Semi-automatic welding device for protecting cover of explosion-proof light

A semi-automatic welding and protective cover technology, applied in welding equipment, resistance welding equipment, metal processing equipment, etc., can solve the problems of slow processing speed, hidden safety hazards, poor positional accuracy of layout, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

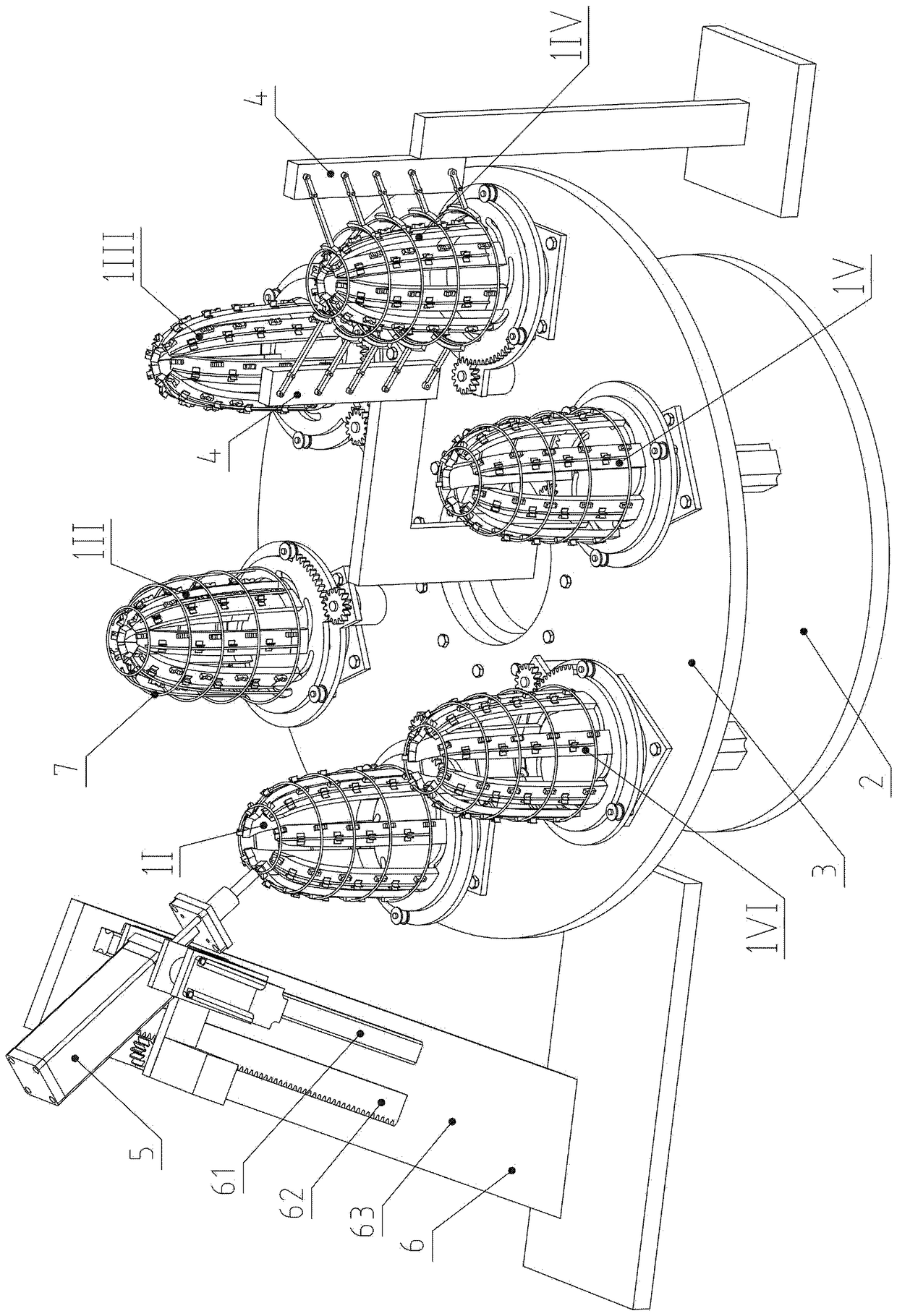

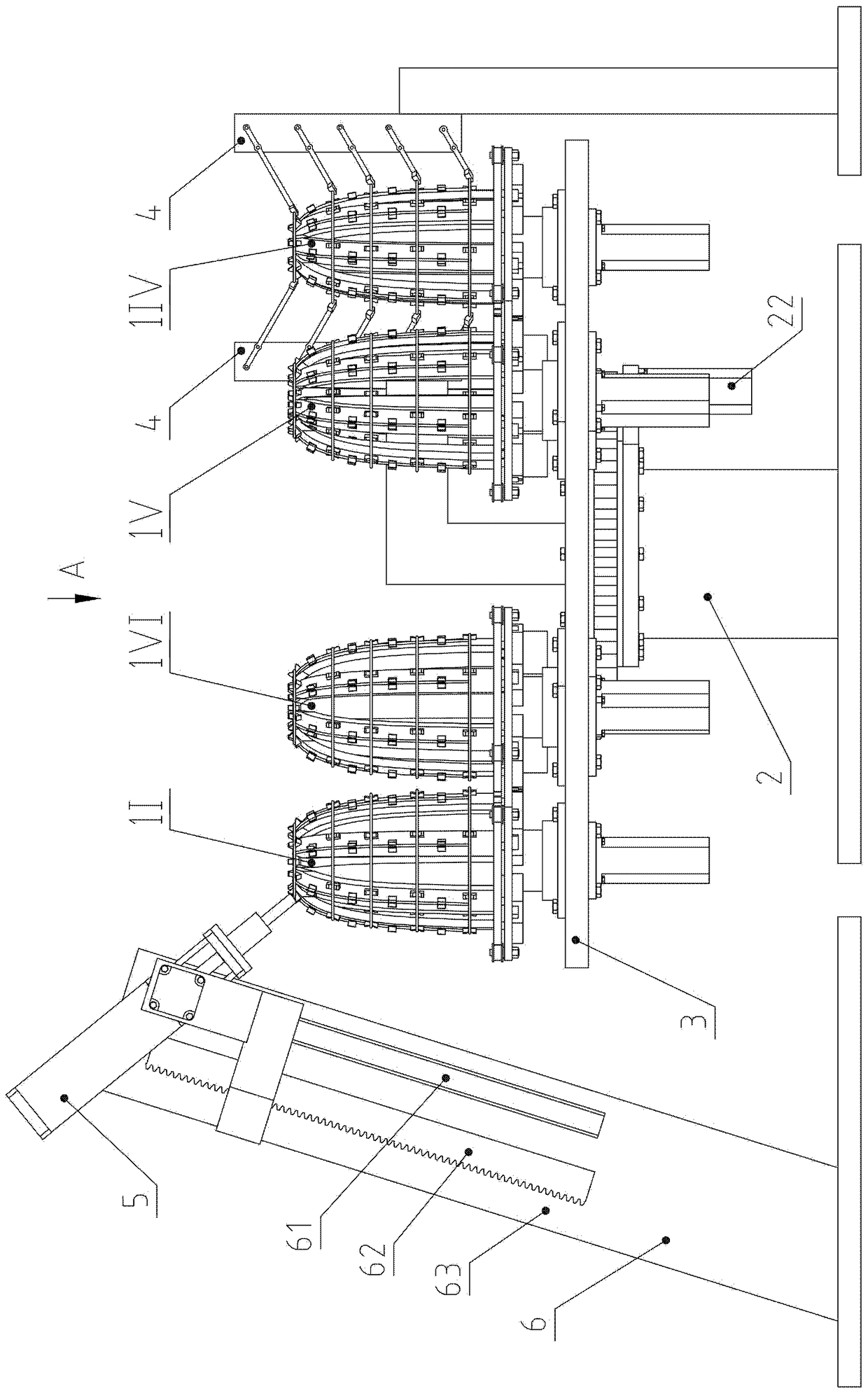

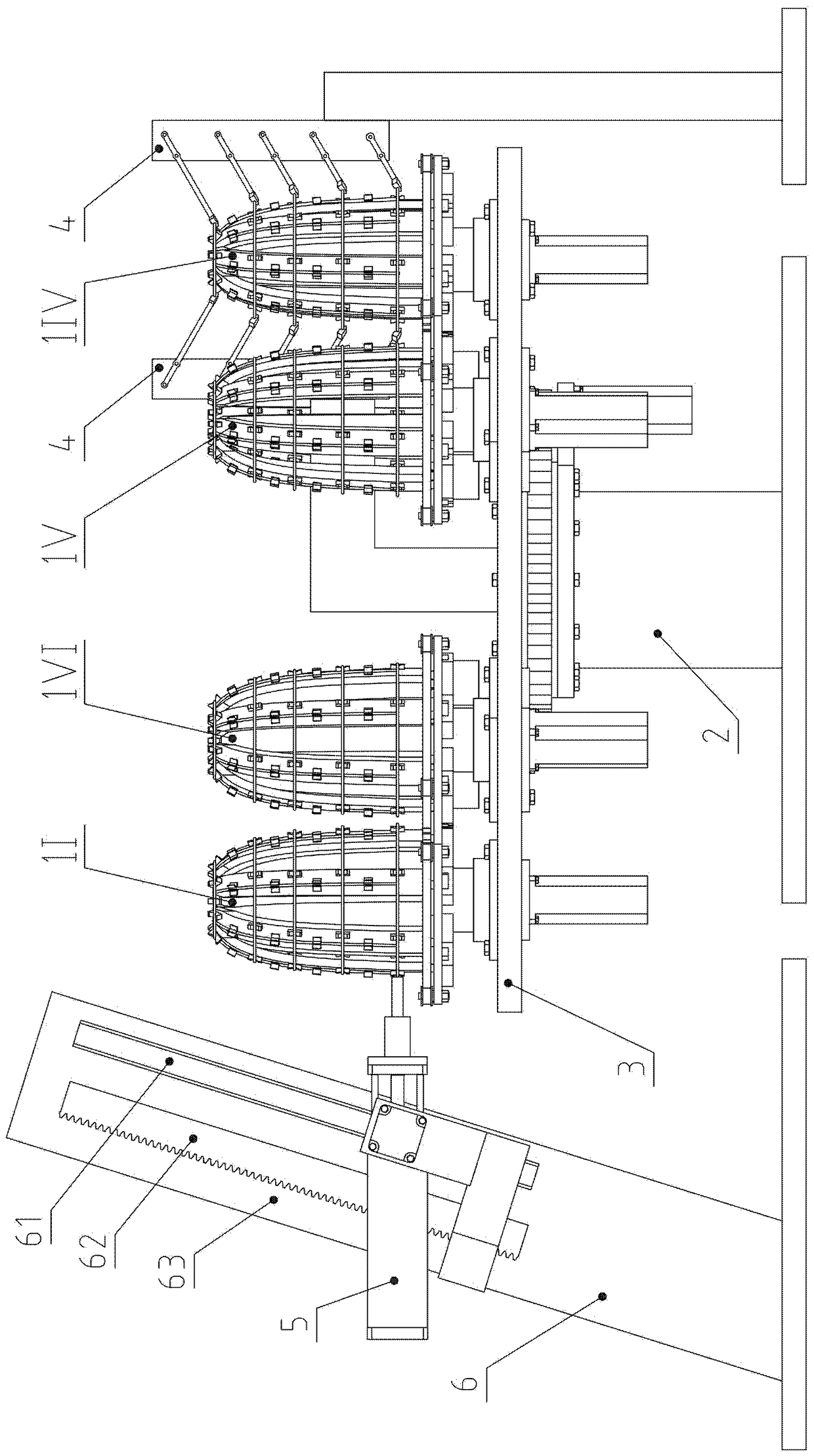

[0061] Example: see Figure 1 to Figure 19 .

[0062] A semi-automatic welding equipment for an explosion-proof lamp protective cover, including six mold assemblies 1, a turntable base assembly 2, a slewing bearing 8, a large turntable 3, two steel ring support assemblies 4, an electrode assembly 5, an electrode lifting frame 6 and welding power supply;

[0063] Six tire components 1 include No. I tire 1I, II tire 1II, III tire 1III, IV tire 1IV, V tire 1V and VI tire 1VI; six mold components 1 have The same shape structure and different station positions;

[0064] The mold assembly 1 includes seven curved surface support plate assemblies, a curved groove disc 12, a planetary wheel 13, a radial groove disc 14, a pinion 16, a split servo motor 17, a bearing 18 and a rotation servo motor 19;

[0065] The seven curved spreader assemblies are respectively curved spreader assembly 1 111, curved spreader assembly 2 112, curved spreader assembly 3 113, curved spreader assembly 4 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com