Automatic assembly line for producing filter material pressing buckles of railway motor train unit

A technology of automatic assembly line and EMU, applied in the direction of manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem of no integrated production equipment, etc., and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

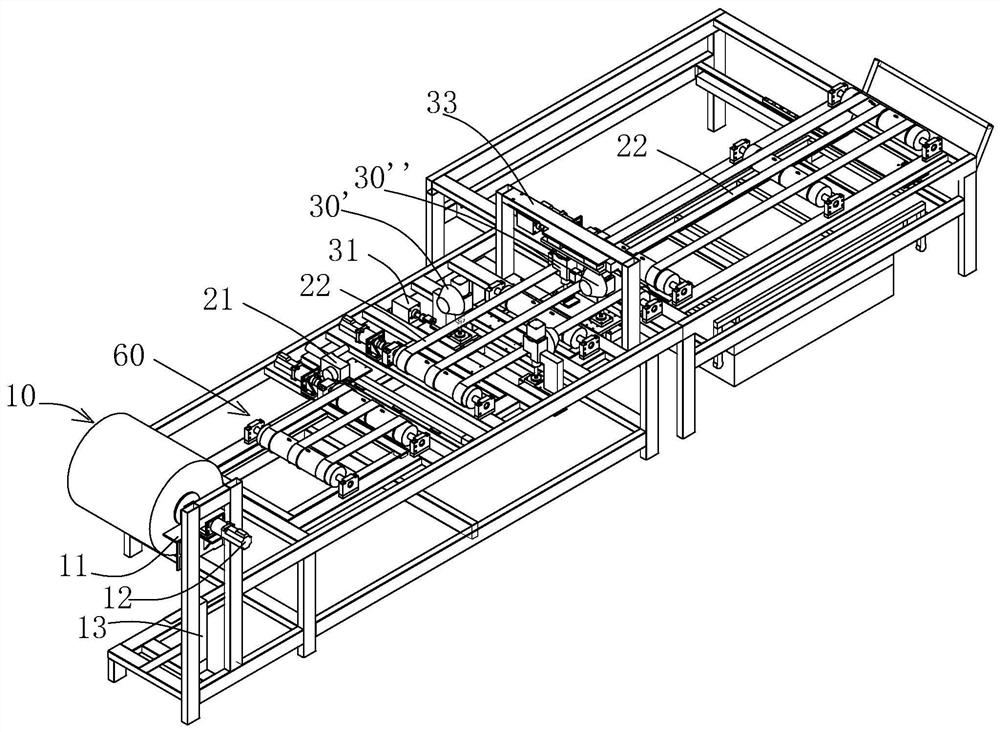

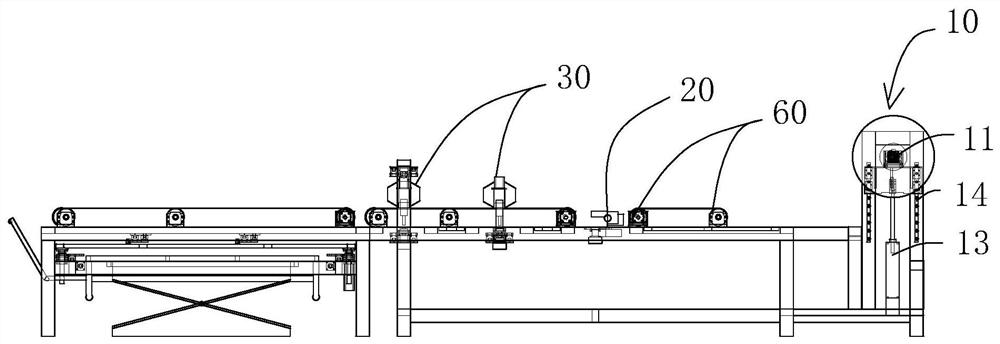

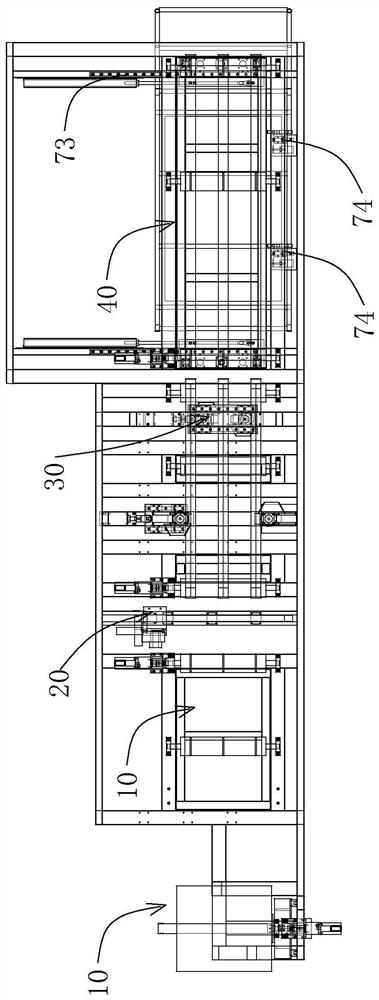

[0042] This example introduces an automatic assembly line for press-button production of filter materials, which has three functions of automatic cutting of filter materials, automatic buttoning, and stacking, and can fully meet the requirements of automatic production of filter materials.

[0043] This production line adopts horizontal structure, beautiful appearance, simple structure and high working efficiency; it has the characteristics of stable and reliable performance, simple operation, sensitive action, convenient use and maintenance, etc.

[0044] The controller of the intelligent control part of the assembly line adopts Delta DVP-EH3 series high-performance PLC controller with 10-inch touch screen. The processing parameters can be set through the touch screen, and the processing and production of the production line can be controlled manually or automatically.

[0045] Cutting the filter material adopts a high-speed cloth cutting machine, and installs a dust removal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com