A step-by-step sheeting system for woolen sweaters

A full-molding, sweater technology, applied in spray/jet textile material processing, knitting, high-pressure cleaning, etc., can solve problems such as reducing work efficiency and affecting product quality, achieving convenient operation, improving work efficiency and product quality, The effect of reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

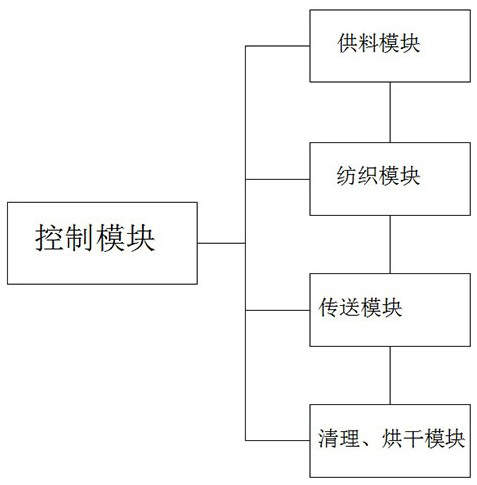

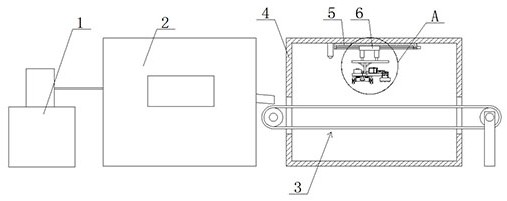

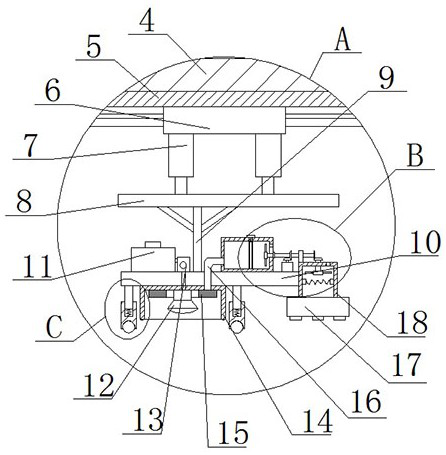

[0028] refer to Figure 1-5 , a step-by-step whole-forming system for woolen sweaters, including a control module, a feeding module, a textile module, a transmission module, and a cleaning and drying module. The feeding module, the textile module, the transmission module, and the cleaning and drying module are all connected with the control module Module connection, the control module is an intelligent controller, the feeding module is connected to the textile module, the textile module is connected to the transmission module, the transmission module is connected to the cleaning and drying module, the feeding module is the wool pay-off machine 1, and the textile module is an automatic textile machine 2. The transmission module is a conveyor belt structure 3. The cleaning and drying module includes a protective shell 4. The two sides of the protective shell 4 are respectively provided with an entrance and an exit. The conveyor belt structure 3 is movably connected with the entra...

Embodiment 2

[0037] refer to Figure 1-5 , a step-by-step whole-forming system for woolen sweaters, including a control module, a feeding module, a textile module, a transmission module, and a cleaning and drying module. The feeding module, the textile module, the transmission module, and the cleaning and drying module are all connected with the control module Module connection, the cleaning and drying module is connected with a cutting module, through which the cleaned and dried textile fabrics can be cut into pieces, the control module is an intelligent controller, the feeding module is connected with the textile module, and the textile module is connected with the transmission module , the transmission module is connected with the cleaning and drying module, the feeding module is a wool pay-off machine 1, the textile module is an automatic textile machine 2, the transmission module is a conveyor belt structure 3, the cleaning and drying module includes a protective shell 4, and both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com