Conveyer for preventing paperboard from upwarping during transportation process

A technology of transportation process and conveying device, which is applied in the direction of transportation and packaging, object supply, pile separation, etc. It can solve the problems of easy bending or warping of cardboard, affecting transmission efficiency, and cardboard warping, so as to save time and simple structure of the device , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

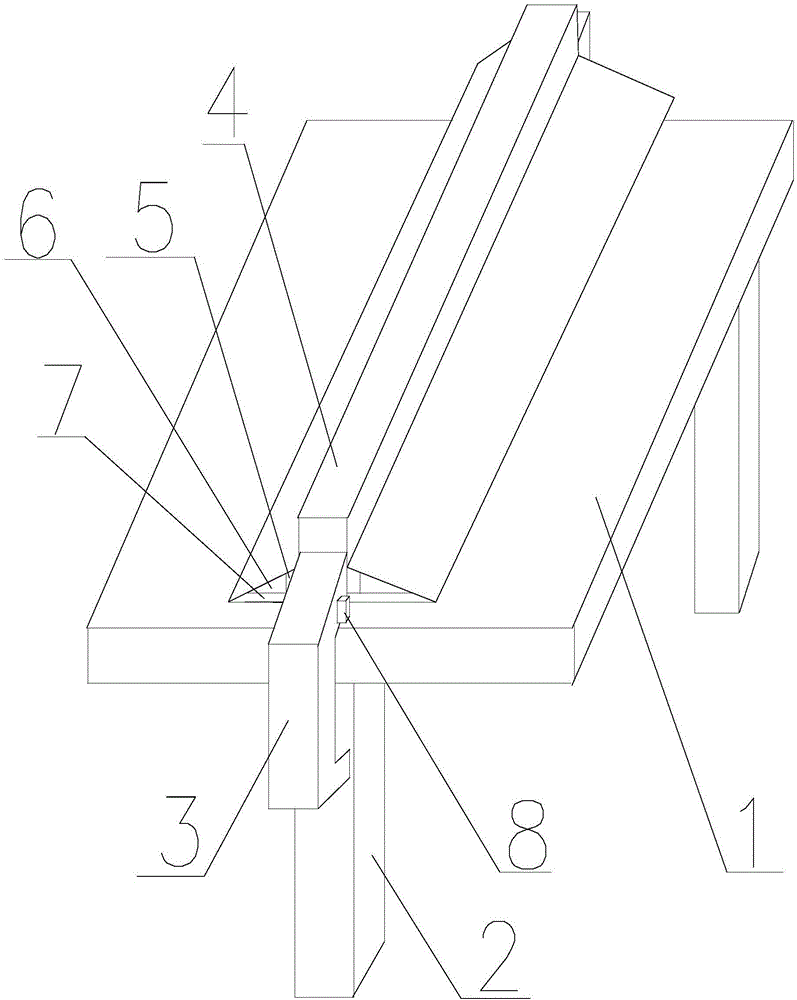

[0022] like figure 1 As shown in the present invention, the conveying device for preventing cardboard from warping during transportation includes a conveyor belt 1 and a support rod 2 located below the conveyor belt 1, and a connecting rod 3 is connected to the supporting rod 2, and a connecting rod 3 is connected to the connecting rod 3. A telescopic pressing plate 4 perpendicular to the conveying direction, both sides of the pressing plate 4 are connected with a telescopic expansion plate 5, and the expansion plate 5 is connected with a pressing plate 6, and the pressing plate 6 is far away from the expansion plate 5 One end is pointed, and the bottom surface of the pressing plate 6 is parallel to the conveyor belt 1, the bottom surface of the pressing plate 6 has a heating layer 7, and the connecting rod 3 has a sensor 8 for sensing the position of the cardboard.

Embodiment 2

[0024] The conveying device for preventing the cardboard from warping during transportation includes a conveyor belt 1 and a support rod 2 located below the conveyor belt 1, the support rod 2 is connected with a connecting rod 3, and the connecting rod 3 is connected with a transmission The stretchable pressing plate 4 with vertical direction, the both sides of described pressing plate 4 are all connected with stretchable expansion plate 5, and described expansion plate 5 is connected with pressing plate 6, and described pressing plate 6 is far away from one end of expansion plate 5 It is pointed, and the bottom surface of the pressing plate 6 is parallel to the conveyor belt 1. There is a heating layer 7 on the bottom surface of the pressing plate 6, and a sensor 8 for sensing the position of the cardboard is arranged on the connecting rod 3. The length of the pressing plate 4 is the same as the width of the conveyor belt 1, and the bottom surface of the pressing plate 4 is ma...

Embodiment 3

[0026] The conveying device for preventing the cardboard from warping during transportation includes a conveyor belt 1 and a support rod 2 located below the conveyor belt 1, the support rod 2 is connected with a connecting rod 3, and the connecting rod 3 is connected with a transmission The stretchable pressing plate 4 with vertical direction, the both sides of described pressing plate 4 are all connected with stretchable expansion plate 5, and described expansion plate 5 is connected with pressing plate 6, and described pressing plate 6 is far away from one end of expansion plate 5 It is pointed, and the bottom surface of the pressing plate 6 is parallel to the conveyor belt 1. There is a heating layer 7 on the bottom surface of the pressing plate 6, and a sensor 8 for sensing the position of the cardboard is arranged on the connecting rod 3. The length of the pressing plate 4 is the same as the width of the conveyor belt 1, and the bottom surface of the pressing plate 4 is ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com