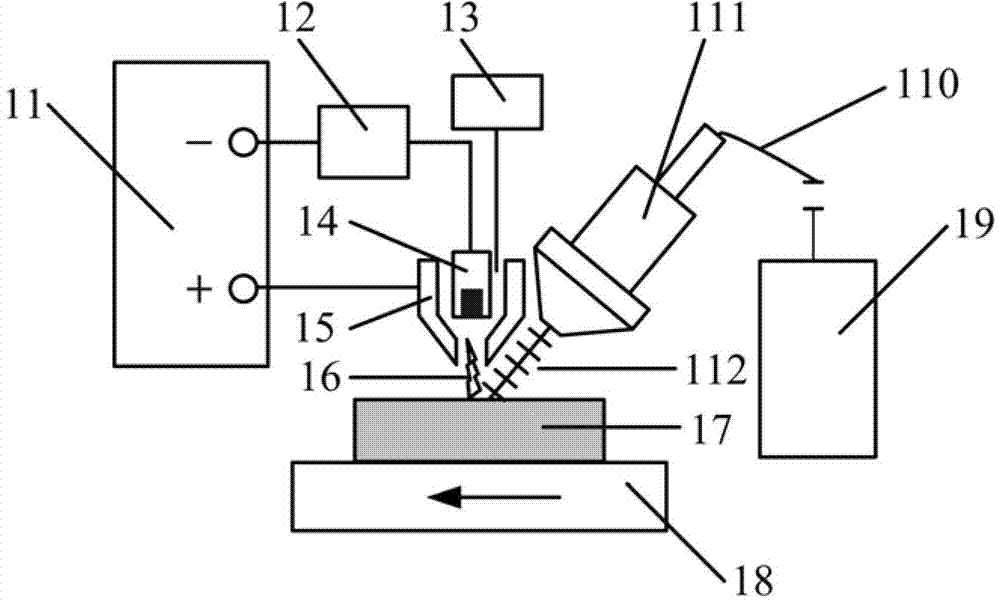

[0040] The first step is to build a processing system. Such as figure 1 As shown, the laser heating assisted arc ignition micro-explosion processing system consists of a dedicated pulse power supply 11, a pulse controller 12, a gas supply device 13, a micro-explosion generator (hafnium cathode 14, anode nozzle 15), a numerically controlled three-dimensional workbench 18, and a laser 19 , optical fiber 110, and laser head 111.

[0041] The second step is laser assisted heating. The laser 19 emits a laser beam, which is transmitted to the laser head through an optical fiber. The focused laser beam 112 is irradiated on the surface of the ceramic workpiece 17 to form an elliptical spot. The su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com