RH nitrogen-blowing alloying process capable of accurately controlling nitrogen content of nitrogen-containing steel grade

A technology of precise control and nitrogen content, applied in the field of iron and steel metallurgy, to achieve the effect of reducing certification cost, narrow composition control, and reducing sewage discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A RH blown nitrogen alloying process for precise control of nitrogen-containing steel nitrogen content, as an example of Q420QC low all-round steel. Q420QC low alloy steel for rolling ≤ 24mm steel sheet, mainly used in bridge construction, engineering and general structural steel.

[0070] Steelmaking production process is: Kr desulfurized iron + high quality scrap → converter smelting → steel alloying → CAS → LF → RH → slab continuous casting → rolling mill rolling.

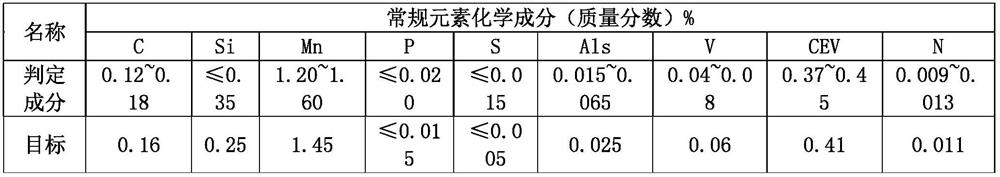

[0071] Table 1

[0072]

[0073] Remarks: CEV = C + 1 / 6Mn + 1 / 15 (Cu + Ni) +1 / 5 (Cr + Mo + V).

[0074] Q420QC steel refining steel includes the following steps:

[0075] In order to achieve the precision control of the steel nitrogen content, the iron-water sulfur content of the inverter furnace is ≤0.005% (actual 0.003%), and the scrap steel (s ≤ 0.010%) of the inverted furnace is adopted. The iron water is in stock, with a waste steel amount of 48 tons, and the steel volume is 221 tons.

[0076] (1) Th...

Embodiment 2

[0089] A RH blown nitrogen alloying process for precise control of nitrogen-containing steel nitrogen content, as an example of Q420QC low all-round steel. Q420QC low alloy steel for rolling ≤ 24mm steel sheet, mainly used in bridge construction, engineering and general structural steel.

[0090] Steelmaking production process is: Kr desulfurized iron + high quality scrap → converter smelting → steel alloying → CAS → LF → RH → slab continuous casting → rolling mill rolling.

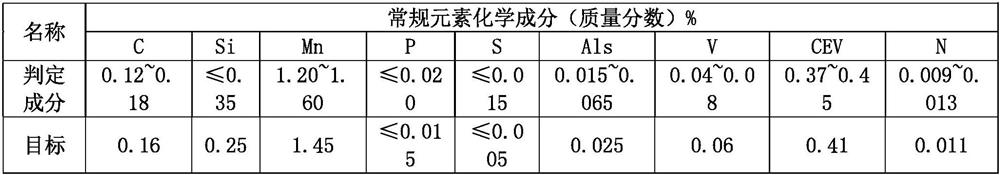

[0091] Table 2

[0092]

[0093] Remarks: CEV = C + 1 / 6Mn + 1 / 15 (Cu + Ni) +1 / 5 (Cr + Mo + V).

[0094] Q420QC steel refining steel includes the following steps:

[0095] In order to achieve the precision control of the steel nitrogen content, the iron-water sulfur content of the inverter is ≤0.005% (actual 0.001%), and the scrap steel in which the incoming furnace adopts high-yield high-quality scrap (s ≤ 0.010%). Iron water is in stock of 195 tons, 45 tons of scrap steel, and 225 tons of steel.

[0096]...

Embodiment 3

[0109] A RH blown nitrogen alloying process for precise control of nitrogen-containing steel nitrogen content, as an example of Q420QC low all-round steel. Q420QC low alloy steel for rolling ≤ 24mm steel sheet, mainly used in bridge construction, engineering and general structural steel.

[0110] Steelmaking production process is: Kr desulfurized iron + high quality scrap → converter smelting → steel alloying → CAS → LF → RH → slab continuous casting → rolling mill rolling.

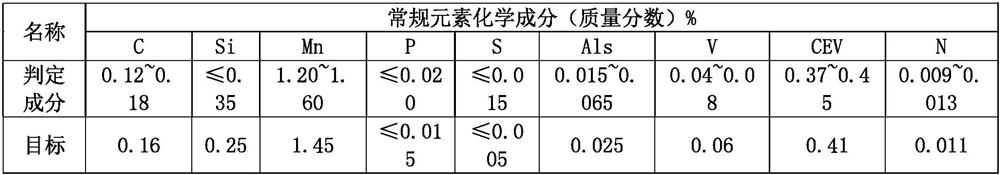

[0111] table 3

[0112]

[0113] Remarks: CEV = C + 1 / 6Mn + 1 / 15 (Cu + Ni) +1 / 5 (Cr + Mo + V).

[0114] Q420QC steel refining steel includes the following steps:

[0115] In order to achieve the precision control of the steel nitrogen content, the iron-water sulfur content of the inverter furnace is ≤0.005% (actual 0.005%), and the scrap steel (s ≤ 0.010%) of the inverted furnace is adopted. The iron water is in stock, with a waste of 50 tons, and the amount of steel is 230 tons.

[0116] (1) The converte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com