Package laminating machine

A packaging and peritoneal technology, applied in the field of packaging and printing, can solve problems such as complicated operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following is further described in detail by specific embodiments:

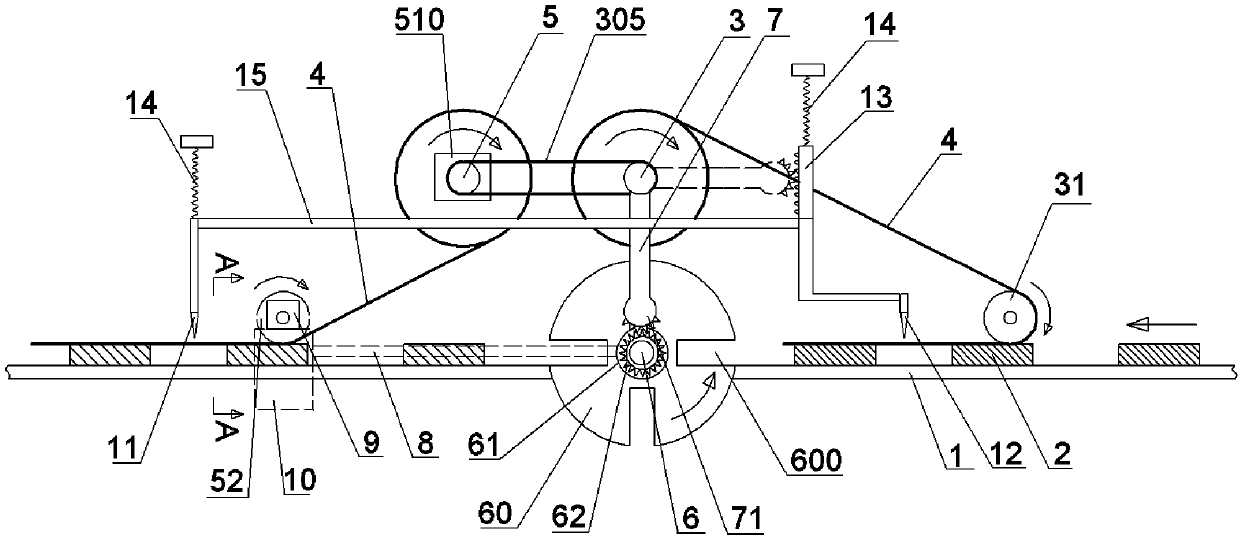

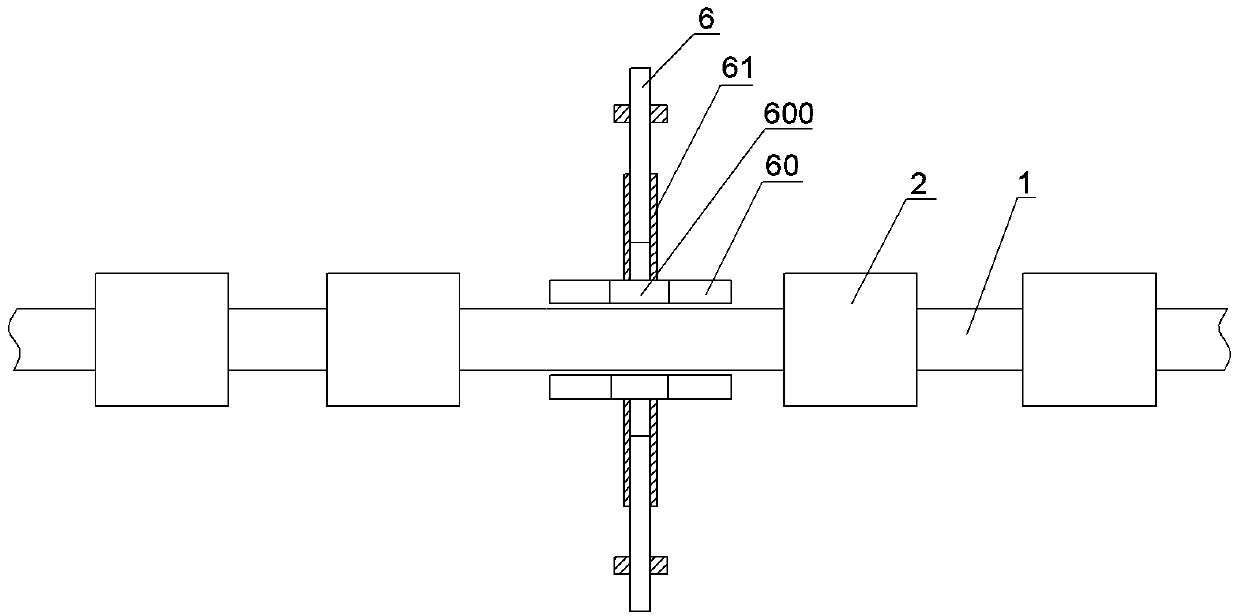

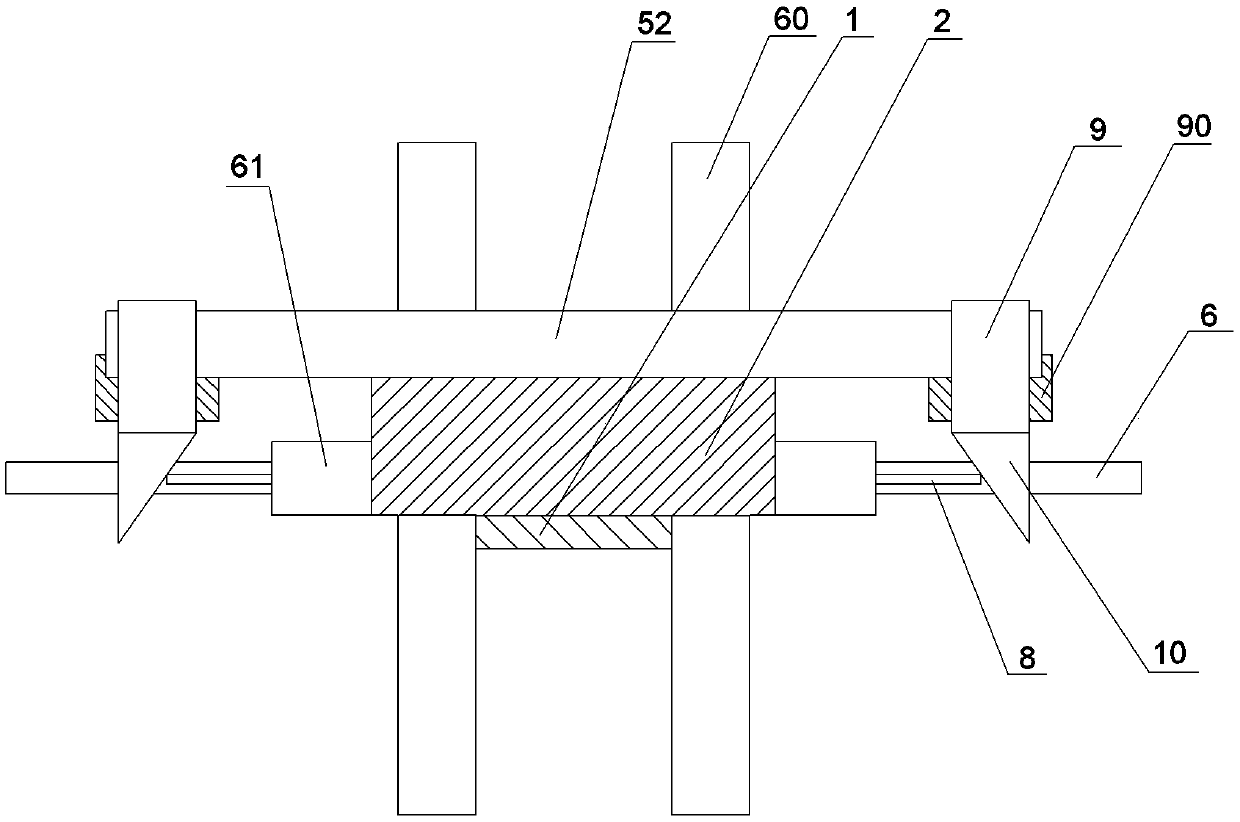

[0022] Reference numerals in the accompanying drawings include: conveyor belt 1, lamination workpiece 2, front film reel 3, front lamination roll 31, belt 305, film 4, back film roll 5, back lamination roll 52, adjustment seat 510, Flip shaft 6, flip disc 60, notch 600, sleeve 61, complete gear 62, rotating arm 7, incomplete gear 71, drive rod 8, sliding seat 9, chute 90, wedge 10, reverse film cutter 11, Front film cutting knife 12 , rack 13 , spring 14 , connecting rod 15 .

[0023] like figure 1 and figure 2 As shown, the packaging peritoneal machine of this embodiment includes a frame, and a conveyor belt 1 is arranged on the frame for conveying the lamination workpiece 2. The conveying direction is from right to left, and along the conveying direction of the conveying belt 1 There are front lamination mechanism, flip mechanism and reverse lamination mechanism.

[0024] The front lamination...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com