Steel plate cross-shearing production line and steel plate cross-shearing process with same applied

A production line and steel plate technology, applied to other manufacturing equipment/tools, shearing devices, shearing equipment, etc., can solve the problems of uneven unwinding, offset, and difficult fixation of rolls, etc., to achieve uniform unwinding and easy use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

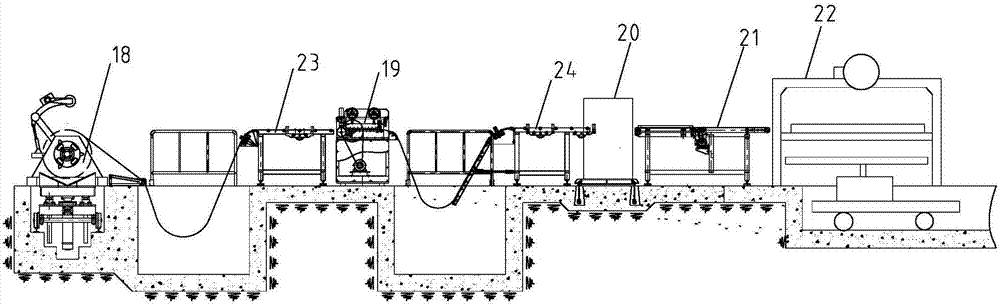

[0047] Such as Figure 1~4 Shown, a steel plate cross-cutting production line, it comprises:

[0048] A steel plate unwinding device 18 for unwinding a steel plate coil;

[0049] A leveler 19 for leveling the steel plate after unwinding by the steel plate unwinding device;

[0050] A cross-cutting machine 20 for cross-cutting the steel plate leveled by the leveler and forming a plurality of cross-cut steel plates;

[0051] Conveyor 21 for sequentially transporting multiple cross-cut steel plates after cross-cutting by the cross-cutting machine;

[0052] A steel plate receiving device 22 for sequentially stacking cross-cut steel plates transported by the conveyor;

[0053] Wherein, the steel plate unwinding device 18 , leveler 19 , cross cutter 20 , conveyor 21 and steel plate receiving device 22 are sequentially arranged along the conveying direction of the steel plate.

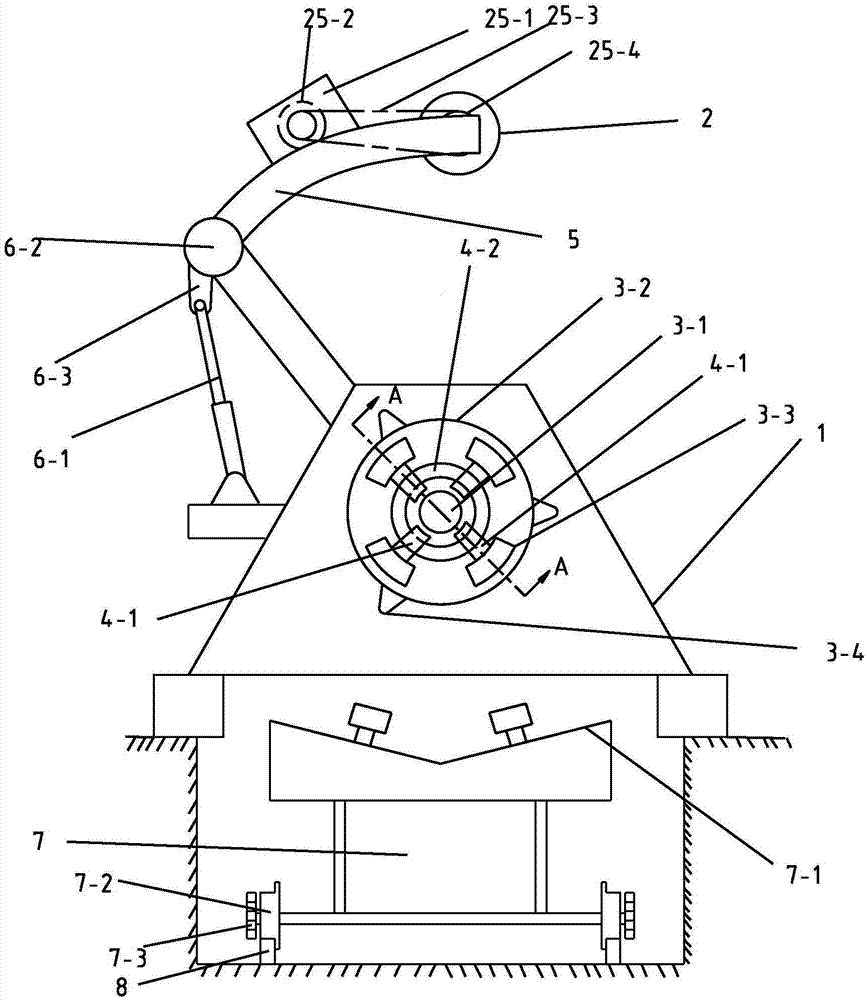

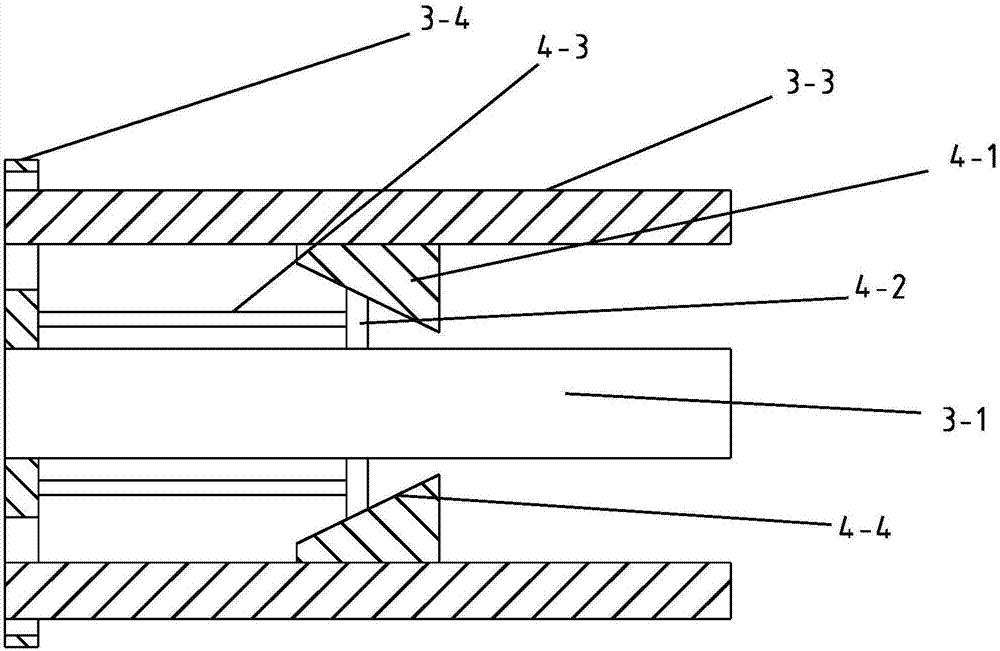

[0054] Such as figure 2 As shown, the steel plate unwinding device includes:

[0055] Unwinding frame...

Embodiment 2

[0079] A kind of steel plate cross-cut process, it applies the steel plate cross-cut production line in the embodiment one, and the concrete steps of technology are as follows:

[0080] (1) the steel plate coil is installed on the steel plate unwinding device 18, and the steel plate on the steel plate coil is uncoiled by the steel plate unwinding device 18;

[0081] (2) The steel plate after unwinding enters the leveler 19 for leveling;

[0082](3) The steel plate after the leveling machine is leveled enters the cross cutting machine 20 for cross cutting and forms a plurality of cross cutting steel plates;

[0083] (4) The cross-cut steel plates cross-cut by the cross-cutting machine 20 are transported to the steel plate receiving device 22 sequentially by the conveyor 21;

[0084] (5) The steel plate receiving device 22 sequentially folds the cross-cut steel plates conveyed by the conveyor 21 .

[0085] The working principle of the present invention is as follows:

[0086]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com