CNC machine tool machining flow optimization method

A process optimization and processing program technology, applied in the field of machining, can solve the problems of difficulty in combining tools of the same size, inability to process, and lack of flexibility, and achieve the effect of reducing manual operation errors and repetitive operation fatigue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The principles and features of the present invention are described below in conjunction with examples, which are only used to explain the present invention and are not intended to limit the scope of the present invention.

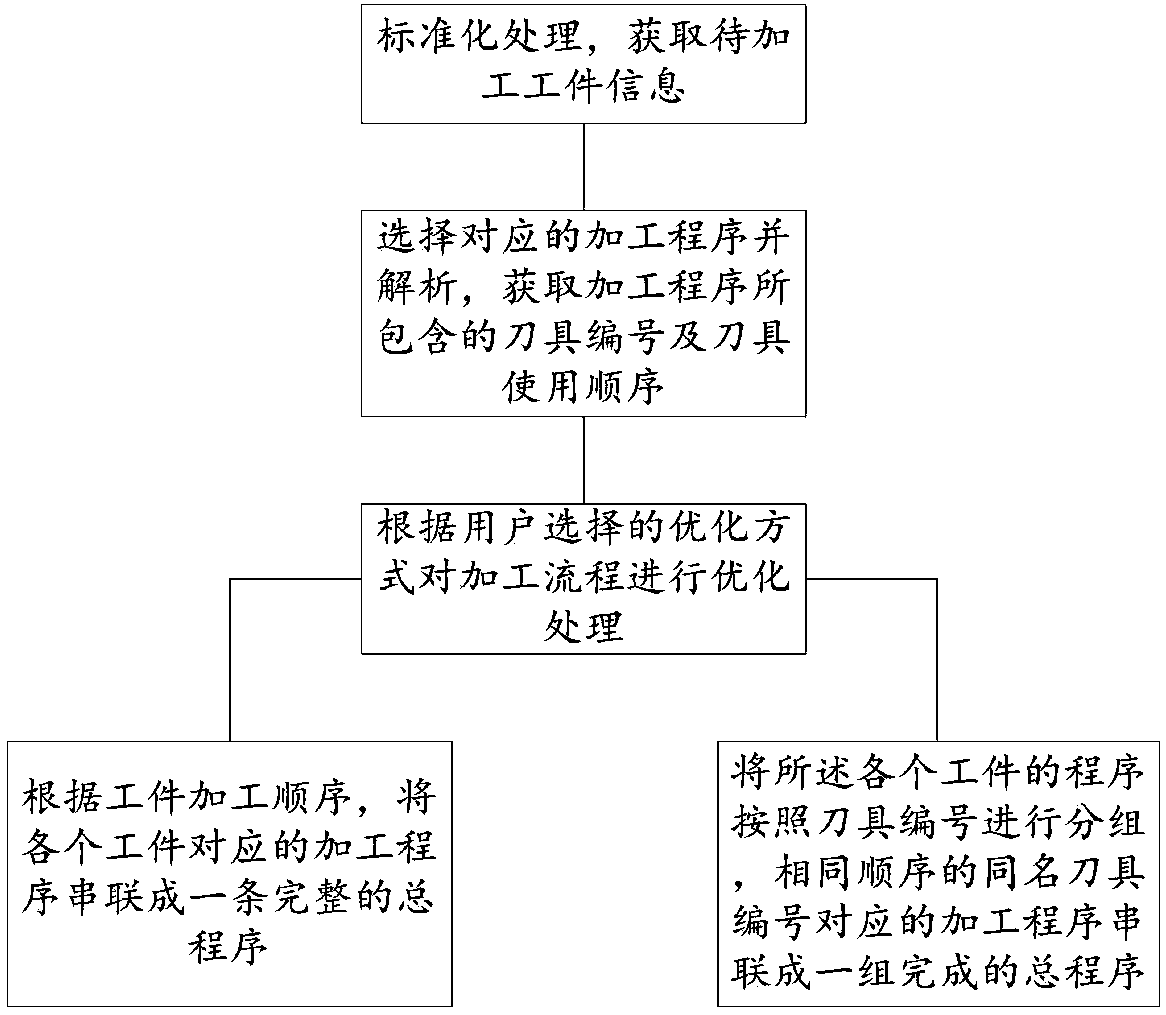

[0019] figure 1 It is a flow chart of a method for optimizing a machining process of a CNC machine tool provided by an embodiment of the present invention. Such as figure 1 As shown, the method includes the following steps:

[0020] Step 1, standardize the processing program format, tool number and its parameters of all models, and obtain the information of the workpiece to be processed at the same time;

[0021] Step 2, selecting the processing program corresponding to the workpiece information to be processed, and analyzing the processing program to obtain the tool numbers and tool usage sequences included in the processing program;

[0022] Step 3, optimize the processing flow according to the optimization method selected by the user, if the us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com