Patents

Literature

34results about How to "Realize unwinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

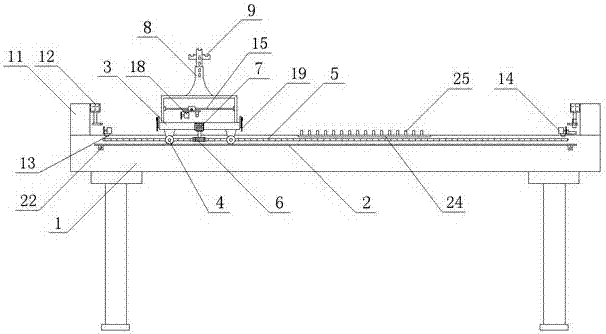

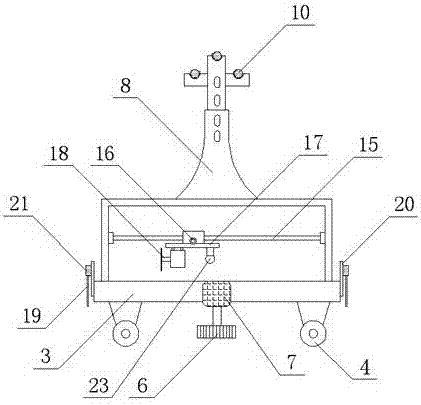

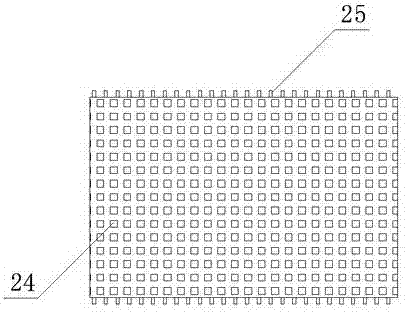

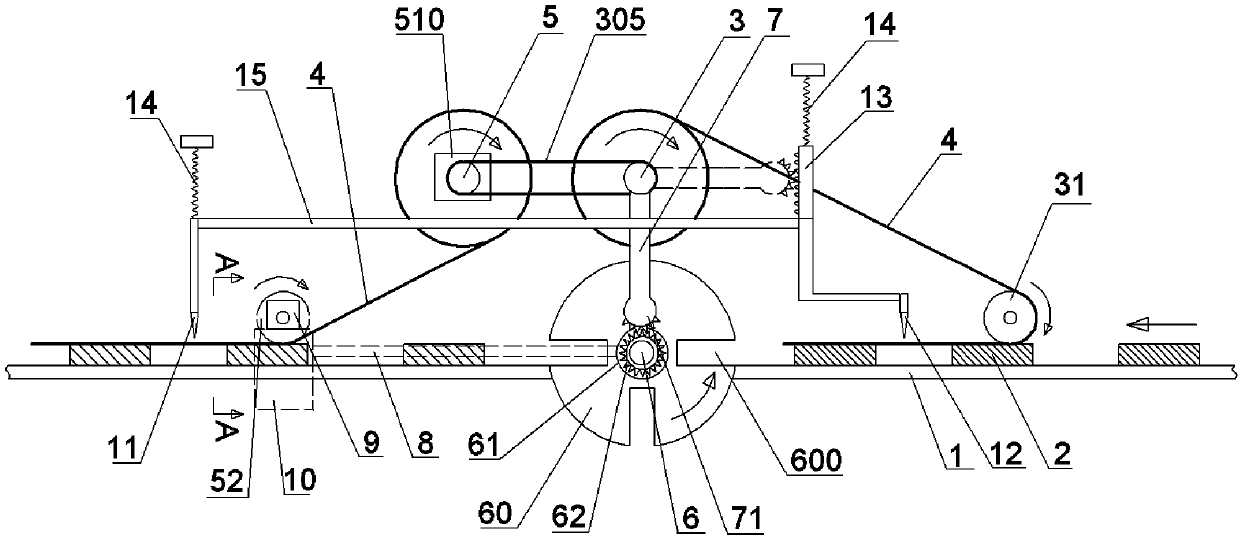

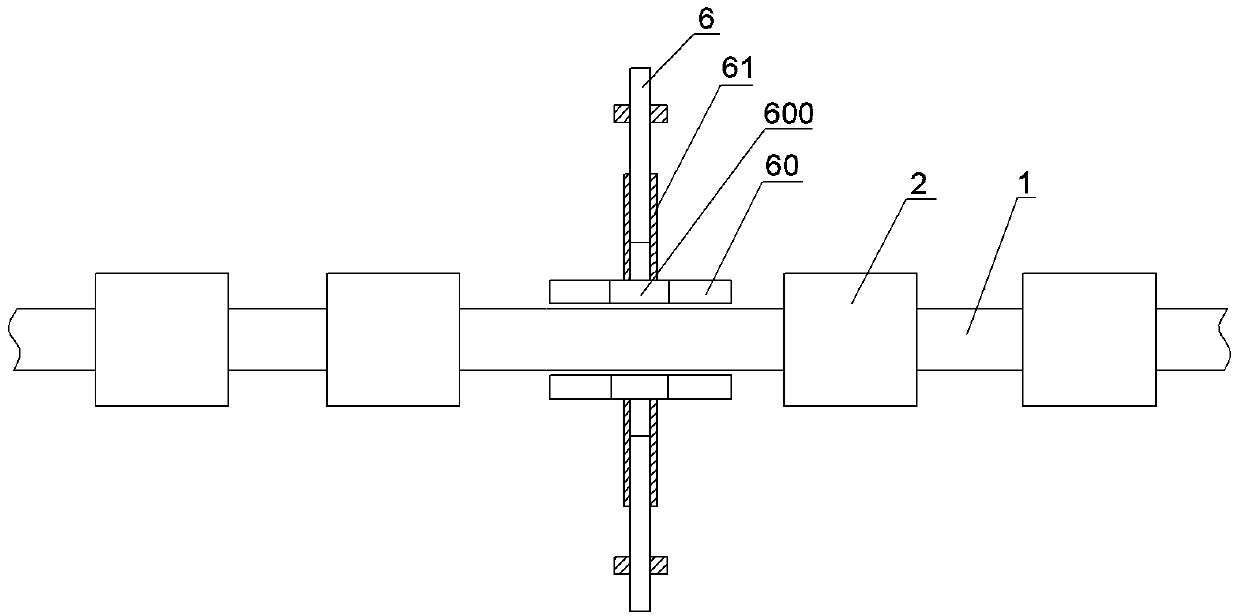

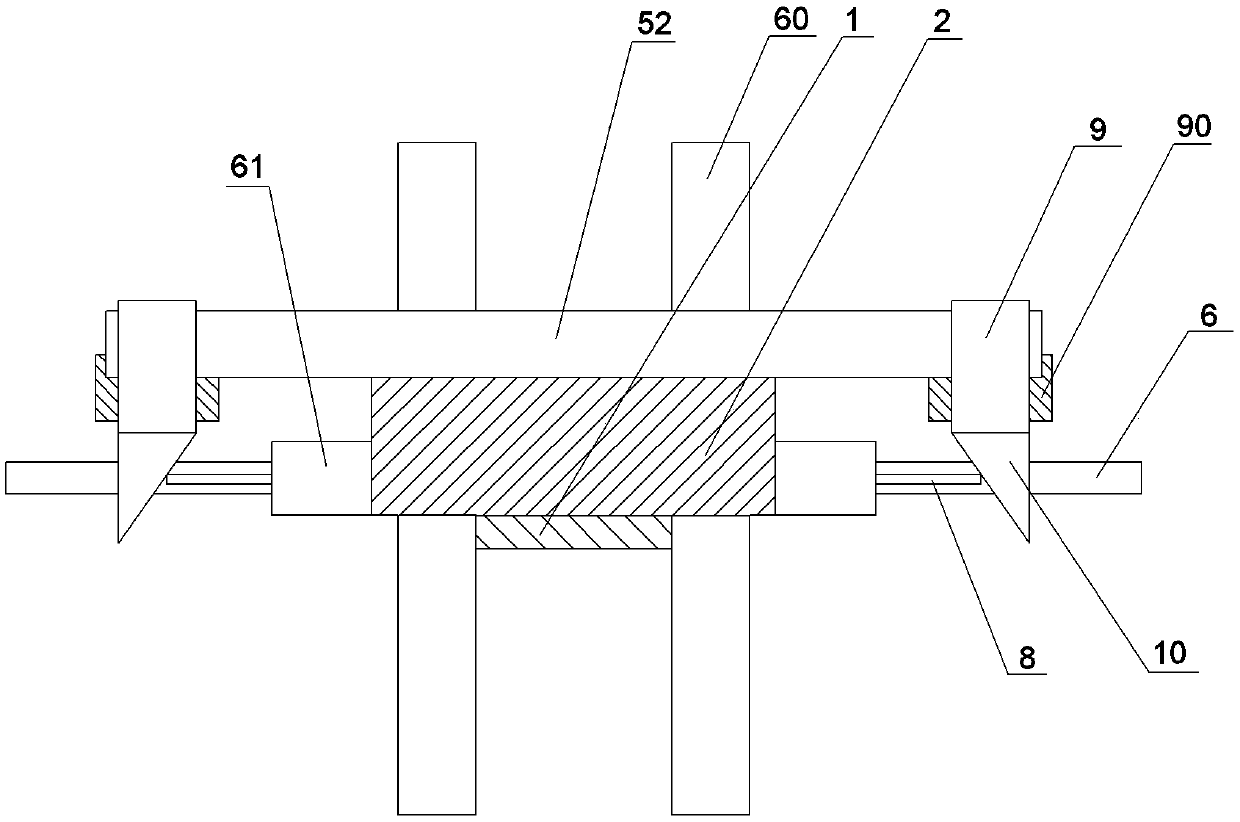

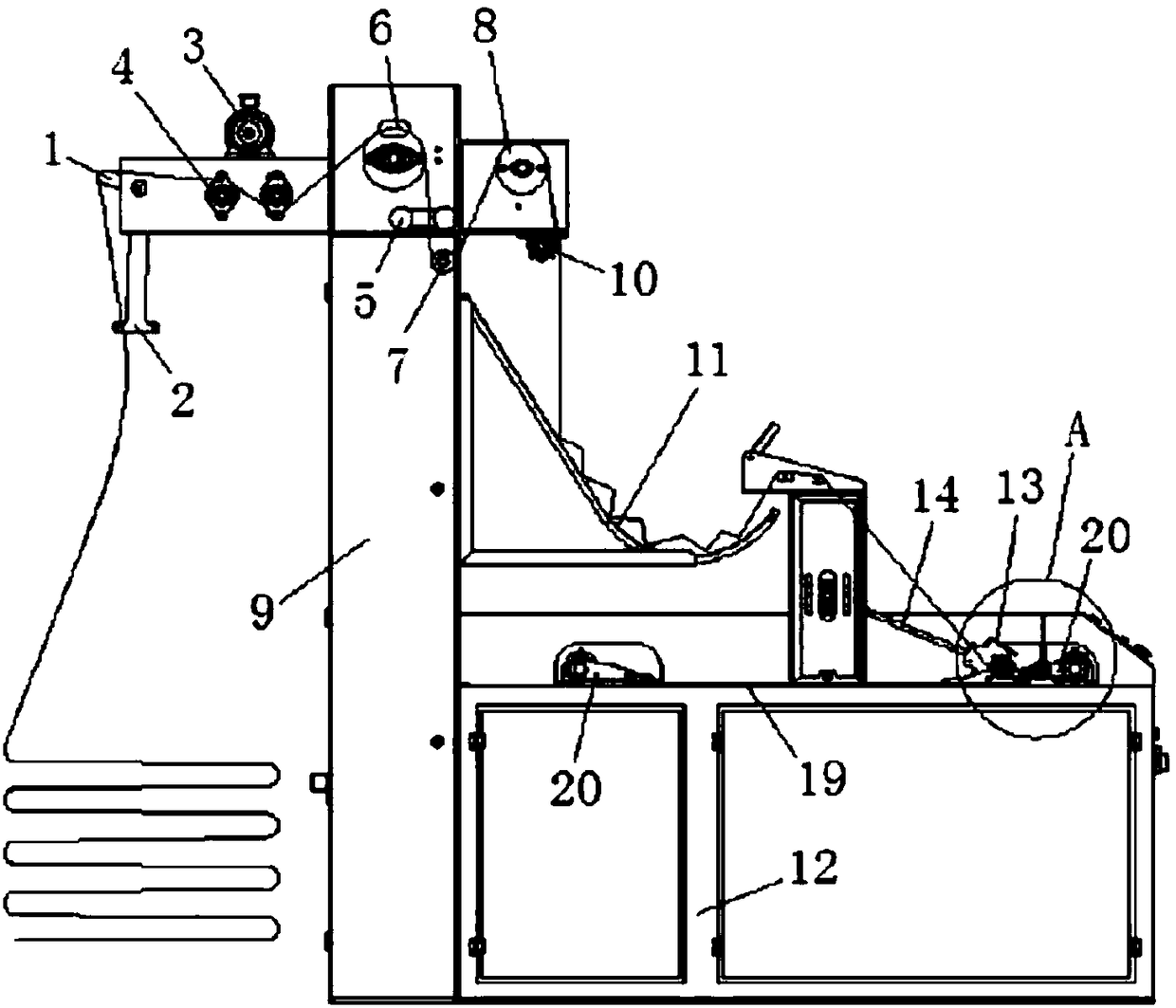

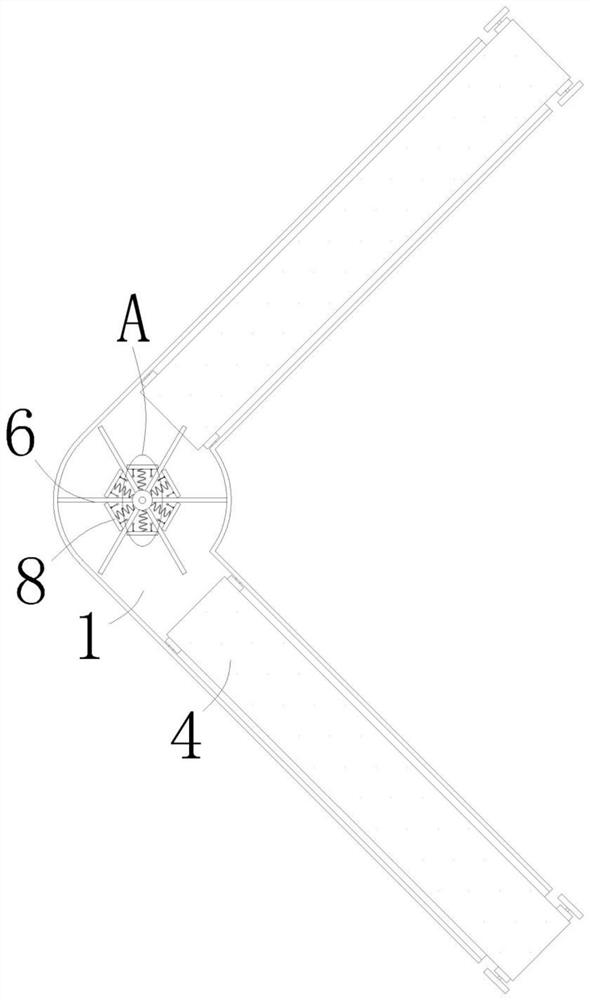

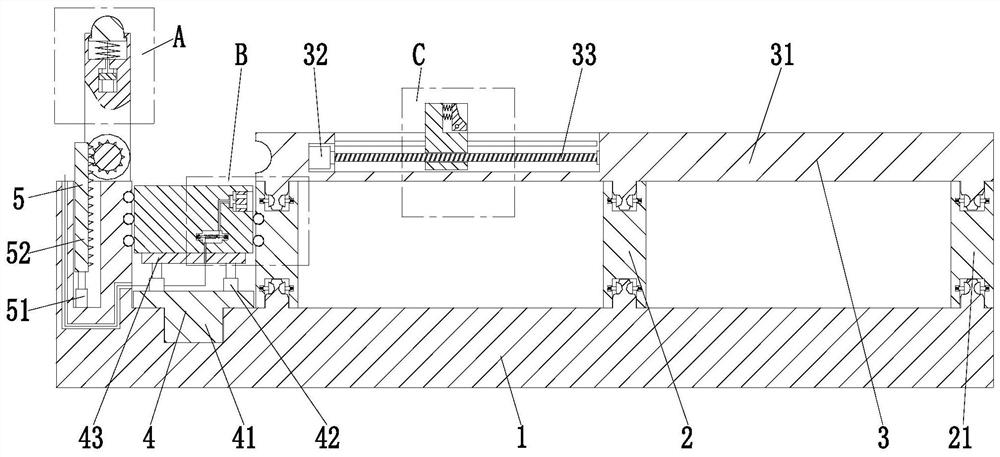

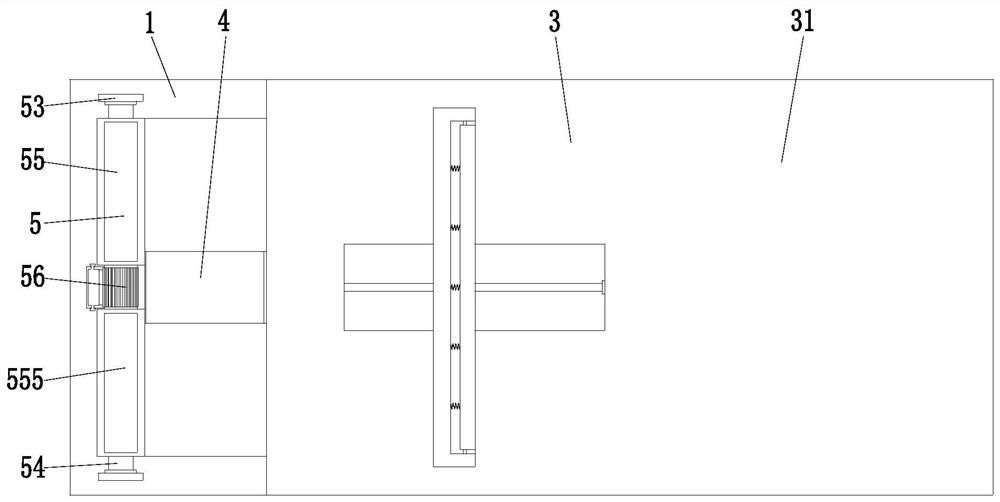

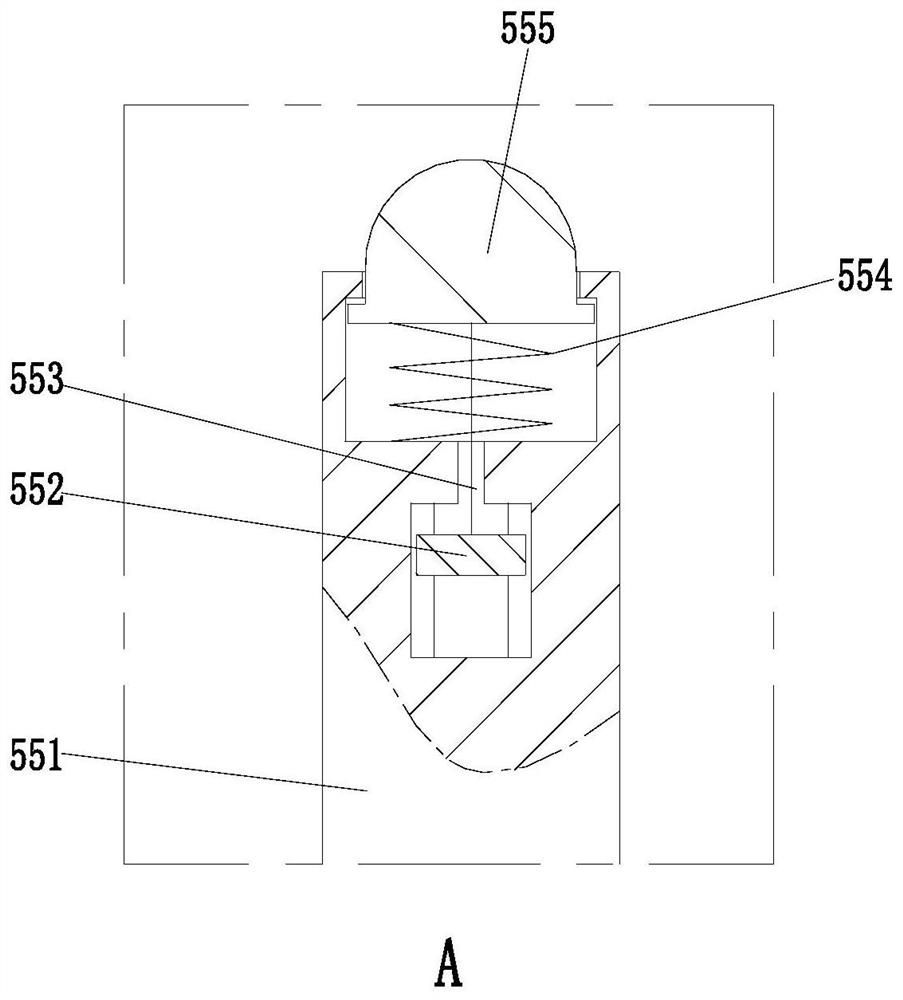

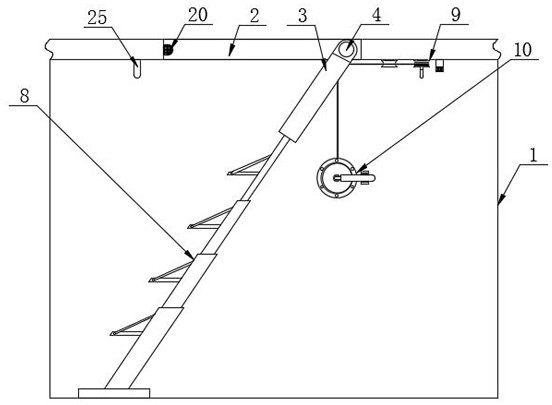

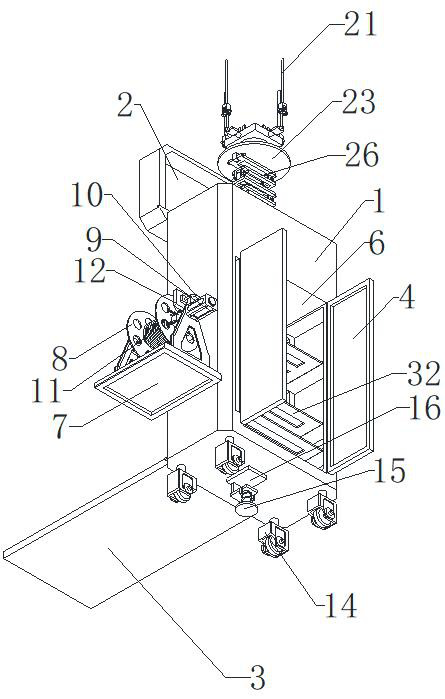

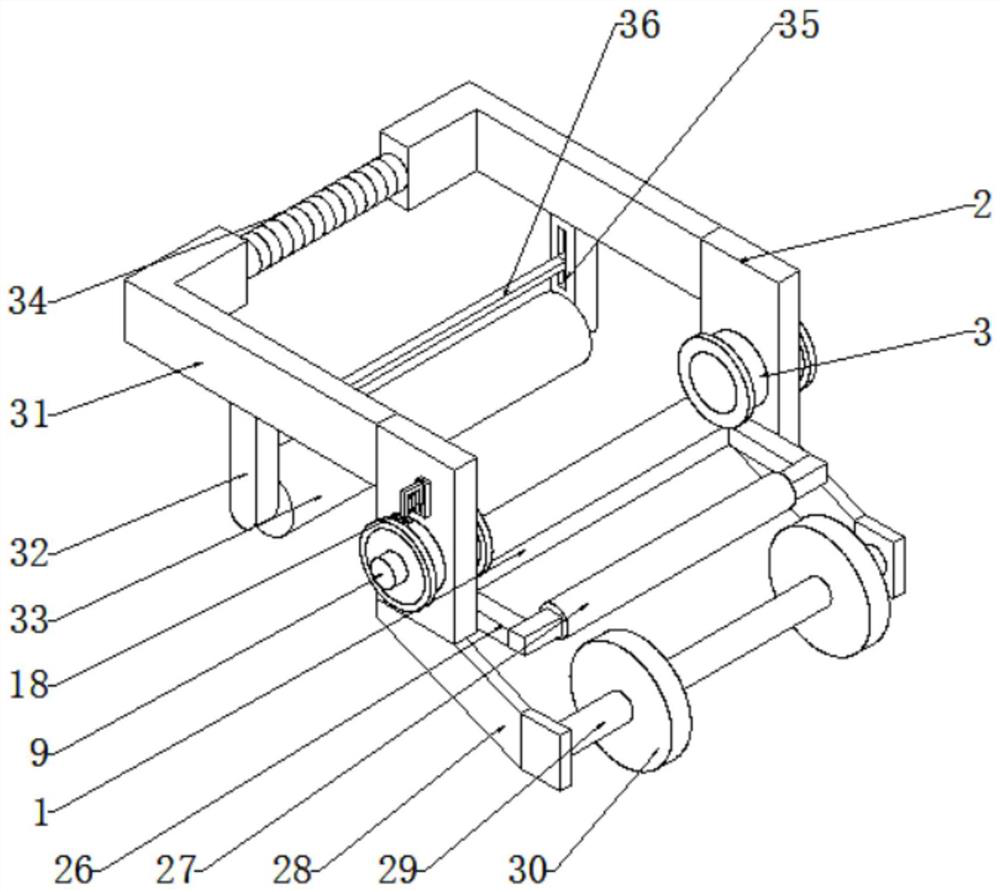

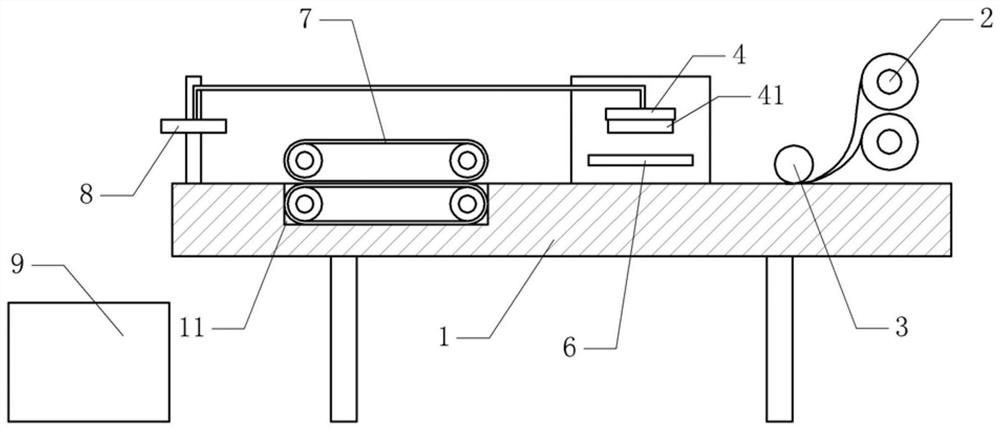

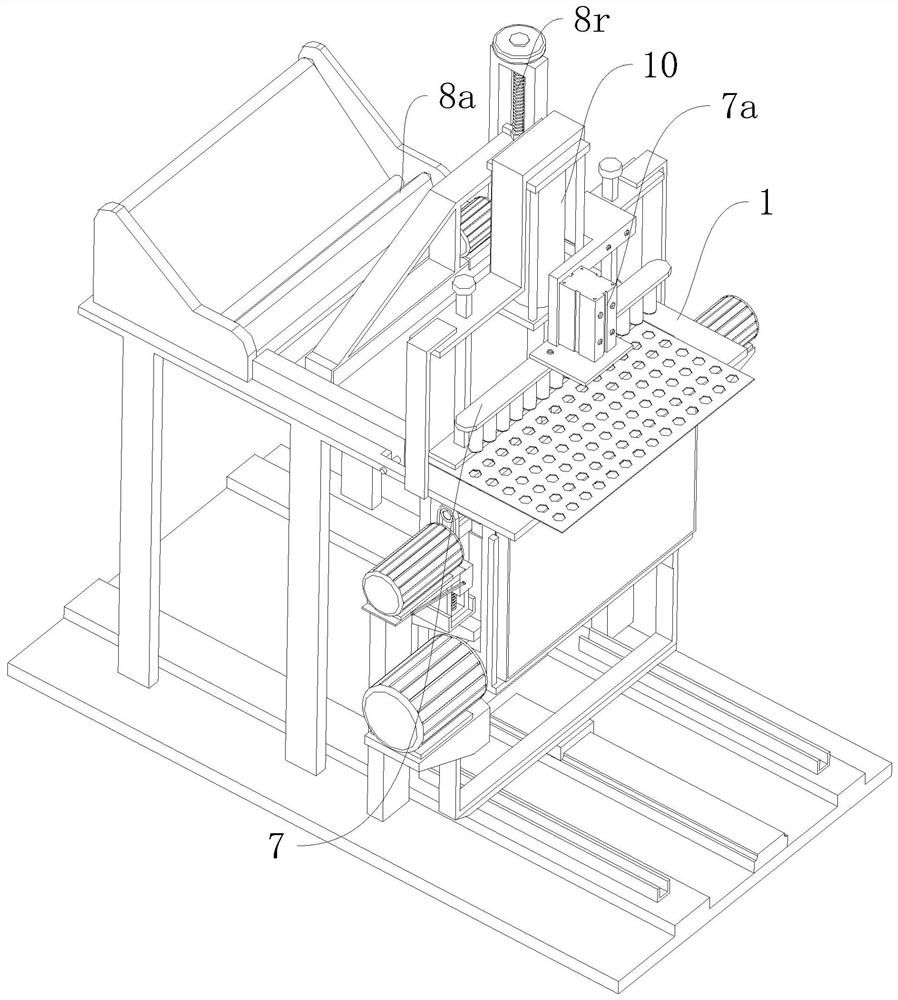

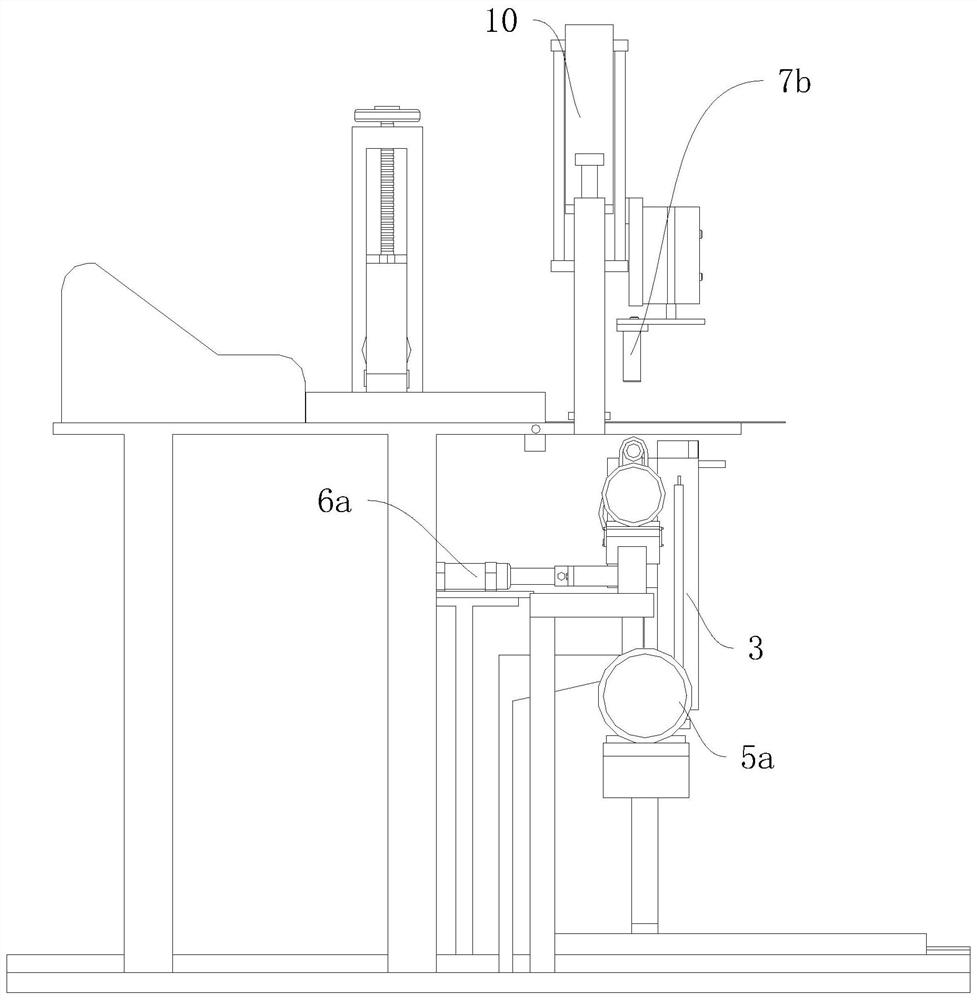

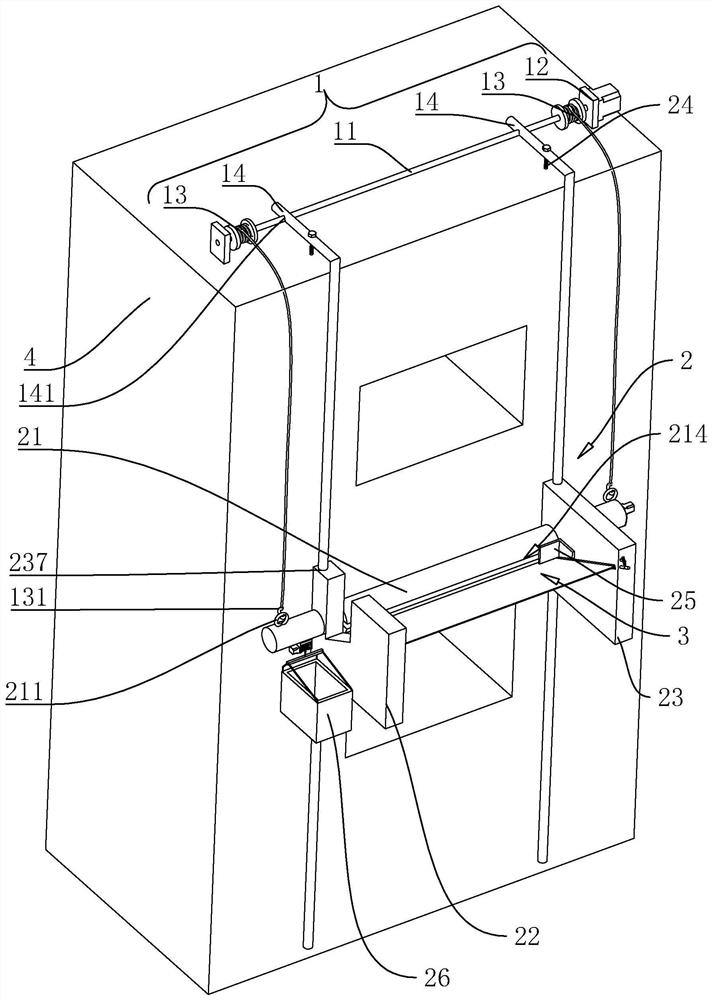

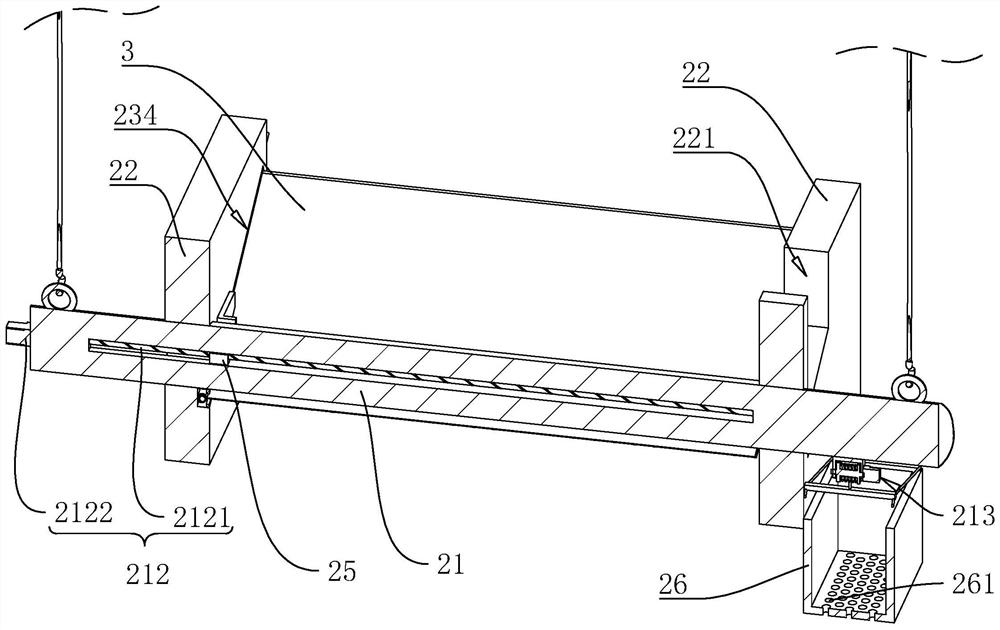

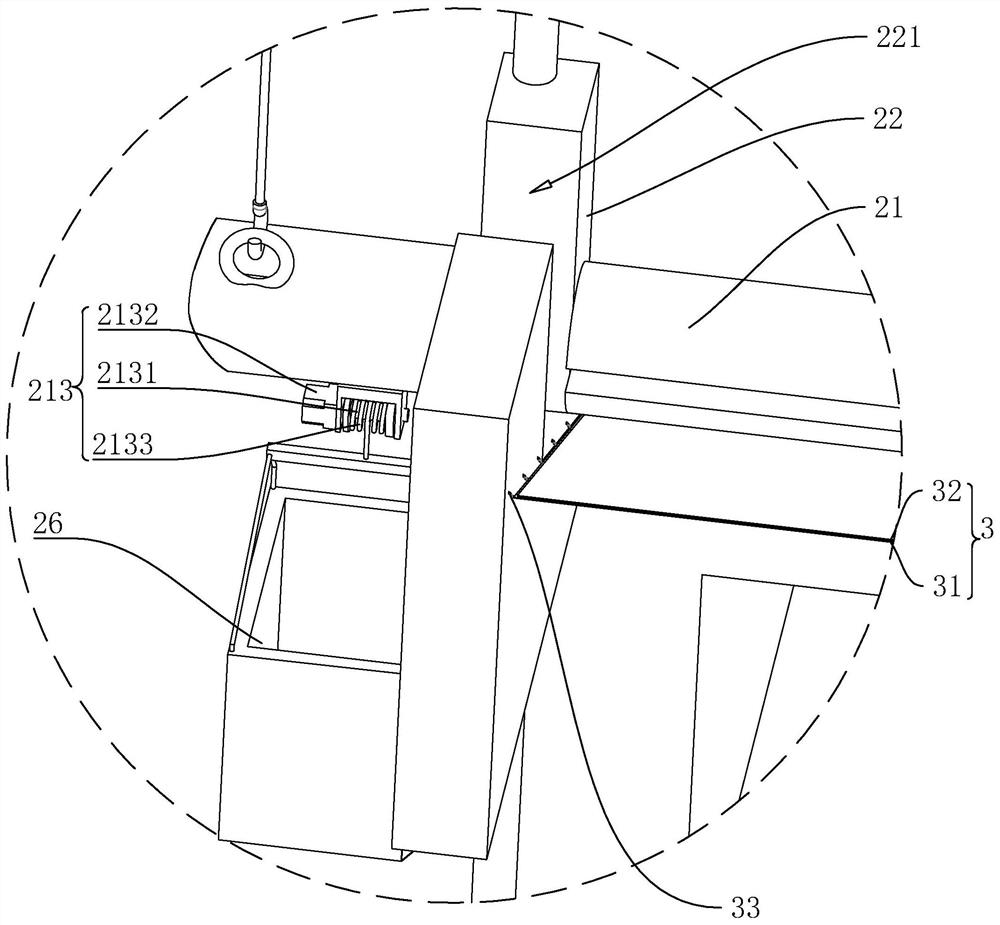

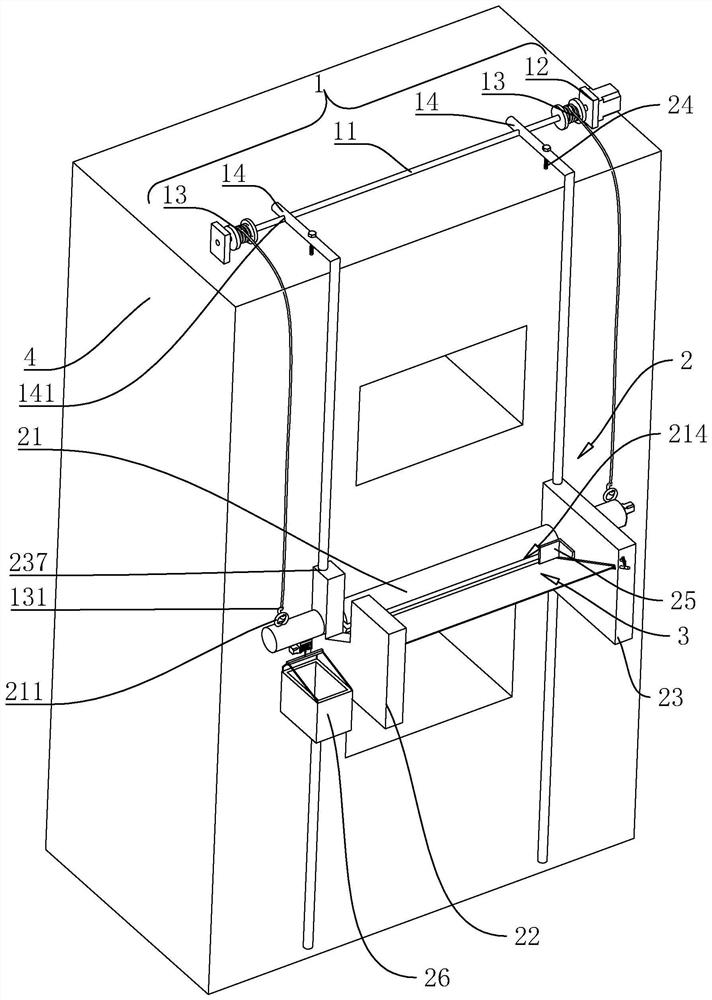

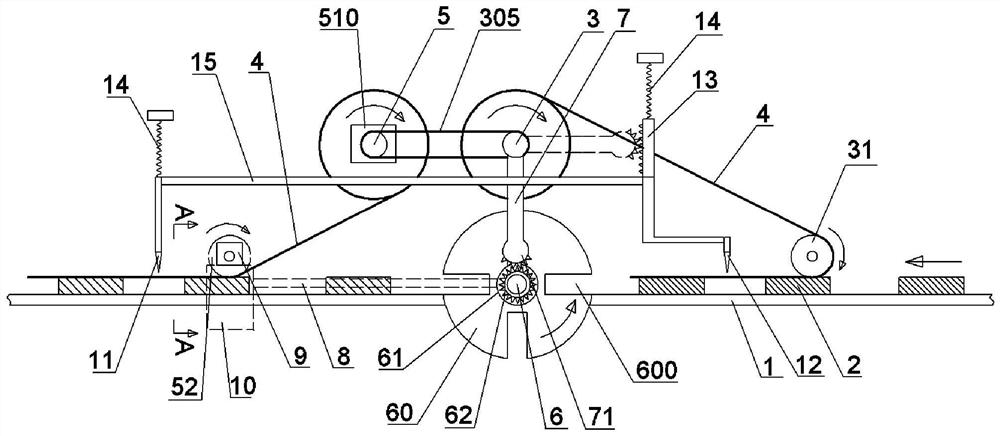

Full-automatic cloth-pulling and tailoring equipment

ActiveCN107190494ARealize unwindingAccurately cut off the materialSevering textilesUltimate tensile strengthAutomation

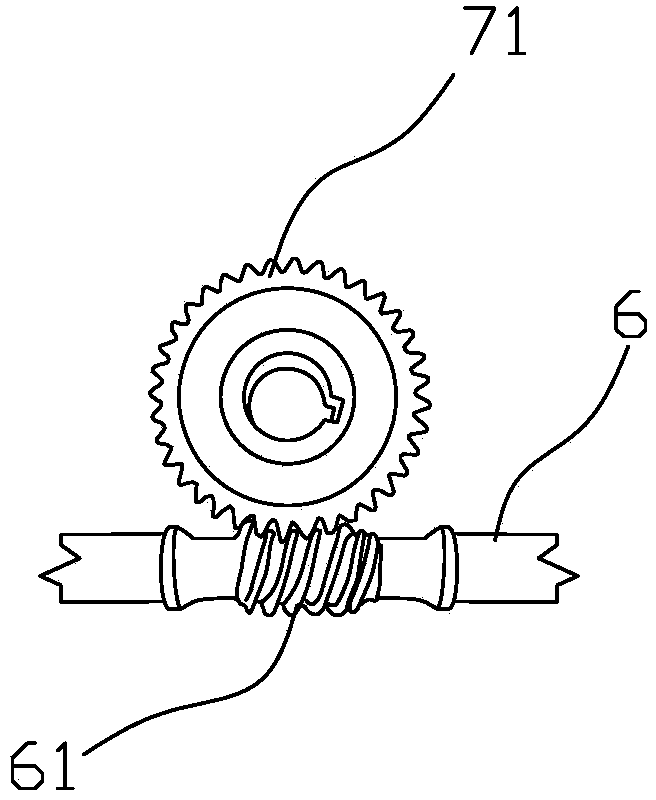

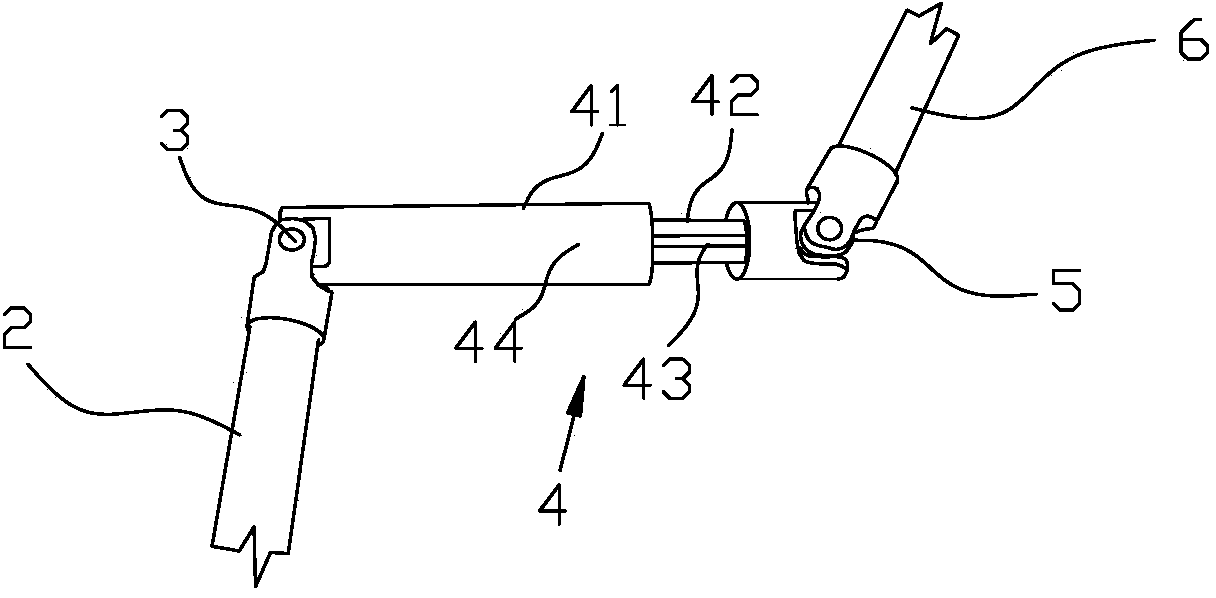

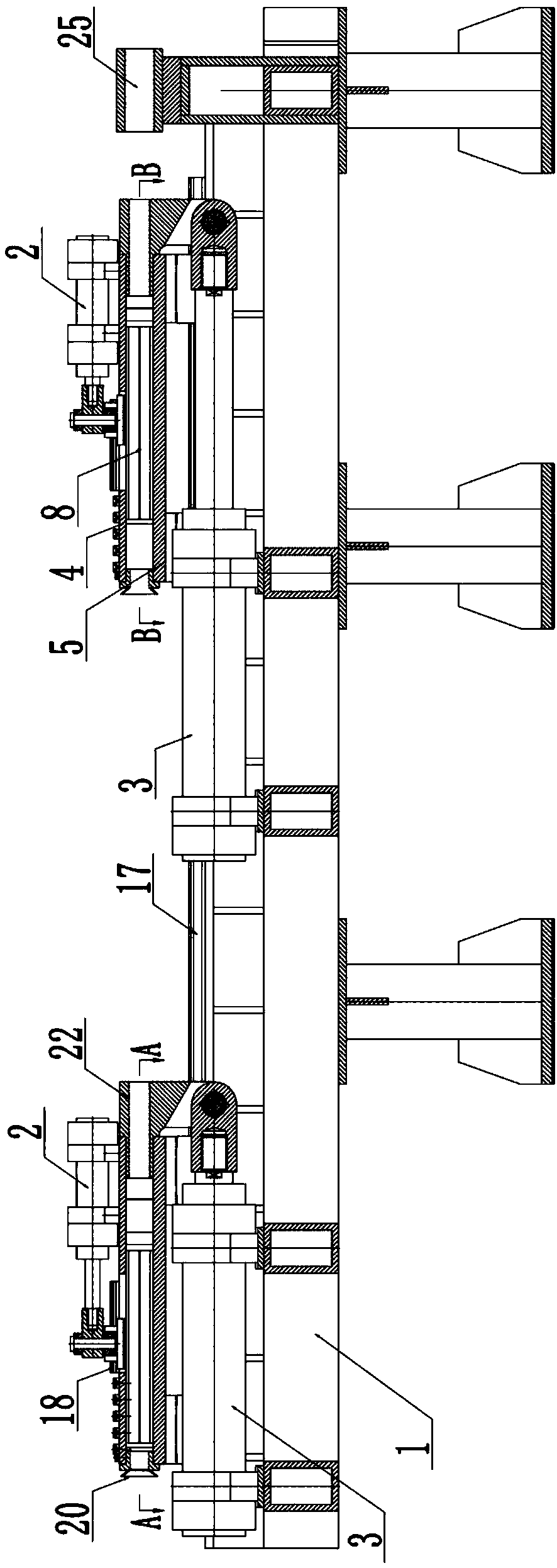

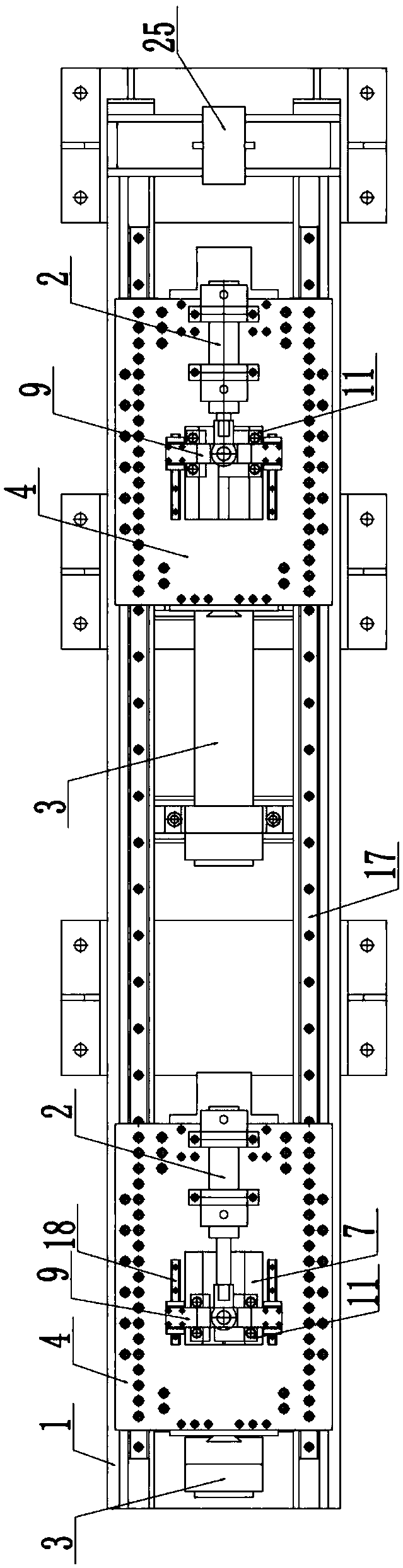

Disclosed is full-automatic cloth-pulling and tailoring equipment. The full-automatic cloth-pulling and tailoring equipment comprises a cloth-pulling platform (1) and is characterized in that a side face rail (2) is horizontally fixed to the bottom of the side face of the cloth-pulling platform (1), the side face rail (2) is provided with a multifunctional sliding table (3), rollers (4) installed on the multifunctional sliding table (3) are located on the side face rail (2), a side face gear rack (5) is fixed to the position, parallel to the side face rail (2), of the side face of the cloth-pulling platform (1), a stepping motor (7) is installed on the multifunctional sliding table (3), an output shaft of the stepping motor (7) is fixedly provided with a transmission gear (6), and the transmission gear (6) is meshed with the side face gear rack (5). The full-automatic cloth-pulling and cutting equipment is compact in structure, positioning, clamping and cutting of cloth can be automatically completed, after unwinding and cutting are completed, the cloth can be automatically tailored on the cloth-pulling platform, the automation degree is high, the labor intensity of workers is greatly reduced, the tailoring quality and specifications are ensured, and the processing efficiency is high.

Owner:JIHUA 3506 TEXTILE & APPL

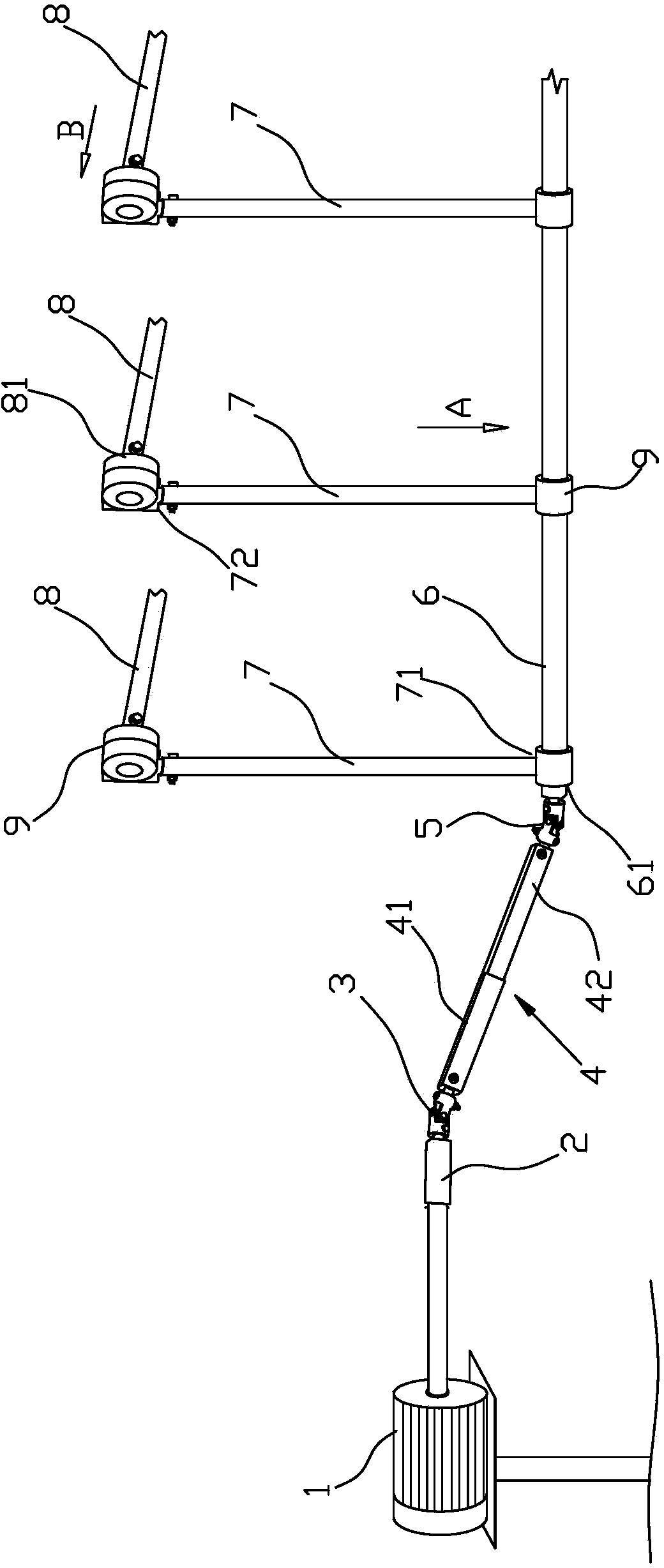

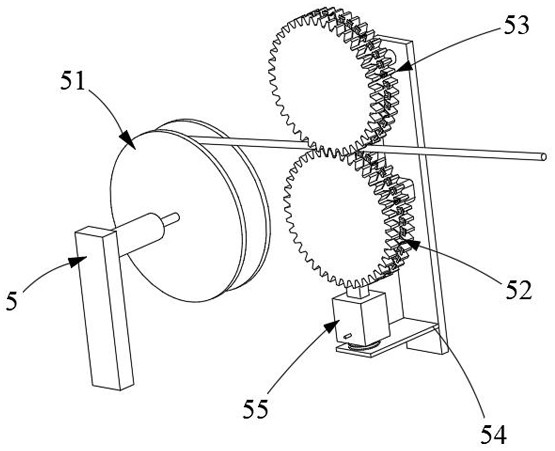

Roller blind device for greenhouse

ActiveCN103503727ARealize unwindingRealize windingClimate change adaptationGreenhouse cultivationAxial displacementDrive shaft

The invention provides a roller blind device for a greenhouse. The roller blind device for the greenhouse comprises a motor, a transmission shaft, a first universal joint, a stretchable rod, a second universal joint, a main shaft, an auxiliary shaft and a reeling shaft. The output end of the motor, the transmission shaft, the first universal joint, the stretchable rod, the second universal joint and the main shaft are connected in sequence, and the auxiliary shaft is connected with the main shaft and the reeling shaft through a non-parallel shaft gear pair. According to the roller blind device, torque is provided by the motor for the main shaft, the main shaft enables the torque to be transmitted to the reeling shaft through rotation of gears, a plastic thin film reels on the reeling shaft, and unreeling and reeling of a thin film roller blind for the greenhouse are electrically controlled. Meanwhile, the multiple universal joints are used in the roller blind device for compensating axial angle differences, the stretchable rod capable of transmitting the torque is further adopted to compensate the axial displacement, the reeling shaft of the roller blind device can depend on the outer contour of a greenhouse support in the reeling process to move, and the roller blind device is suitable for the roller blind of the greenhouse.

Owner:王爱冬

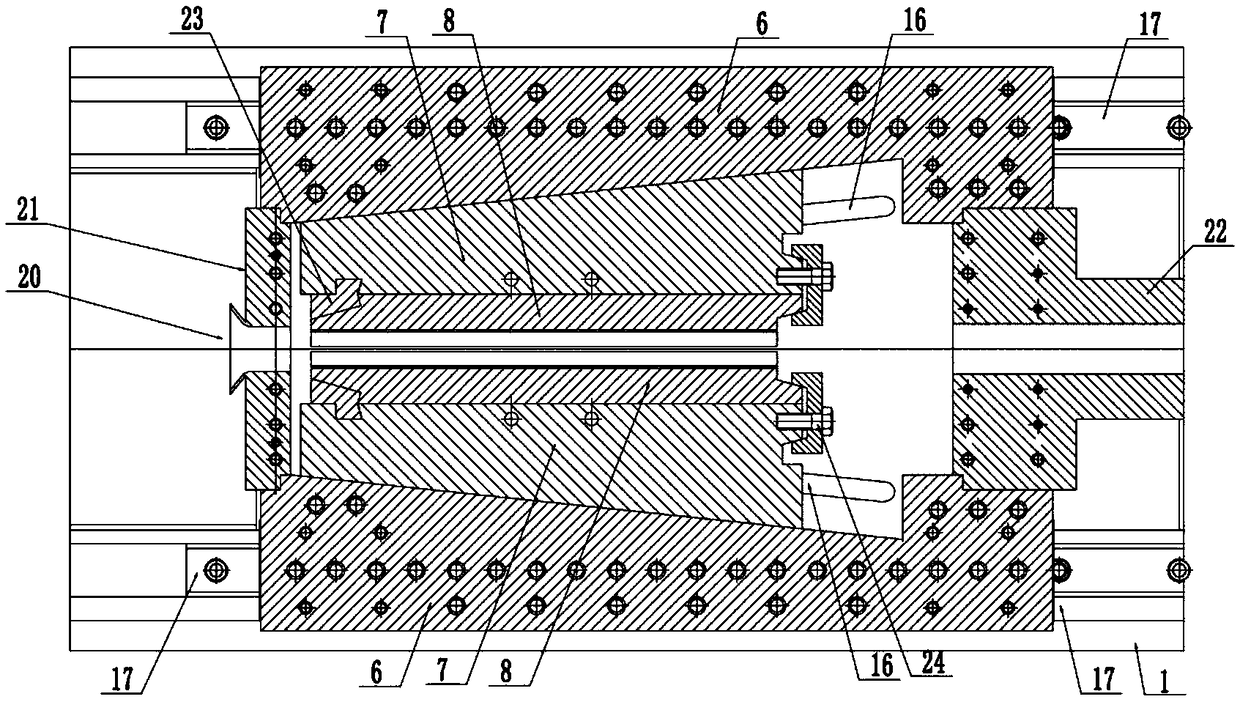

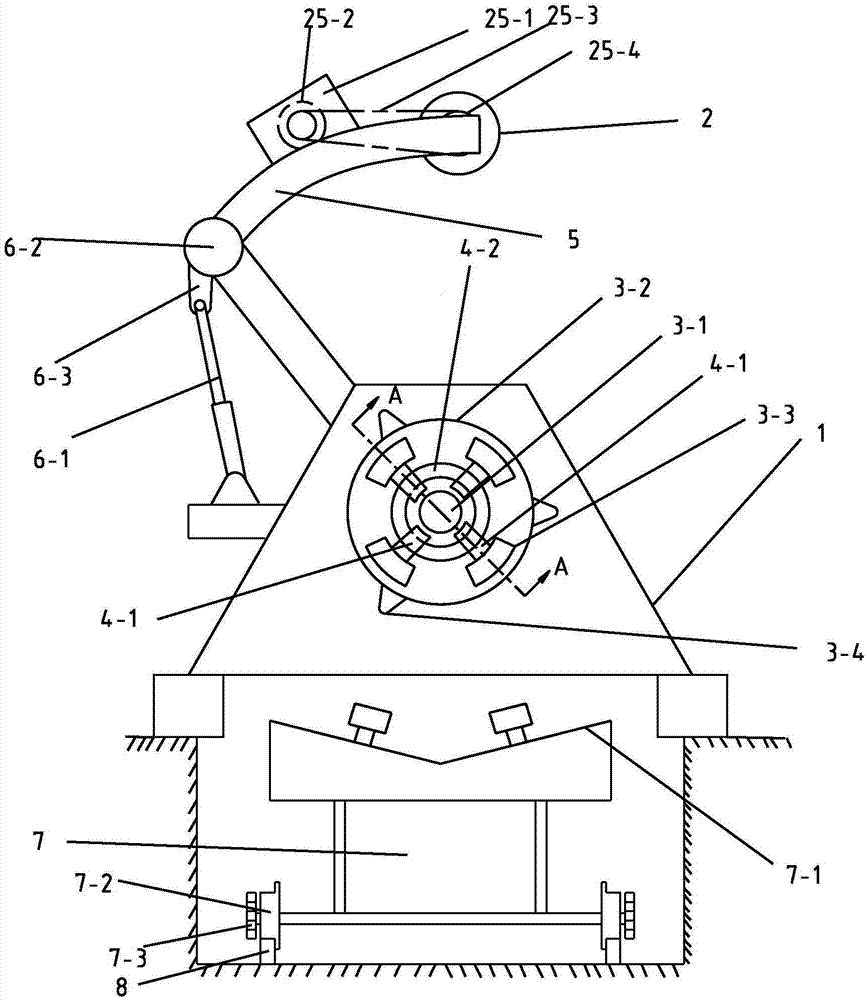

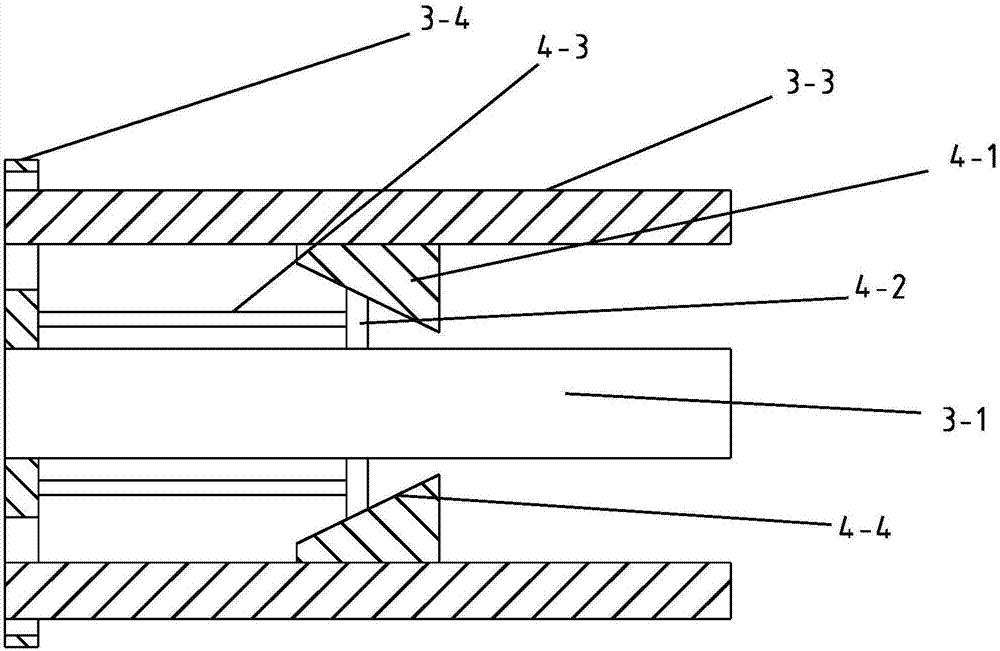

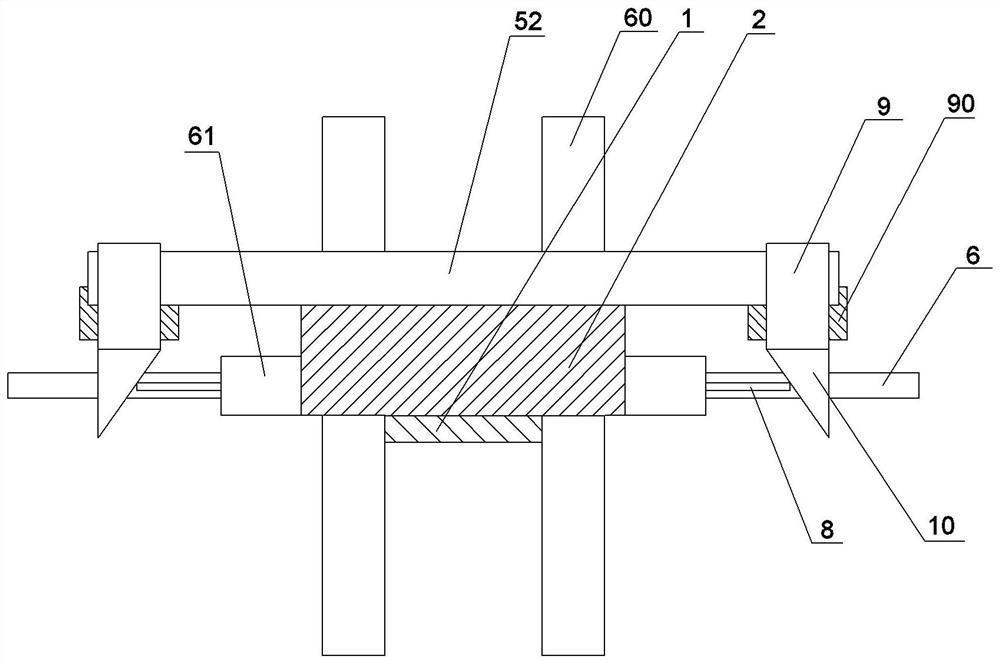

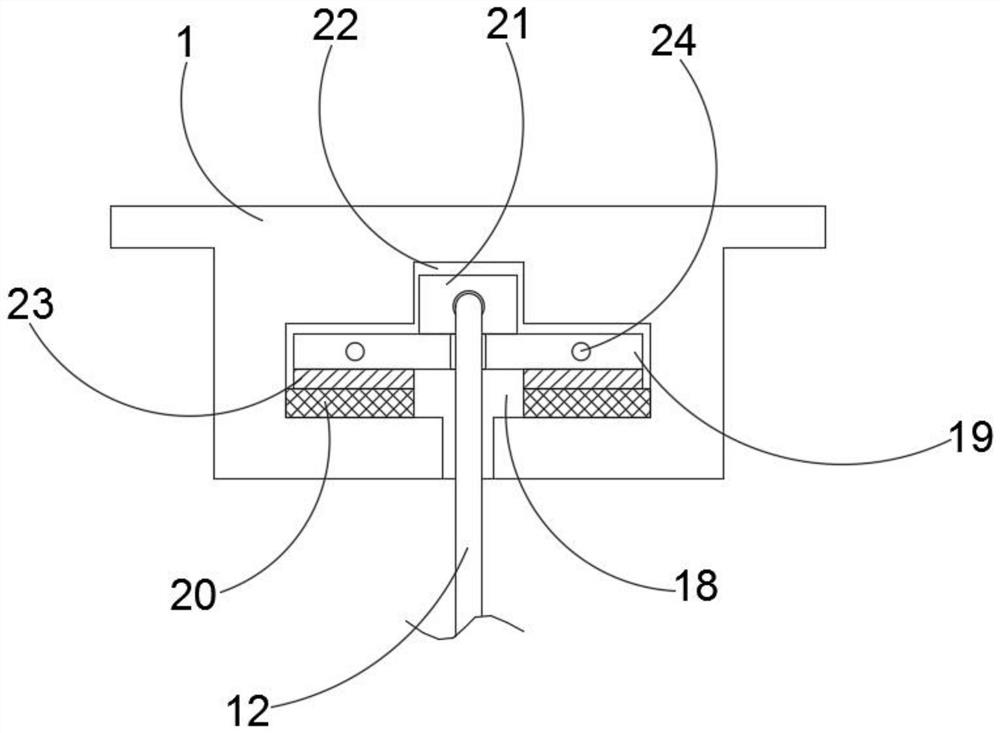

Hydraulic continuous drawing mechanism and copper alloy wire rod surface peeling system

PendingCN109396201ARealize continuous drawingNo damageWire straightening devicesExtrusion cleaning devicesWire rodSmall amplitude

The invention discloses a hydraulic continuous drawing mechanism and a copper alloy wire rod surface peeling system adopting the drawing mechanism. The drawing mechanism comprises a drawing workbench,a front drawing mechanism body and a rear drawing mechanism body. Each drawing mechanism body comprises a moving table, a die, a large oil cylinder and a small oil cylinder, wherein the moving tablemoves forwards and backwards under the action of the large oil cylinder, the moving table comprises a top plate, a bottom plate, a pair of positioning plates, sliding plates and a half die, a movablespace with a narrow front portion and a wide rear portion is formed between the pair of positioning plates, and the sliding plates are arranged on the inner sides of the positioning plates and can move back and forth along the inclined planes of the inner sides of the positioning plates. The peeling system comprises a paying-off mechanism, a vertical roller straightening mechanism, a vertical roller straightening mechanism, a straightening die, a turning peeling machine, the hydraulic continuous drawing mechanism and a take-up mechanism. The concentric or small-amplitude eccentric peeling of awire rod is realized, and the surface is clean and bright; meanwhile, the speeds of the oil cylinders of the hydraulic continuous drawing mechanism are matched to alternately work, the whole wire rodcan be continuously peeled, continuous peeling is achieved, and the production efficiency is high.

Owner:YANTAI WANLONG VACUUM METALLURGY

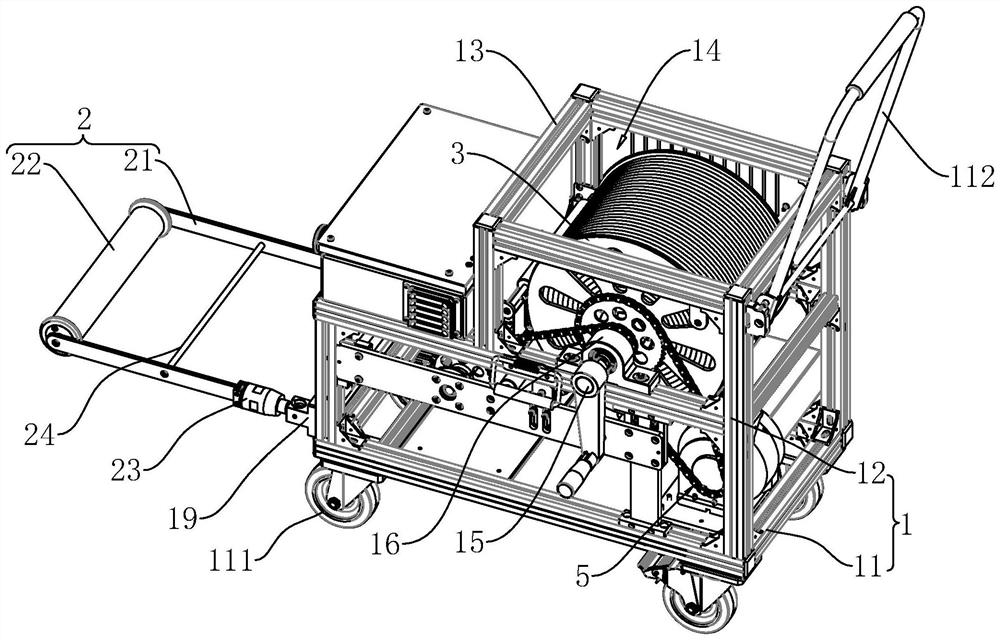

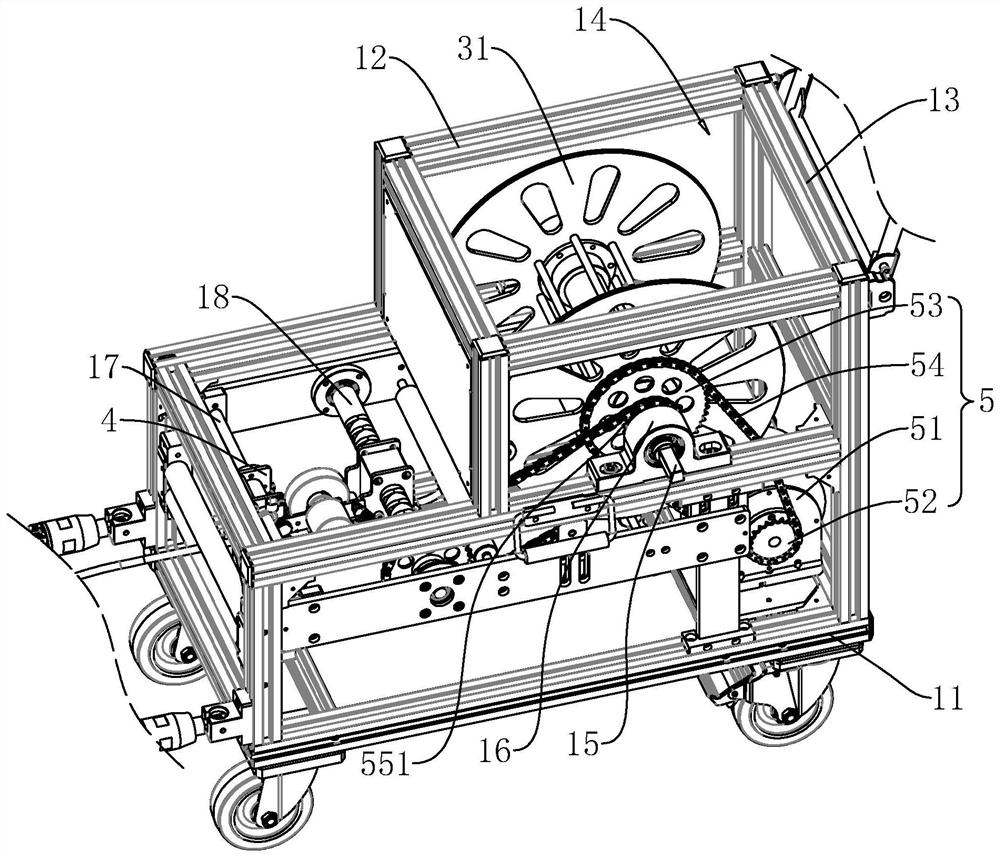

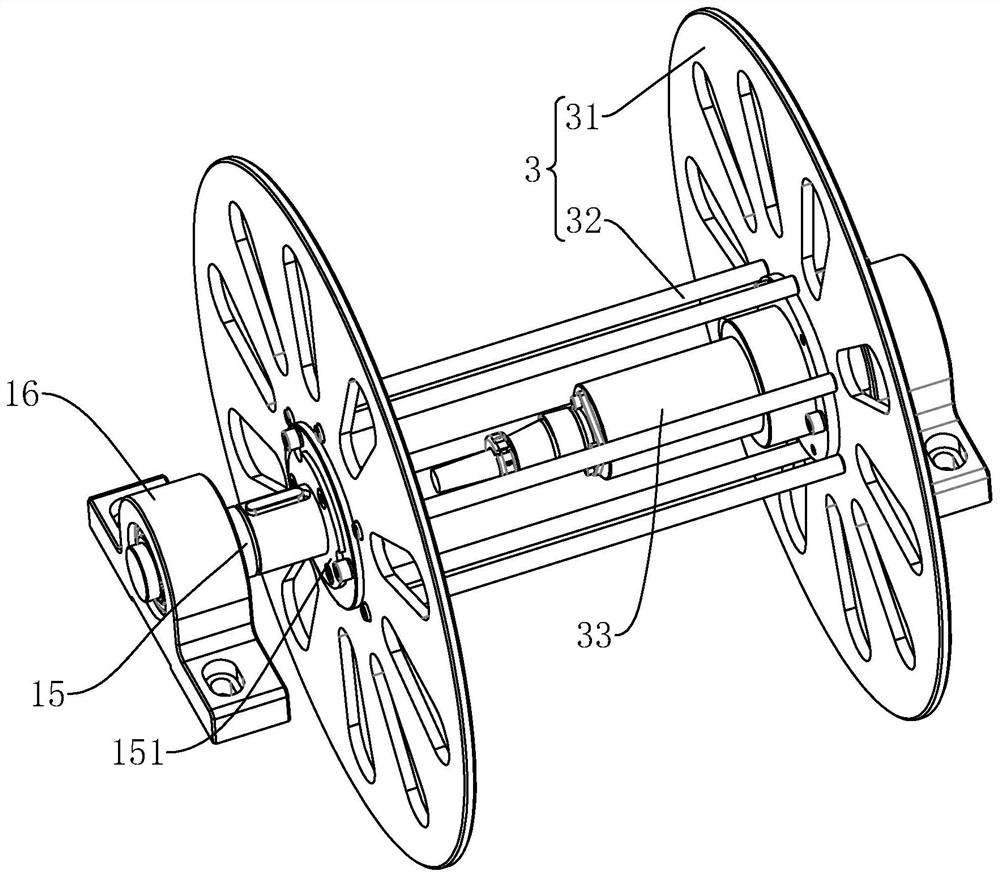

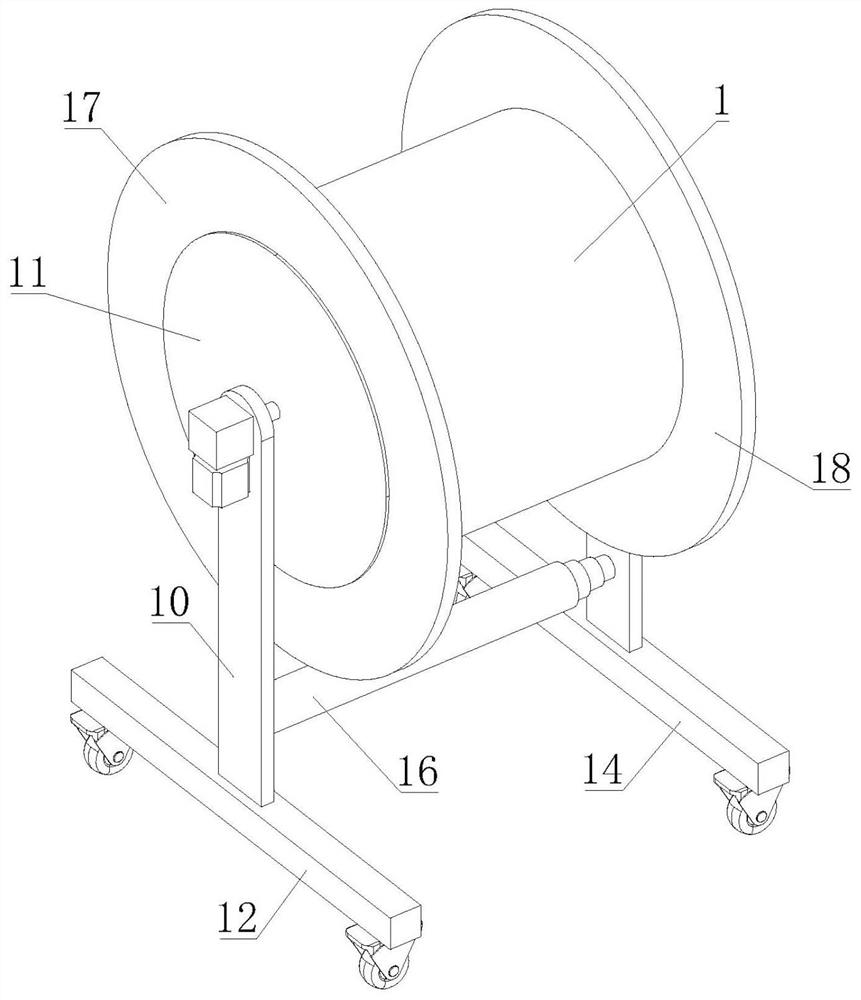

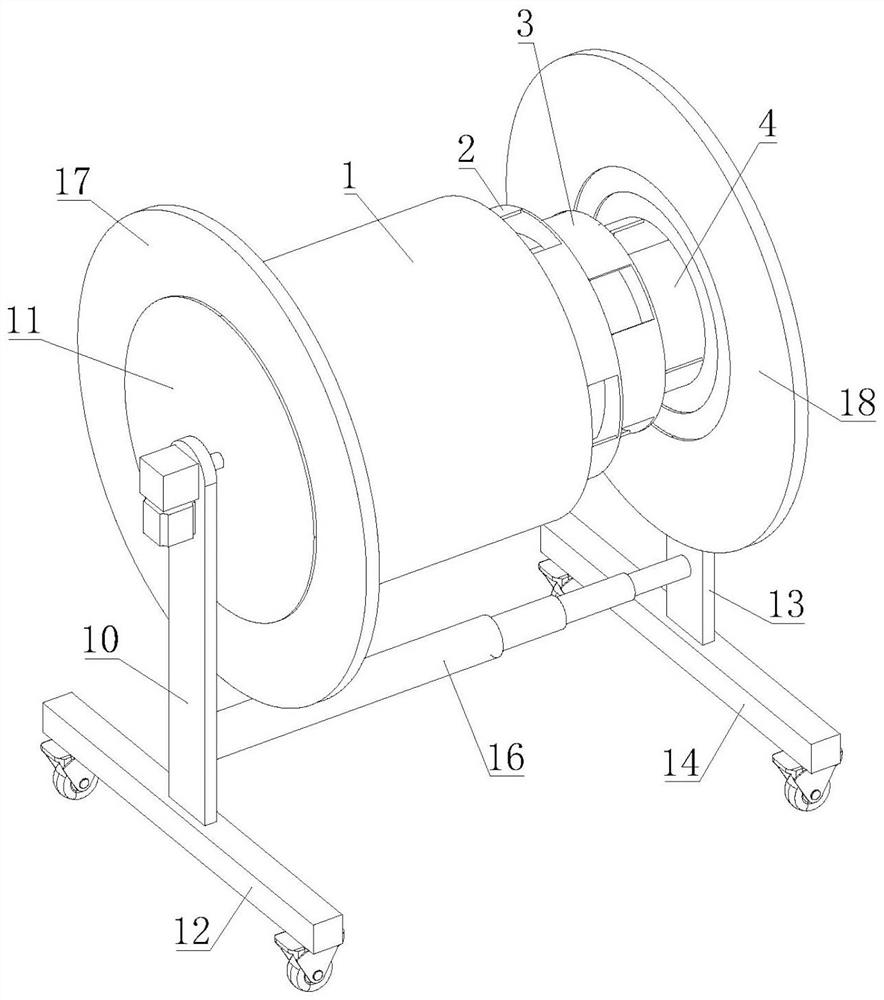

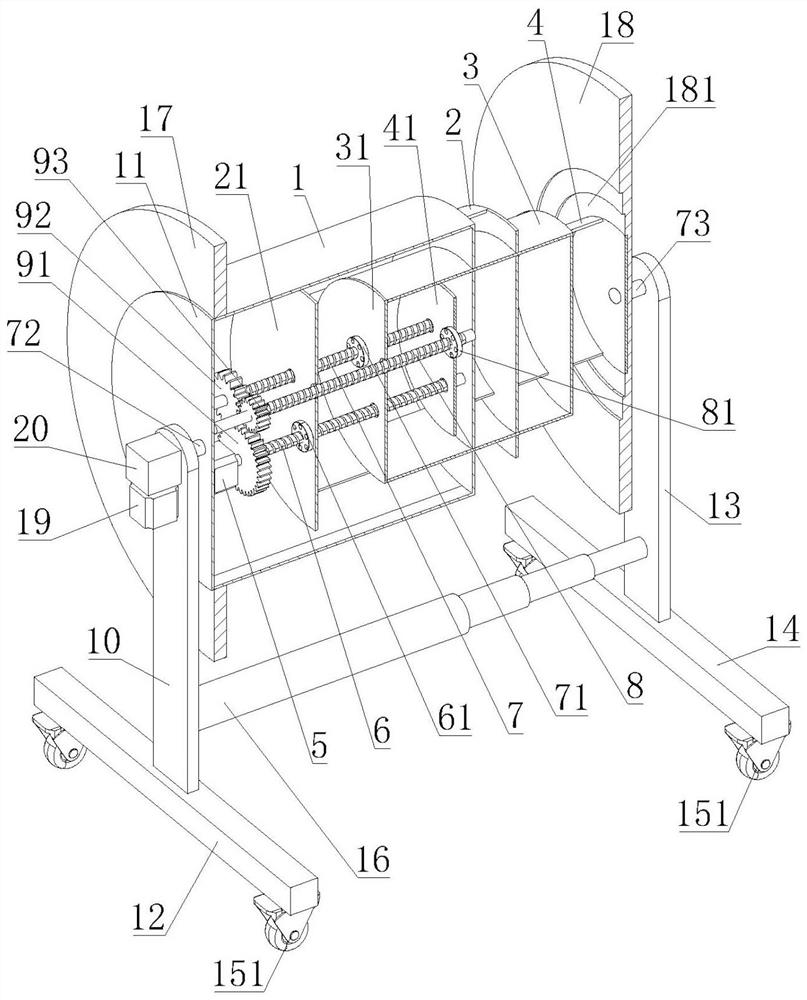

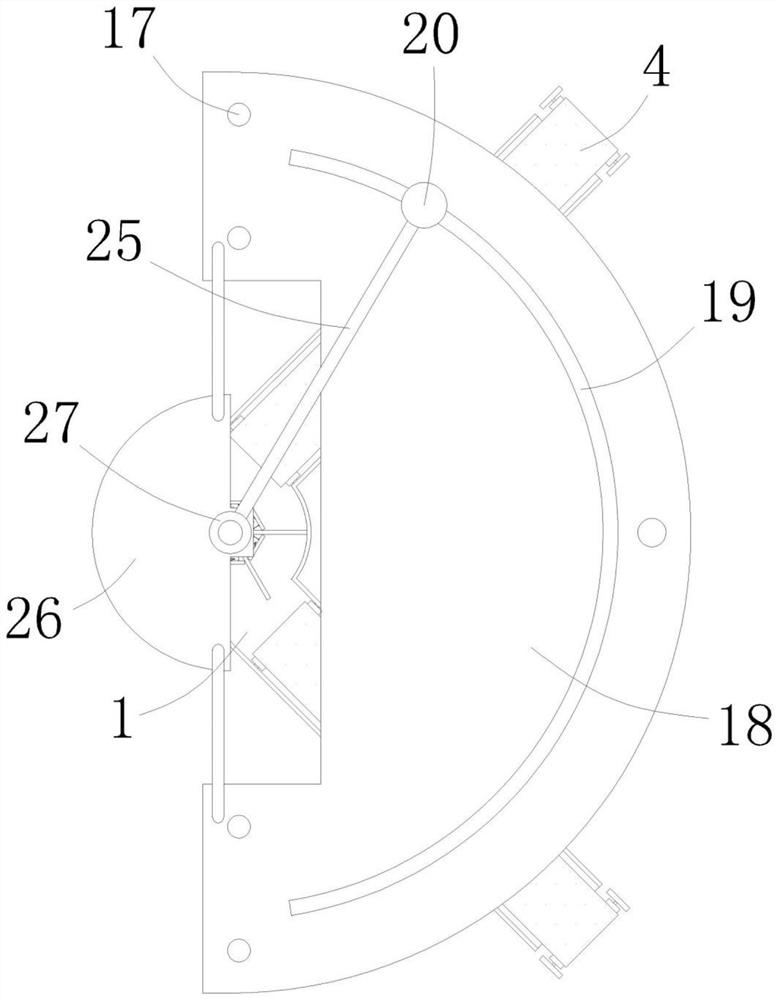

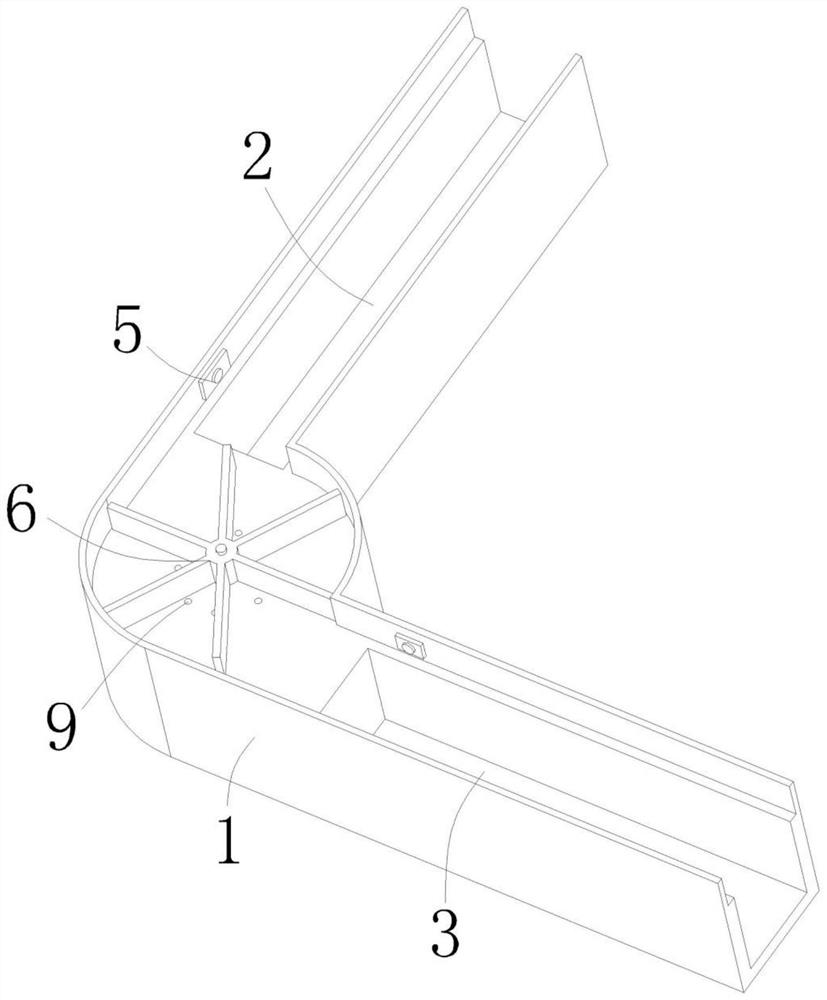

Automatic wire barrow

PendingCN113998548ASmall footprintAchieving Rotational LimitationFilament handlingCleaning using toolsVehicle frameEngineering

Owner:深圳市众汇智能科技有限公司

Package laminating machine

InactiveCN109677676AFlipTo achieve the effect of double-sided laminationPackagingEngineeringMechanical engineering

The invention belongs to the field of package printing, and particularly discloses a package laminating machine. A rack is included and provided with a conveying belt. A front face laminating mechanism, an overturning mechanism and a back face laminating mechanism are sequentially arranged in the conveying direction of the conveying belt. The front face laminating mechanism comprises a front facelaminating roller and a front face film cutter. The back face laminating mechanism comprises a sliding base, the sliding base is rotationally connected with a back face laminating roller, and a back face film cutter is arranged on the rack in a vertical sliding manner. The overturning mechanism comprises two overturning shafts rotationally connected to the rack and coaxially arranged, the two overturning shafts are located on the two sides of the conveying belt correspondingly and are in sliding connection with overturning discs, the overturning discs are provided with notches in which laminating workpieces are inserted, and the upper portions of the overturning shafts are rotationally connected with a front face film roll shaft and a back face film roll shaft. An overturning driving mechanism for driving the overturning shafts to intermittently rotate is connected between the front face film roll shaft and the overturning shafts. The package laminating machine can be universal for panel single-face laminating and double-face laminating.

Owner:重庆朝旭印务有限公司

Steel plate cross-shearing production line and steel plate cross-shearing process with same applied

PendingCN107470916AEasy to useRealize unwindingMetal-working feeding devicesShearing machinesSteel platesStructural engineering

The invention discloses a steel plate cross-shearing production line and a steel plate cross-shearing process with the same applied. The steel plate cross-shearing production line comprises a steel plate uncoiling device for uncoiling a steel plate coil, a flattening machine for flattening the steel plate uncoiled by the steel plate uncoiling device, a cross-cutting machine for cross-cutting the steel plate flattened by the flattening machine to form a plurality of cross-cut steel plate pieces, a conveying machine for sequentially conveying the multiple cross-cut steel plate pieces which are cross-cut by the cross-cutting machine, and a steel plate collecting device for sequentially collecting and stacking the cross-cut steel plate pieces which are conveyed by the conveying machine, wherein the steel plate uncoiling device, the flattening device, the cross-cutting machine, the conveying machine and the steel plate collecting device are sequentially arranged in the conveying direction of the steel plate. By means of the steel plate cross-shearing production line and the steel plate cross-shearing process with the same applied, the cross-cutting procedure of the steel plate can be well achieved, and using is quite convenient.

Owner:CHANGZHOU CHANGFA REFRIGERATION TECH CO LTD

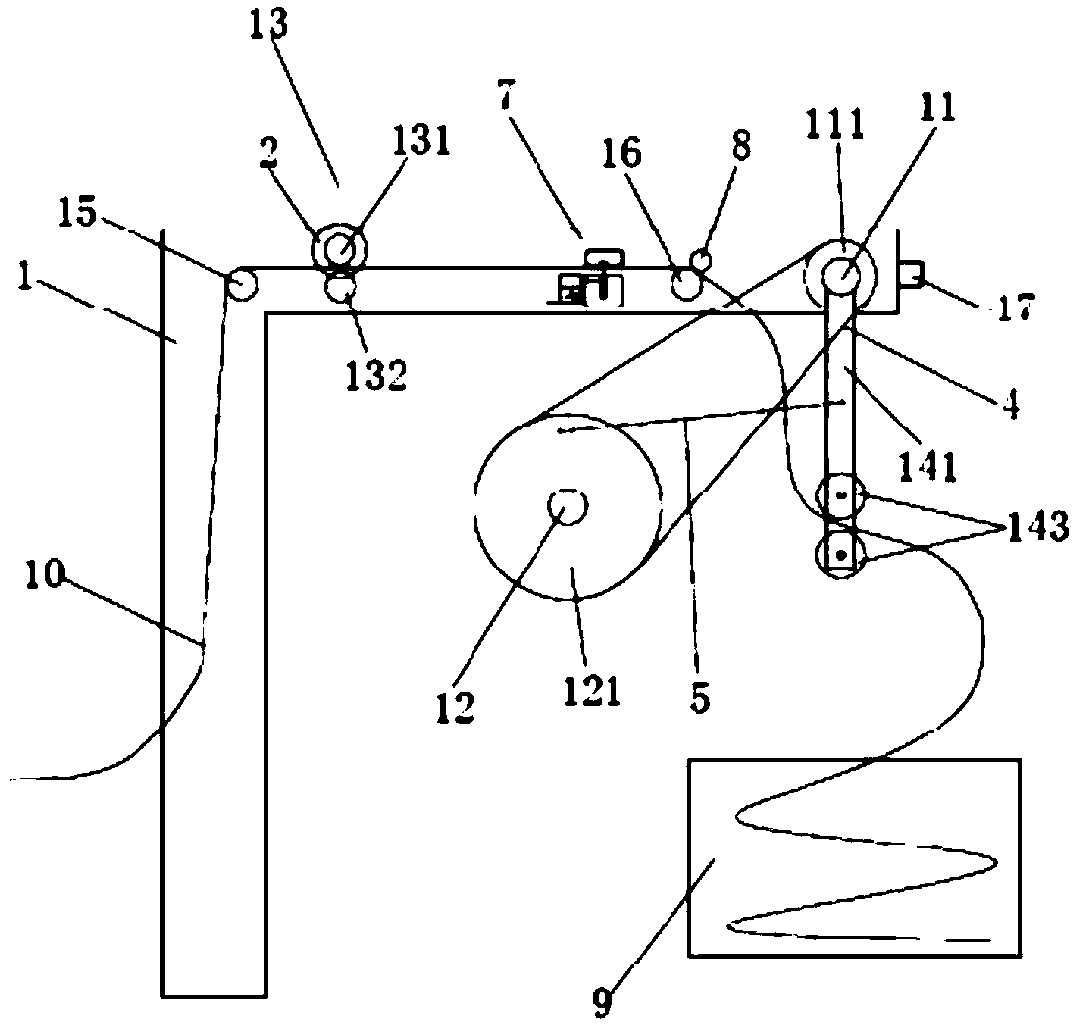

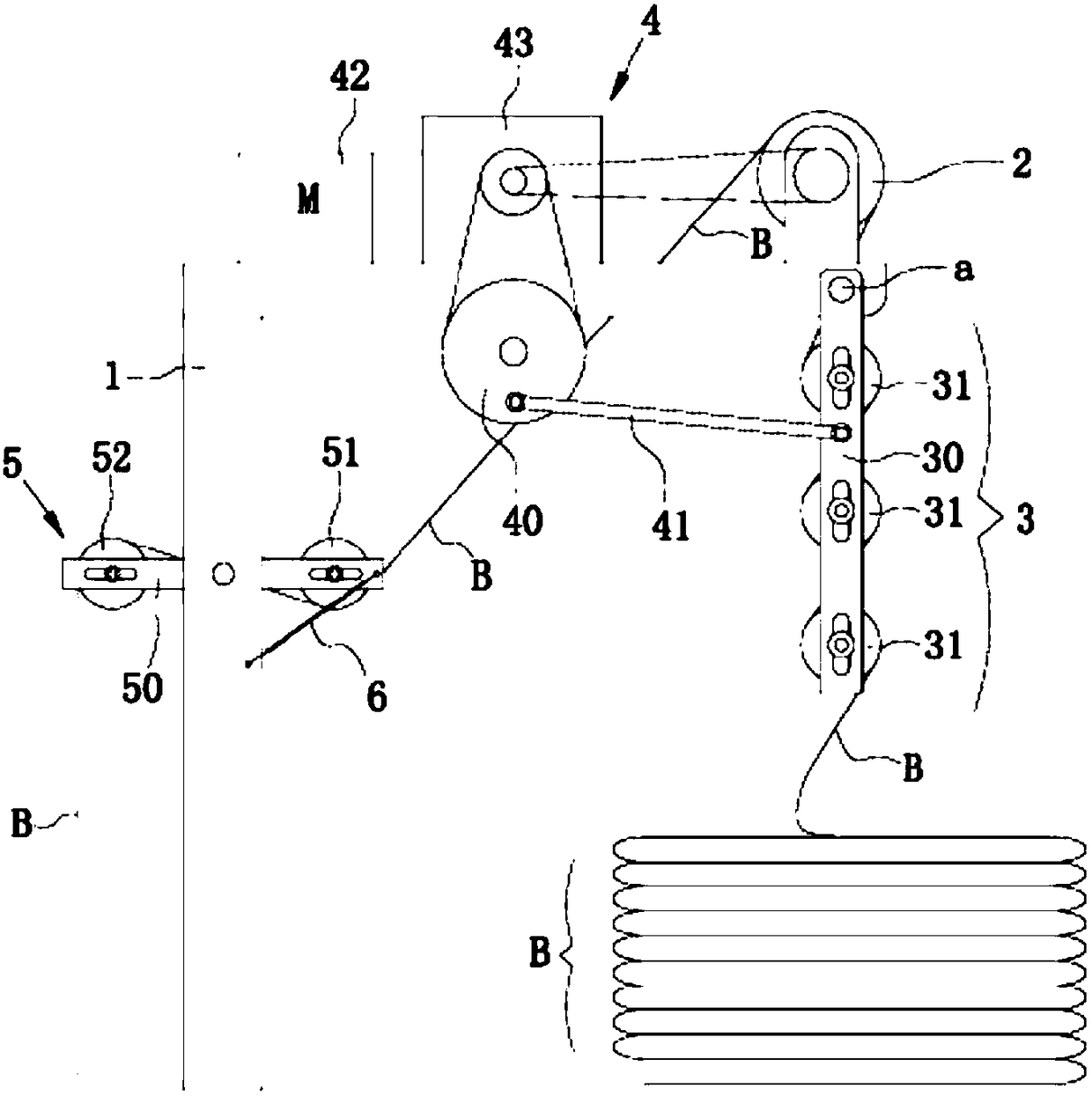

Swinging cloth collecting machine

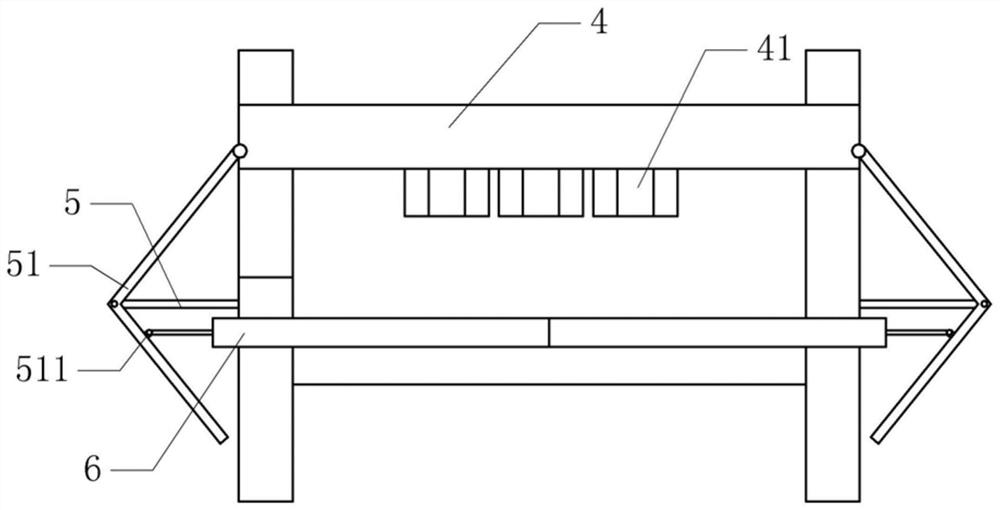

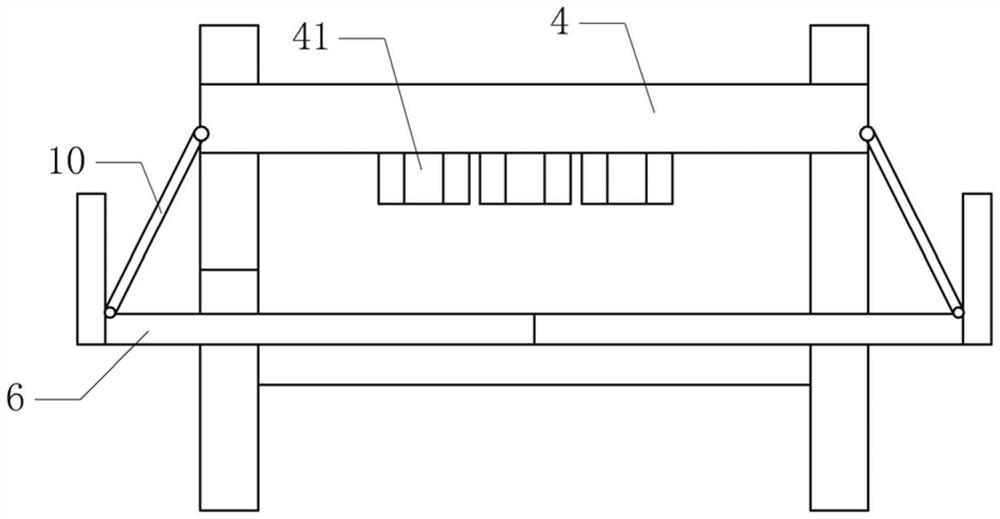

ActiveCN108529308ARealize unwindingFolding stableFolding thin materialsEngineeringMechanical engineering

The invention relates to a swinging cloth collecting machine. The swinging cloth collecting machine comprises a support and a swinging cloth collecting device arranged on the support; and the swingingcloth collecting device is used for unwinding and folding a cloth roll. The swinging cloth collecting machine is characterized in that the swinging cloth collecting device swings the cloth roll; dueto the fact that cloth conveying rollers and a cloth roll roller are both arranged on a first connection rod, a triangular transmission plate drives the first connection rod to swing around a first driving belt wheel shaft, and therefore the cloth roll roller and the two cloth conveying rollers are driven to swing and be matched with unwinding of the cloth roll roller, and it can be achieved thatpiece goods are folded more stably.

Owner:江苏盐渎百鸣农业有限公司

A kind of numerical control opening and shearing plate integrated machine

ActiveCN111872688BRealize unwindingAvoid offsetOther manufacturing equipments/toolsStructural engineeringMechanical equipment

The invention discloses a numerical control all-in-one machine for opening, leveling and shearing, which belongs to the technical field of mechanical equipment; A length adjustment mechanism is installed along the length direction of the installation shell. The top of the mobile platform rotates and cooperates with a horizontal rotation table. Two splints, the second splint and the first splint are arranged in parallel, the front and rear positions between the second splint and the installation shell are equipped with fixed ball joints, the front and rear positions between the first splint and the second splint Both are equipped with adjustable length ball joints; the inventive concept of the present invention is ingenious and practical, which can effectively reduce the workload of the staff, improve the work efficiency of plate leveling and shearing plates, and can also cut plates with different inclination angles. It has a wide range and is suitable for promotion and use.

Owner:鞍钢实业金属制品有限公司

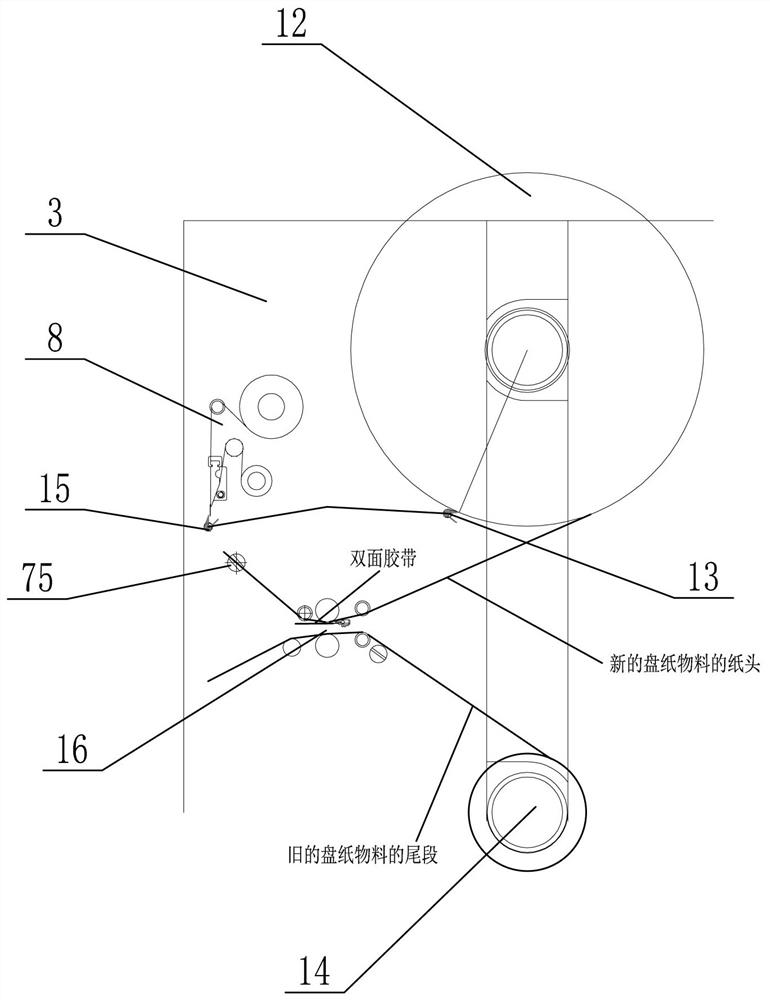

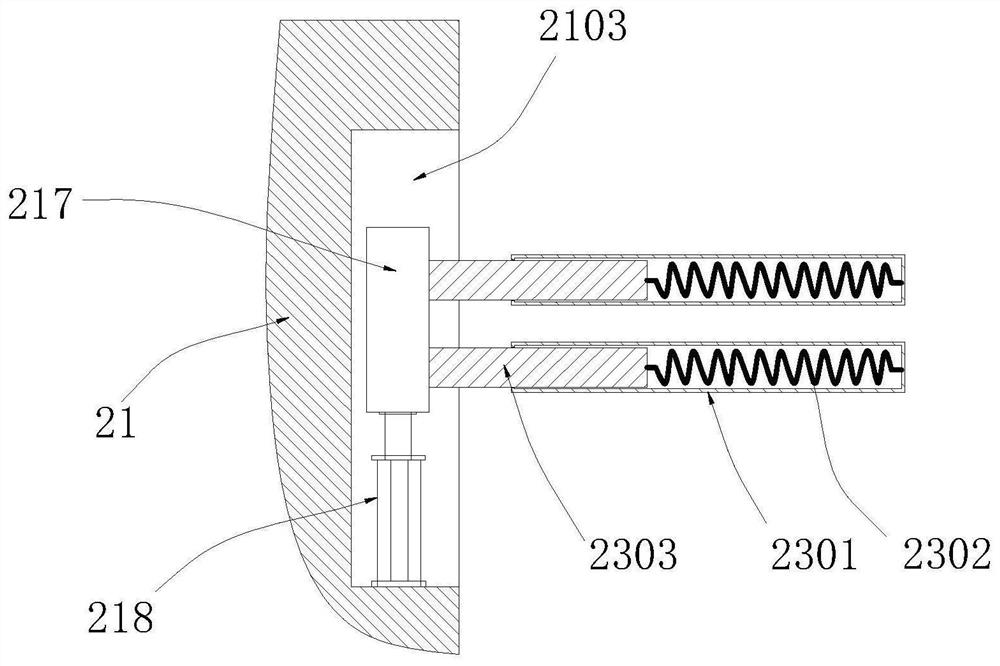

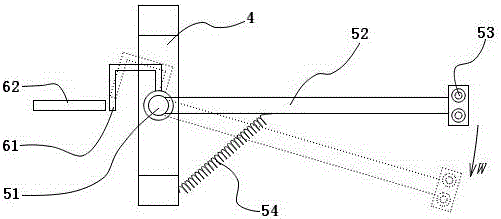

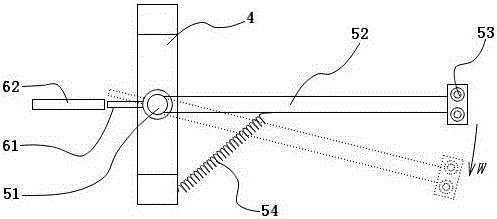

Station changing and unwinding mechanism of material station for belt material processing

PendingCN111908216ARealize roll changeRealize unwindingWebs handlingCigarette manufactureEngineeringStructural engineering

The invention provides a station changing and unwinding mechanism of a material station for belt material processing. The station changing and unwinding mechanism comprises two vertically-arranged andbilaterally-symmetric vertical station changing devices, wherein unwinding driving heads of the vertical station changing devices are driven by electric cylinder assemblies to vertically move up anddown, can turn over relative to the electric cylinder assemblies, and then can be arranged vertically upward or perpendicular to the electric cylinder assemblies; furthermore, the unwinding driving heads of the two vertical station changing devices are arranged on a common axis, namely a symmetric axis between the two vertical station changing devices; when arranged vertically upward, the unwinding driving heads move up and are used for grabbing belt material trays at a material supply station; when arranged perpendicular to the electric cylinder assemblies, the unwinding driving heads are used for performing the unwinding operation; and the the unwinding driving heads of the two vertical station changing devices act alternately, so that the reel replacement and the unwinding of belt materials can be achieved.

Owner:HENAN XINZHILIN ELECTROMECHANICAL DEVICE CO LTD

Power cable winding and unwinding equipment and using method thereof

Owner:GANSU SHINING SCI & TECH

E-commerce goods sorting and transferring device

The invention discloses an E-commerce goods sorting and transferring device, which comprises an operation table, a top plate located above the operation table and a side plate fixed to the right side of the top plate; a first cavity and a second cavity are arranged on the upper surfaces of the front side and the rear side of the operation table correspondingly; conveying belts are installed in the first cavity and the second cavity correspondingly; a volume detector is fixedly connected with the inner wall of the top of the operation table; a through hole is reserved in the middle of the upper surface of the operation table; a connecting rod located in the operation table is arranged below the through hole; a supporting rod is fixed to the lower surface of the top plate; a sleeve is welded to the upper surface of the side plate; a second PLC is installed on the upper surface of the sleeve; and a second driving motor is installed in the sleeve, and an output end of the second driving motor is fixedly connected with an adjusting rod. By arranging a series of structures, on the premise that the sorting accuracy of e-commerce goods is ensured, the goods sorting and transferring cost is reduced.

Owner:靖州喜乐购电子商务有限公司

An intelligent parking garage and its installation and construction method

ActiveCN111206804BReduce inertiaImprove comfortCharging stationsElectric vehicle charging technologyStructural engineeringMechanical engineering

Owner:贵州新兆停车设备有限公司

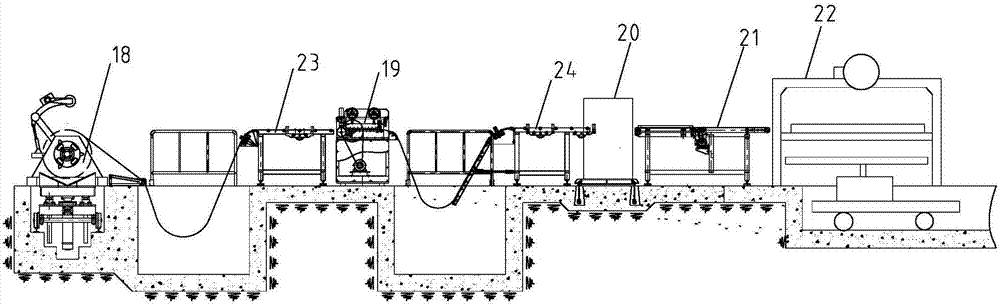

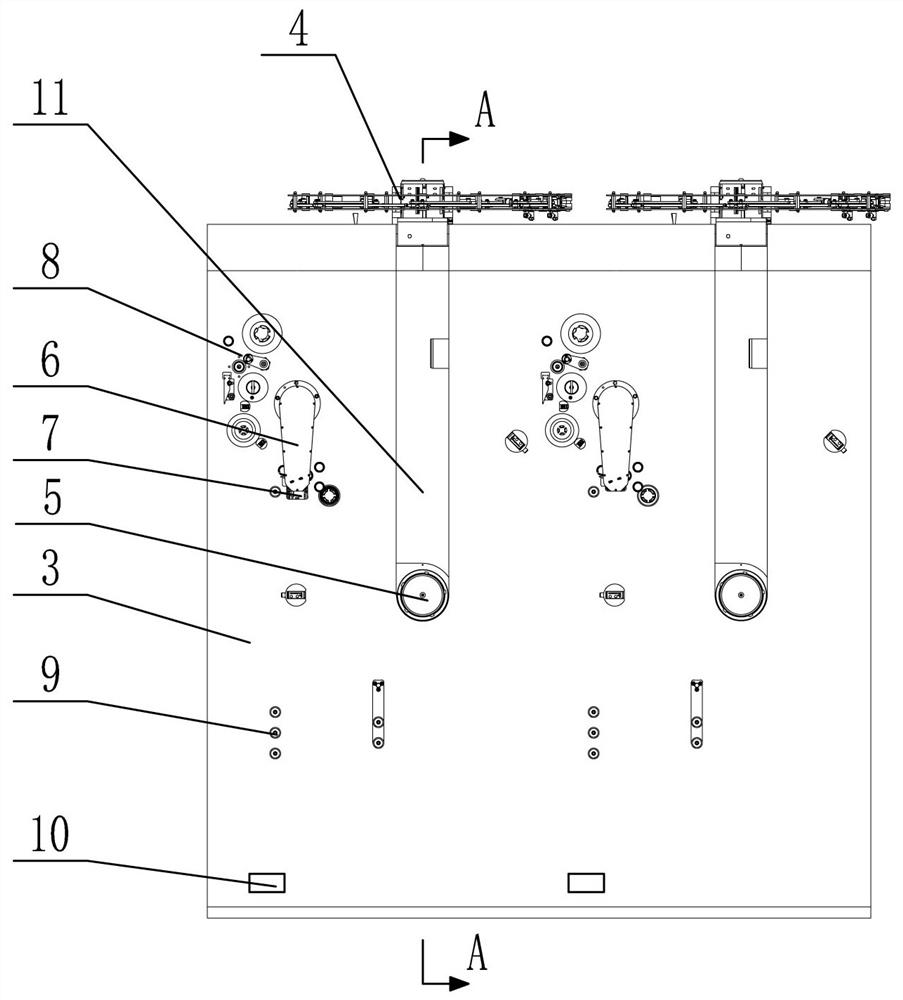

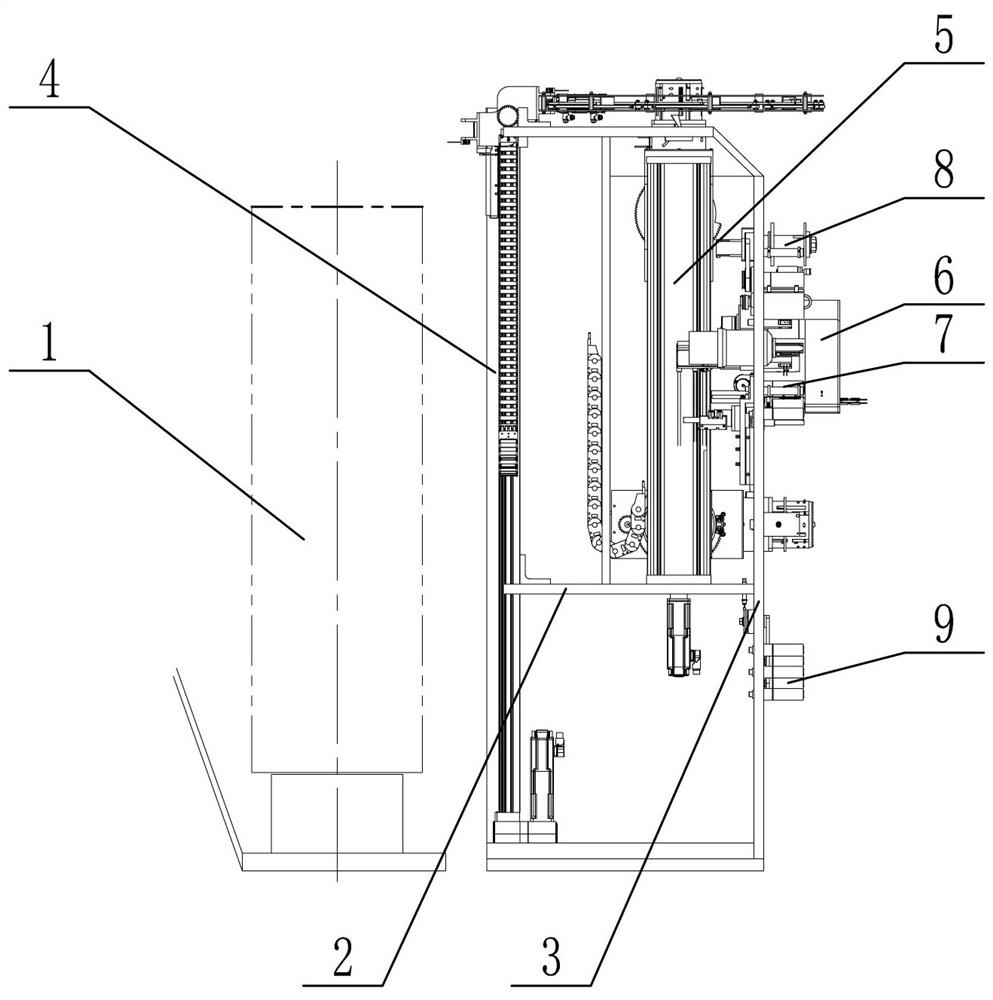

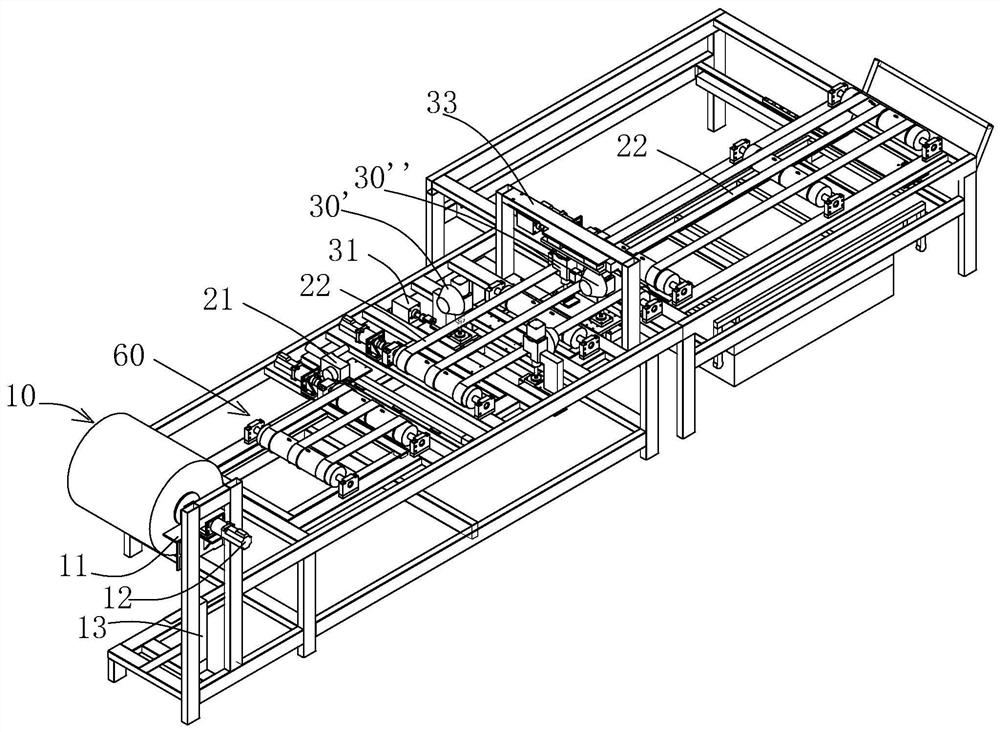

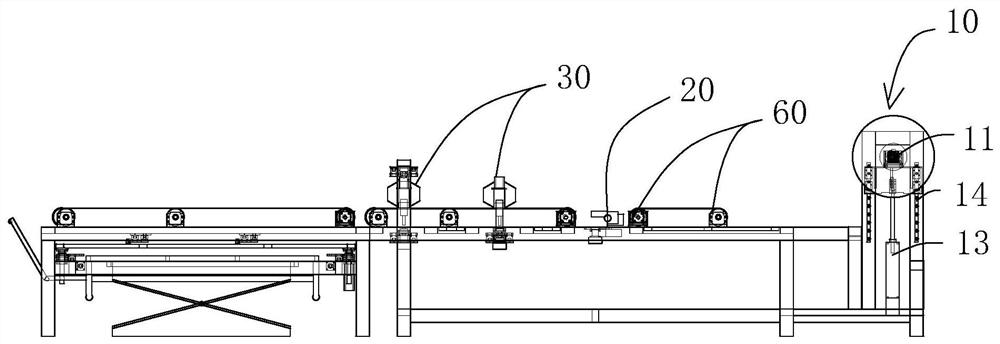

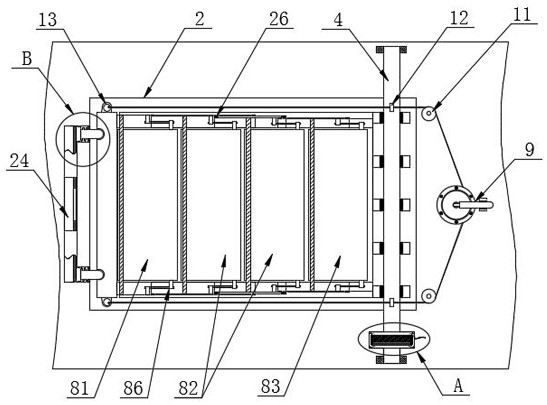

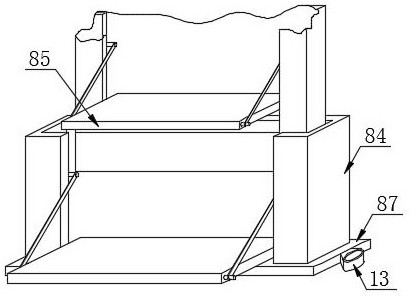

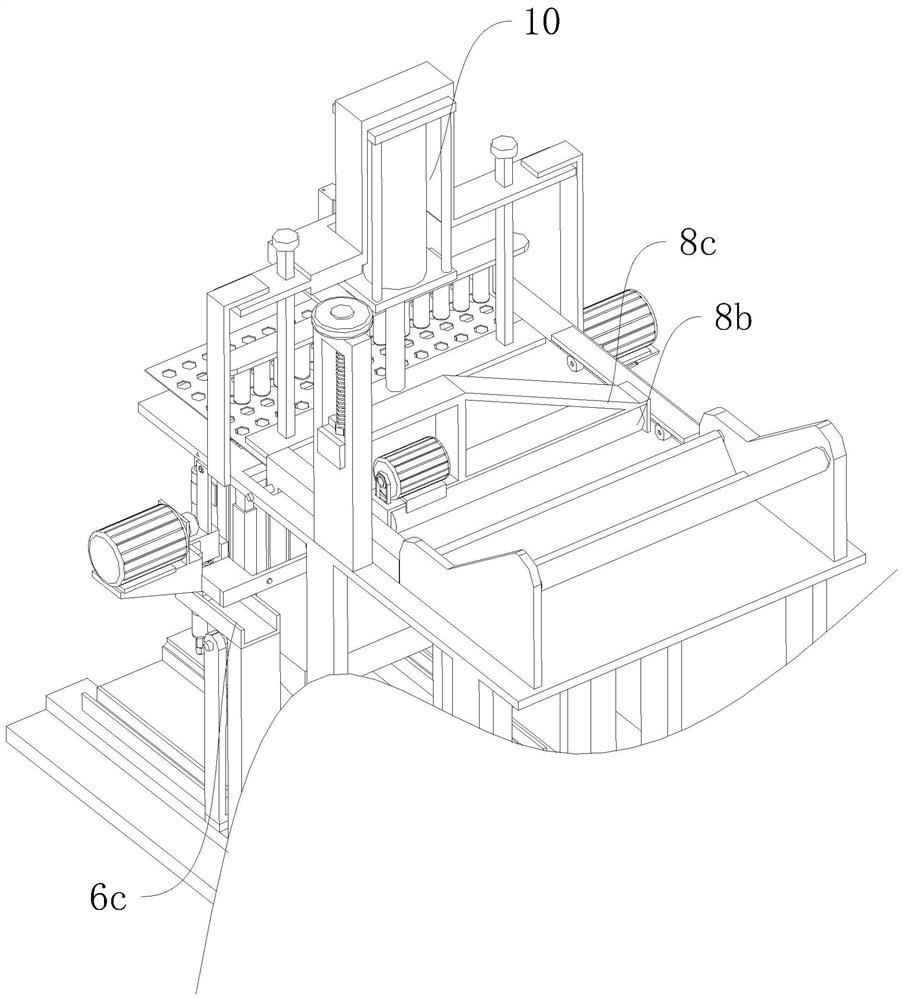

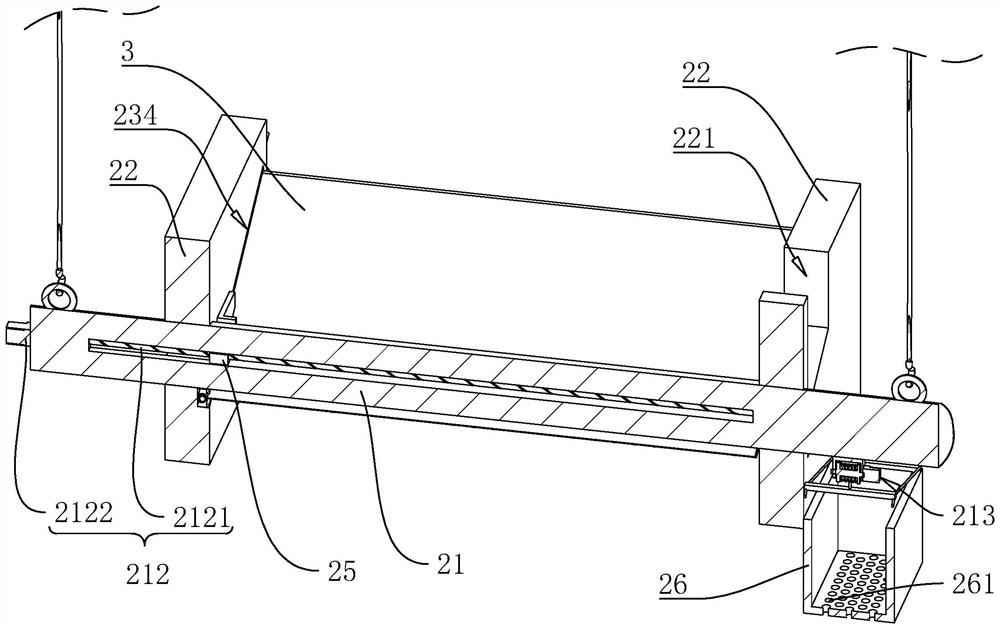

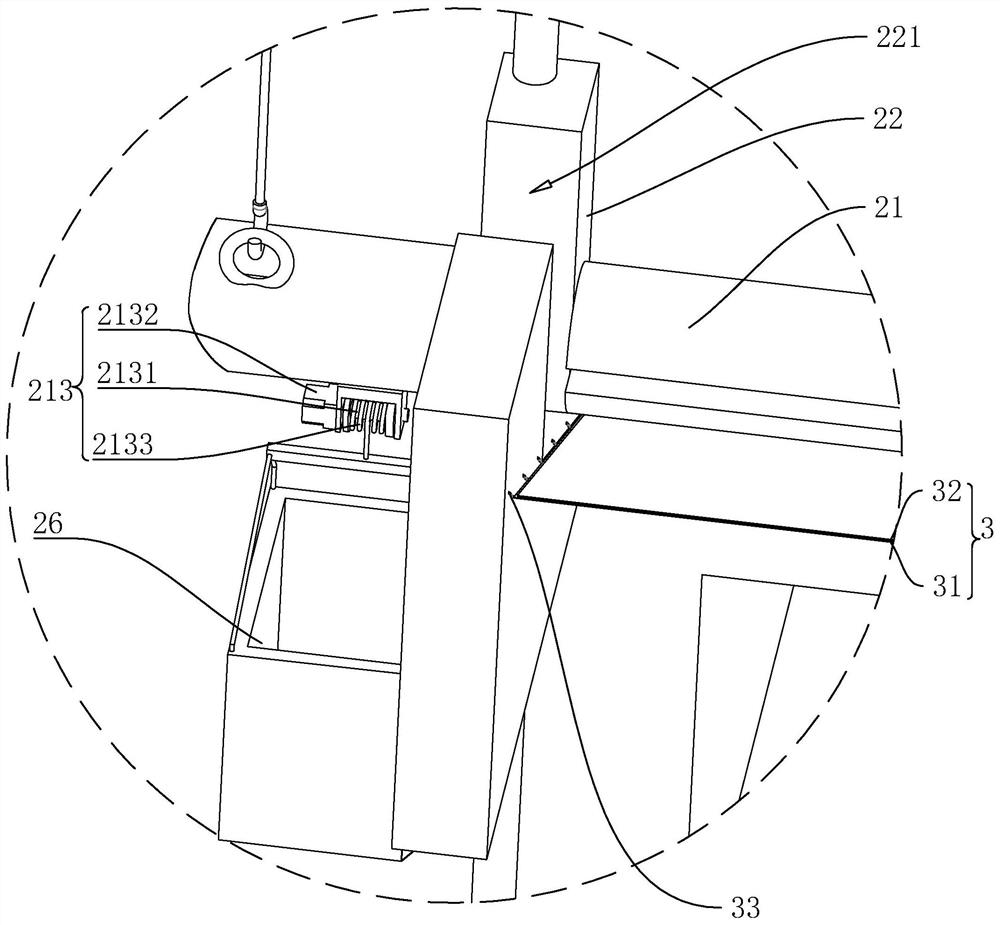

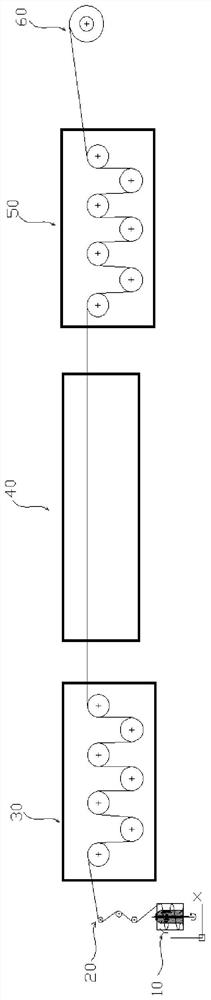

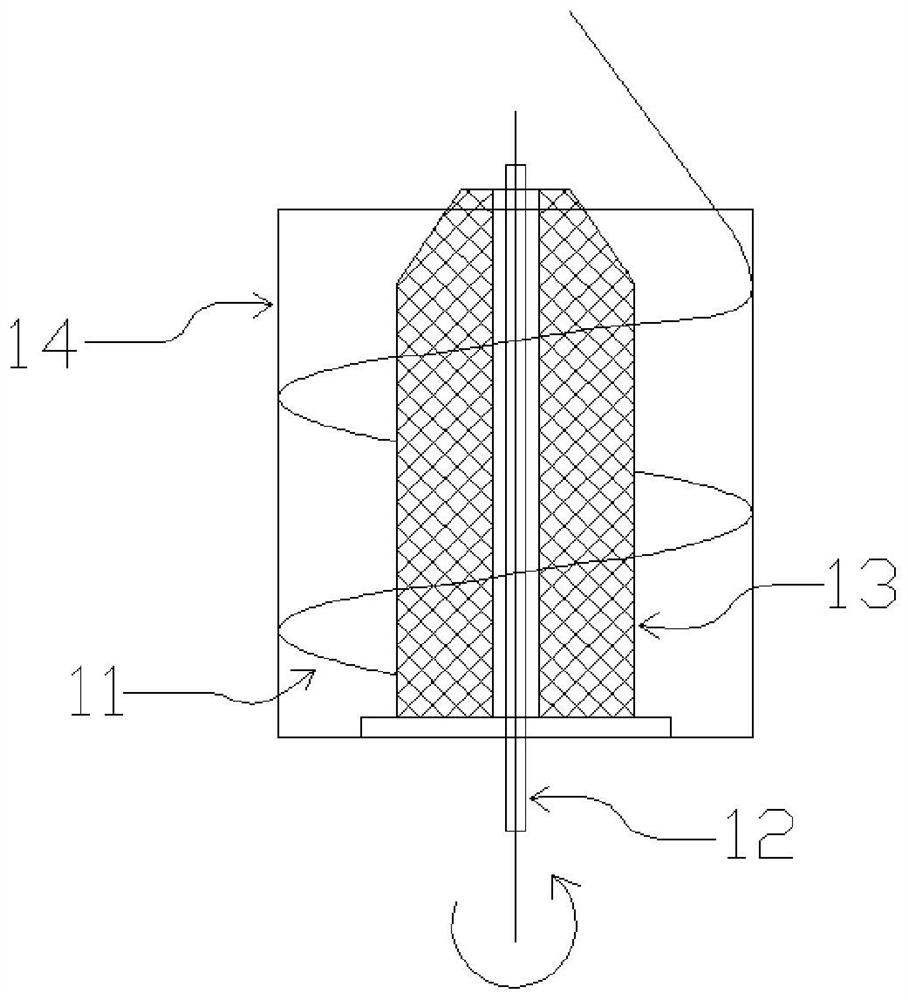

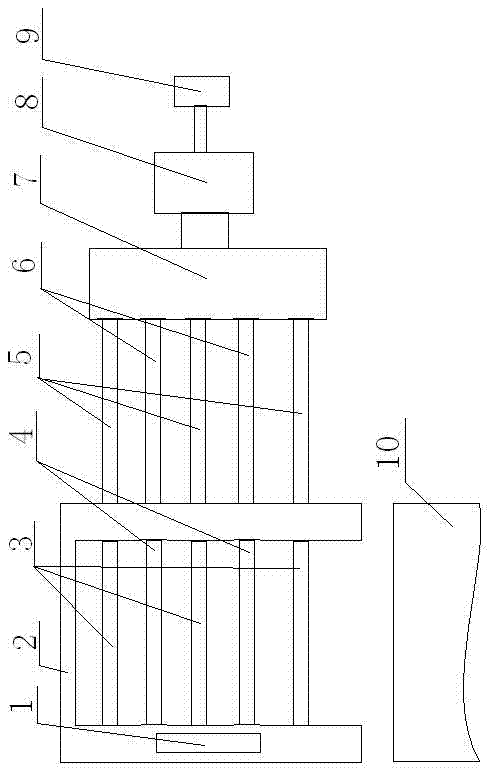

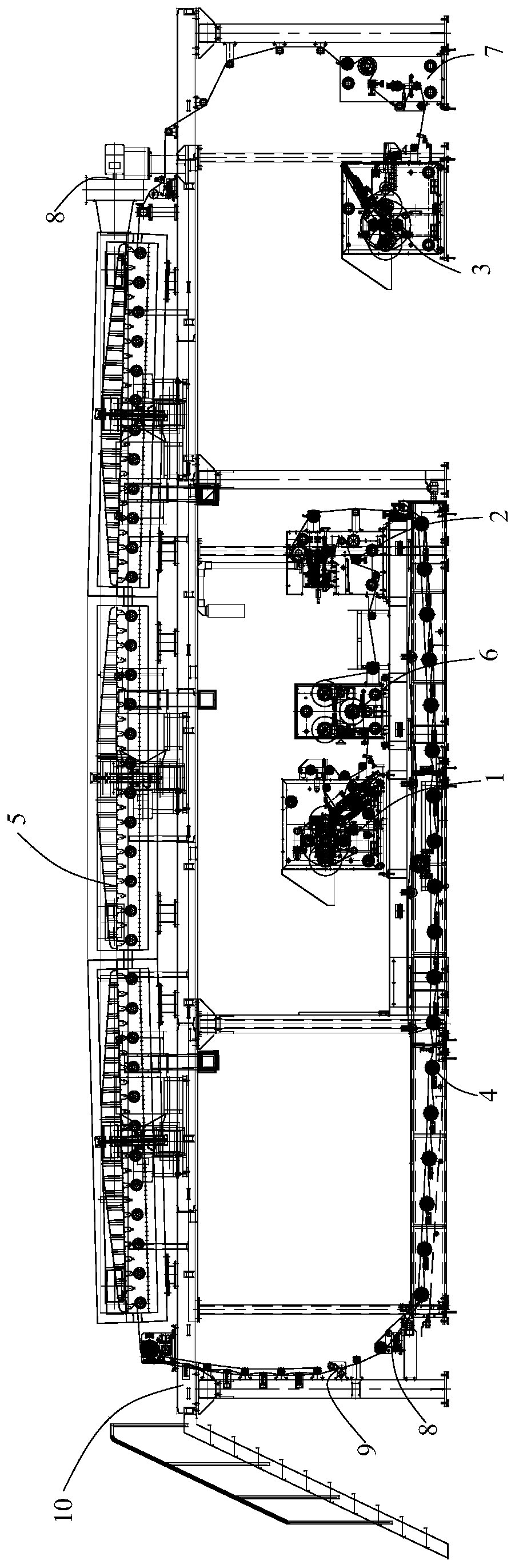

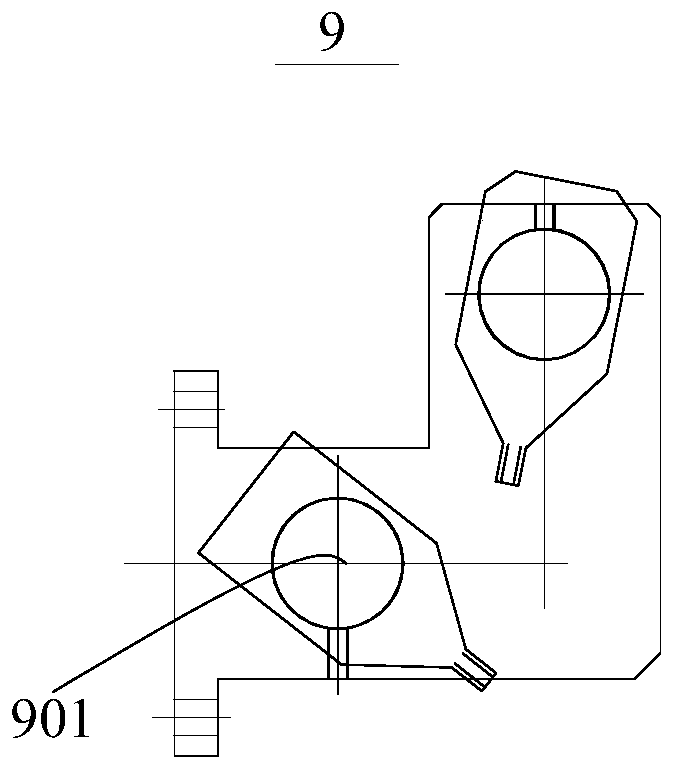

Automatic assembly line for producing filter material pressing buckles of railway motor train unit

ActiveCN113798861ARealize unwindingAchieve croppingOther manufacturing equipments/toolsPunchingControl system

The invention provides an automatic assembly line for producing filter material pressing buckles of a railway motor train unit. The technical defect that no integrated production equipment exists in the prior art is overcome. Equipment comprises an uncoiling mechanism, a fixed-length cutting mechanism, a full-automatic button punching mechanism, a stacking mechanism, an electrical control system and a workbench, and a fabric cutting machine is located between a belt conveying assembly and the uncoiling mechanism; the full-automatic button punching mechanism is composed of four full-automatic button punching machines, two of the four full-automatic button punching machines are used for transverse button punching, the other two full-automatic button punching machines are used for longitudinal button punching, and the transverse working distance between the two longitudinal full-automatic button punching machines can be adjusted; the transverse working distance between the two transverse full-automatic button punching machines can be adjusted; and the stacking mechanism is composed of a lifting machine and a tray installed on the top of the lifting machine and located right under the belt conveying assembly at the rear end of the workbench. The automatic assembly line for producing the filter material pressing buckles of the railway motor train unit can realize the functions of uncoiling, cutting, buckling and stacking, and all the parts are coordinated.

Owner:山东济铁轨道车辆装备有限公司

Passenger car safety transom window with rapid escape device

ActiveCN111845572AImprove stabilityIncrease injury ratePedestrian/occupant safety arrangementSteps arrangementEngineeringCar passenger

The invention discloses a passenger car safety transom window with a rapid escape device, which particularly relates to the technical field of passenger car safety. The passenger car safety transom window comprises a car body, a groove is formed in the top of the car body in a penetrating mode, a sealing plate is arranged in the groove, a storage groove is formed in one end of the sealing plate, and a telescopic mechanism is arranged in the storage groove; the telescopic mechanism comprises a bottom layer, a middle layer and a top layer, each of the bottom layer, the middle layer and the top layer comprises a guide frame plate and a pedal, and the end, close to the bottom layer, of the guide frame plate of the middle layer is movably sleeved with the guide frame plate of the bottom layer.The retractable safety ladder hidden in the storage groove in the sealing plate is put down, the guide frame plates on the adjacent layers are limited and clamped through the clamping blocks, meanwhile, the pedal can be turned over by hand, one end of the pedal is turned over with the cross rod as the center axis, the pedal is converted into the horizontal state from the inclined state, and therefore the treading space is enlarged, and the injury rate of passengers in the escape process is reduced.

Owner:丹阳市车船装饰件有限公司

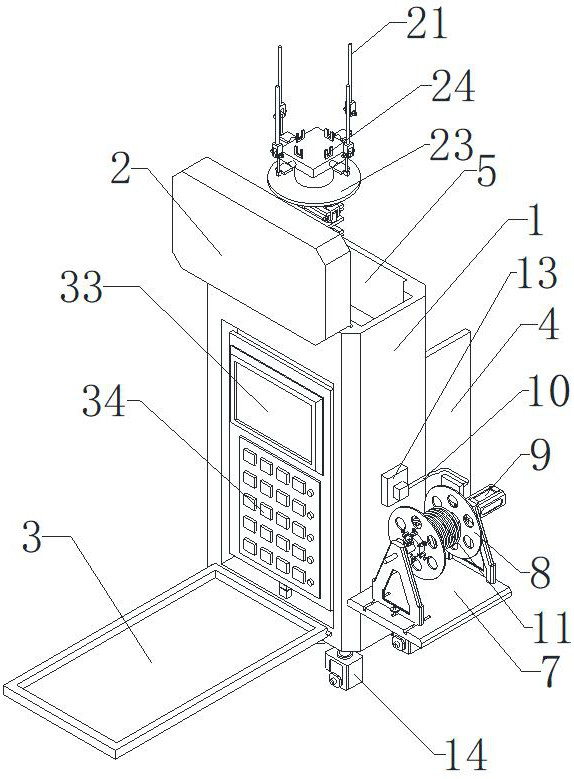

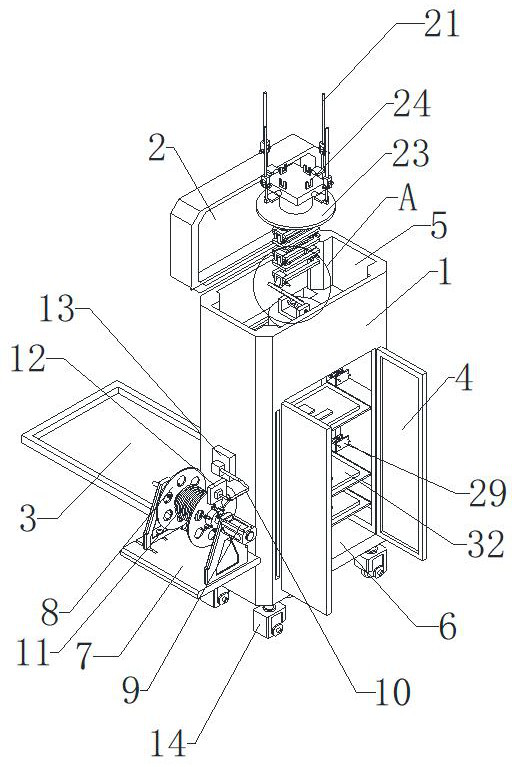

Communication equipment for power system

ActiveCN113141741AEasy to adjust the height of the displayEasy to operateCollapsable antennas meansCasings/cabinets/drawers detailsElectric power systemWire wheel

The invention relates to the technical field of communication equipment, in particular to communication equipment for an electric power system, which comprises a metal cabinet, a storage groove is formed in the upper end of the metal cabinet, a plurality of folding pieces distributed up and down are arranged at the bottom end in the storage groove, a second bolt is in threaded connection between every two adjacent folding pieces, and a supporting disc is arranged above the folding piece at the uppermost end. A fourth bolt is in threaded connection with the lower end of the supporting disc and the head end of the folding piece at the uppermost end, a third bolt is in threaded connection between the tail end of the folding piece at the lowermost end and the inner bottom end of the containing groove, and the fourth bolt, the second bolt and the third bolt are rotated to enable the folding pieces to stretch and contract so that the supporting disc can ascend and descend. The extension folding part can adjust the placing height of the antenna, the motor drives the wire wheel to rotate so that the cable can be wound and unwound, universal wheels can conveniently move the position of the metal cabinet, and the problems that the installation position of existing communication equipment for the electric power system is fixed, the position moving is too inconvenient, and use is inconvenient are solved.

Owner:TIANJIN UNIV +1

A flame retardant fireproof high temperature resistant polyethylene film laying device

Owner:建邦技术集团有限公司

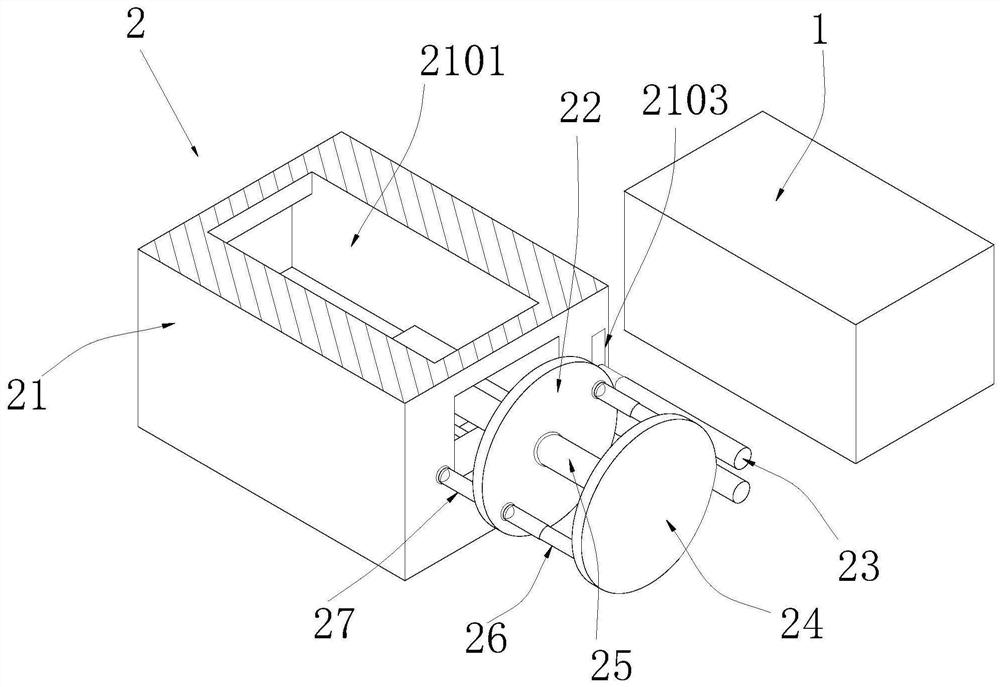

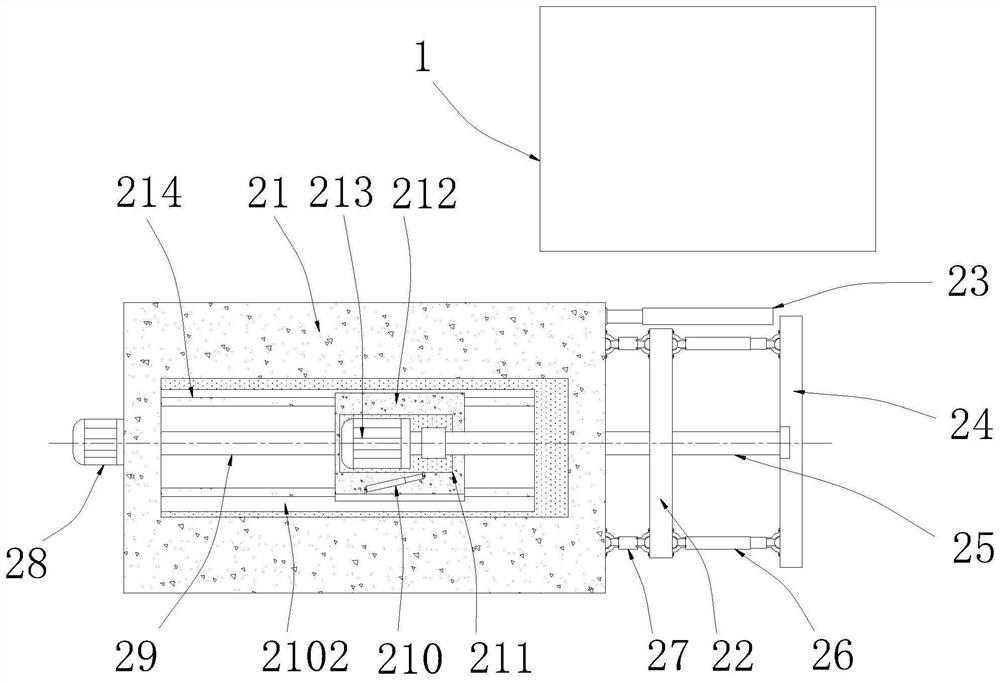

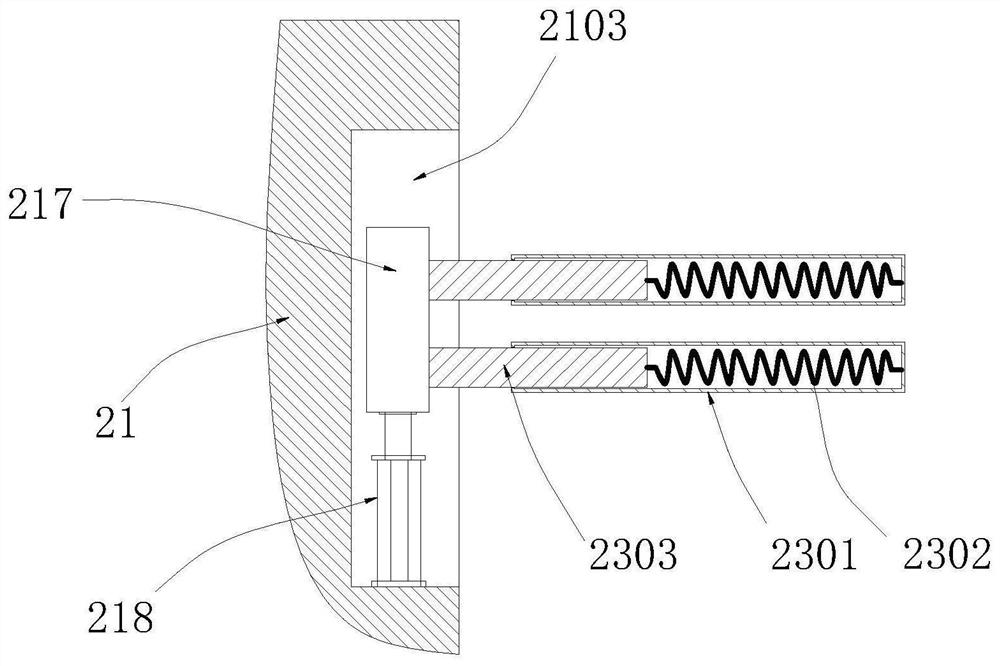

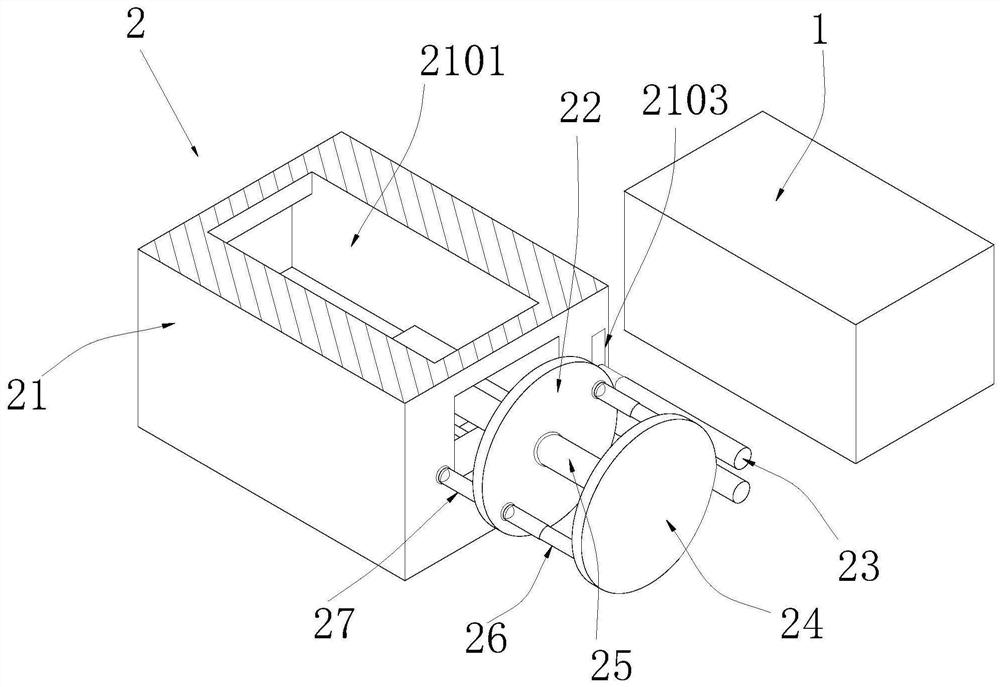

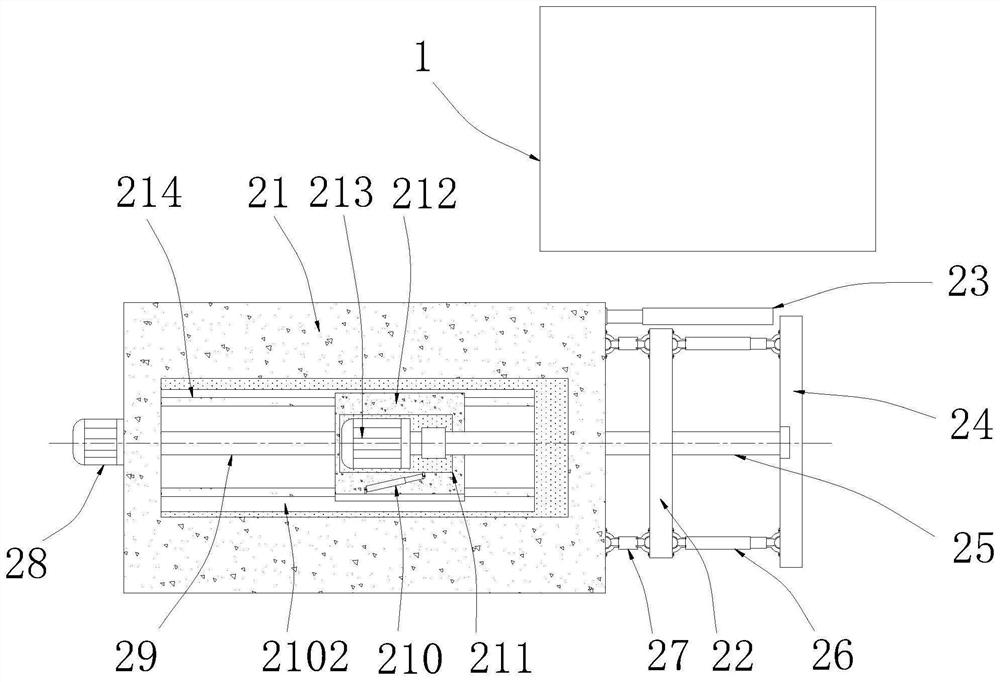

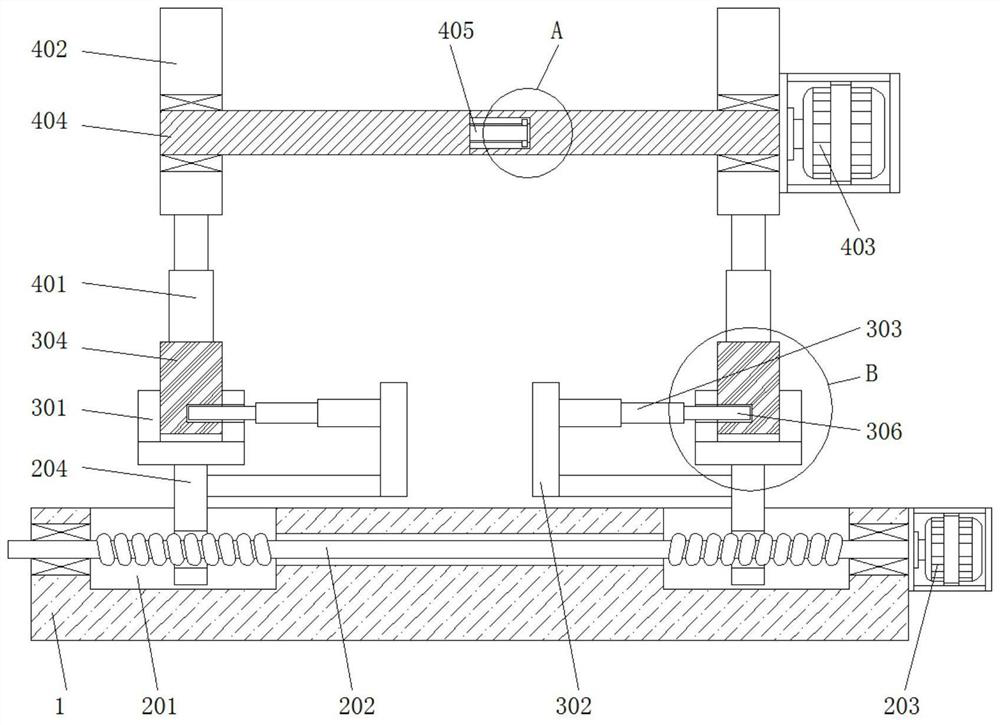

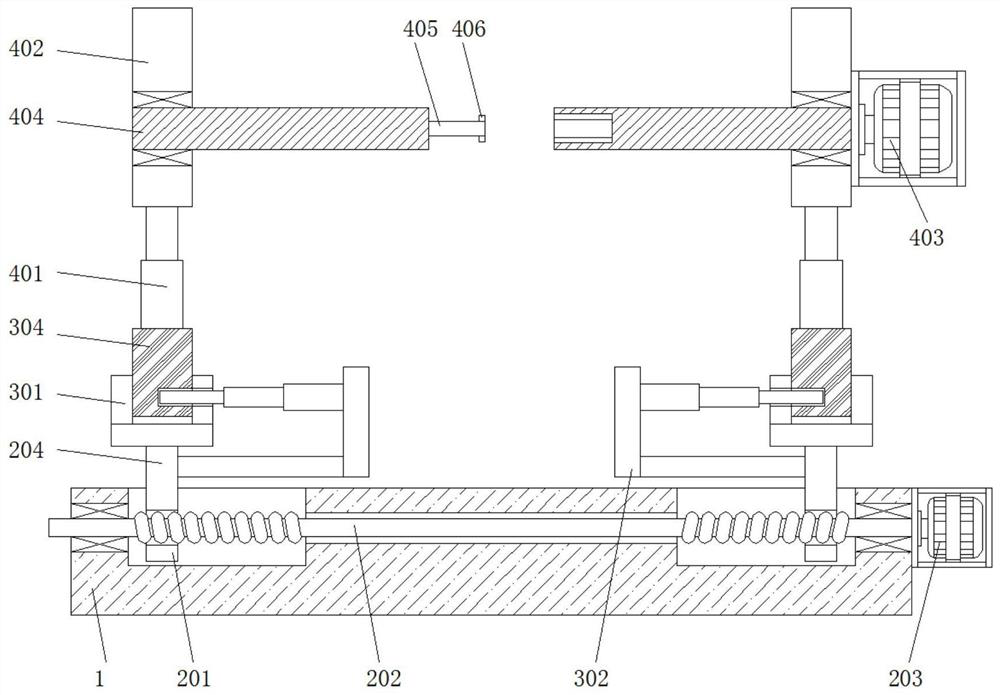

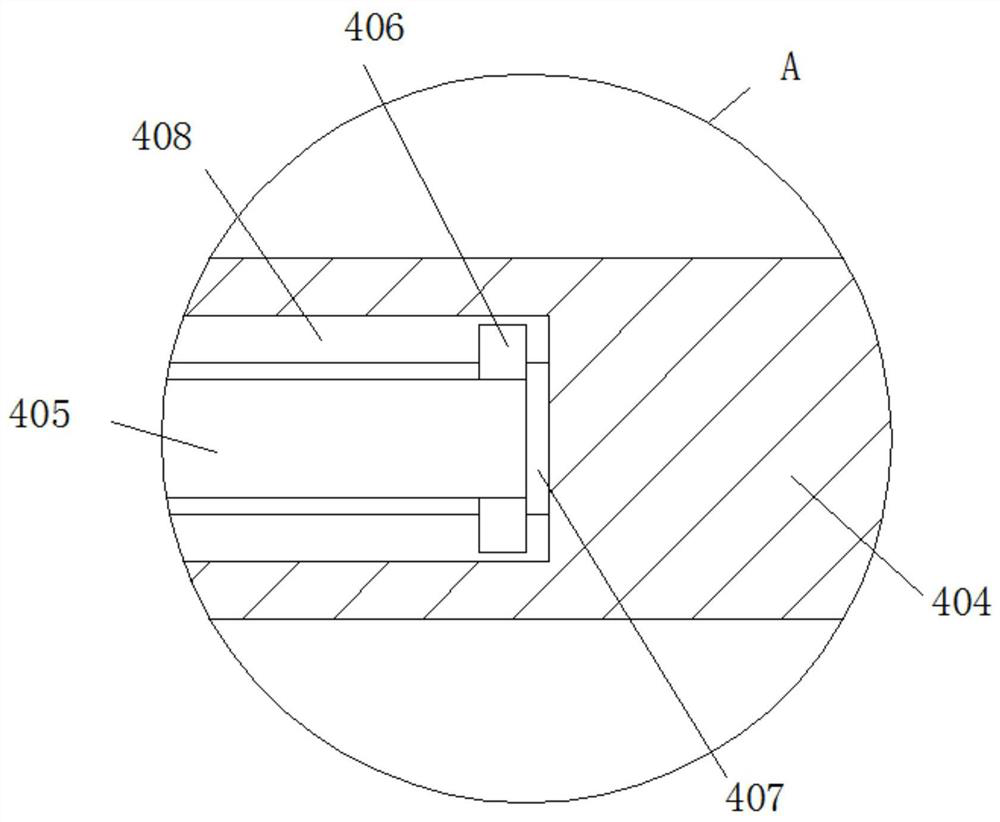

Numerical control decoiling and plate shearing integrated machine

ActiveCN111872688AAdjustable lengthRealize unwindingOther manufacturing equipments/toolsNumerical controlMechanical equipment

The invention discloses a numerical control decoiling and plate shearing integrated machine, and belongs to the technical field of mechanical equipment. The machine comprises a decoiling and plate shearing device and an adjustable feeding mechanism, the adjustable feeding mechanism comprises a mounting shell, a length adjusting mechanism is mounted in the mounting shell in the length direction ofthe mounting shell, and a horizontal rotating table is mounted on the top of a moving platform in a rotating fit manner. A reel movably penetrates through the mounting shell and then is mounted on a vertically-arranged first clamping plate in a rotation fit manner, the reel is movably sleeved with a second clamping plate, the second clamping plate and the first clamping plate are arranged in parallel, and fixed ball joint rods are arranged at the positions, between the second clamping plate and the mounting shell, of the front and back positions correspondingly. Length-adjustable ball joint rods are arranged at the positions, between the first clamping plate and the second clamping plate, of the front position and the rear position. The decoiling and plate shearing integrated machine is ingenious in concept, high in practicability, capable of effectively reducing the workload of workers, and improving the working efficiency of plate leveling and shearing, capable of shearing plates with different inclination angles, wide in application range and suitable for application and popularization.

Owner:鞍钢实业金属制品有限公司

Packaging bag forming and printing label all-in-one machine

ActiveCN110843260BRealize unwindingAchieve teleportationBag making operationsPaper-makingMarking outElectric machinery

The invention belongs to the technical field of marking equipment for packaging materials, and discloses a packaging bag forming and labeling integrated machine, which includes a workbench, on the workbench, an unwinding part, a hot-pressing part and a conveying part are sequentially arranged on the workbench, and the conveying part It includes two overlapping conveyor belts, the conveyor belts are driven by a motor, the worktable is provided with a placement slot, the bottom conveyor belt is located in the placement slot, and the upper surface of the bottom conveyor belt is coplanar with the upper surface of the worktable; The mounting frame on the table is vertically slidably connected with a plurality of heat-pressed blocks arranged side by side, and the adjacent heat-pressed blocks are fixed by connecting rods; The first cam that drives the push rod to move up and down; icons are set on the working surface of the hot pressing block. The invention solves the problem that an additional process needs to be added for label printing in the prior art, resulting in lower production efficiency of packaging bags.

Owner:重庆富美包装印务有限公司

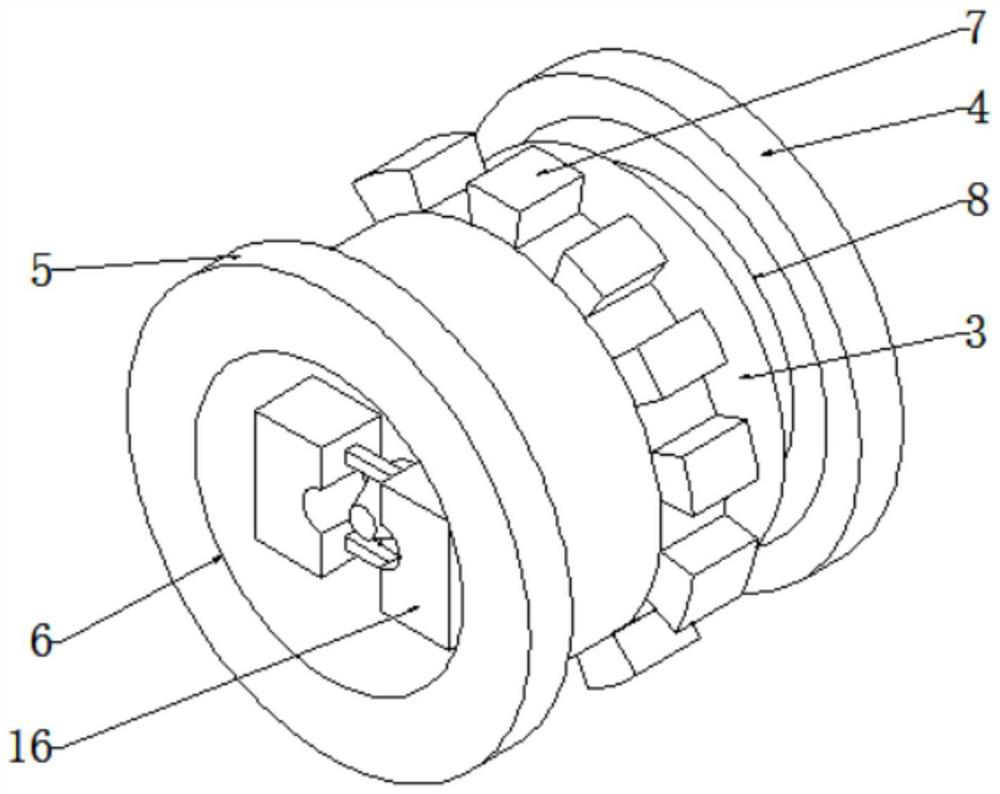

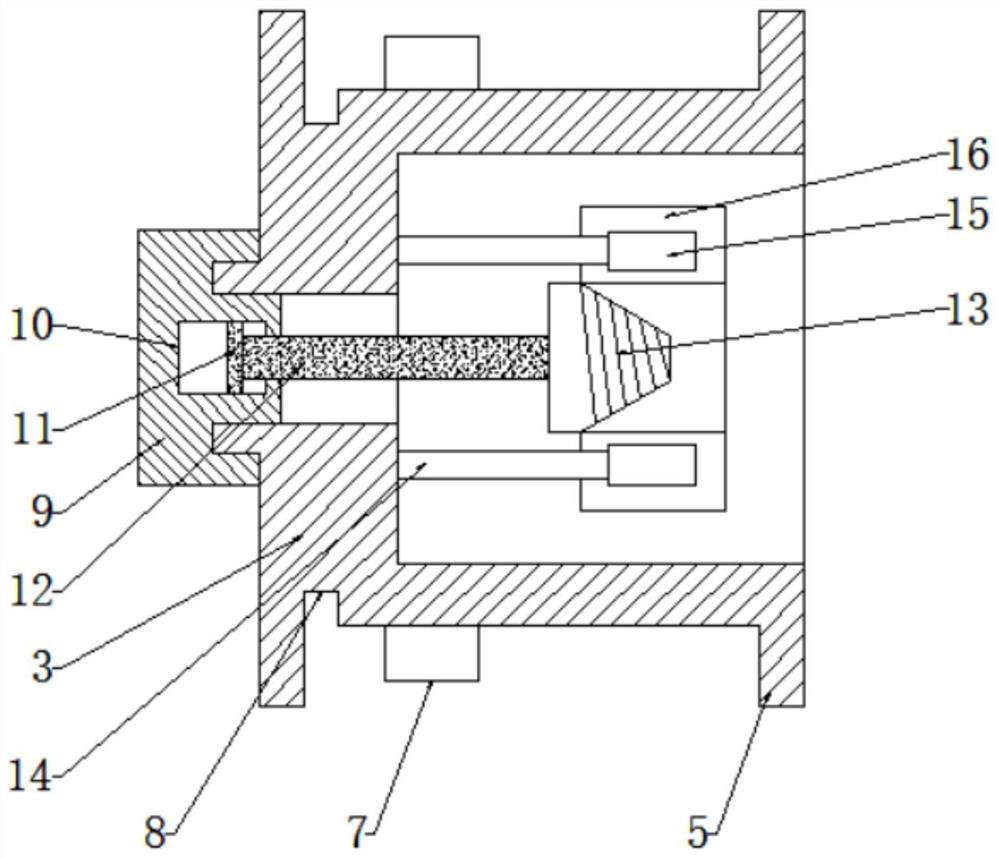

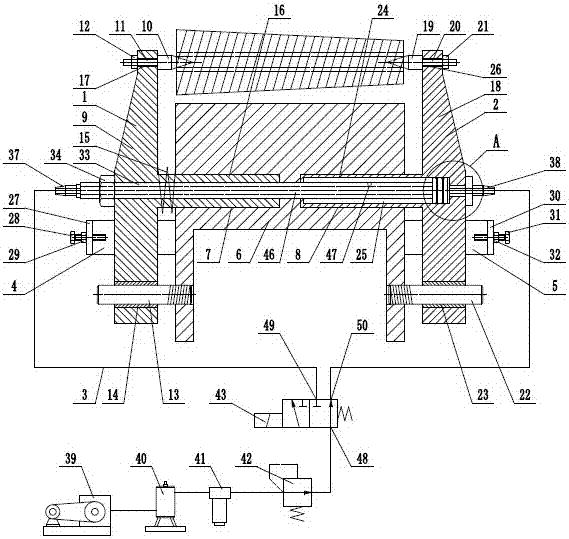

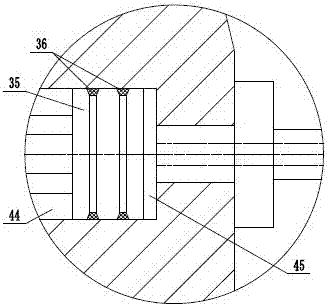

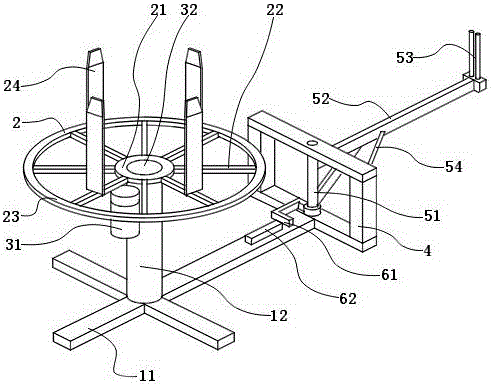

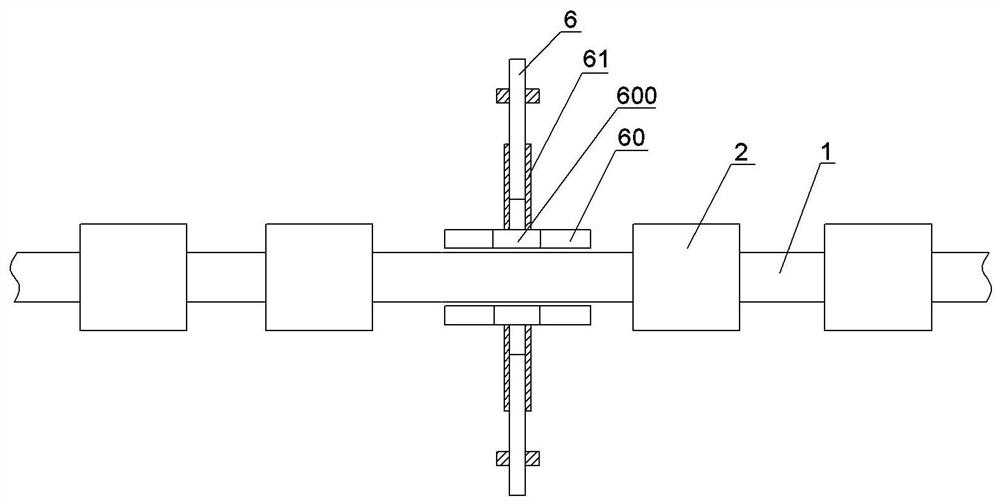

Dual-centre bobbin yarn unwinding device

The invention provides a dual-centre bobbin yarn unwinding device, and belongs to the technical field of textile machines. The dual-centre bobbin yarn unwinding device comprises a left centre assemblyand a right centre assembly, a left movement base of the left centre assembly is arranged in a left sliding groove of a bearing support through a left sliding column in a left-and-right sliding manner, a right movement base of the right centre assembly is arranged in a right sliding groove of the bearing support through a right sliding column in a left-and-right sliding manner, a piston of a driving assembly is arranged in a piston cavity in the right sliding column of the right movement base in a left-and-right sliding manner, a left connector is arranged on the left side of the piston rod,an air inlet groove is connected to the left connector, a gas exchange hole is led to a left cavity, a right connector is led to a right cavity, a compressor is sequentially connected with a gas storing tank, an oil mist separating device and one end of a reducing valve, the other end of the reducing valve is connected with a first valve opening of a two-position three-way reversing valve, a second valve opening is connected with the left connector, and a third valve opening is connected with a right connector. By means of dual-centre bobbin yarn unwinding device, continuous bobbin yarn unwinding is achieved, the bobbin rotating stability is good, and bobbin installing and demounting are very convenient.

Owner:浙江银汇高纤材料股份有限公司

Winding roller replacing device on corrugated board production line

InactiveCN111942923AEasy to assemble and disassembleRealize unwindingWebs handlingStructural engineeringManufacturing line

The invention relates to the technical field of production of corrugated boards, and particularly discloses a winding roller replacing device on a corrugated board production line. The winding rollerreplacing device comprises a base, and further comprises a horizontal moving mechanism, a clamping mechanism and a winding mechanism; the horizontal moving mechanism is arranged on the base, and comprises an elongated slot shaft rod and a first motor, elongated slots are symmetrically formed in the base, the shaft rod is rotationally connected between the two elongated slots, and the first motor is fixedly connected to the right side of the base; the clamping mechanism is arranged above the base; and the winding mechanism is arranged above the clamping mechanism. According to the winding roller replacing device, the first motor drives the shaft rod to rotate, so that two moving plates are driven to move, the moving plates and a connecting plate are driven to move in a back-to-back mode, two circular shafts are separated, and base paper can be conveniently disassembled and assembled; and meanwhile, the two circular shafts are driven to rotate through a second motor, so that unwinding ofthe base paper is realized, and the production efficiency of corrugated paper is improved.

Owner:京山双王纸板技术服务有限公司

An evaporating tube unwinding device

ActiveCN105032985BEasy to straightenRealize unwindingWire straightening devicesMetal working apparatusEngineeringMechanical engineering

Owner:ANHUI KINGPOWER EQUIP & MOLD MFR

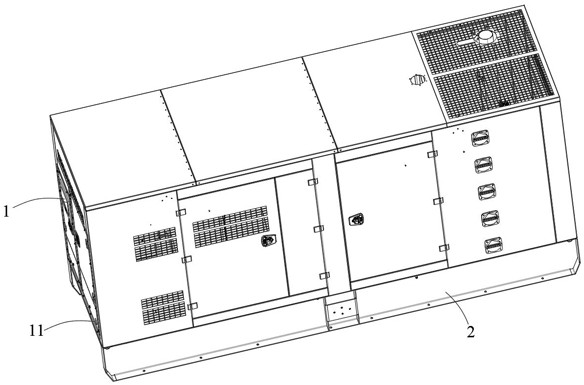

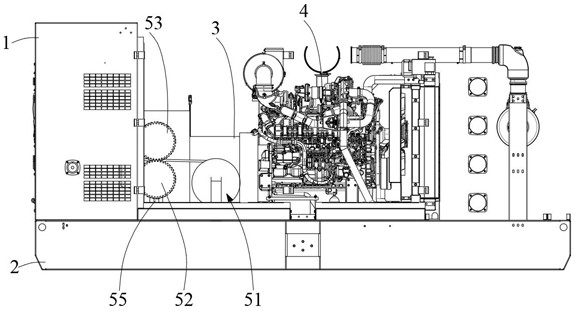

Multifunctional integrated intelligent control generator set

ActiveCN114744809ARealize windingRealize unwindingWindingsFilament handlingGear wheelControl engineering

The invention relates to the technical field of power generation equipment, in particular to a multifunctional integrated intelligent control generator set. A base is fixed to the inner bottom wall of a box body, a generator is fixed to the base, a winding part is fixed to the position, close to the generator, of the base, and a winding disc is rotatably fixed to the base; a plurality of first linkage pieces are slidably arranged on the side wall of the first ring groove in the circumferential direction; a plurality of second linkage pieces are slidably arranged on the side wall of the second annular groove in the circumferential direction, and one first linkage piece corresponds to one second linkage piece; the oiling assembly is fixed below the driving gear, and the oiling assembly is linked with the driving gear; the driving gear is rotated anticlockwise, and the power line extrudes the first linkage piece and the second linkage piece to synchronously contract inwards in the radial direction, so that the first linkage piece and the second linkage piece can blow air to the outer wall of the power line to clean dirt attached to the outer wall of the power line; when the driving gear abuts against the oil smearing assembly, the oil smearing assembly can smear protection oil to the outer wall of the power line through the driving gear.

Owner:雅柯斯电力科技(中国)有限公司

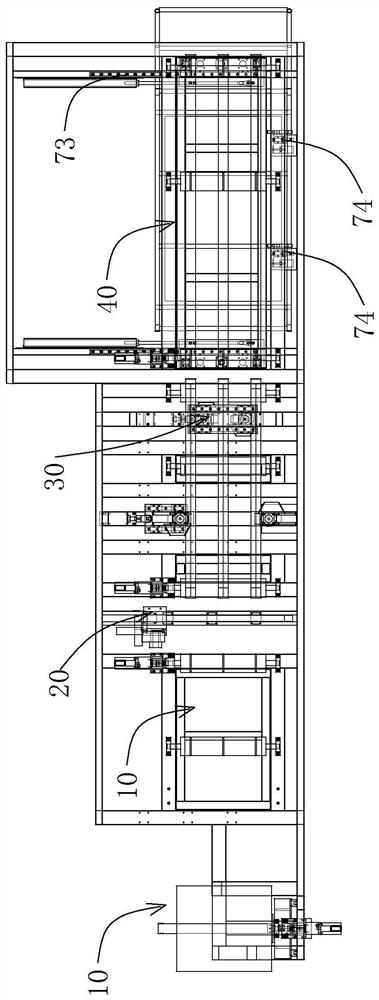

A continuous die-cutting and arranging equipment for polarizer and its production process

ActiveCN109773888BEasy to stackImprove work efficiencyMetal working apparatusWebs handlingPosition sensorMachining

The invention relates to the technical field of polaroid preparation, in particular to continuous die cutting and arranging equipment for polaroids and a production technology thereof. The continuousdie cutting and arranging equipment for the polaroids comprises a controller, a machining workbench, an unwinding mechanism, a die cutting mechanism, an unloading mechanism and an arranging mechanism,and the unwinding mechanism, the die cutting mechanism, the unloading mechanism and the arranging mechanism are sequentially arranged on the machining workbench along the linear sequence; the interval distance between the unloading mechanism and the die cutting mechanism is between 2.5 cm and 3.5 cm; the downstream end of the machining workbench is provided with an unloading gap groove; the arranging mechanism comprises a replacing plate installed under the unloading gap groove, a storing assembly arranged beside the replacing plate and a material poking assembly arranged over the replacing plate, and a lifting assembly used for driving the replacing plate to vertically move to the unloading gap groove is arranged under the replacing plate; and a position sensor which is electrically connected with the controller is installed on one side of the interior of the unloading gap groove. According to the continuous die cutting and arranging equipment for the polaroids and the production technology thereof, the cut polaroids can be automatically collected in a unified mode, full-automatic connection of polaroid unwinding and full-automatic die cutting and arranging is achieved, and the production efficiency of the polaroids is greatly improved.

Owner:惠州市富丽电子有限公司

A movable building decoration protective net installation component

ActiveCN113216667BRealize unwindingRealize construction protectionBuilding material handlingArchitectural engineeringStructural engineering

The application relates to a movable architectural decoration protective net installation member, and relates to the technical field of building protective nets; it includes a support, a protective net body is arranged on one side of the support, and the support is away from a part of the protective net body. The building body is arranged on the side, and also includes a lifting member located above the support member, the lifting member includes a first winding roller, a driving member for driving the circumferential rotation of the first winding roller, and a rope detachably connected to both ends of the supporting member, The end of the rope away from the support is fixedly connected to the outer side wall of the first roll, and the first roll is rotatably connected to the top of the building body; the application has the function of adjusting the height of the protective net according to the construction height, reducing the The effect of using the protective net in a more energy-saving and environmentally friendly way.

Owner:NANTONG BUILDING DECORATION DECORATION

Movable building decoration protective net mounting component

ActiveCN113216667ARealize unwindingRealize construction protectionBuilding material handlingConstruction engineeringStructural engineering

Owner:NANTONG BUILDING DECORATION DECORATION

Fiber untwisting and shaping device, preparation device and method

ActiveCN113737348ASimple structureEasy to operateTextiles and paperEngineeringMechanical engineering

The invention relates to a fiber untwisting and shaping device, preparation device and method. The untwisting and shaping device is used for shaping semi-finished fibers, the semi-finished fibers are obtained by twisting and heat treatment of nascent fibers, the shaping device comprises an untwisting assembly and a stretching and shaping assembly, the untwisting assembly is used for untwisting the semi-finished fibers, and the stretching and shaping assembly is used for stretching and shaping the semi-finished fibers. The stretching and shaping assembly is used for carrying out stretching and shaping treatment on the untwisted fibers, wherein the untwisting assembly comprises a winding drum, a guiding untwisting drum and a rotating part; the semi-finished fiber is wound on the winding drum; the guiding untwisting drum is provided with a cavity, and the winding drum is located in the cavity; and the rotating part is used for driving the winding drum and the guiding untwisting drum to rotate. The fiber untwisting and shaping device is simple in structure, easy and convenient to operate, free of damage to fibers and capable of achieving effective untwisting.

Owner:广东彩艳股份有限公司

A peritoneal machine for packaging

InactiveCN109677676BFlipTo achieve the effect of double-sided laminationPackagingClassical mechanicsEngineering

The invention belongs to the field of package printing, and particularly discloses a package laminating machine. A rack is included and provided with a conveying belt. A front face laminating mechanism, an overturning mechanism and a back face laminating mechanism are sequentially arranged in the conveying direction of the conveying belt. The front face laminating mechanism comprises a front facelaminating roller and a front face film cutter. The back face laminating mechanism comprises a sliding base, the sliding base is rotationally connected with a back face laminating roller, and a back face film cutter is arranged on the rack in a vertical sliding manner. The overturning mechanism comprises two overturning shafts rotationally connected to the rack and coaxially arranged, the two overturning shafts are located on the two sides of the conveying belt correspondingly and are in sliding connection with overturning discs, the overturning discs are provided with notches in which laminating workpieces are inserted, and the upper portions of the overturning shafts are rotationally connected with a front face film roll shaft and a back face film roll shaft. An overturning driving mechanism for driving the overturning shafts to intermittently rotate is connected between the front face film roll shaft and the overturning shafts. The package laminating machine can be universal for panel single-face laminating and double-face laminating.

Owner:重庆朝旭印务有限公司

Device for hot-rolled strip steel production line to achieve uncoiling of steel coils in small batches

The invention belongs to the field of steel industry and discloses a device for a hot-rolled strip steel production line to achieve uncoiling of steel coils in small batches. The device for the hot-rolled strip steel production line to achieve uncoiling of the steel coils in small batches is capable of effectively utilizing equipment for checking strip steel and capable of supplying individual scattered steel coils. A pinch roll rolling device is correspondingly mounted behind a strip steel checking line after final output of hot-rolled strip steel, and the pinch roll rolling device is structurally characterized in that upper rolls and lower rolls are mounted on a frame, the distance between each upper roll and the corresponding lower roll is equal to the thickness of the strip steel, an adjusting mechanism for adjusting the distance between each upper roll and the corresponding lower roll is arranged on the frame, the upper rolls are connected with upper universal drive shafts, the lower rolls are connected with lower universal drive shafts, the upper universal drive shafts and the lower universal drive shafts are connected with a shaft of a motor through a gear box, and a band-type brake is mounted on the shaft of the motor. The device is simple in structure, reasonable in design and capable of performing simple equipment upgrading and optimizing layout of process equipment in an existing workshop without adding lifting equipment, and accordingly product yield can be effectively increased, equipment usage rate is increased, and product manufacturing cost is reduced.

Owner:吉林建龙钢铁有限责任公司

Oily PVDF diaphragm coating system

PendingCN110434024ARealize unwindingAchieve coatingLiquid surface applicatorsCoatingsCoating systemEngineering

The invention relates to an oily PVDF diaphragm coating system. The oily PVDF diaphragm coating system comprises an unwinder, a coater and a winder which are arranged in the direction of travel of a PVDF diaphragm. The oily PVDF diaphragm coating system further comprises a water tank, wherein the unwinder and the coater are fixed on the water tank. A substrate can be unwinded by the unwinder and then coated by the coater, the water tank is used for diluting glue, and the substrate is stored by the winder. By the adoption of the oily PVDF diaphragm coating system with convenient feeding and storage functions, by arranging the unwinder, the coater and the winder, the unwinding, coating and winding effects are achieved. By arranging the water tank, NMP in the coating glue is diluted. Becausethe water tank is located under the unwinder, the coater and the winder, loop feed is formed, and the direct contact with the glue surface of the substrate is avoided.

Owner:常州恒锌禹晟智能装备股份有限公司

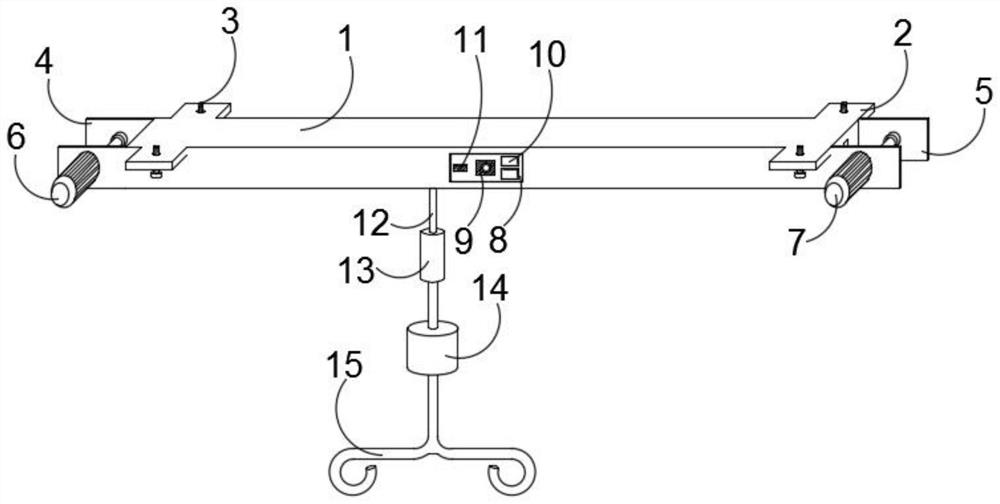

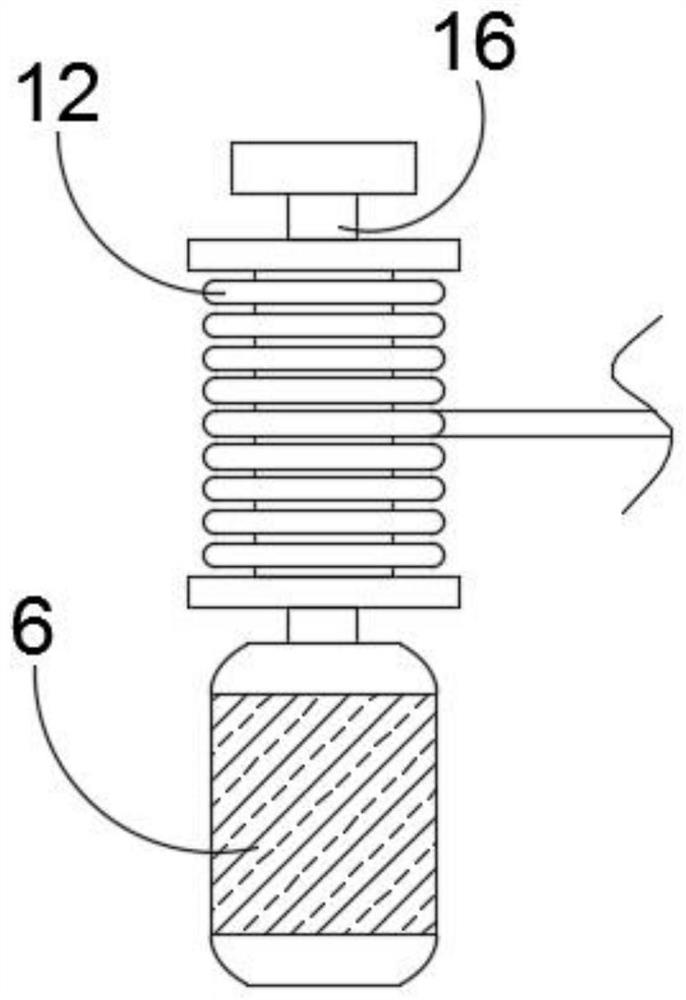

Clinical infusion bottle support

InactiveCN112402724AEasy to adjustAdjustable positionInfusion devicesFlow controlElectric machineryDropped ceiling

The invention discloses a clinical infusion bottle support. The clinical infusion bottle support comprises a hanging frame, a suspended ceiling frame, a height adjusting mechanism, an adjusting mechanism, a positioning mechanism, a monitoring mechanism, a reset mechanism and a control mechanism, a plurality of hooks are integrally formed at a bottom end of the hanging frame, two connecting lugs are symmetrically and integrally formed at positions, close to a left side and a right side, of a top part of the suspended ceiling frame, besides, each connecting lug is threadedly provided with a connecting bolt, the height adjusting mechanism comprises two mounting frames A, a height adjusting shaft is rotatably connected between the two mounting frames A, a height adjusting motor used for driving the height adjusting shaft to rotate is fixedly arranged on one of the mounting frames A, a height adjusting rope is wound around the height adjusting shaft, and an end of the height adjusting ropeis in a transmission connection with the hanging frame. The infusion bottle support solves problems that an existing infusion bottle support has a poor height adjustment automation degree and a troublesome adjustment, and can also remind medical staff in time to replace a medicine bottle or finish infusion.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com