Uncharged time-control overlapped combustion-resistant treatment and rehabilitation electric blanket

An electric blanket and anti-stacking technology, applied in the direction of electric heating devices, ohmic resistance heating, sleeping blankets, etc., can solve the problems of poor quality, easy breaking of heating wires, uneven quality, etc., and achieve the effect of light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

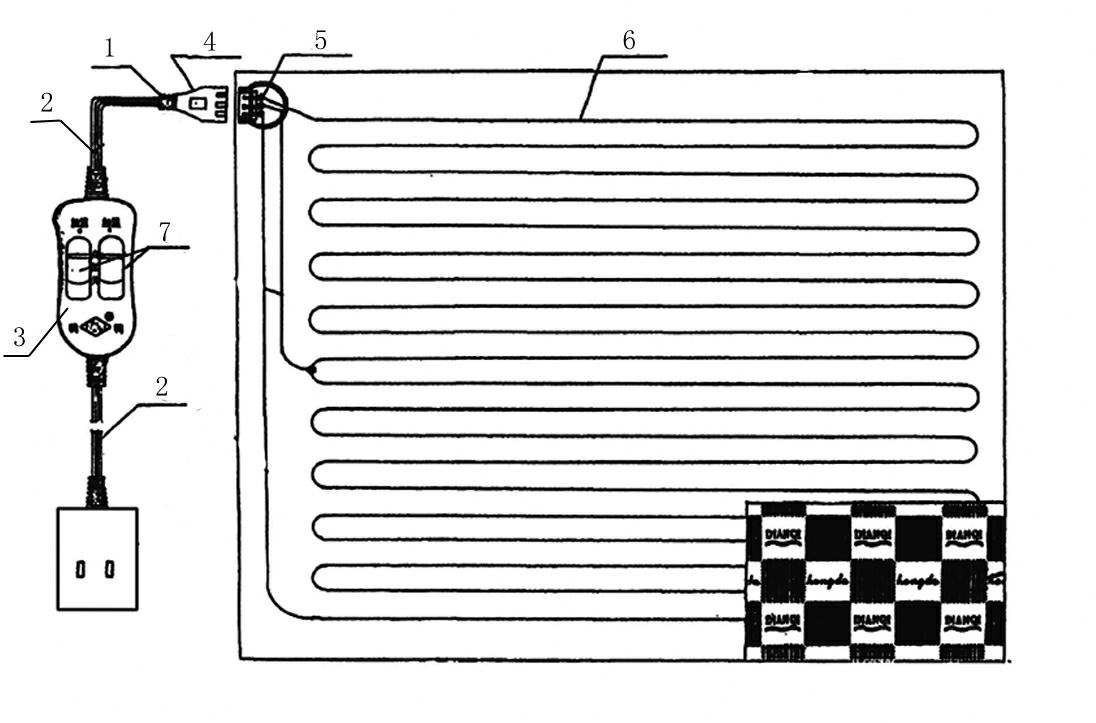

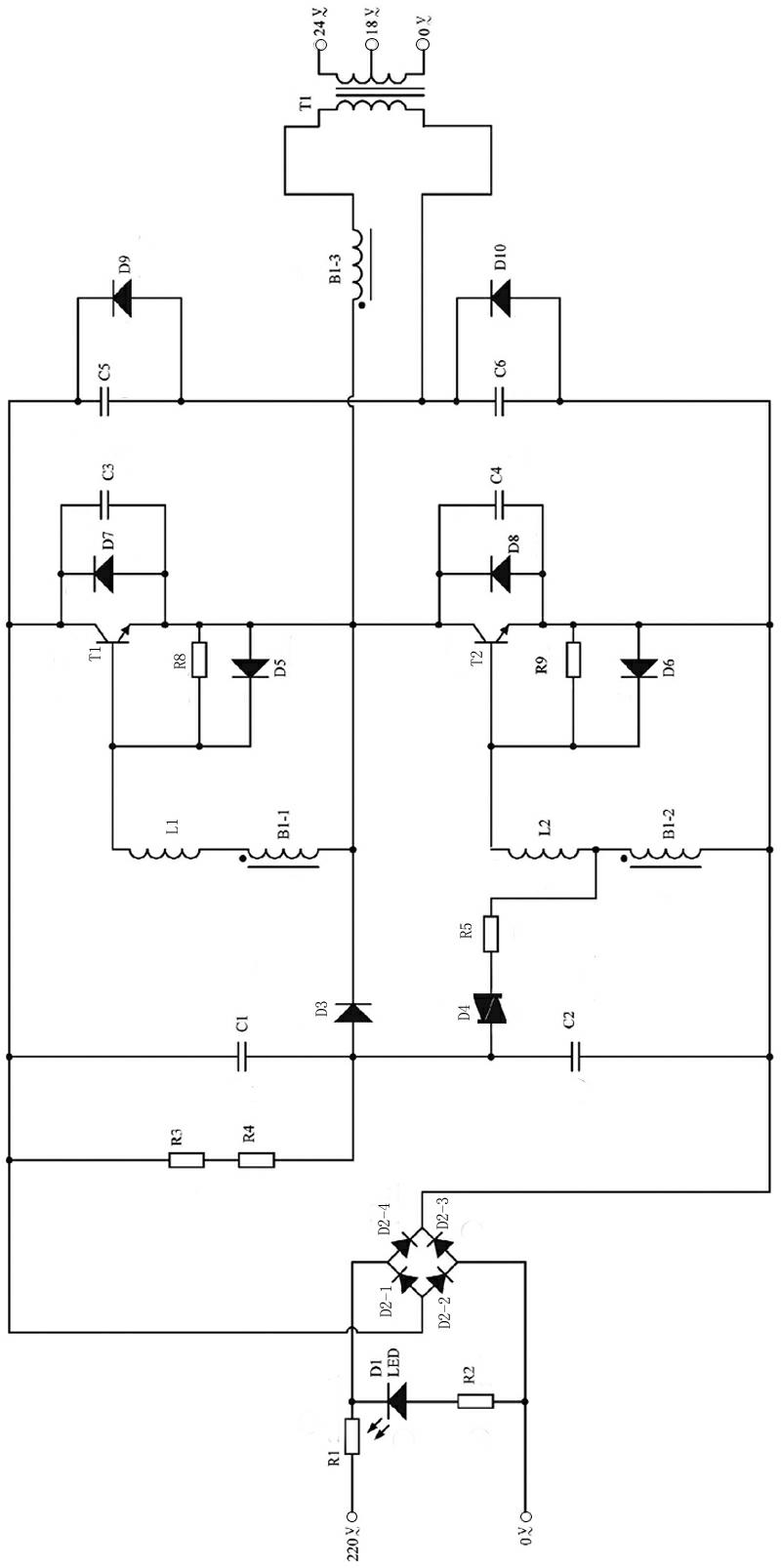

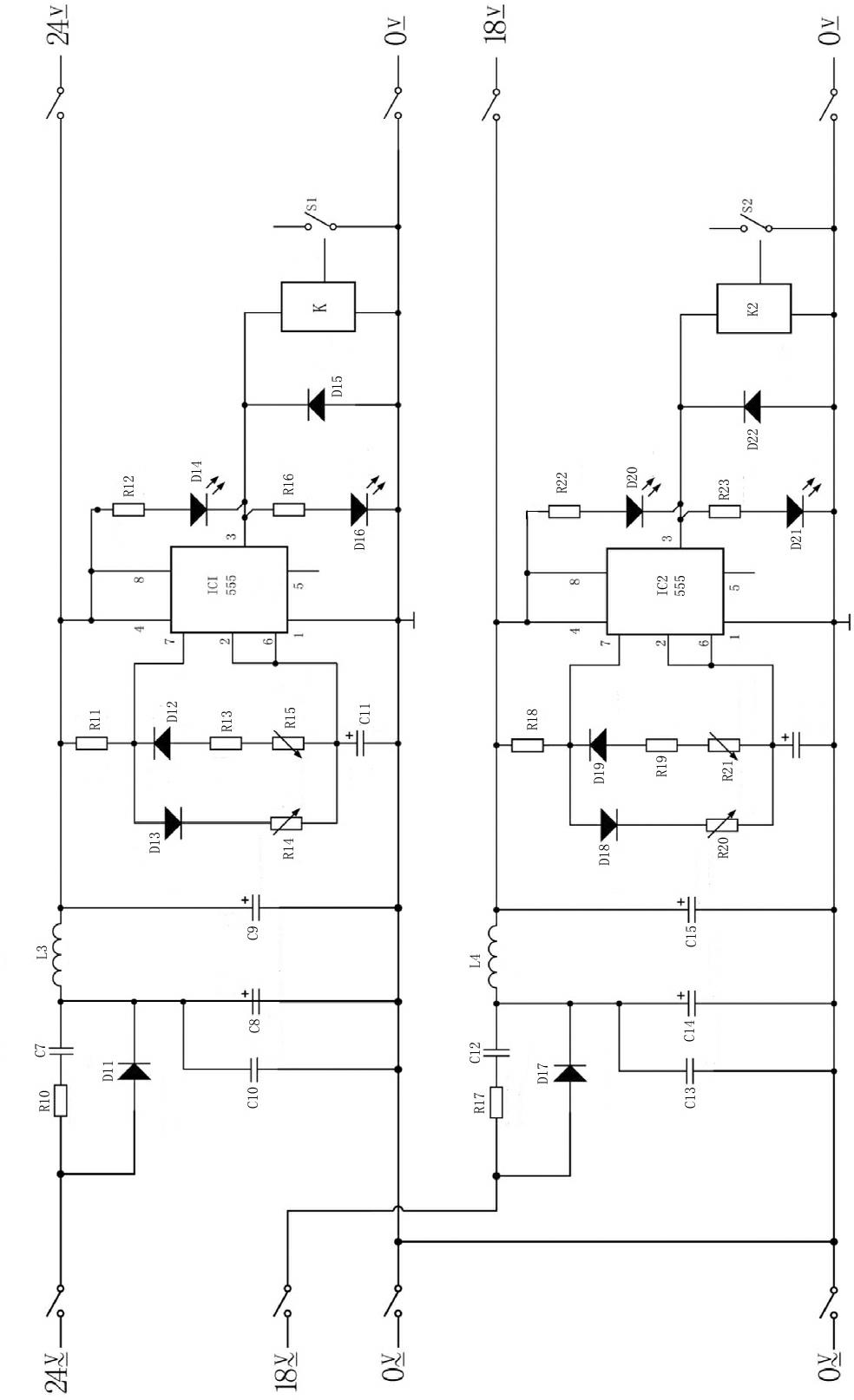

[0035] Refer to attached Figure 1~8 , the non-charged time-controlled anti-stack combustion electric blanket of the present invention includes a surface layer, a bottom layer, an electronic voltage reducer 1, a power lead 2, a control switch box 3, a power lead connector 4, a socket 5 and an anti-stack ignition heating element 6. The surface layer and the bottom layer are combined together. The surface layer is made of needle-punched non-woven electric blanket surface fabric, and the bottom layer is made of needle-punched non-woven electric blanket bottom fabric; the anti-overlapping heating element 6 is installed on the bottom layer The output end of the electronic voltage reducer 1 is connected to one end of the control switch box 3 through the power wire 2, and the other end of the control switch box 3 is connected to the socket 5 of the electric blanket through the power wire 2 and the power wire connector 4 Connect, the tail of the plug in the socket 5 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com