Patents

Literature

93results about How to "Achieve cropping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

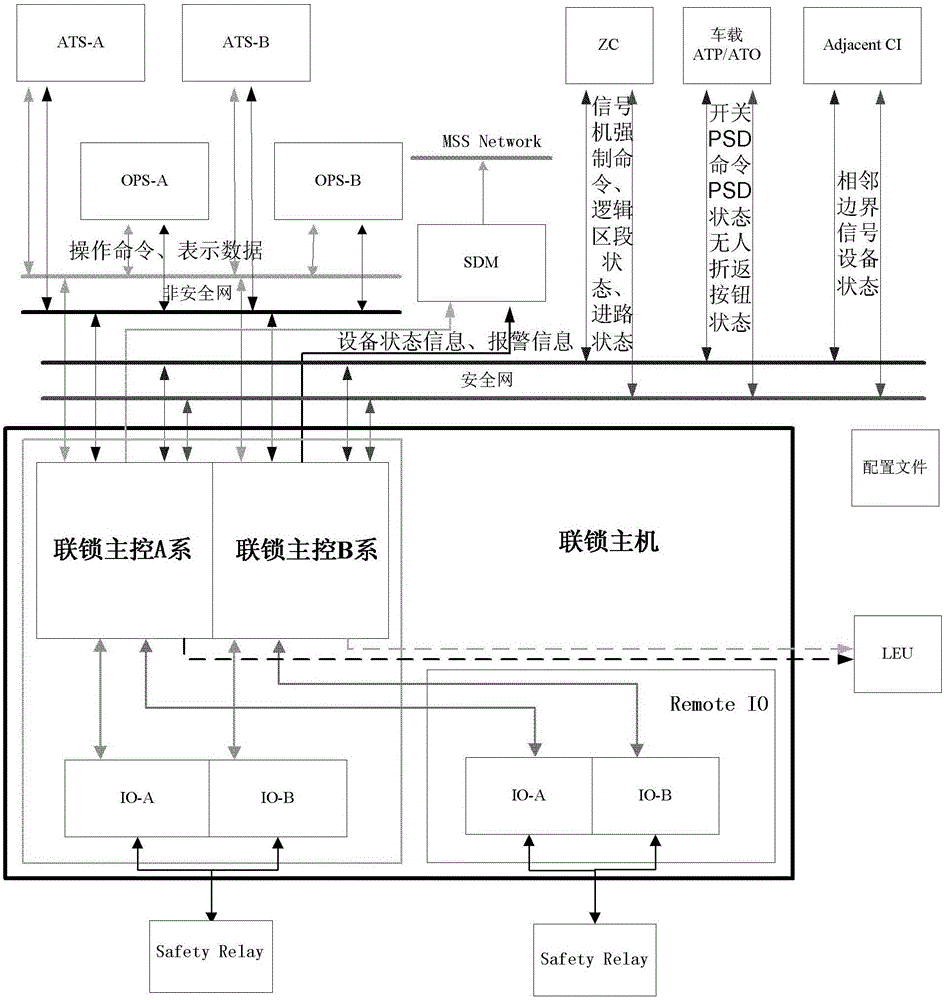

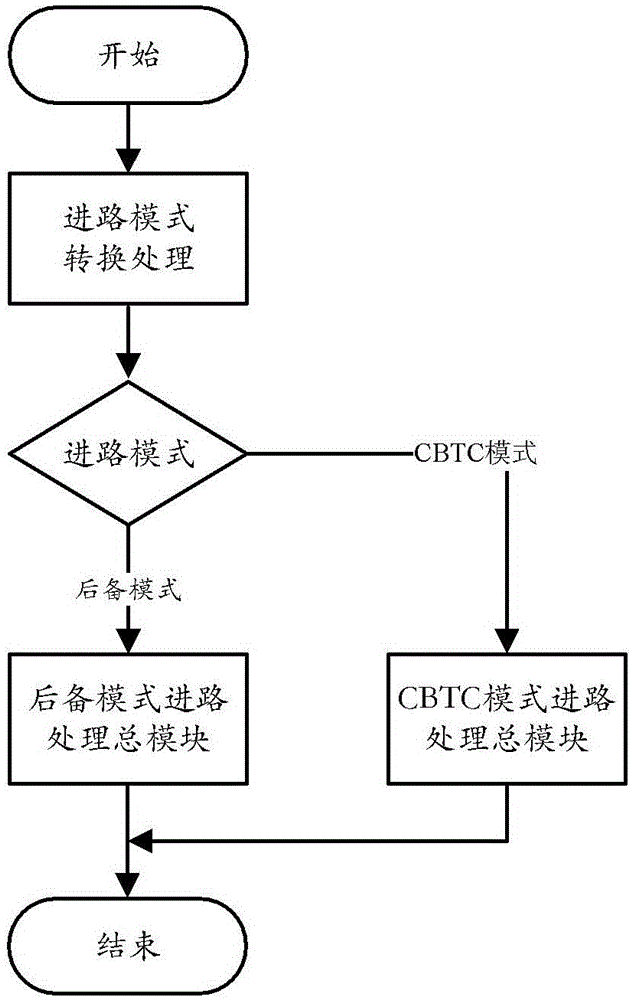

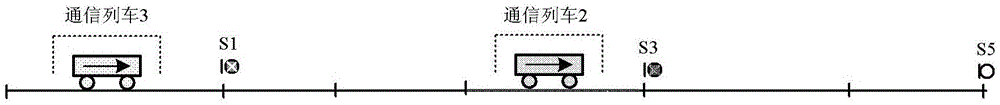

Computer interlock method and system

InactiveCN105128895AImprove flexibility and usabilityIncrease the level of automationAutomatic systemsProtective systemAutomatic train control

The invention discloses a computer interlock method and system, and belongs to the technical field of train control. The system disclosed by the invention comprises a plurality of signal devices and an interlock master control module connected with the plurality of signal devices, the interlock master control module exchanges data with an automatic train monitor system (ATS), a train automatic protective system / train automatic operation system (ATP / ATO), a train control system (CBTC) and a railway signal device (LEU), and the interlock master control module controls signal devices in an area of jurisdiction through interlocking. The signal device includes at least one or more of the following devices: a signal device, a track switch, a section and platform screen doors. The invention further discloses a computer interlock system. The technical schemes of the application can be used as a safety processing mode in connection between different railways, the interlock function of a computer can be achieved. Associated functions under a CBTC mode are expanded according to needs of urban mass transit system.

Owner:BEIJING HOLLYSYS

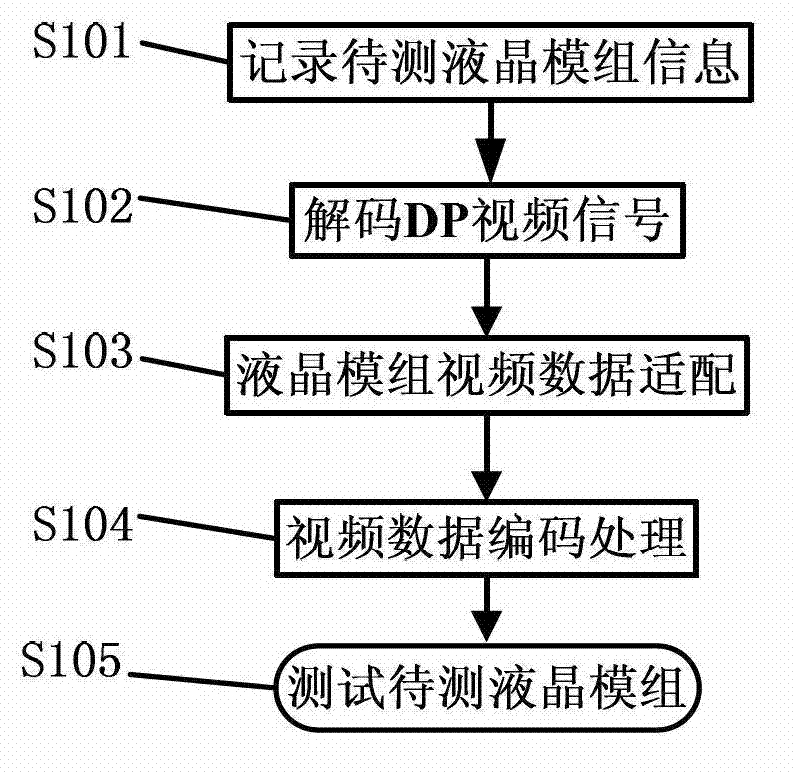

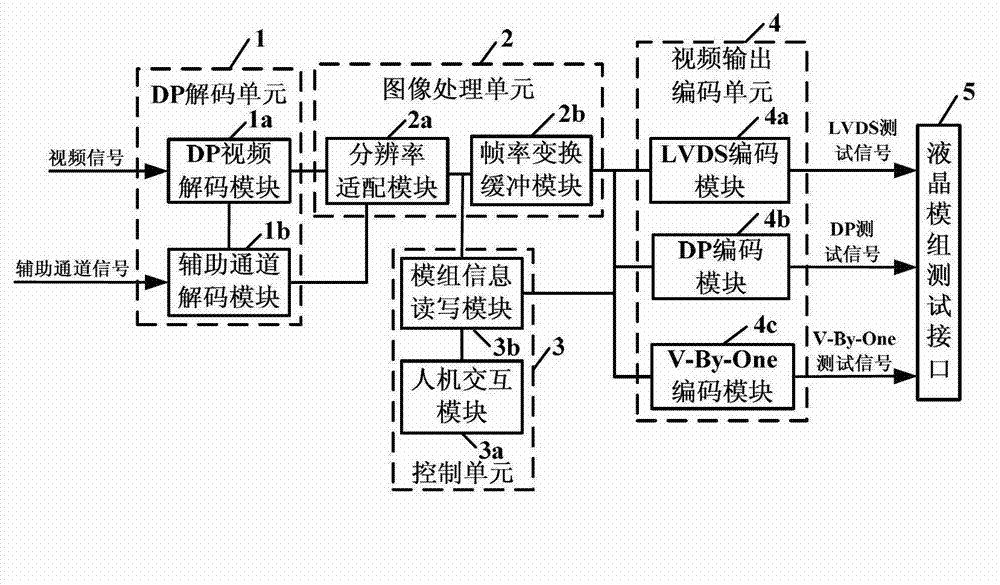

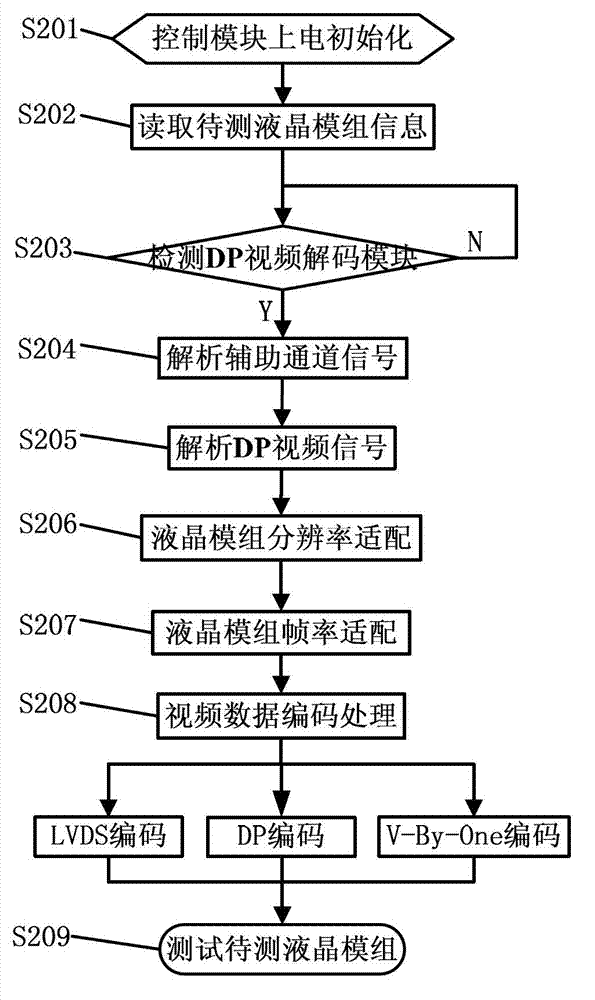

DP (Digital Processing) decoding and automatic resolution adjusting liquid crystal display module testing method and device

ActiveCN103050073AShorten adjustment timeImprove test efficiencyStatic indicating devicesCommunication interfaceTest efficiency

The invention discloses a DP (Digital Processing) decoding and automatic resolution adjusting liquid crystal display module testing method and a device, and relates to the field of liquid crystal display module testing. The testing method comprises the following steps of: decoding DP video signals to obtain video data and video parameter information thereof, wherein the video parameter information comprises resolution parameters; matching the video data with video data required by a liquid crystal display module to be tested according to the video parameter information and the video parameter information of the liquid crystal display module to the tested; conducting video encoding processing to the matched video data according to the communication interface and the video time sequence parameter of the liquid crystal display module to be tested to obtain video testing signals which are matched with the communication interface of the liquid crystal display module to be tested, and the video testing signals test the liquid crystal display module to be tested. The DP decoding and automatic resolution adjusting liquid crystal display module testing method and the device have the advantages that the energy consumption is lower during liquid crystal display module testing, the resolution can be automatically adjusted according to the liquid crystal display module, the liquid crystal display modules of different types can be automatically adapted, and not only is the testing cost lower and the testing efficiency higher, but also the energy consumption is lower and the stability and the reliability are higher.

Owner:WUHAN JINGCE ELECTRONICS GRP CO LTD

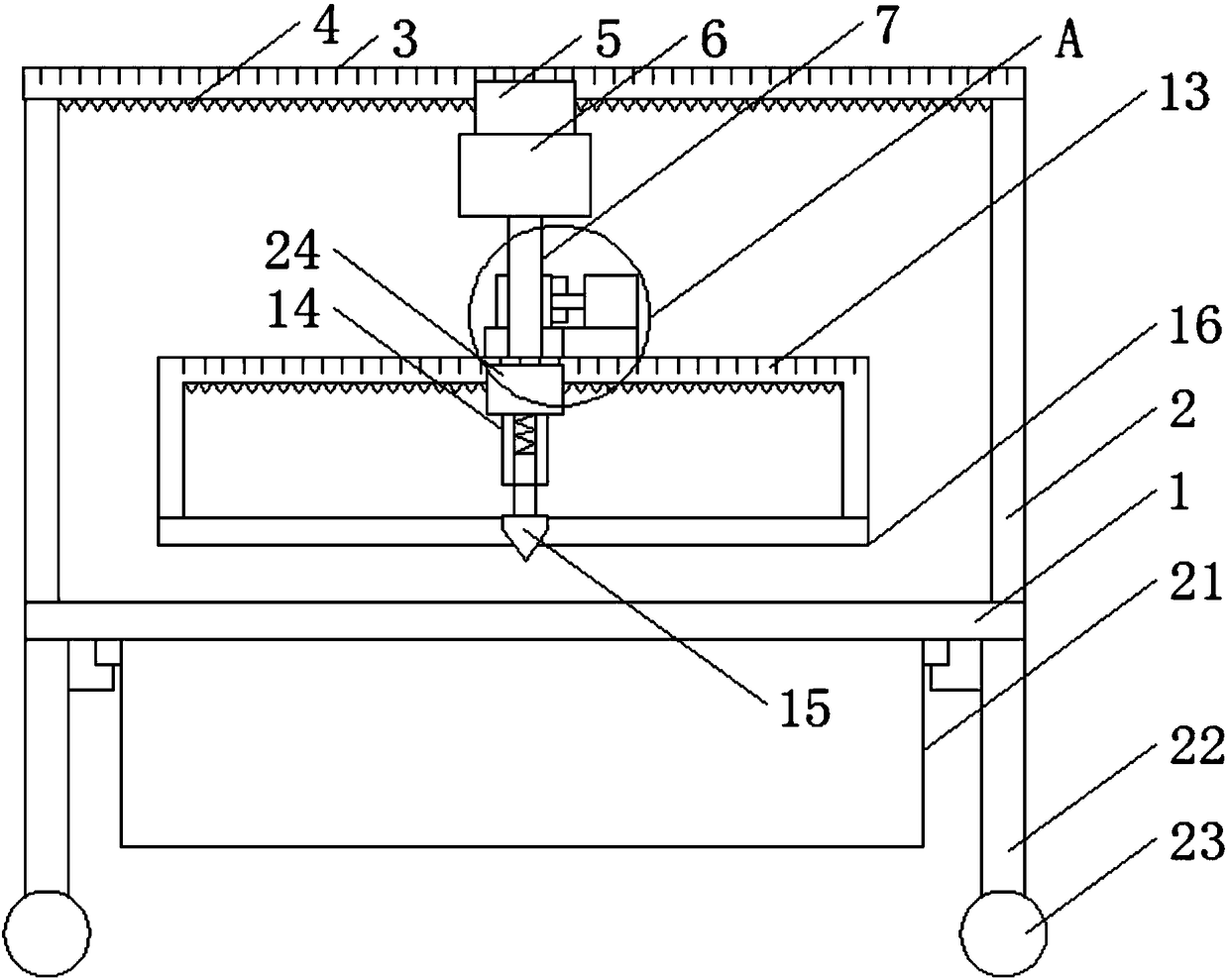

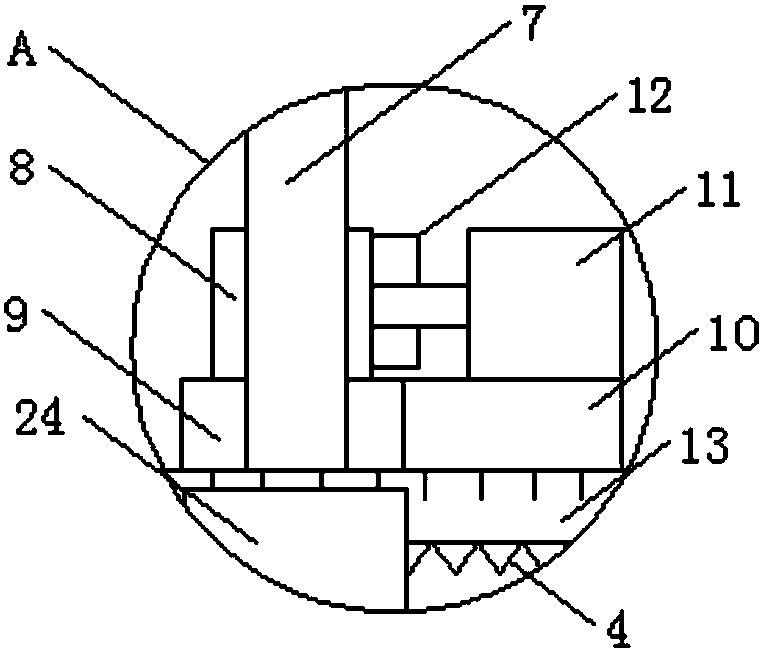

Cutting machine for processing tie cloth and cutting method

ActiveCN108214582AEasy to processPlay a role in absorbing heatSevering textilesMetal working apparatusEngineeringMechanical engineering

The invention discloses a cutting machine for processing a tie cloth in the field of a cutting machine, which comprises a cutting table; the bottom part of a mandril is moveably provided with a firstmoving mechanism, and the bottom part of a flexible rod is provided with a cutter; bottom parts at left and right sides of the supporting bracket are connected with pressing plates; through the walking of a first walking mechanism and the matching of a motor through an active gear and a driven gear, the supporting bracket is rotated, and a second walking mechanism is matched to drive the cutter towalk and cut the cloth; the cloth cutting can be realized at different angles and positions; the pressing plates can prevent cloth from displacement in cutting, the cutting opening is flat and burr-free after cutting the cloth; the cutting quality is good and the working efficiency is high; through the flexible device, height of the bottom part of the cutter blade out of the pressing plate is changed along with the thickness of the cloth, different thicknesses of clothes can be cut.

Owner:浙江佳米特服饰有限公司

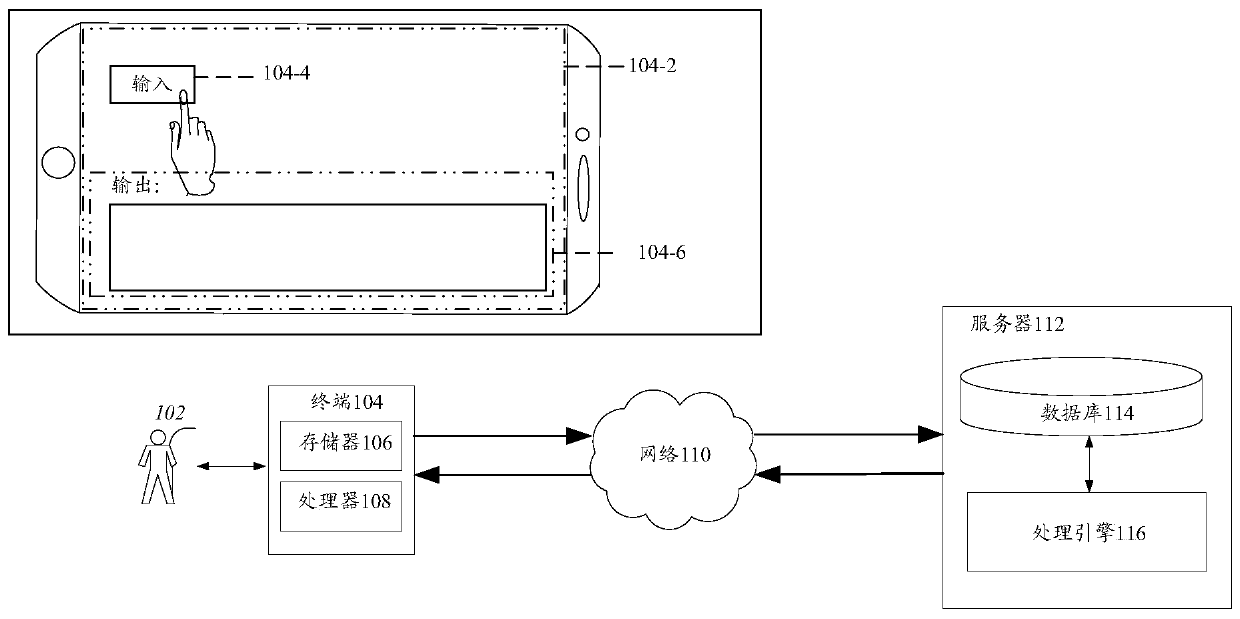

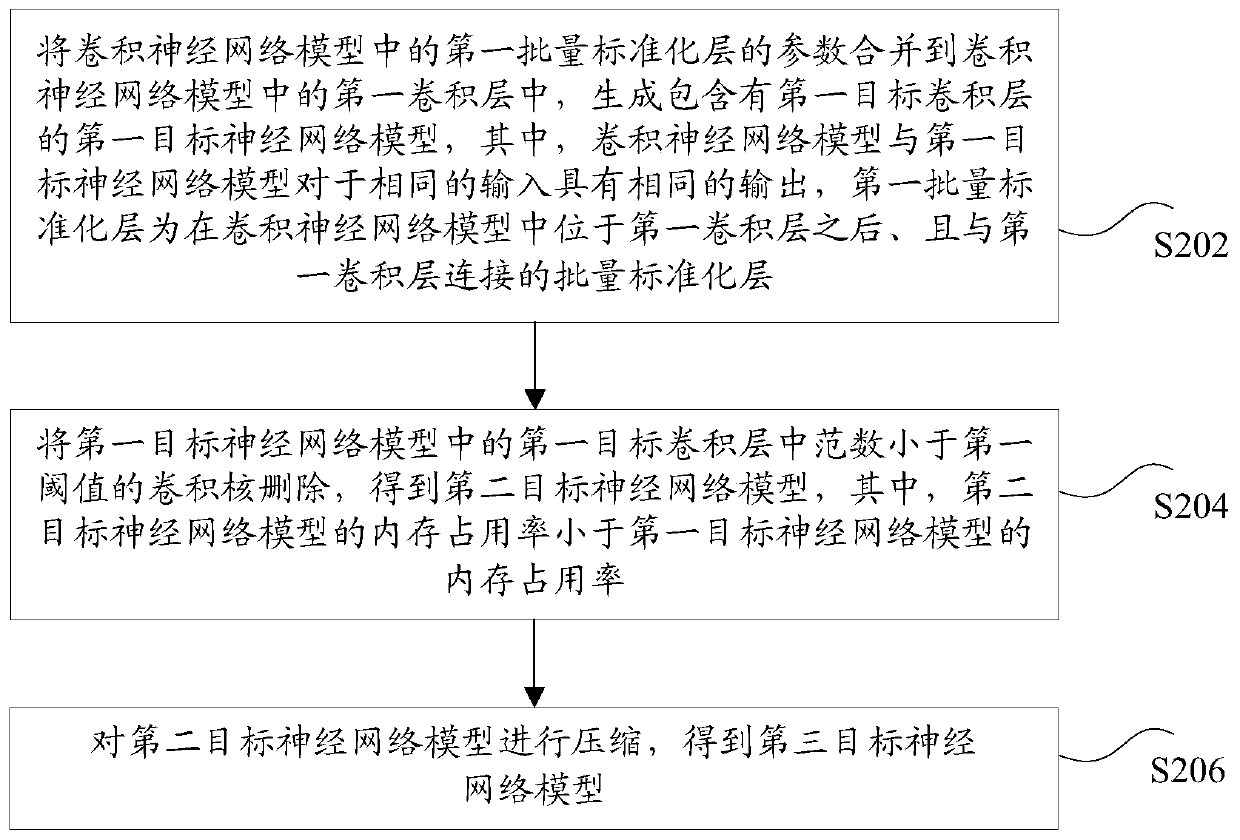

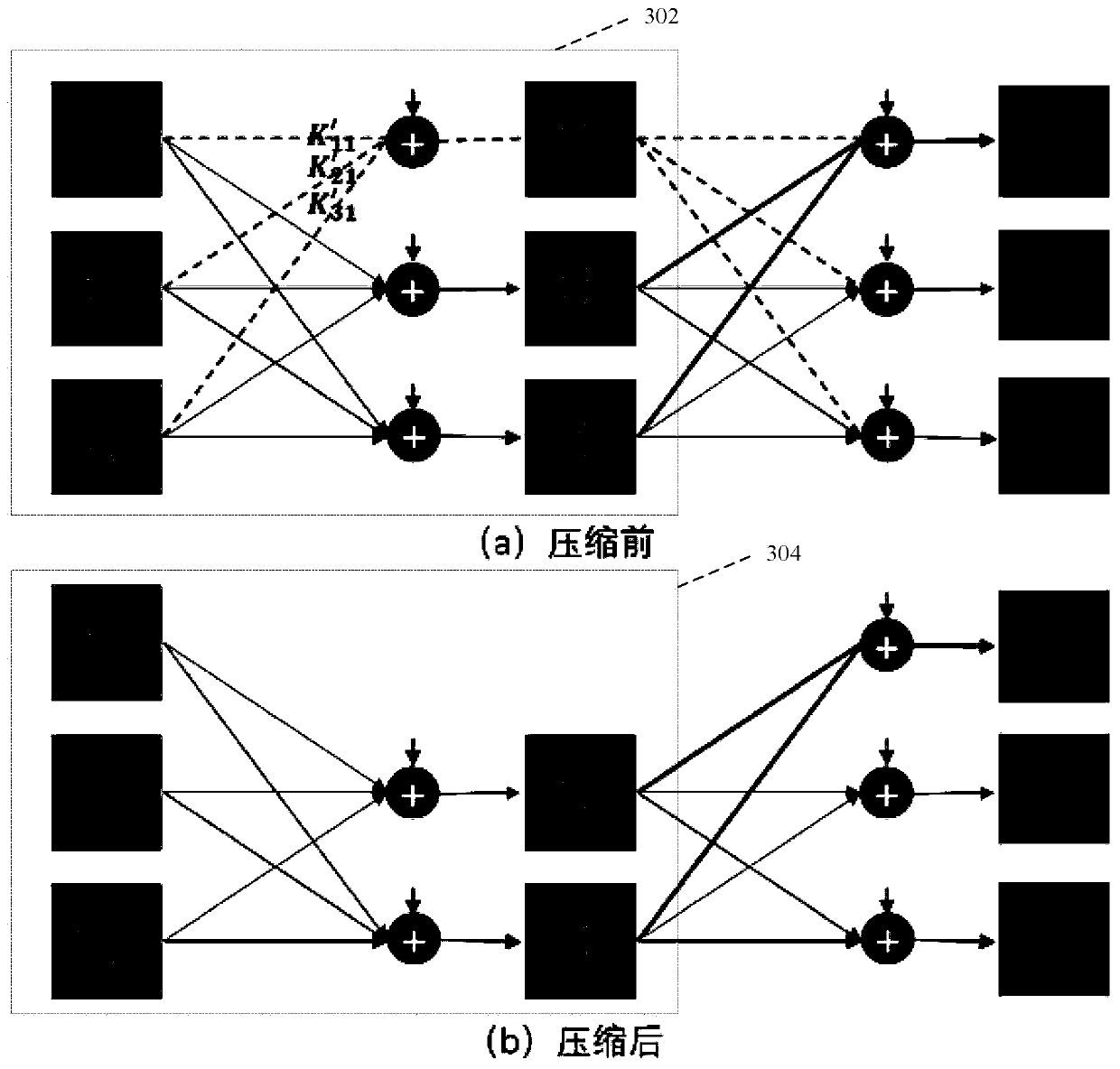

Convolutional neural network model compression method and device, storage medium and electronic device

ActiveCN110033083AReduce memory usageImprove efficiencyNeural architecturesEnergy efficient computingNerve networkNetwork model

The invention discloses a convolutional neural network model compression method and device, a storage medium and an electronic device. The method comprises the following steps of merging the parameters of a first batch of standardized layers in a convolutional neural network model into a first convolutional layer in the convolutional neural network model to generate a first target neural network model comprising a first target convolutional layer, the convolutional neural network model and the first target neural network model having the same output for the same input; deleting a convolution kernel with a norm smaller than a first threshold value in a first target convolution layer in the first target neural network model to obtain a second target neural network model; and compressing thesecond target neural network model to obtain a third target neural network model, so that the technical problems of low use efficiency and poor flexibility of a neural network model in the prior art are solved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

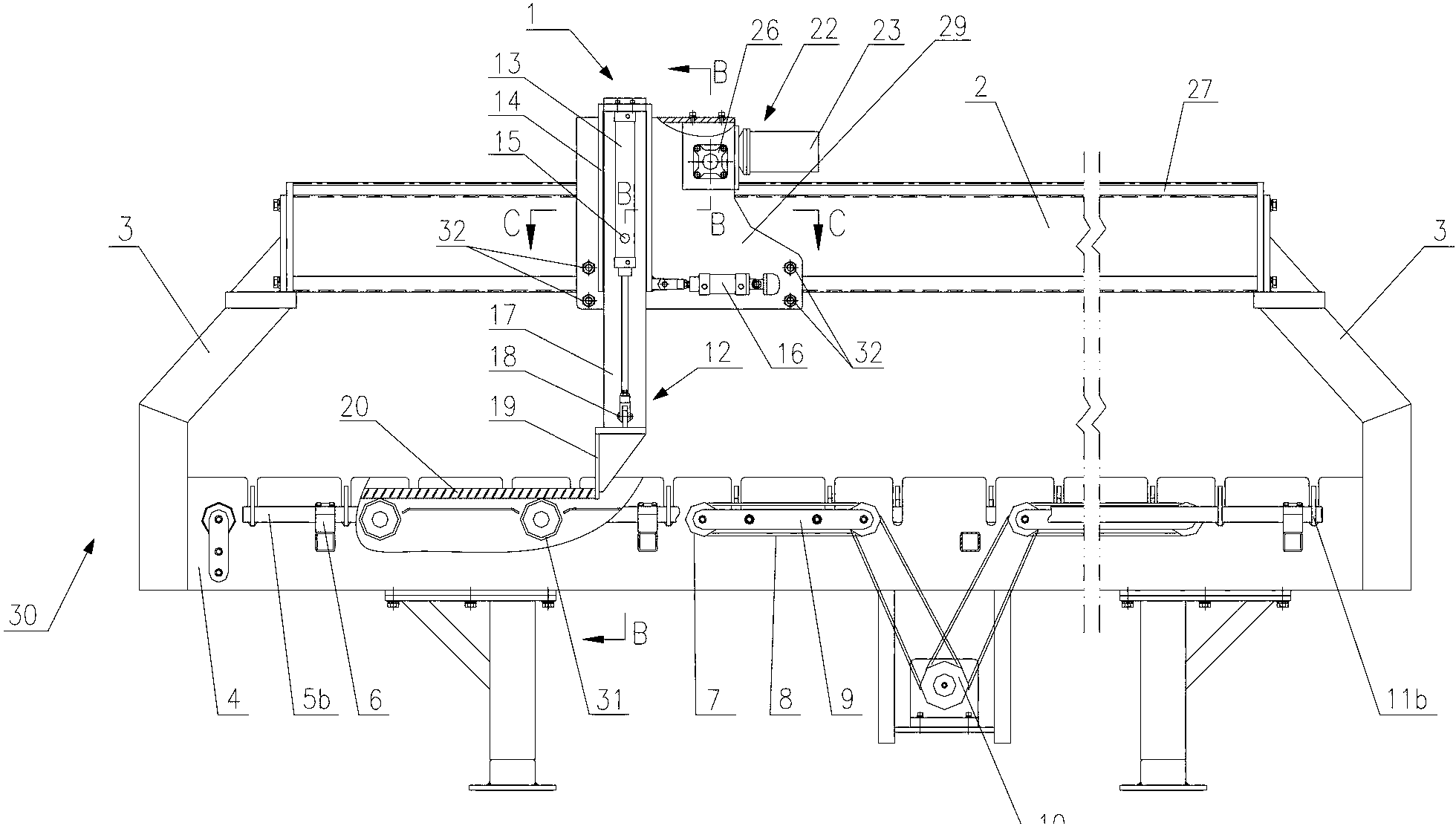

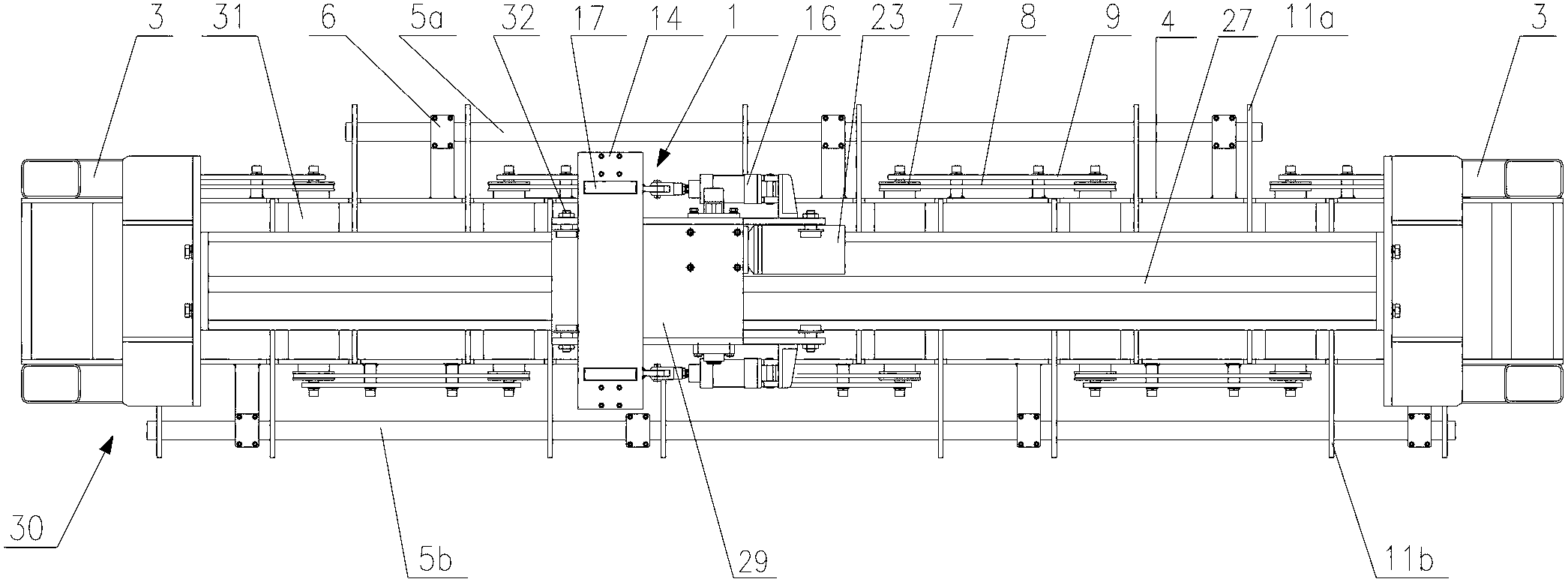

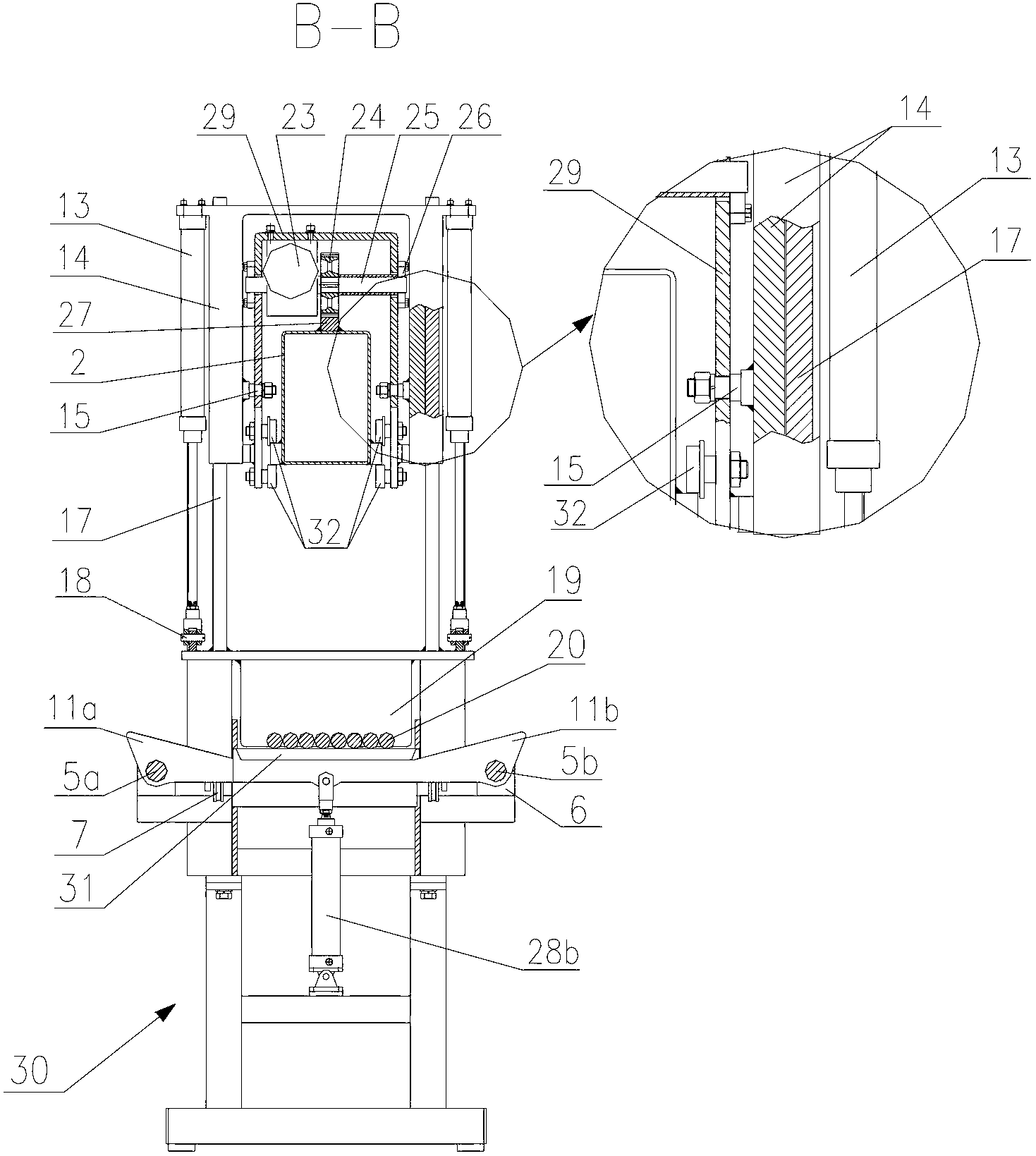

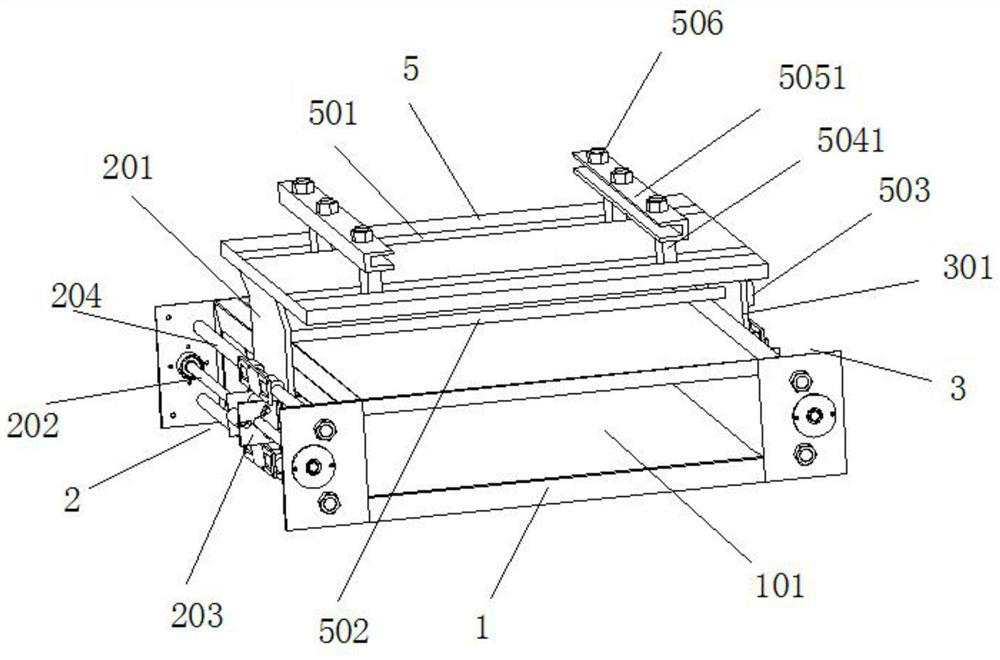

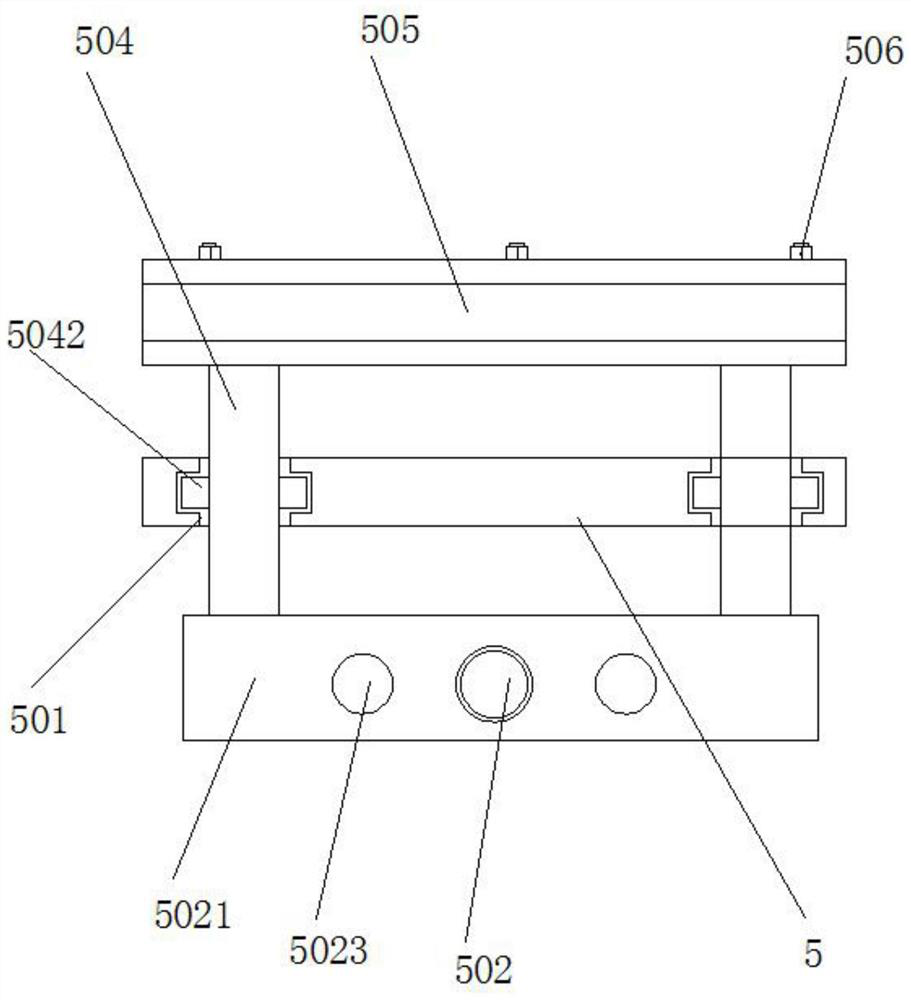

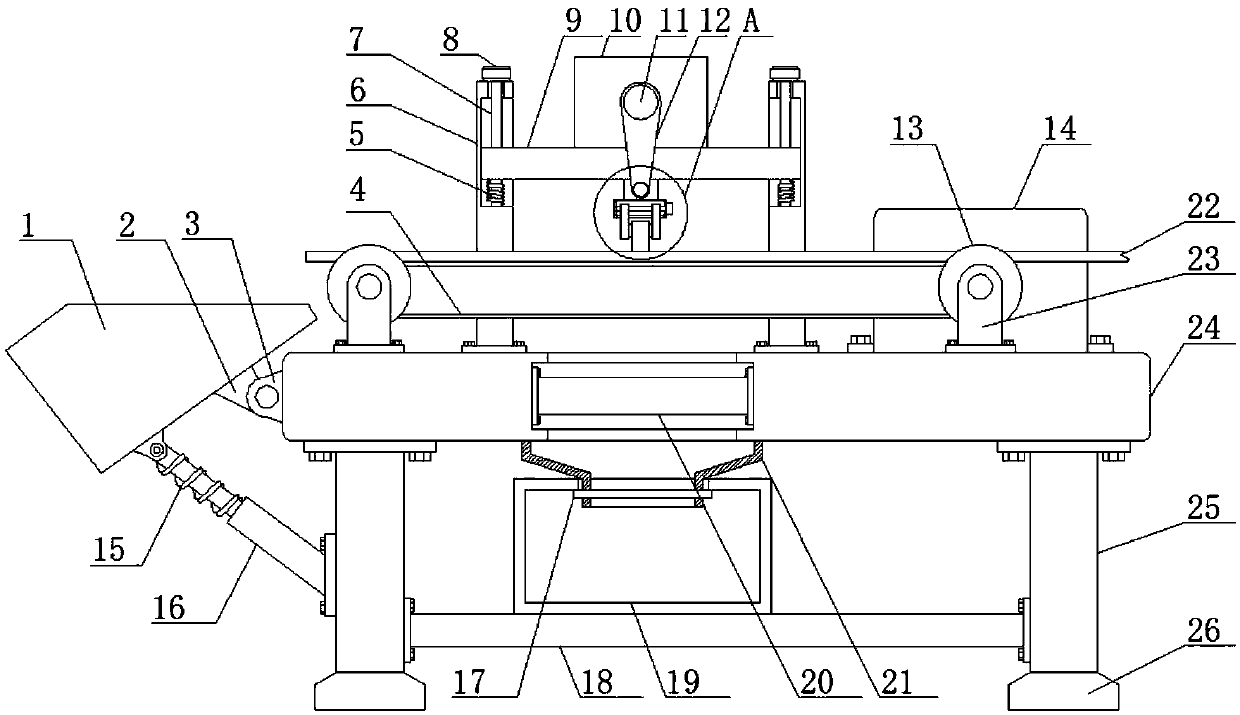

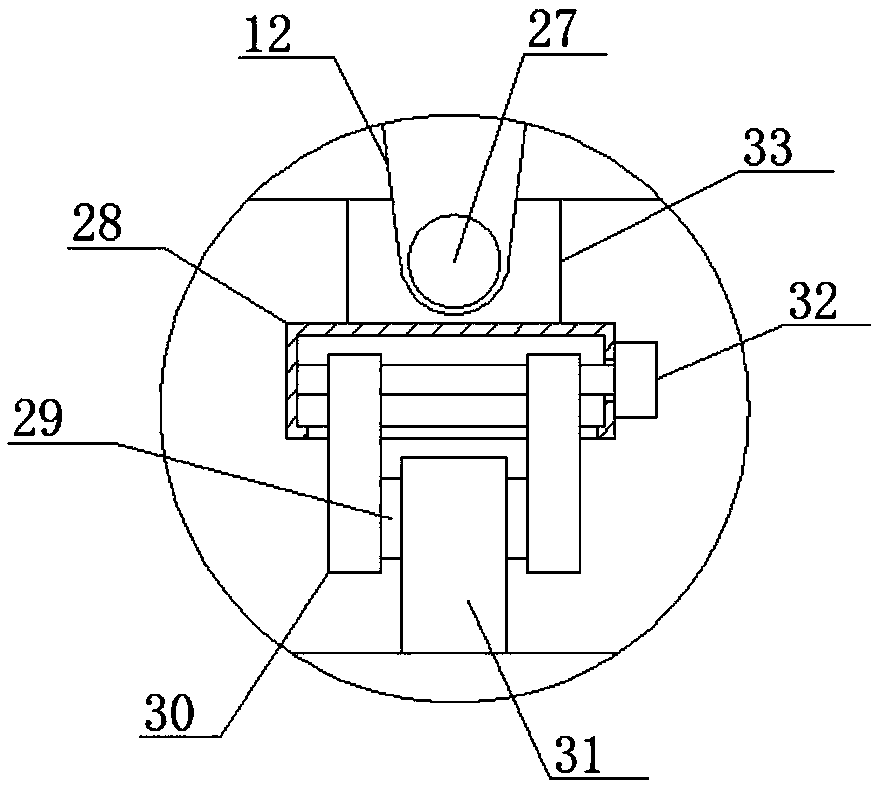

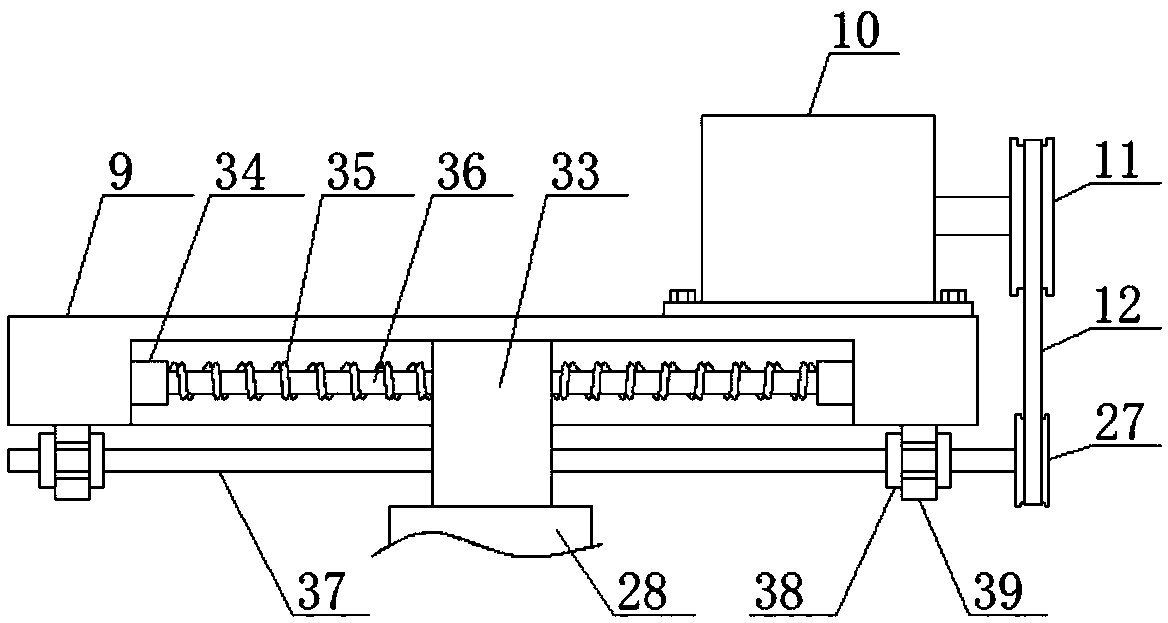

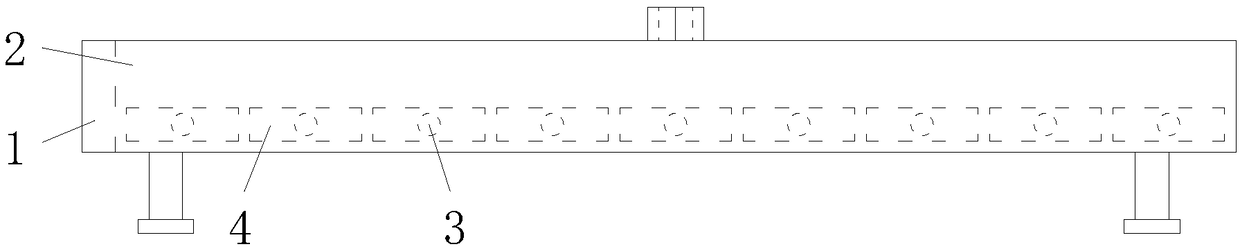

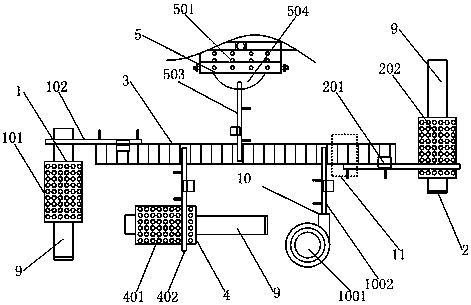

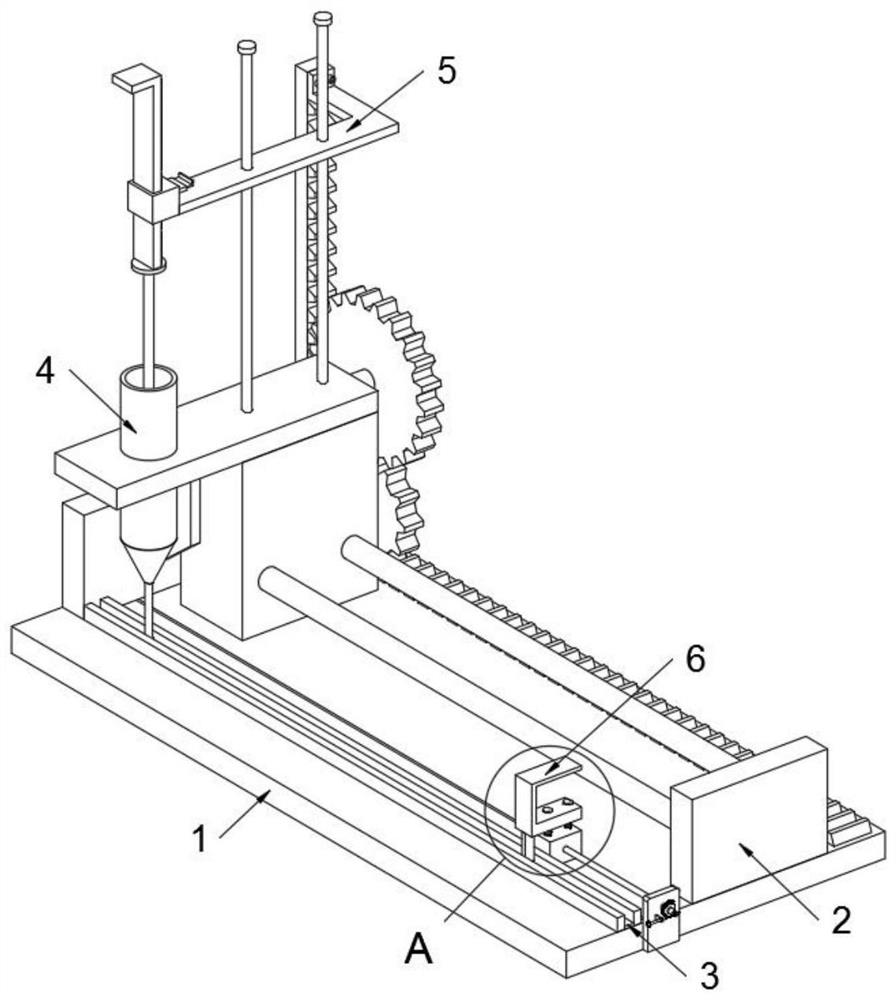

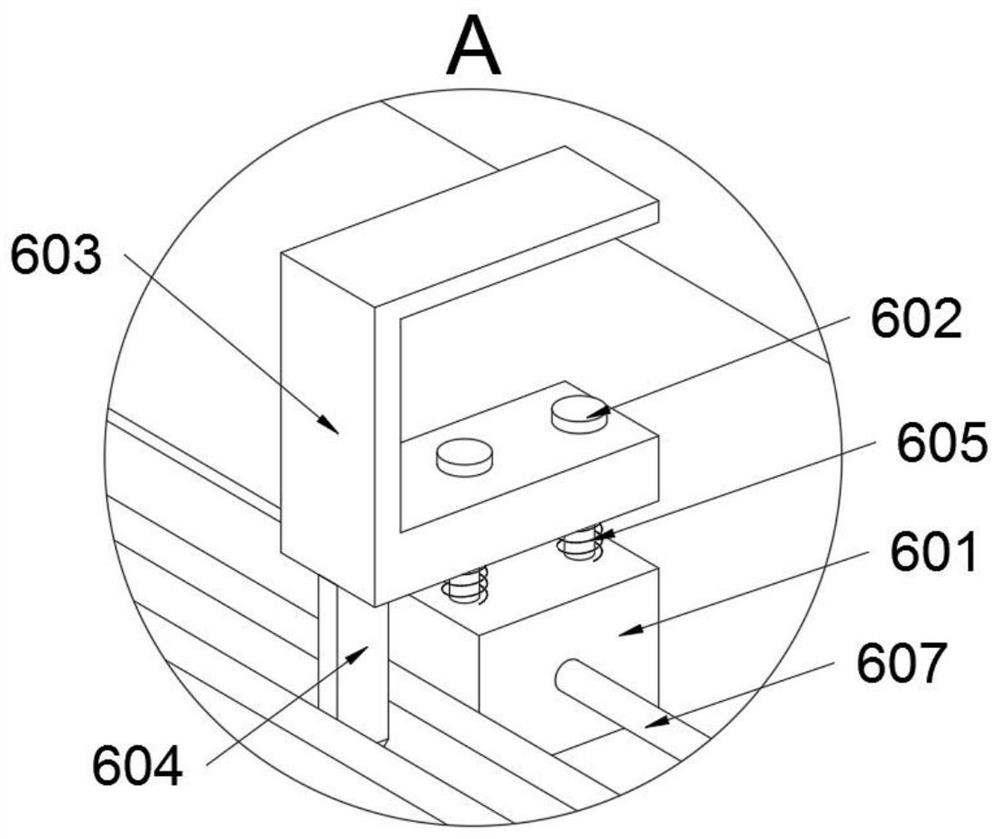

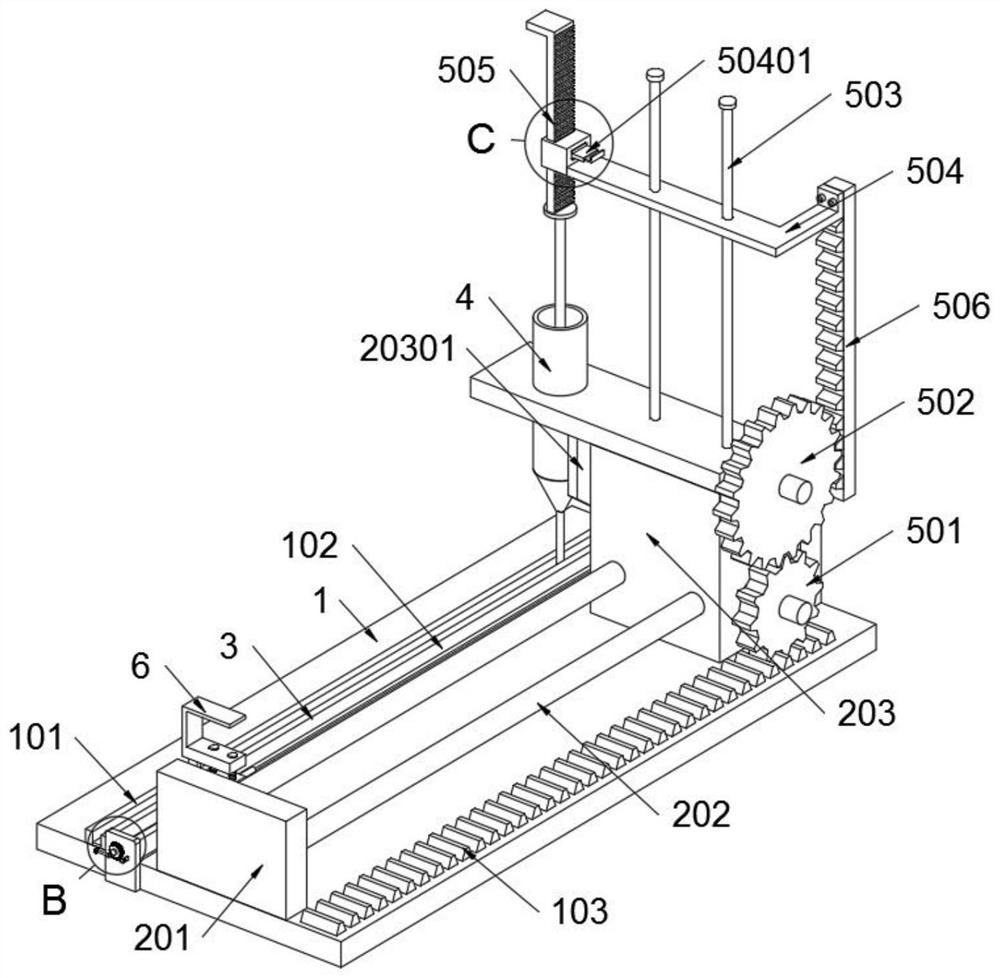

Bridge frame movable type steel bar sizing device of steel bar conveying device

The invention discloses a bridge frame movable type steel bar sizing device of a steel bar conveying device. The bridge frame movable type steel bar sizing device comprises a material conveying part, wherein the upper part of the material conveying part is supported by a bridge frame, the bridge frame is provided with a sizing trolley which comprises a sizing trolley frame, the sizing trolley frame is provided with a moving driving mechanism and a hoisting mechanism, and a steel bar on the material conveying part is retained by a sizing baffle. The bridge frame movable type steel bar sizing device of the steel bar conveying device disclosed by the invention has the beneficial effects that the sizing baffle is driven by the moving driving mechanism to move along the bridge frame so as to retain the steel bar in any size as required, and automatic arbitrary sizing on the steel bar is completed, so that the steel bar is cut in any size by a cutting mechanism; only one sizing baffle is arranged, and the bridge frame movable type steel bar sizing device is low in cost, and has a simple structure and high working efficiency; and the sizing baffle is moved in an overhanging mode so as to realize left and right bidirectional material turning.

Owner:TJK MACHINERY TIANJIN

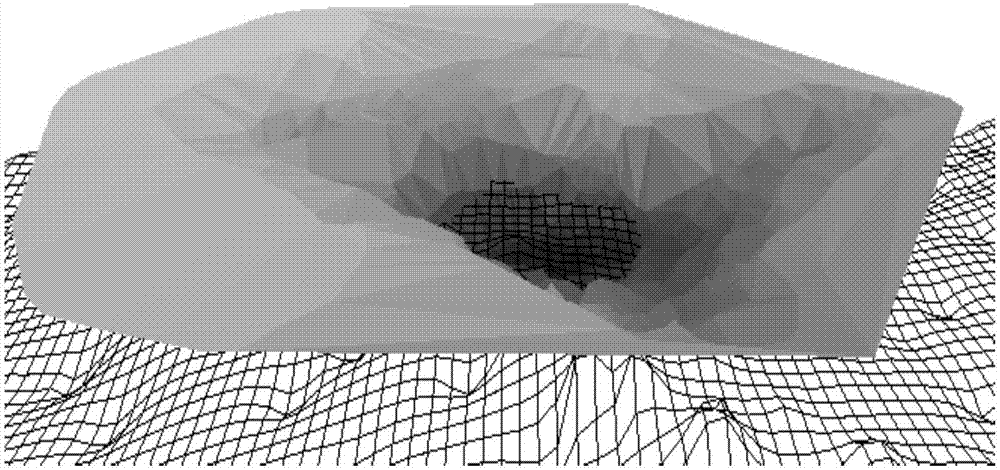

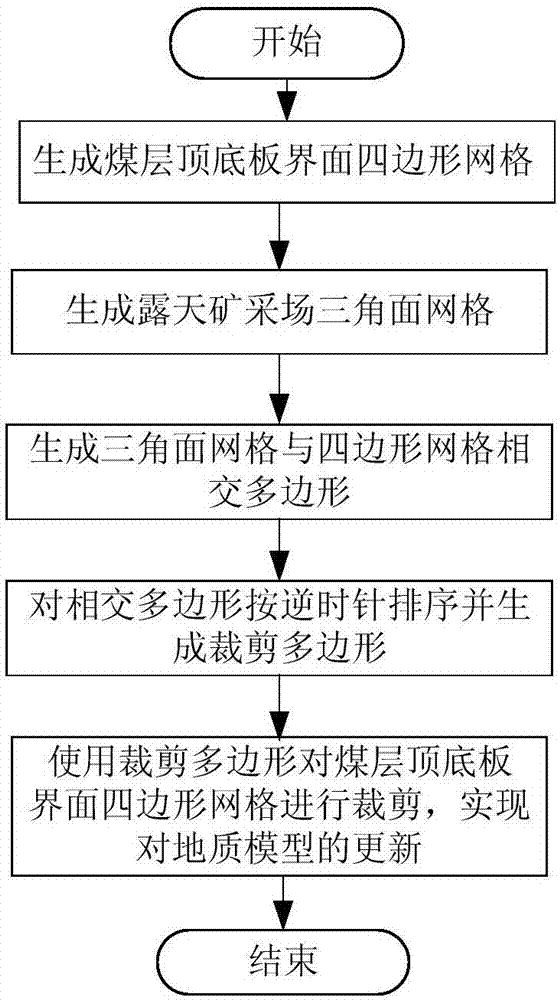

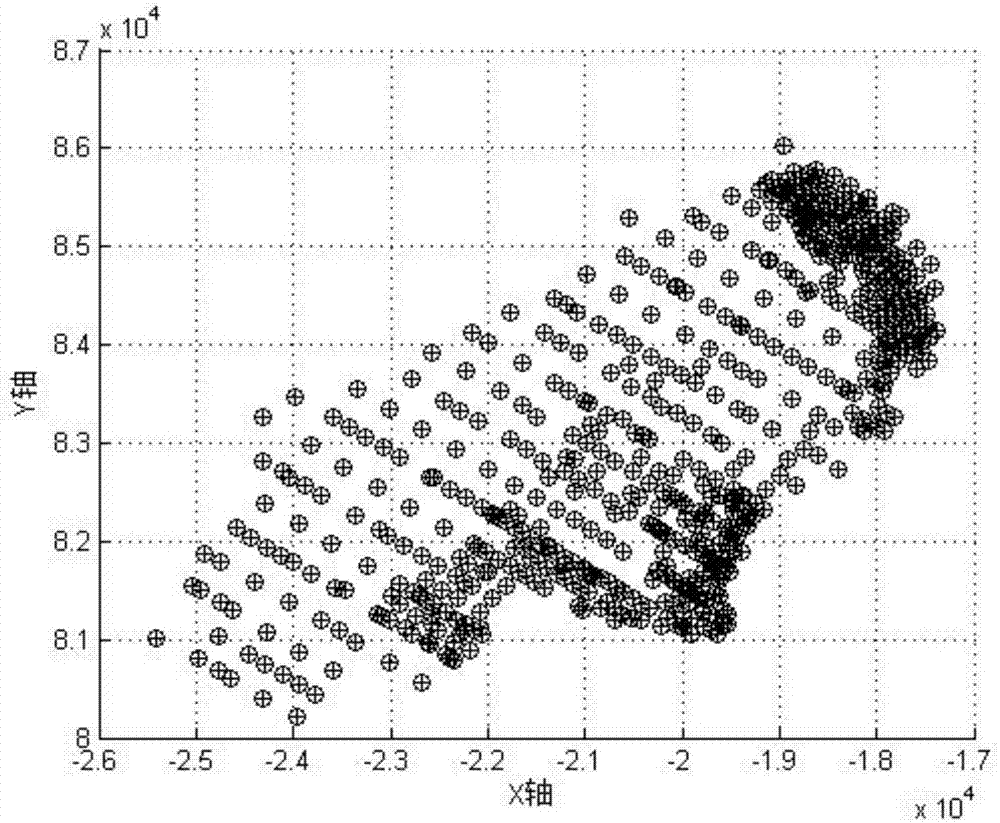

Method of clipping quadrilateral grids of coal seam by triangular grid of open-pit mine stope

InactiveCN107886575AAchieve croppingSolve the problem that the intersection line is a space curveImage generation3D modellingQuadrilateral gridComputer science

The invention provides a method of clipping quadrilateral grids of a coal seam by a triangular grid of an open-pit mine stope, and relates to the technical field of coal seam geology. According to themethod, firstly, the quadrilateral grids of coal seam roof and floor interfaces and the triangular grid of the open-pit mine stope are generated; then intersecting-line polygons obtained by intersection of the triangular grid and the quadrilateral grids are generated, and sorted counterclockwise to obtain clipping polygons; and finally, the clipping polygons are used to clip the quadrilateral grids of the coal seam roof and floor interfaces to realize updating for a coal seam geology model. According to the method of clipping the quadrilateral grids of the coal seam by the triangular grid ofthe open-pit mine stope provided by the invention, the problem that intersecting lines of quadrilateral curved surfaces and triangular surfaces are space curves is effectively solved, and practical application is enabled to be realized. The method of directly utilizing the triangular grid to clip the quadrilateral grids highly efficiently realizes, on the premise of not increasing a storage amount, operations of clipping the quadrilateral grids by the triangular grid.

Owner:LIAONING TECHNICAL UNIVERSITY

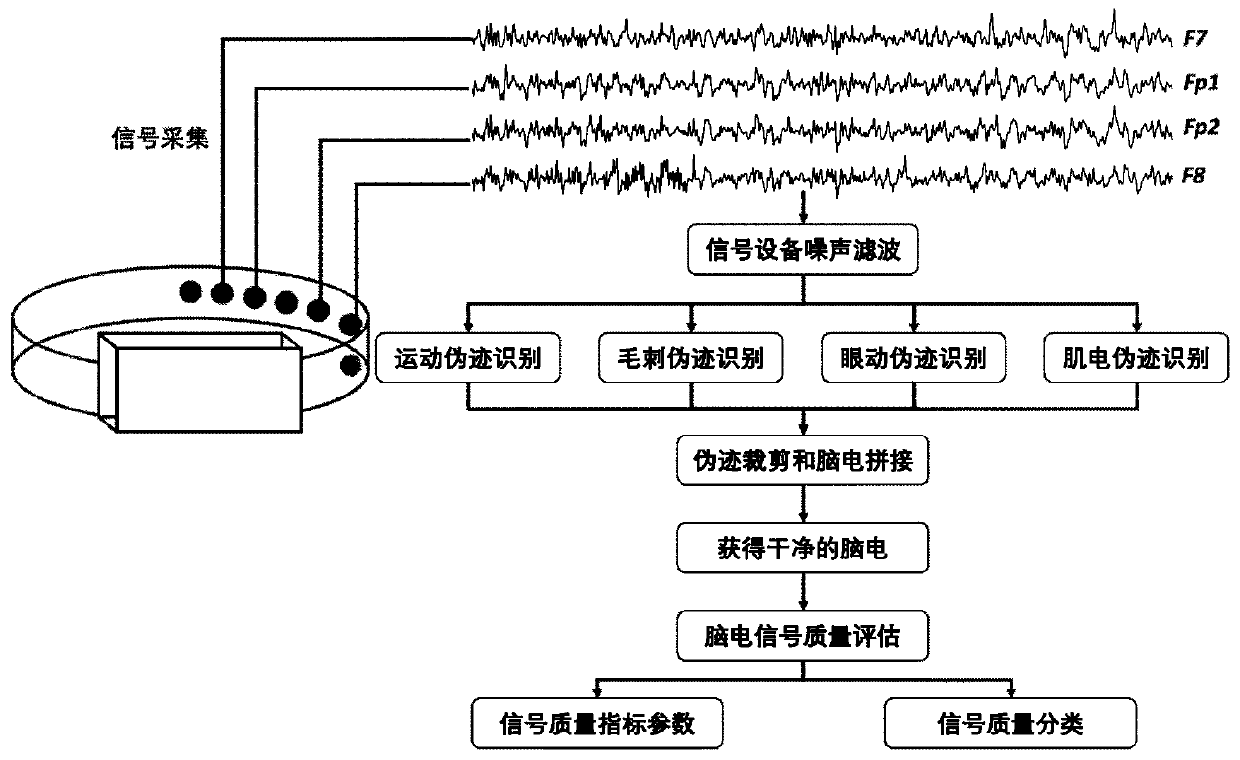

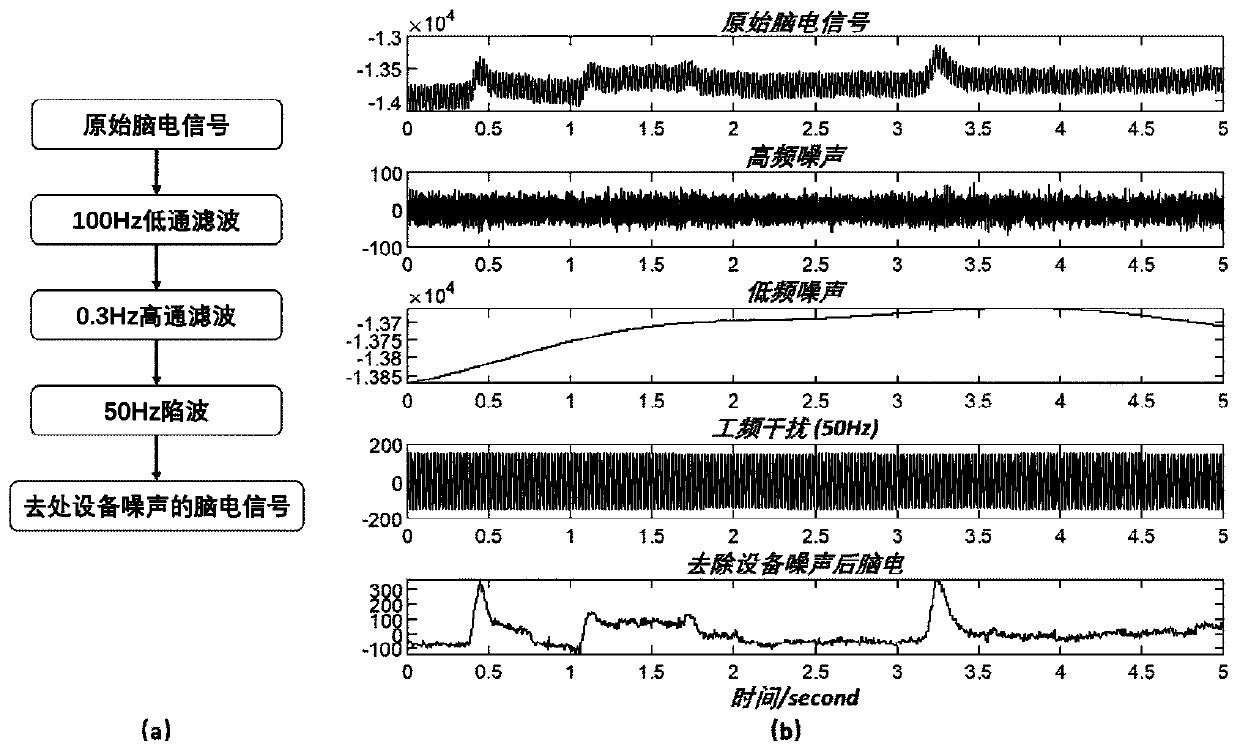

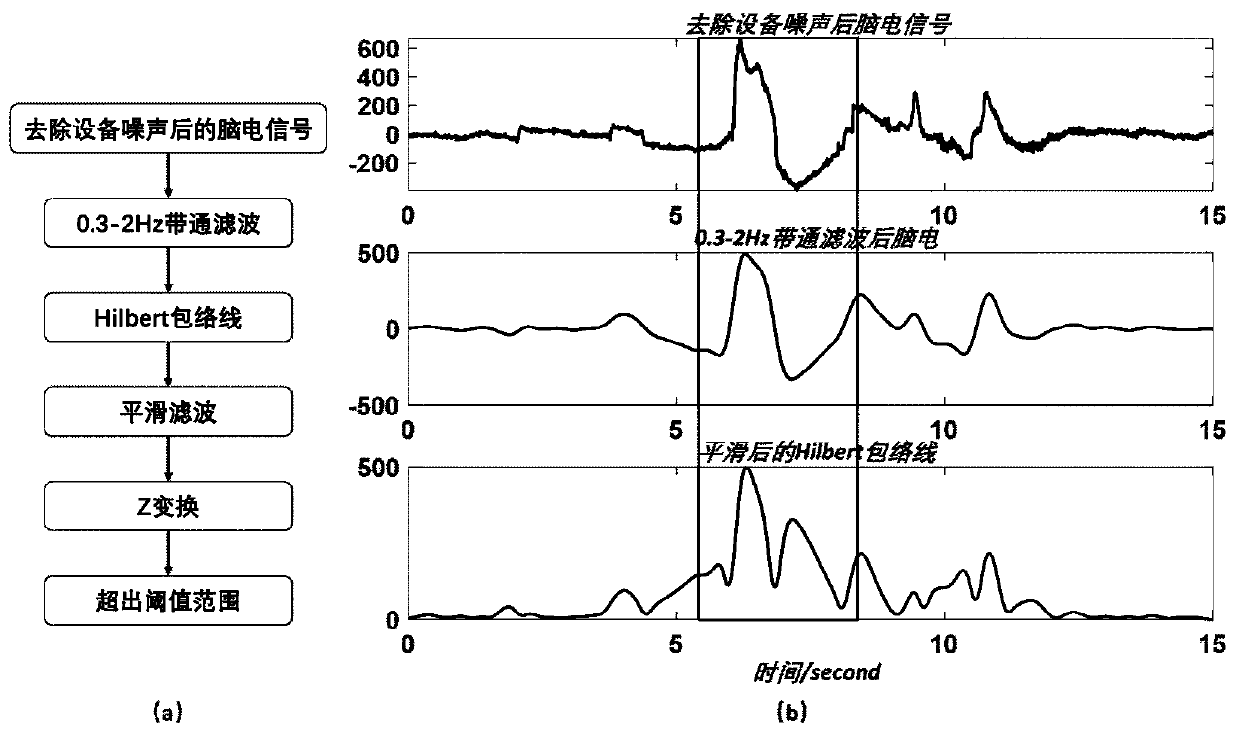

Artifact removal and electroencephalogram signal quality evaluation method based on wearable electroencephalogram equipment

ActiveCN111012341ARealize automatic identificationAchieve croppingDiagnostic recording/measuringSensorsPattern recognitionSignal quality

The invention discloses an artifact removal and electroencephalogram signal quality evaluation method based on wearable electroencephalogram equipment. The method comprises the following steps: original electroencephalogram signals on the scalp surface layer are collected through the wearable electroencephalogram equipment; equipment noises in the original electroencephalogram signal are filtered;various artifact noises in the original electroencephalogram signal, comprising motion artifacts, burr artifacts, eye movement artifacts and myoelectricity artifacts, are recognized; adaptive artifact clipping and signal splicing are carried out based on the artifact recognition result to obtain a clean electroencephalogram signal; and comprehensive quality evaluation is carried out on the cleanelectroencephalogram signal by adopting neural network classification and index parameters. The problems that artifacts of the wearable electroencephalogram equipment are difficult to remove due to channel number limitation and real-time performance, and an electroencephalogram signal quality evaluation method is lacked are solved.

Owner:SOUTHEAST UNIV

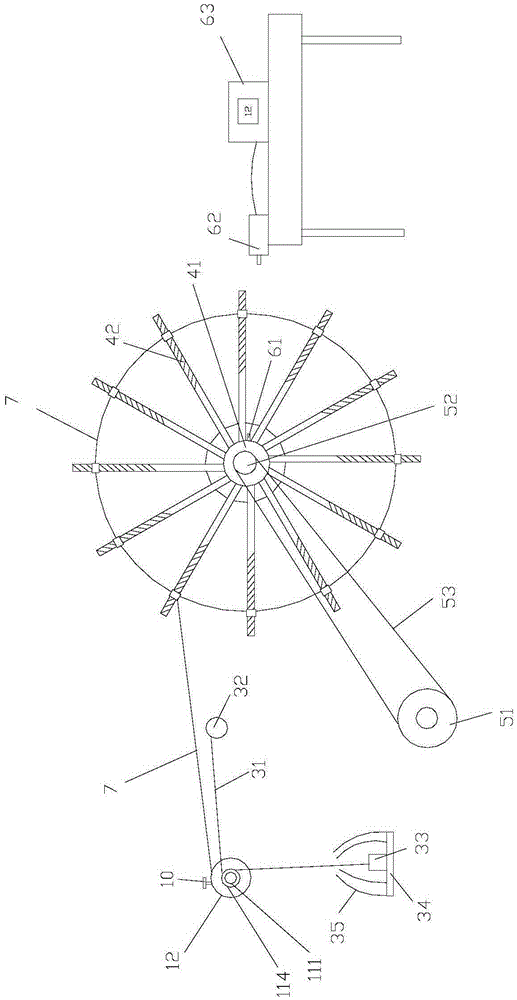

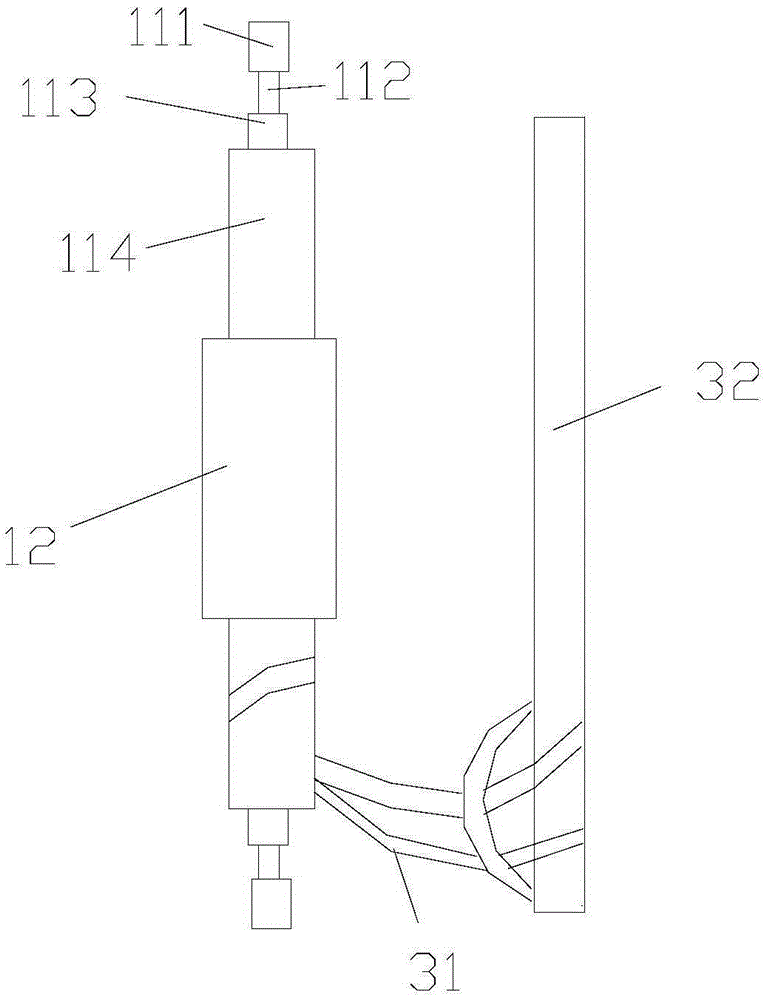

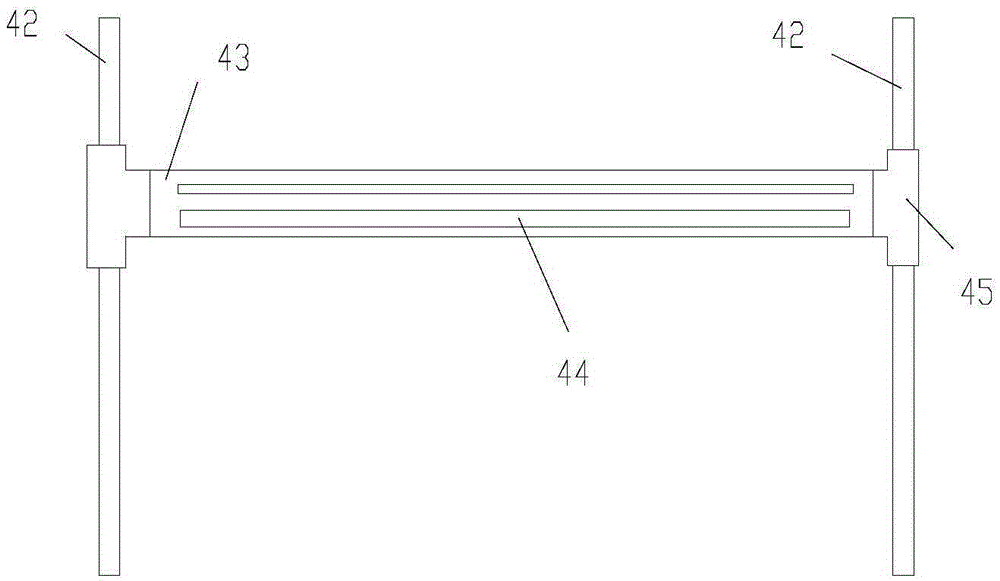

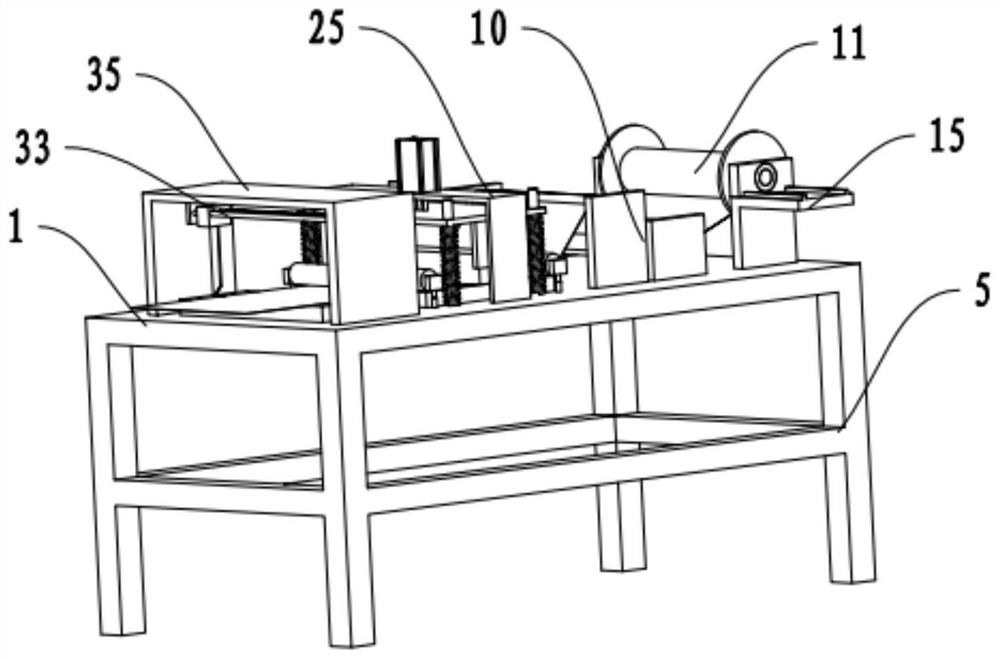

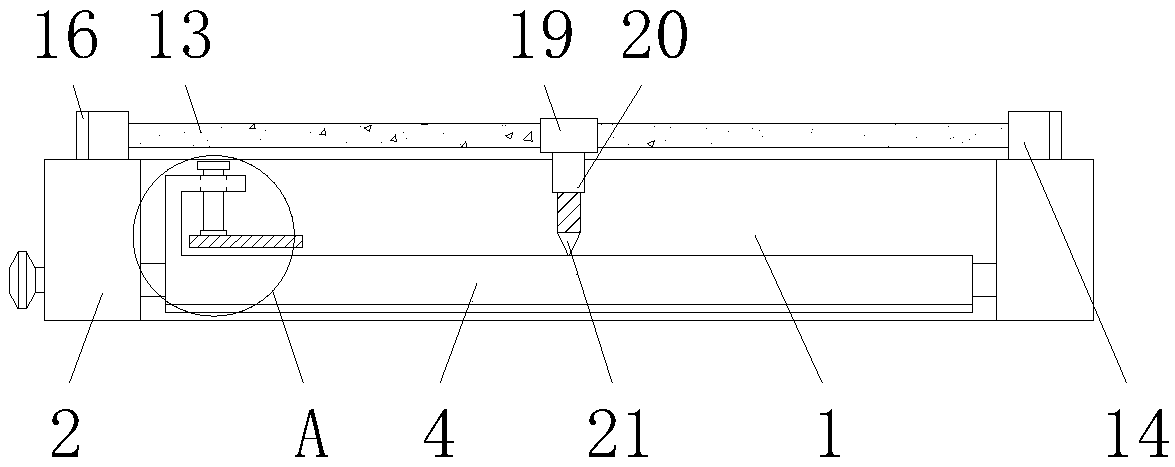

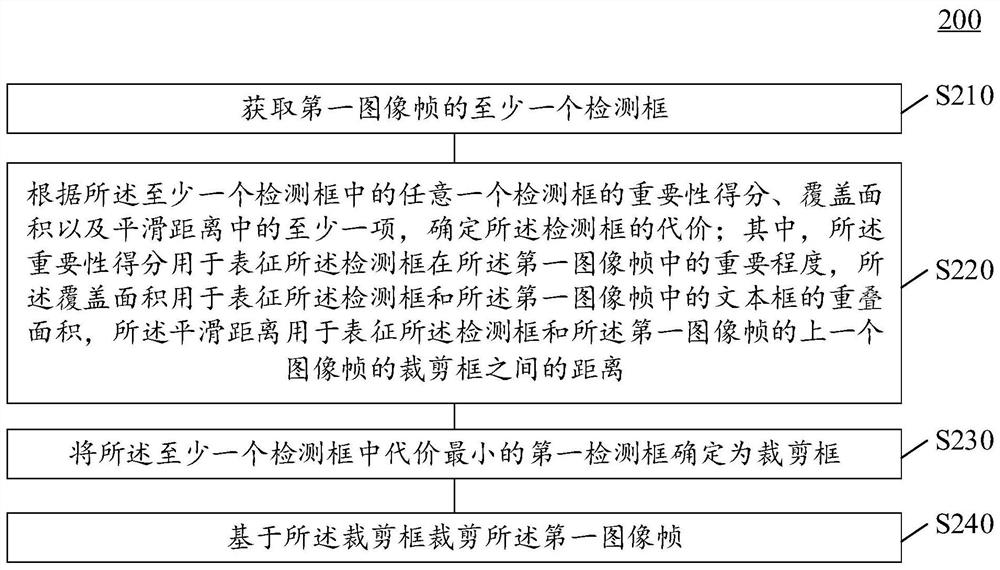

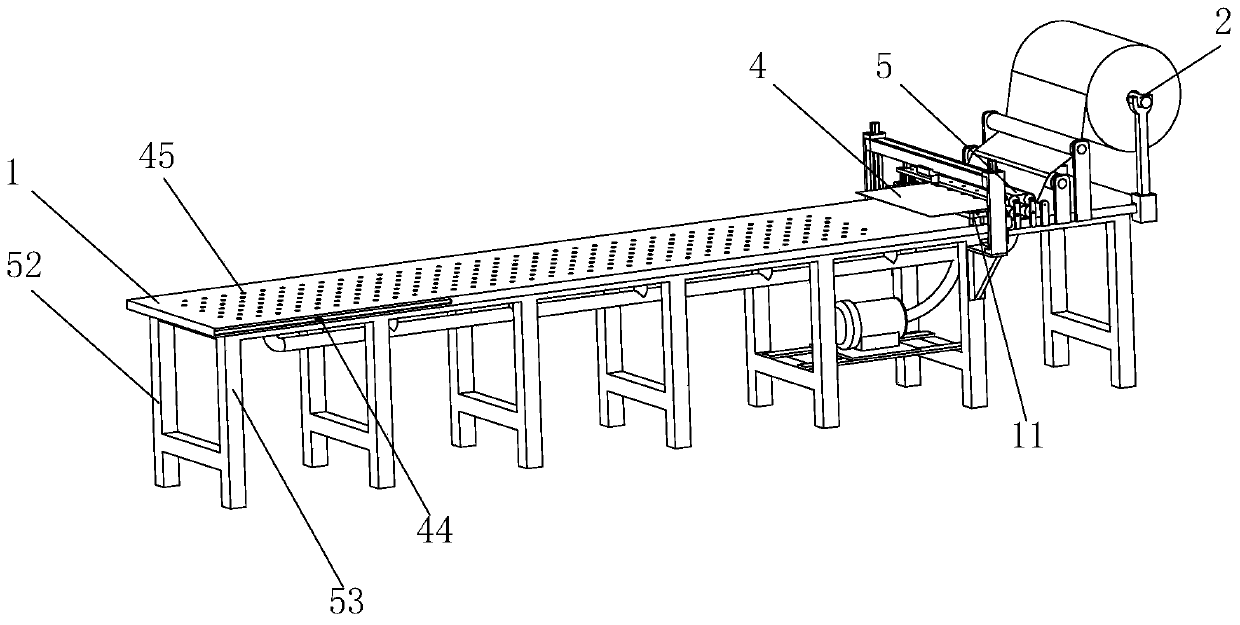

Fixed-length film cutting machine

InactiveCN105366420AEasy to adjustAchieve croppingFilament handlingArticle deliveryEngineeringMechanical engineering

The invention discloses a fixed-length film cutting machine. The fixed-length film cutting machine comprises a feeding device, a fixed-length winding device and a driving device, wherein the feeding device is arranged in front of the fixed-length winding device and is used for feeding a thin film to the fixed-length winding device; the driving device is in outputting connection to the fixed-length winding device; and a film cutting structure is arranged on the fixed-length winding device. The fixed-length film cutting machine has the advantages of simple structure and good flexibility on adjustment of lengths of films.

Owner:ANQING XINSHUN PLASTIC CO LTD

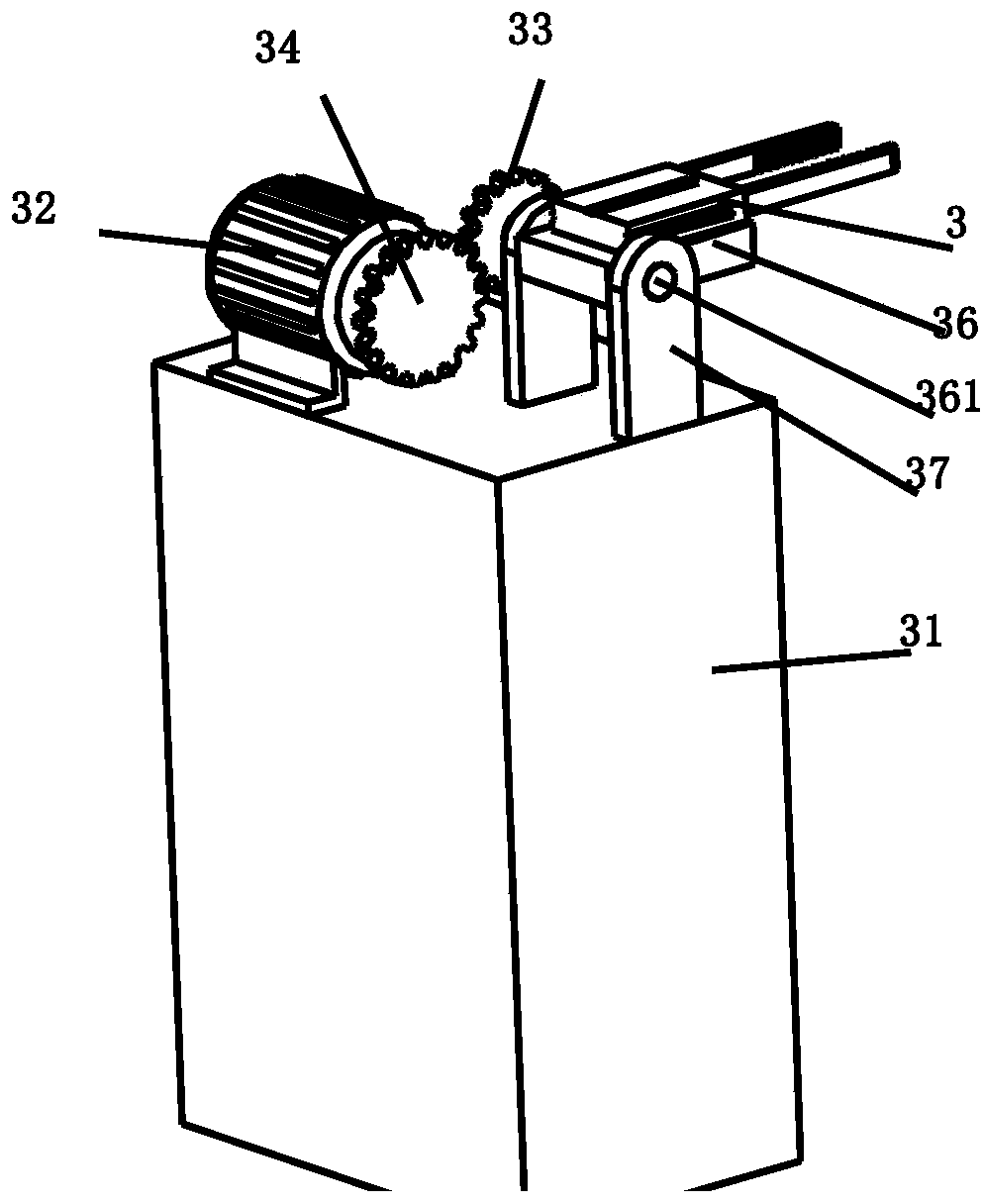

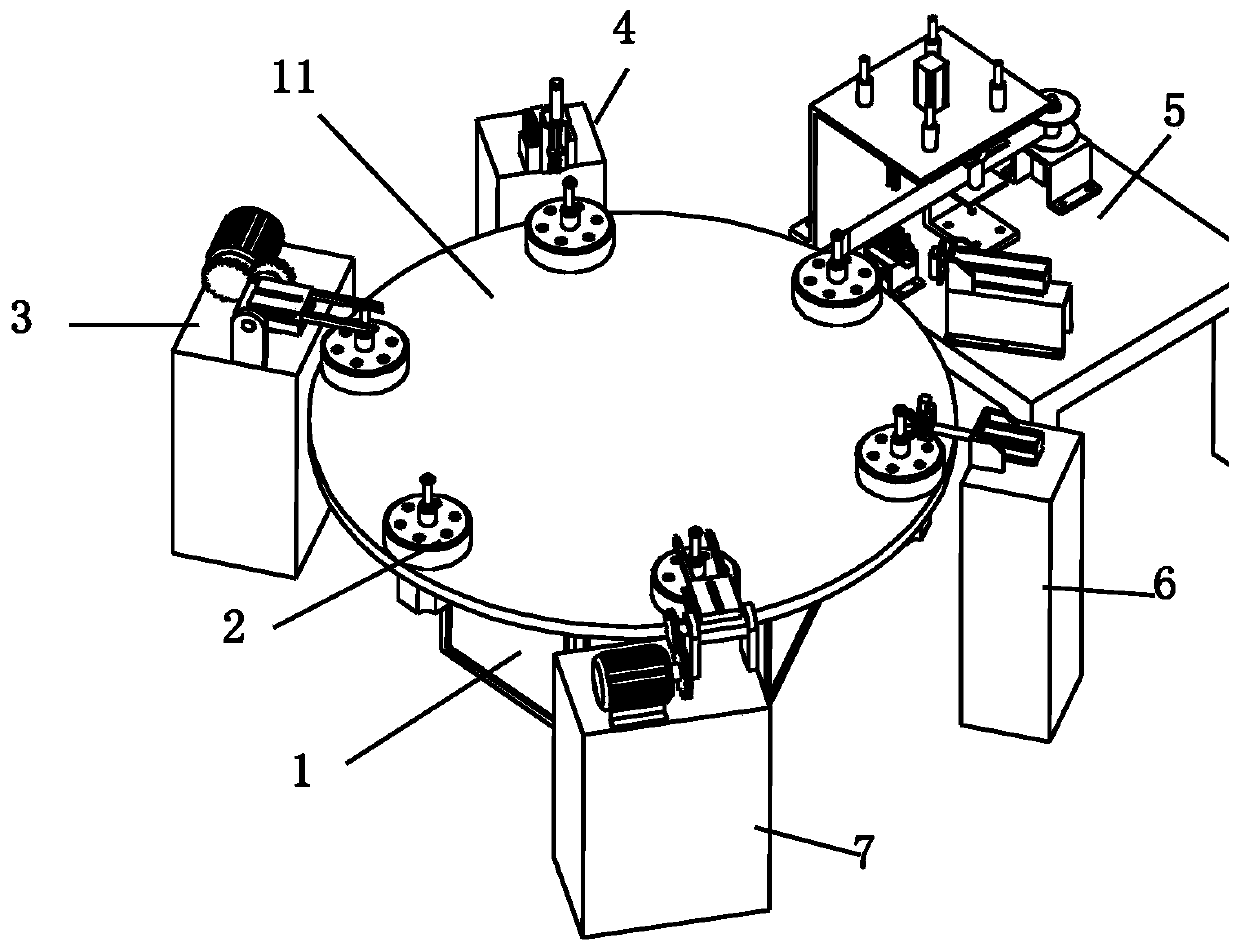

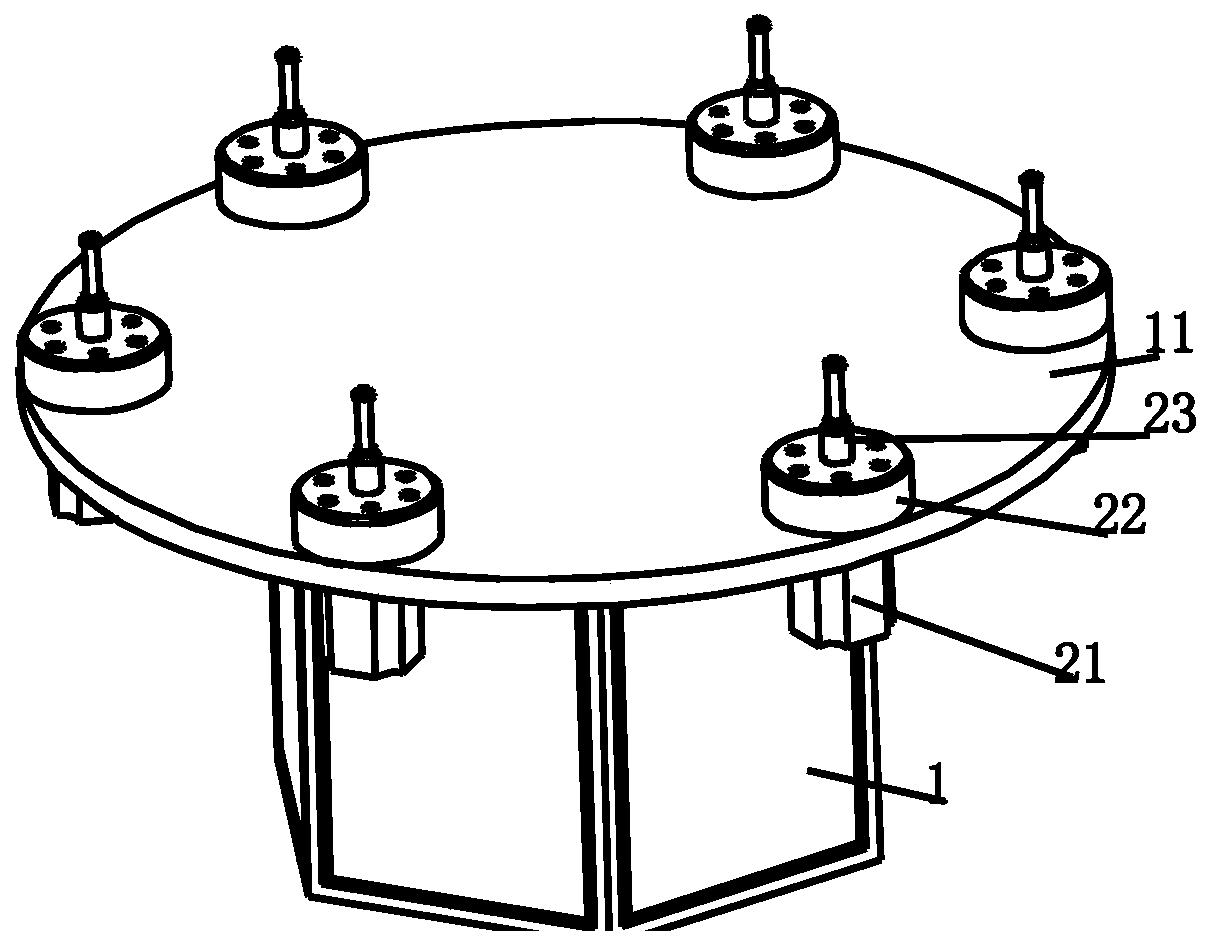

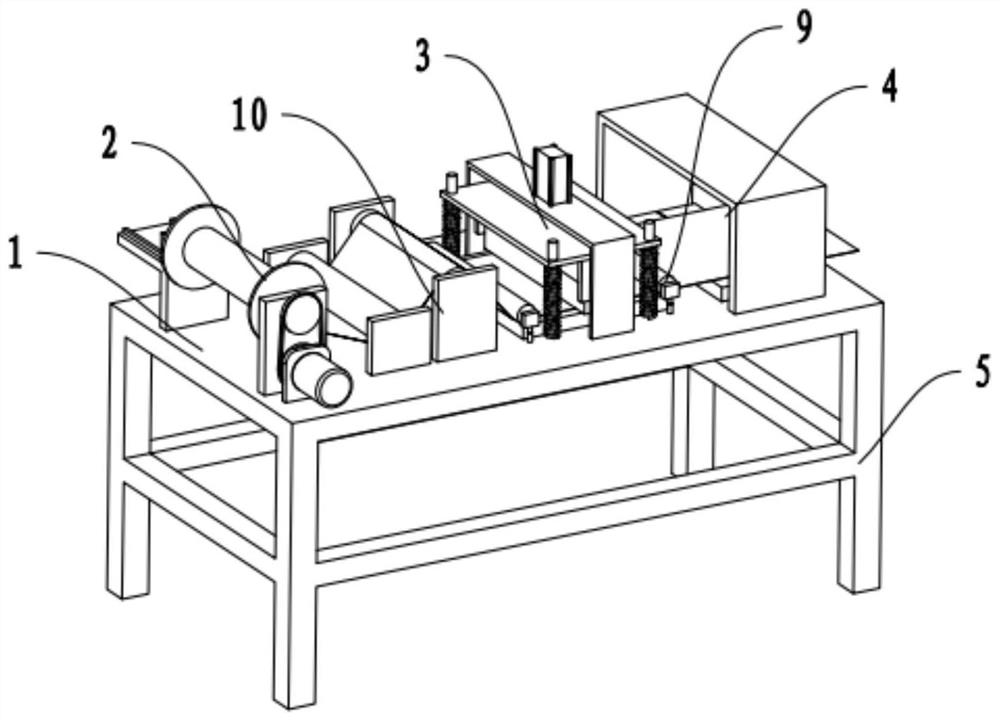

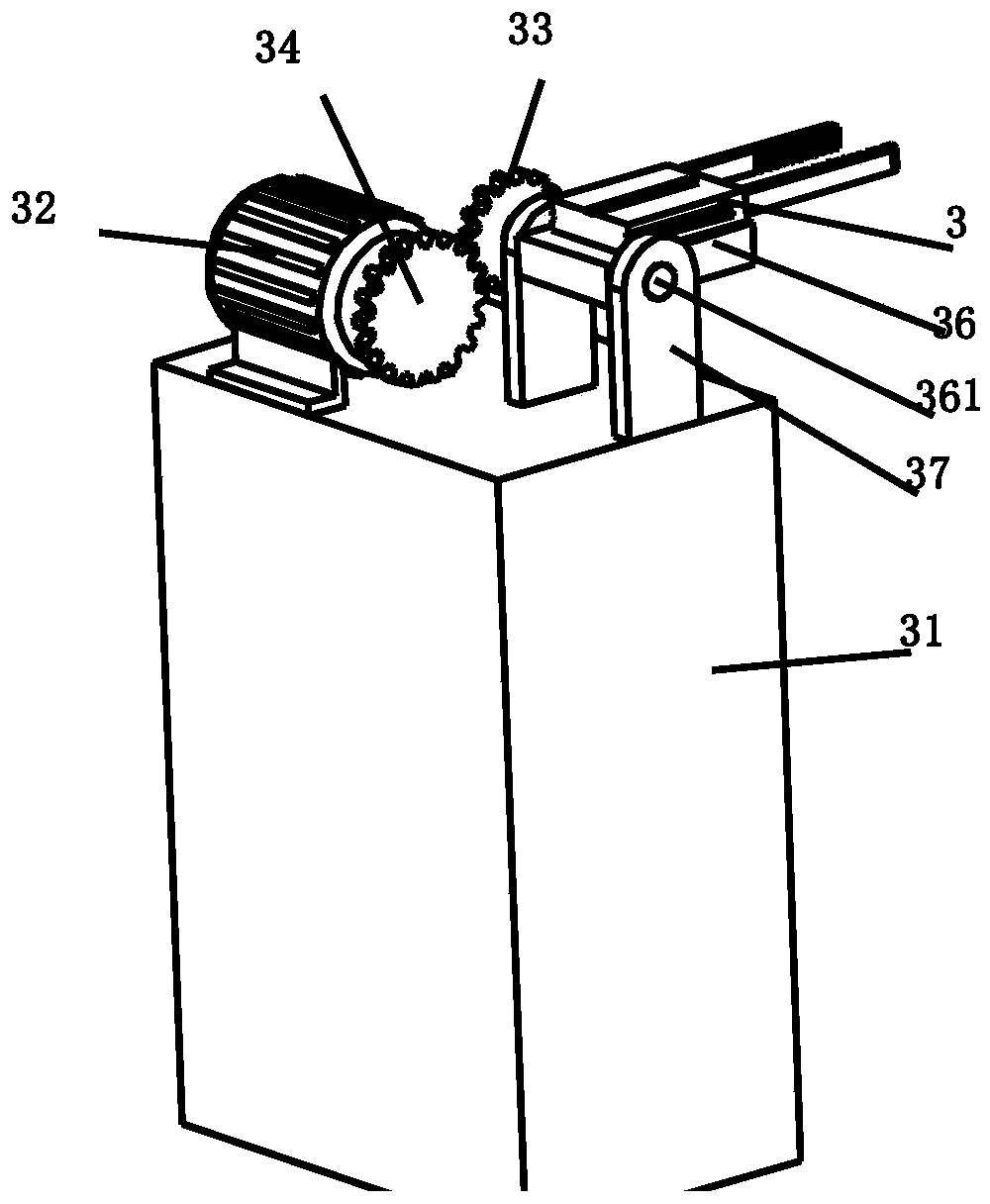

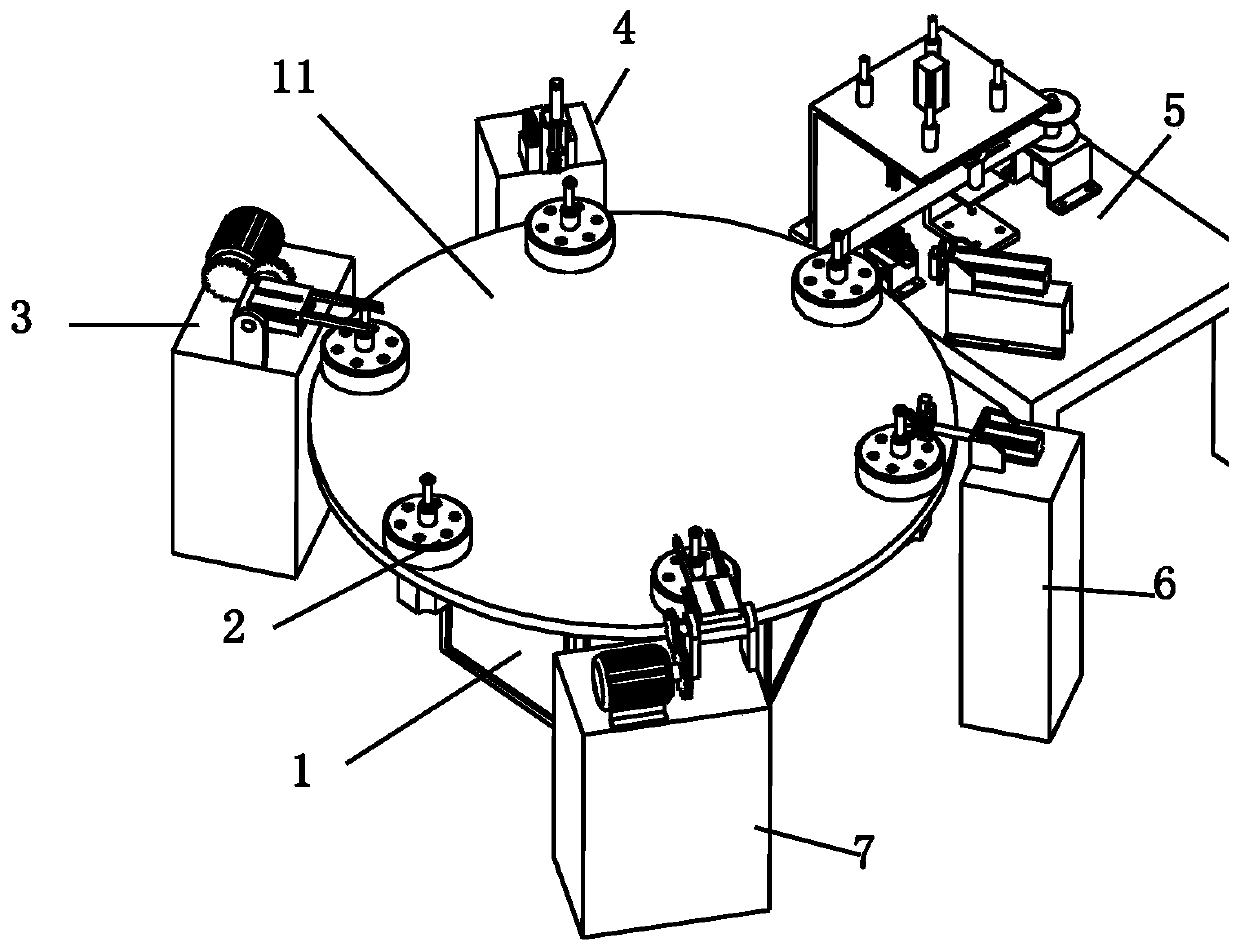

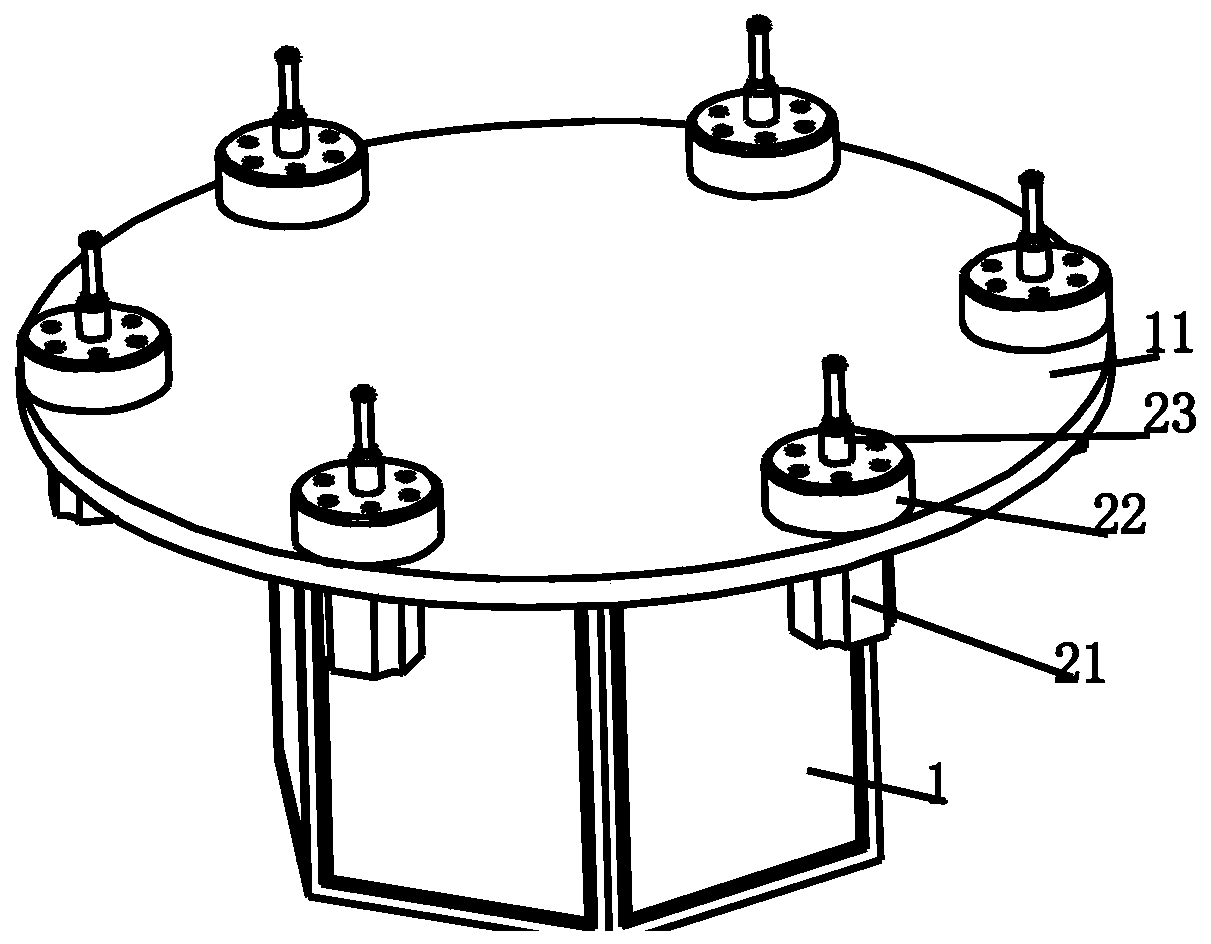

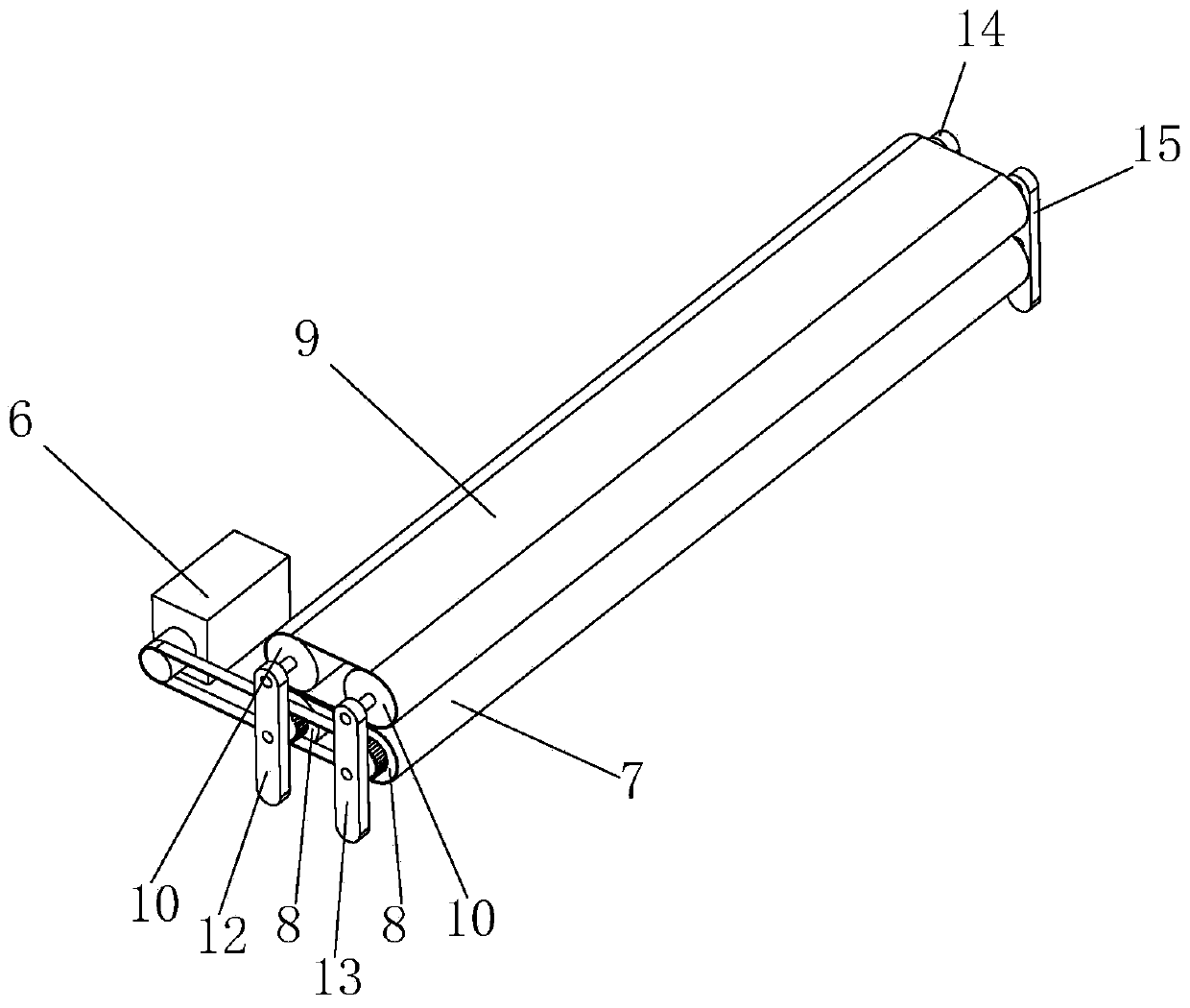

Rapid lead automatic production line

ActiveCN110561127AQuick and automatic transport awayRapid automated productionOther angling devicesOther manufacturing equipments/toolsProduction lineEngineering

The invention discloses a rapid lead automatic production line, and belongs to the technical field of fishing articles. The rapid lead automatic production line comprises a machining table, wherein astepping motor is arranged in the machining table; the output end of the stepping motor penetrates through the top of the machining table; a turntable is mounted on the output end of the stepping motor; a plurality of winding devices arranged along the circumferential direction of the turntable are arranged on the turntable; a lead sheath base feeding device, a lead sheath base roughening device,a lead sheath feeding device, a polishing device and a finished product discharging device are sequentially arranged around the machining table; the lead sheath feeding device comprises a support frame, a lead sheath placing mechanism, a lead sheath positioning mechanism, a lead sheath cutting mechanism, a lead sheath traction mechanism and a lead sheath pressing mechanism; the lead sheath placingmechanism, the lead sheath positioning mechanism and the lead sheath cutting mechanism are arranged on the support frame along a straight line; and the lead sheath traction mechanism and the lead sheath pressing mechanism are respectively positioned on the two sides of the lead sheath cutting mechanism. According to the rapid lead automatic production line, the automatic production of rapid leadwith various sizes is realized, the manual output is reduced, the efficiency is more than ten times higher than the efficiency of manual work, and the yield is 99.99% or over.

Owner:南京六合高新建设发展有限公司

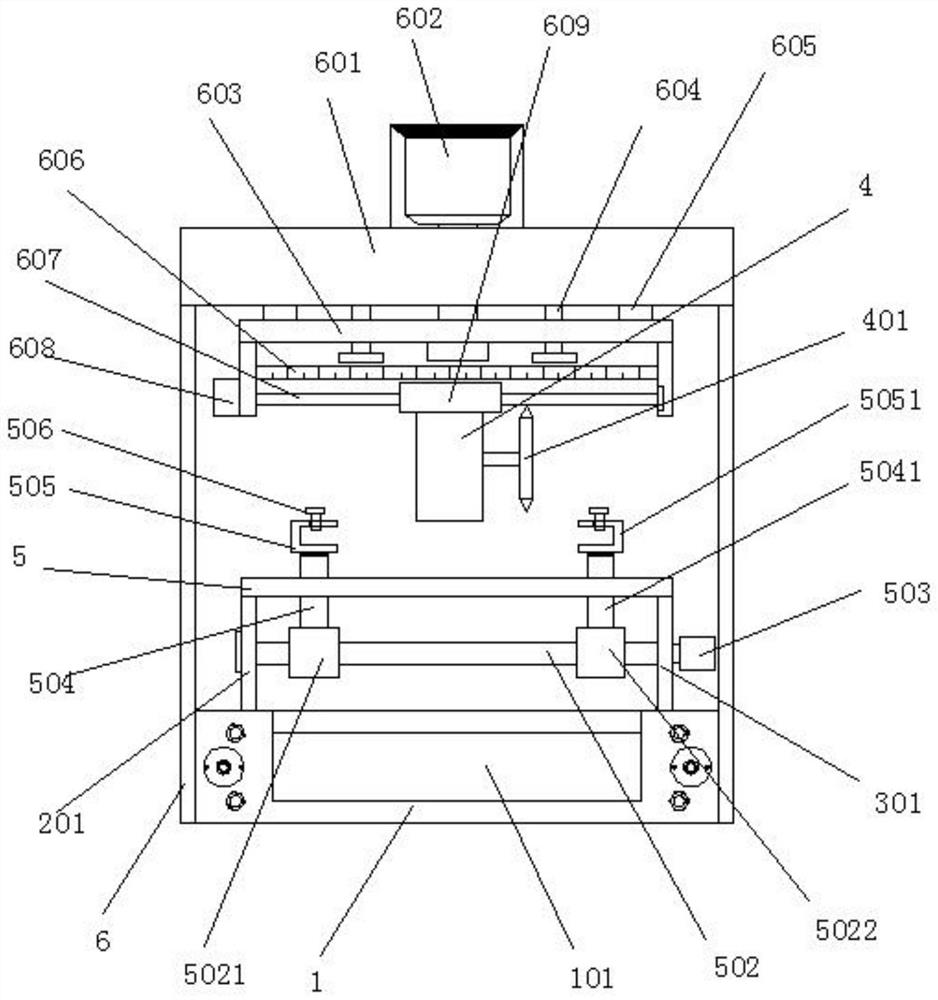

Exhibition advertising board cutting device and cutting method thereof

InactiveCN111673825AWide applicabilityAchieve circular croppingMetal working apparatusEconomic benefitsEngineering

The invention discloses an exhibition advertising board cutting device and a cutting method thereof. The exhibition advertising board cutting device comprises a base. The two ends of the horizontal direction of the front and rear sides of the base are provided with folded edges. A left guide cavity and a right guide cavity are arranged inside the folded edges of the two ends of the front and rearside faces of the base correspondingly. A supporting platform is fixedly arranged over a table top of the base. A C-shaped clamping block I and a C-shaped clamping block II are arranged on the supporting platform. The ends of the folded edges at the two ends of the base are provided with vertical boards. A cutting platform is erected at the top ends of the vertical boards on the two sides. The cutting platform is provided with a cutting cavity. The exhibition advertising board cutting device is simple in structure, novel in design, reasonable in design, capable of realizing cutting of circularadvertising boards and square advertising boards and high in practicality. The two cutting modes are completed through one set of cutting device. The exhibition advertising board cutting device has great economic benefits.

Owner:马鞍山极趣信息技术股份有限公司

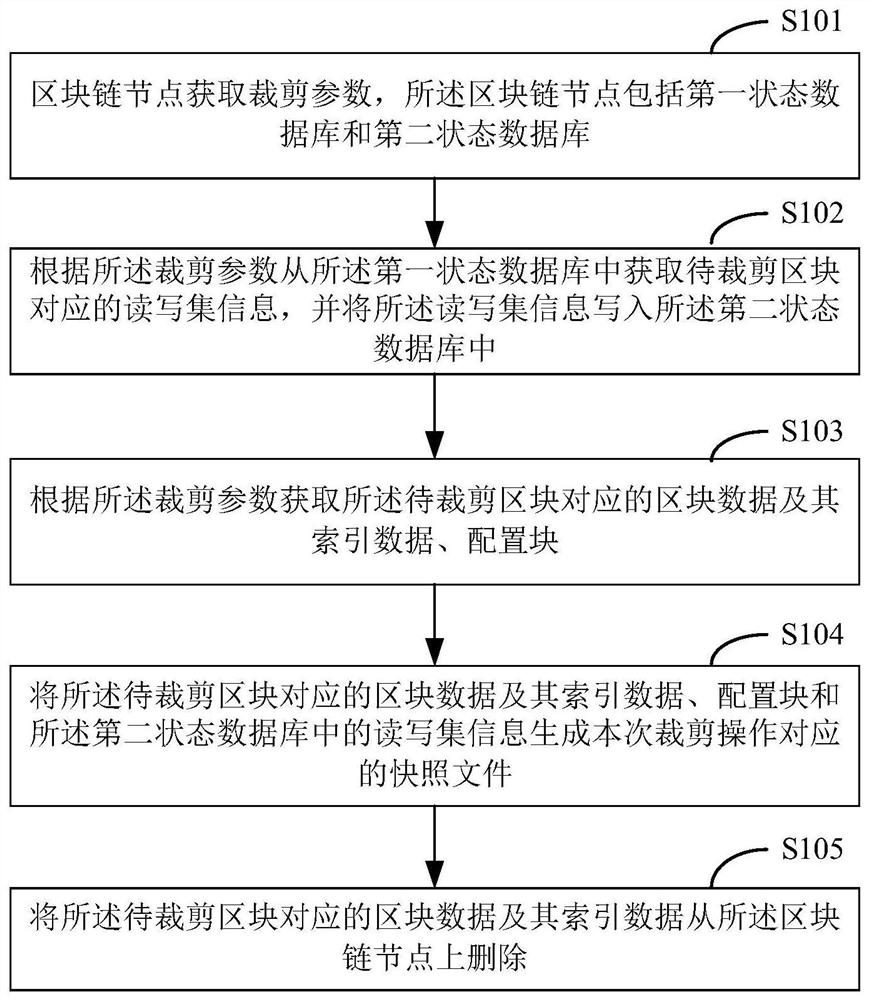

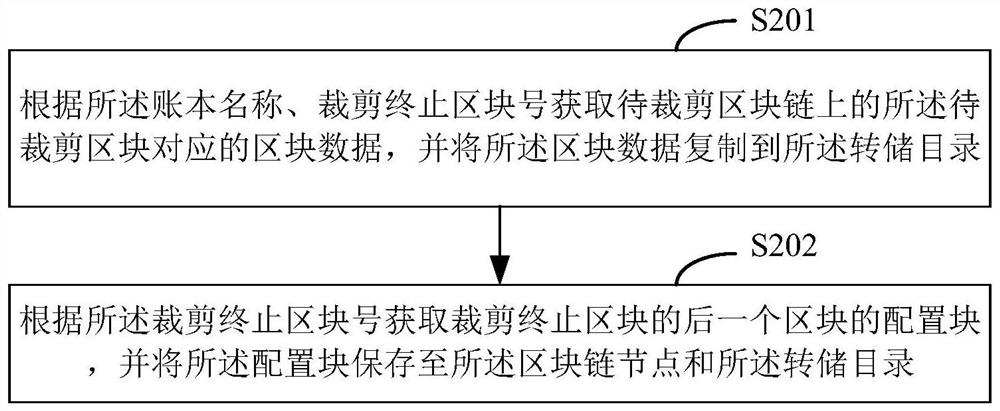

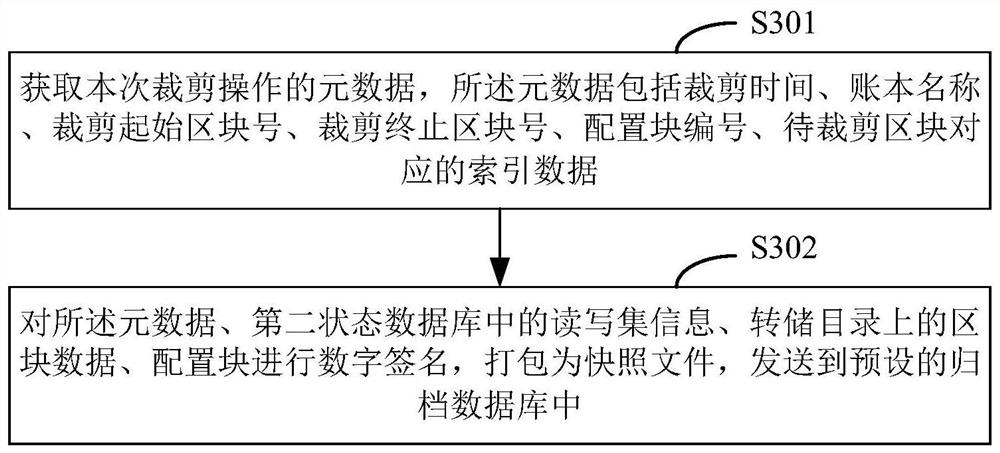

Block chain data cutting method and device, node recovery method and device, equipment and medium

PendingCN111611310AAchieve croppingReduce occupancyInput/output to record carriersDatabase distribution/replicationAlgorithmData library

The invention discloses a block chain data cutting method, which comprises the steps of a block chain node acquiring a cutting parameter, wherein the block chain node comprises a first state databaseand a second state database; obtaining read-write set information corresponding to a to-be-clipped block from the first state database according to clipping parameters, and writing the read-write setinformation into the second state database; acquiring block data corresponding to the to-be-clipped block and index data and configuration blocks thereof according to the clipping parameters; generating a snapshot file corresponding to the cutting operation according to the block data corresponding to the to-be-cut block, the index data of the to-be-cut block, a configuration block and read-writeset information in the second state database; and deleting the block data corresponding to the to-be-clipped block and the index data of the to-be-clipped block from the block chain node. According tothe method, the problems of disk space expansion and bandwidth generated when block data in an existing Fabric block chain account book is continuously increased are solved.

Owner:ONE CONNECT SMART TECH CO LTD SHENZHEN

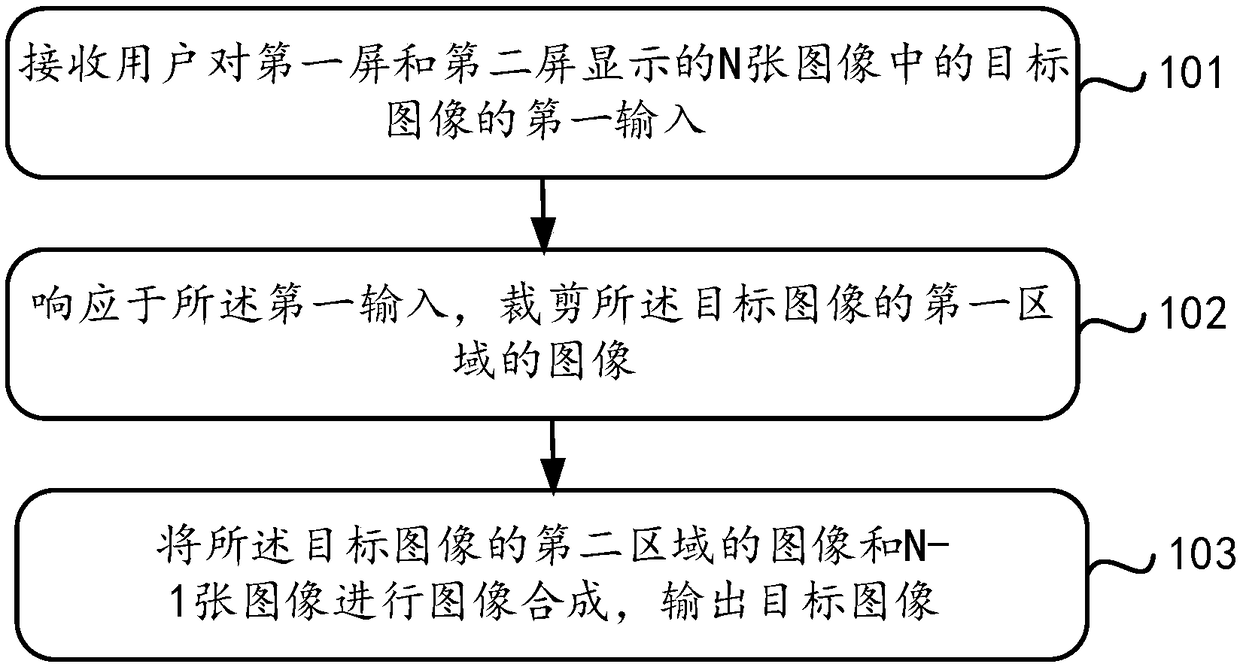

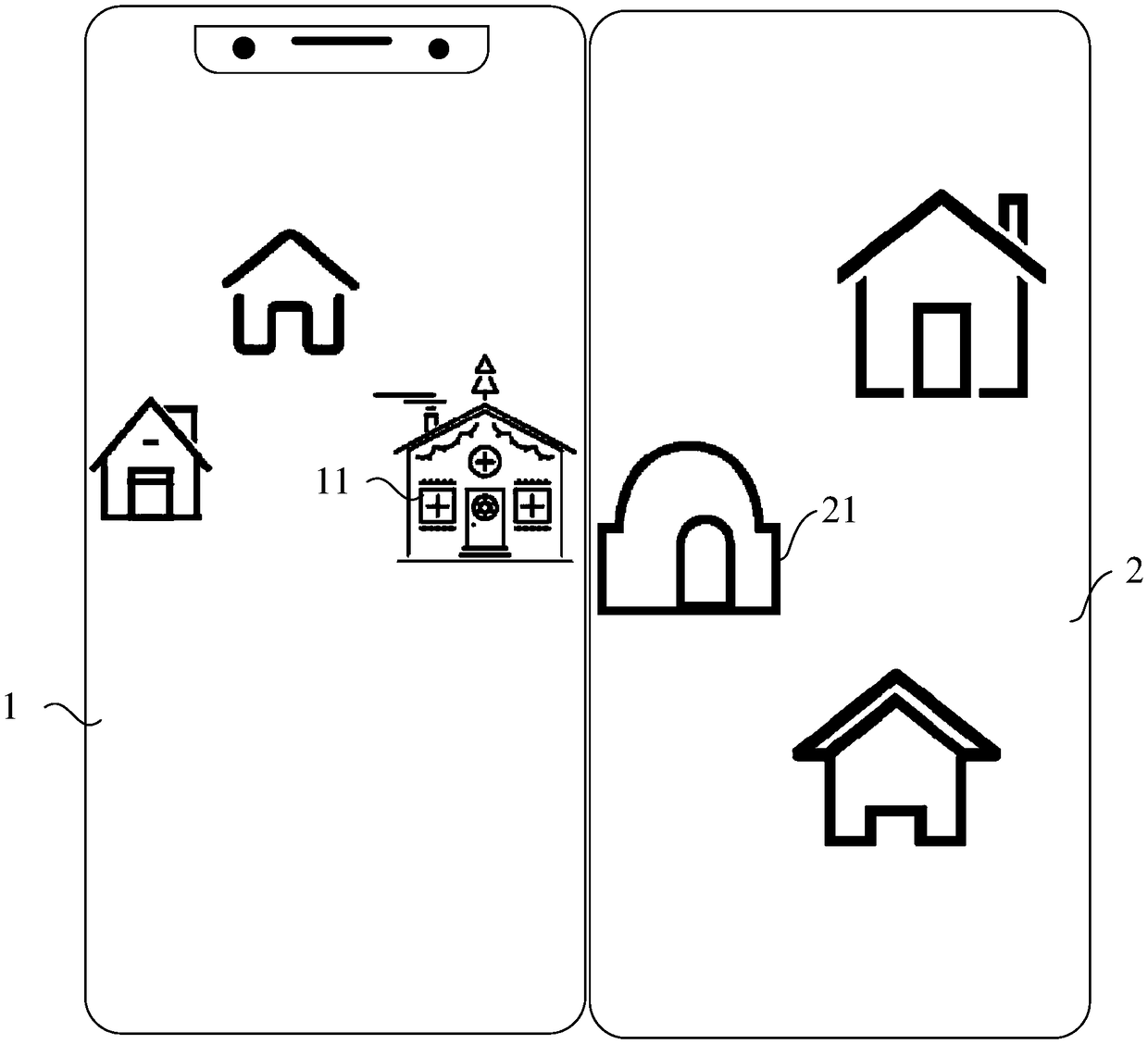

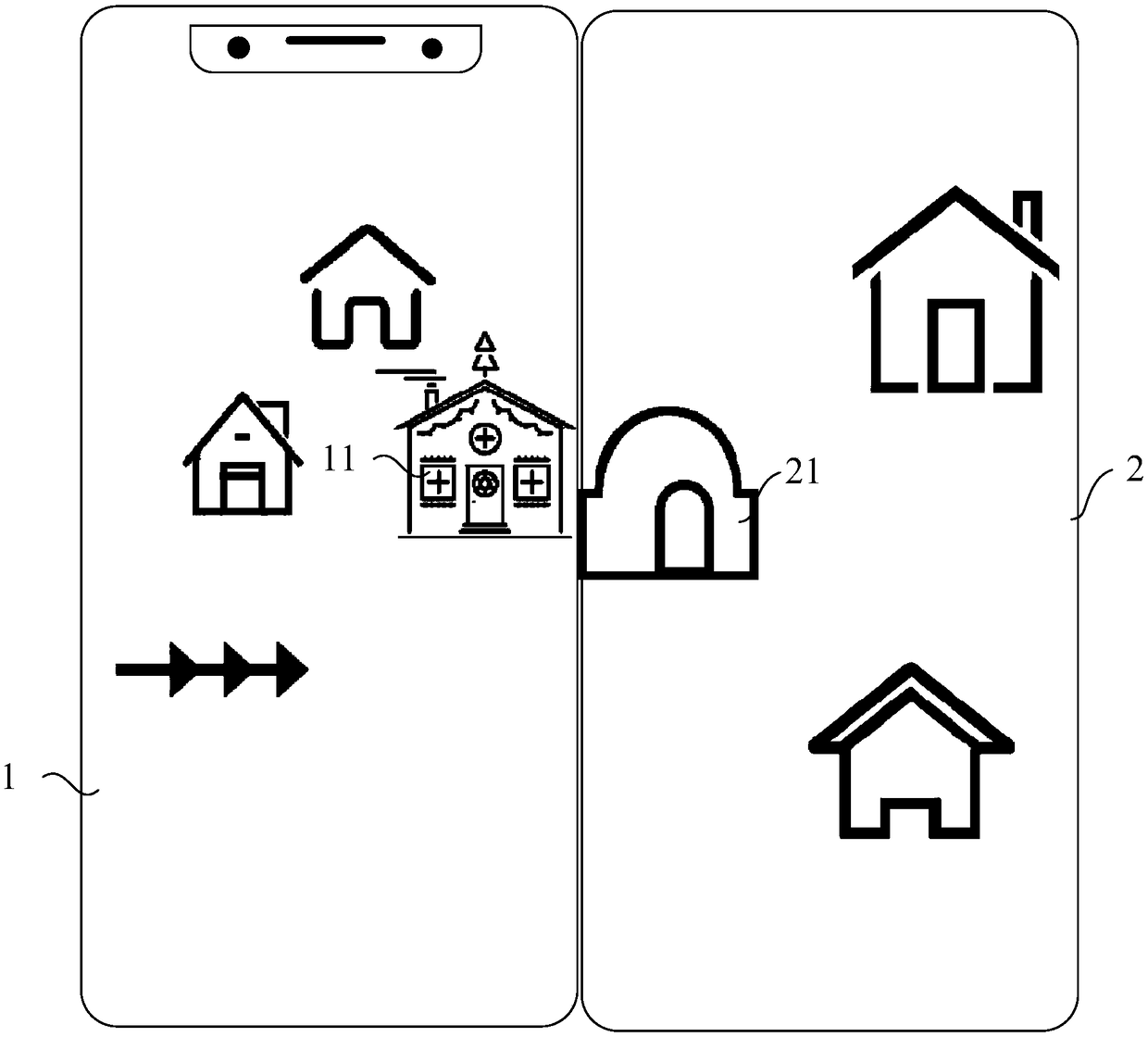

Image processing method and terminal equipment

ActiveCN108898555AAchieve croppingEasy to operateGeometric image transformationImaging processingTerminal equipment

The invention discloses an image processing method and terminal equipment. The method comprises the following steps: receiving first input of a target image among N images displayed by a first screenand a second screen of a user; responding to the first input, cutting an image in a first area of the target image; synthesizing the image in a second area of the target image with (N-1) images, and outputting the target image, wherein the images in the first area and the second area define the target image; when the number of the target images is greater than or equal to 1, enabling the cut imageof the first area to be invisible, displaying at least one image among the N images on the first screen, and displaying at least one image on the second screen; receiving the first input of the target image among the N images displayed by the first screen and the second screen of the user when N is an integer greater than 1, thereby realizing cutting the image in the first area of the target image. The image processing method does not need to start professional image retouching software, so that operation steps are simplified.

Owner:VIVO MOBILE COMM CO LTD

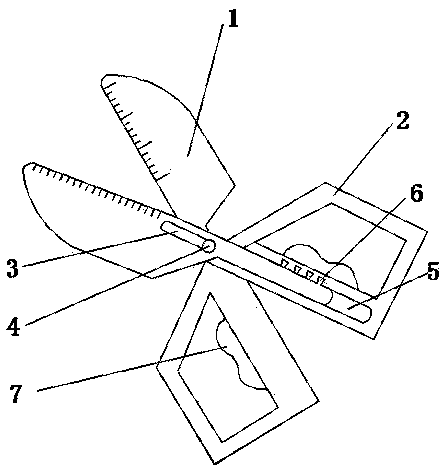

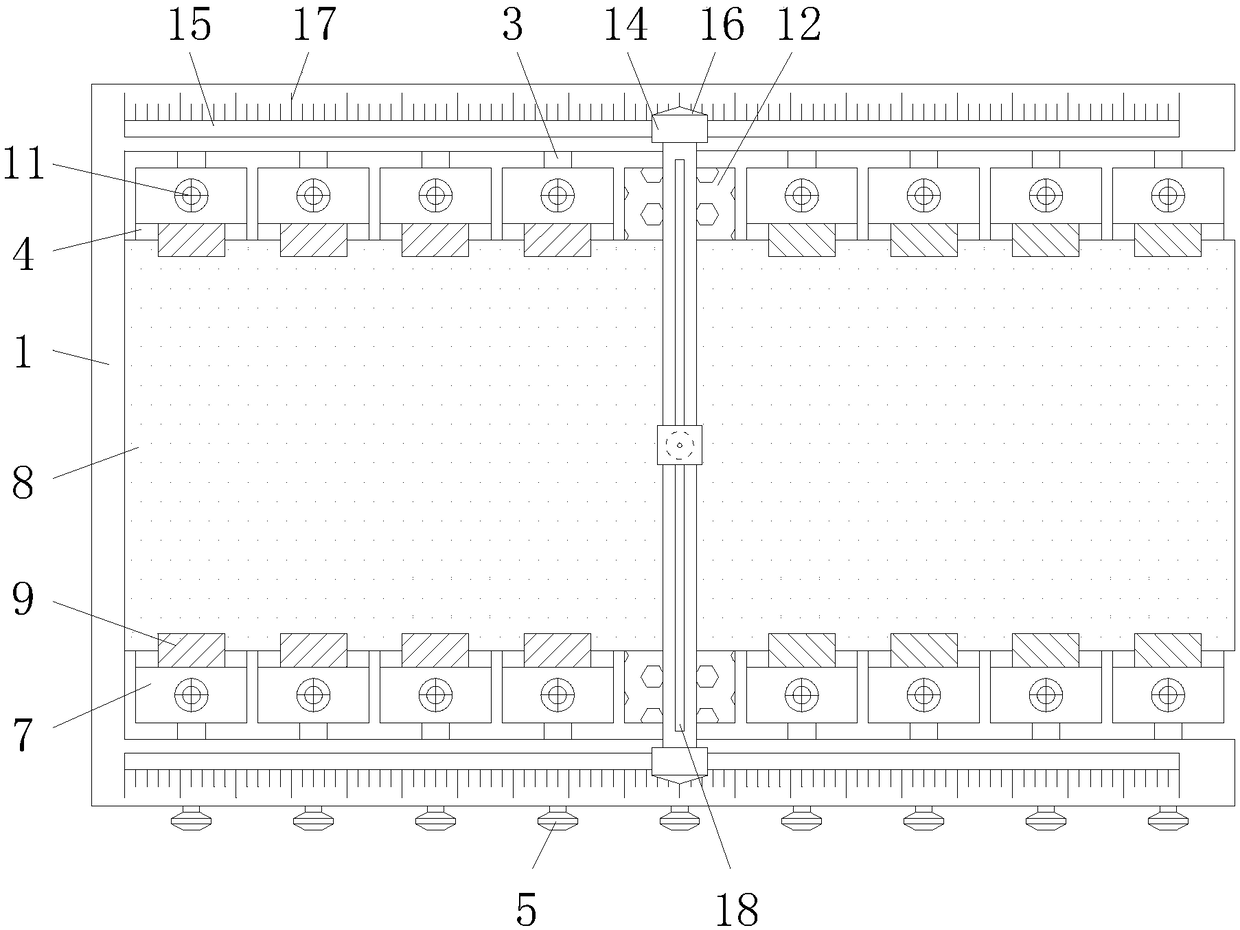

Cloth scissors

The invention relates to scissors, in particular to scissors provided with scale marks, and discloses cloth scissors. The cloth scissors comprise a scissor body and a scissor handle which are detachable, wherein the scissor body comprises a tailoring part and a connecting end which are formed integrally, the connecting end is connected with the scissor handle, a riveting part is arranged in the middle of the scissor body and is a first strip-shaped sliding groove parallel to a tailoring edge of the tailoring part, a hinge joint rivet is arranged in the first strip-shaped sliding groove, and the width of the first strip-shaped sliding groove is equal to the diameter of the rivet; a second strip-shaped sliding groove is formed in the scissor handle, a clamping groove is formed in the lateral portion of the second strip-shaped sliding groove, and a protrusion matched with the clamping groove is arranged at the connecting end. According to the cloth scissors, the rivet can move in the first strip-shaped sliding groove, the clamping groove is formed in the scissor handle and is fixed to a clamping part at the connecting end of the scissor body in a clamping mode, and therefore the length of the cloth scissors can be adjusted, and textile cloth in different sizes can be tailored; due to the fact that the scale marks are arranged on the scissor body, fixed-length tailoring can be achieved without the need of drawing lines in advance.

Owner:JIANGSU HAIDA DYEING & PRINTING MACHINERY

Textile fabric ironing device integrating tailoring and ironing

PendingCN112391778AEasy to replaceEfficient ironingSevering textilesTextile shapingWorkbenchIndustrial engineering

The invention provides a textile fabric ironing device integrating tailoring and ironing. The textile fabric ironing device comprises a workbench, a discharging device, an ironing assembly and a cutting device fixedly arranged on the side portion of the ironing assembly, the workbench is of a rectangular plate-shaped structure, a plurality of supporting leg frames are fixedly arranged at the bottom of the workbench, the discharging device is fixedly mounted at one end of the workbench, the ironing assembly comprises a lifting mechanism, a mounting plate, an ironing machine and a bottom plate fixedly mounted in the middle of the workbench, leveling mechanisms are fixedly mounted at two ends of the bottom plate, the lifting mechanism is fixedly mounted on the bottom plate, the mounting plateis fixedly connected with the output end of the lifting mechanism, the ironing machine is fixedly mounted on the mounting plate, and a guide device is fixedly mounted between the discharging device and the ironing assembly. The textile fabric ironing device integrating tailoring and ironing provided by the invention has the effects of high ironing efficiency and high cutting efficiency.

Owner:WUJIANG KESHIDA TEXTILE

Cutting device for carton production

The invention discloses a cutting device for carton production. The cutting device for carton production comprises a workbench. Two supporting plates are symmetrically fixed to the lower end of the workbench. A transverse plate is fixedly arranged between the two supporting plates. A dust collection box is arranged at the upper end of the transverse plate. The upper end of the dust collection boxcommunicates with a sealing cover. The upper end of the sealing cover abuts against the side wall of the lower end of the workbench. A article containing groove is arranged inside the workbench. A turbo fan is fixedly arranged in the article containing groove. Openings communicating with the article containing groove are formed in both the two sides of the workbench respectively. The turbo fan islocated over the sealing cover. According to the cutting device for carton production, a cutting knife is convenient to replace, paper scraps generated in the cutting process can be dealt with in time, the quality of cutting is improved, adjustment is convenient to carry out, the cutting device is suitable for cutting paperboards of different thicknesses, and the service efficiency is improved.

Owner:常兴忠

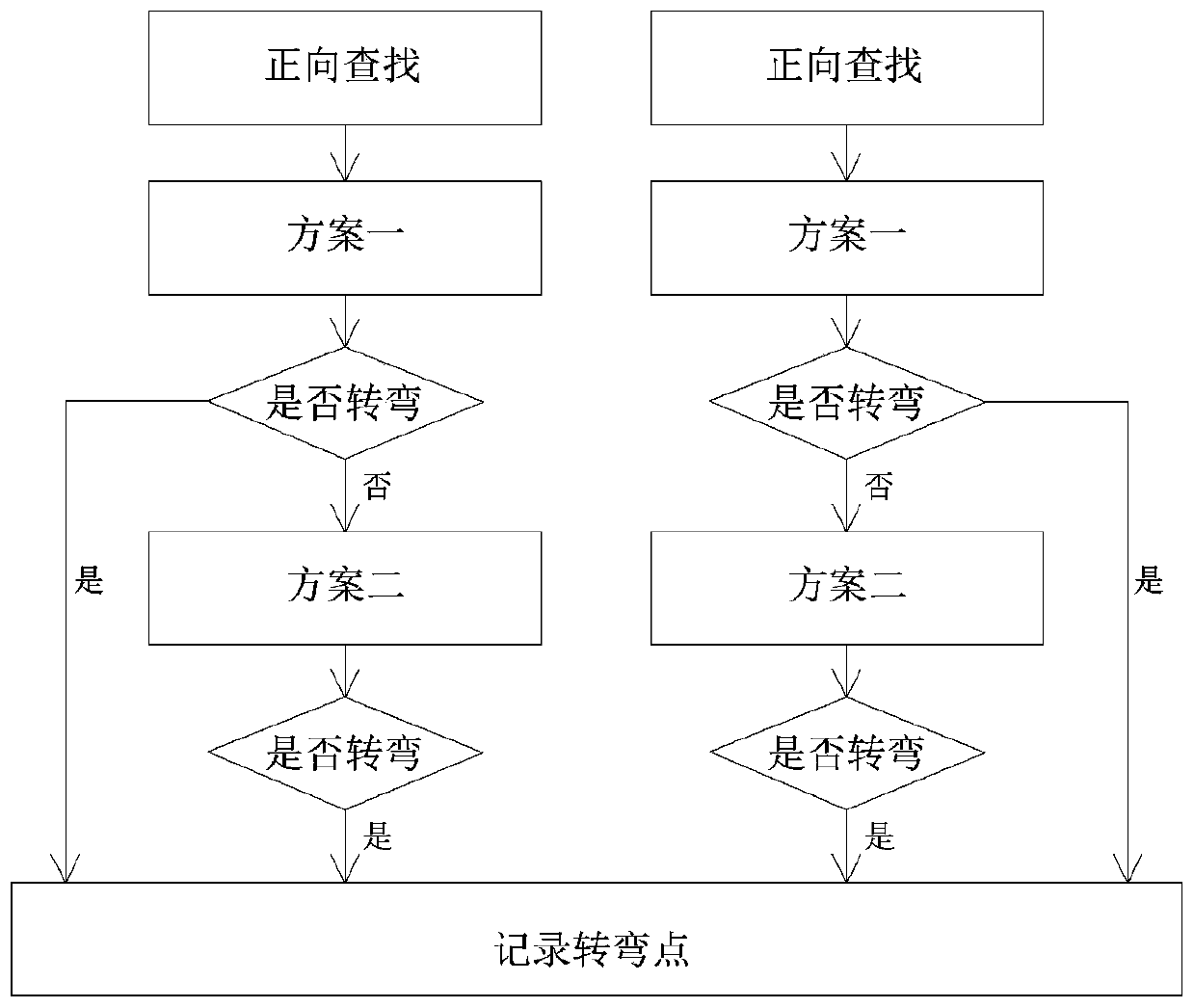

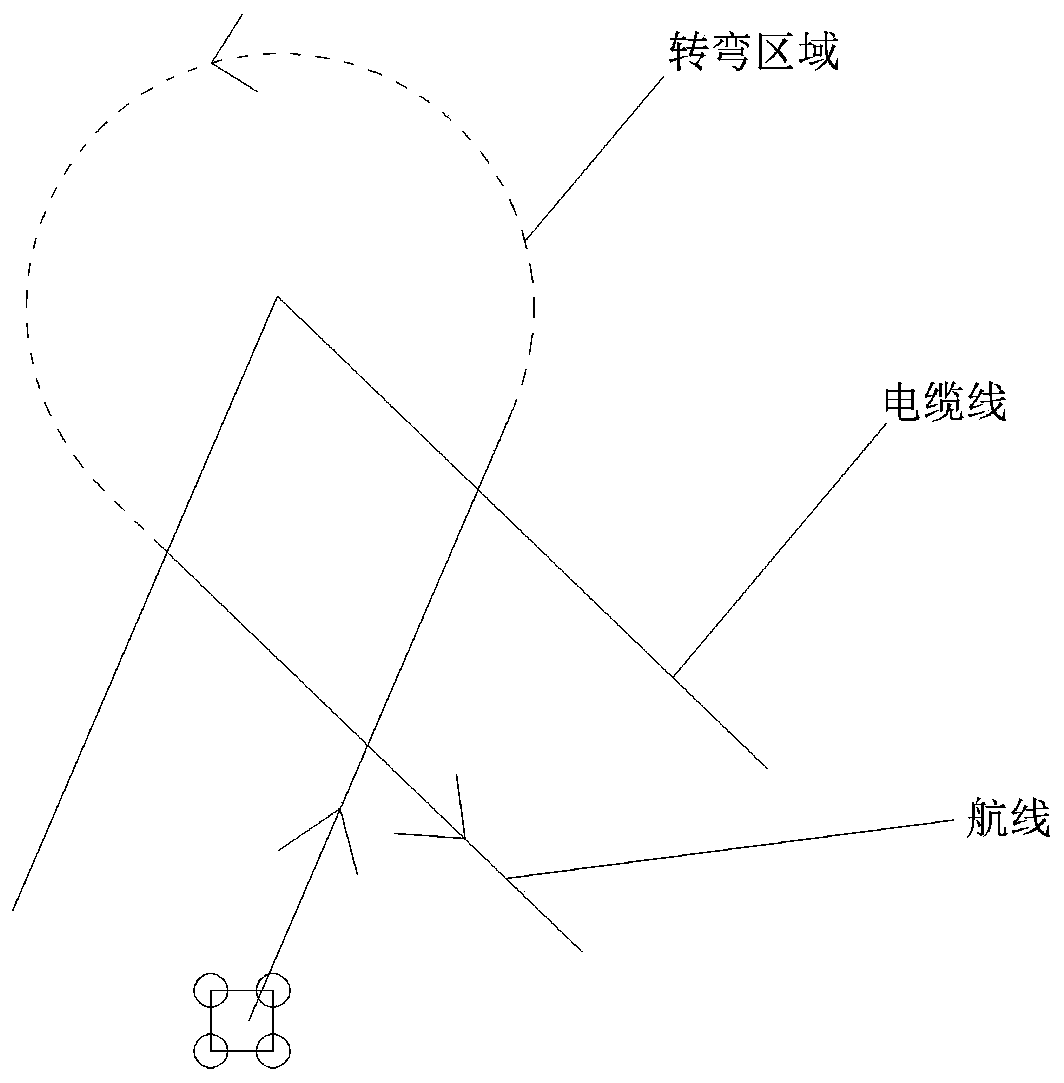

Swerving filtering method for fixed-wing unmanned aerial vehicle-mounted laser radar system

ActiveCN110632611AAchieve filteringAchieve croppingElectromagnetic wave reradiationRadar systemsPoint cloud

The invention provides a swerving filtering method for a fixed-wing unmanned aerial vehicle-mounted laser radar system. According to the method, whether a fixed-wing unmanned aerial vehicle is locatedat a swerving waypoint or not is judged; when the fixed-wing unmanned aerial vehicle is located at the swerving waypoint, all laser data of the swerving waypoint are automatically deleted; on the basis of the flight characteristics, swerving radius, speed characteristics and the like of the vertical take-off and landing fixed-wing unmanned aerial vehicle, an automatic swerving clipping algorithmis innovatively provided; since the vertical take-off and landing fixed-wing unmanned aerial vehicle has almost no horizontal speed in a taking-off and landing process; and taking-off and landing datacan be filtered out according to horizontal speed; the flight process of the fixed-wing unmanned aerial vehicle is basically uniform in speed, and a minimum swerving radius and speed during swervingare determined, and an algorithm and a scheme are formulated according to the characteristics; when three-dimensional laser point cloud is generated, swerving clipping and filtering are automaticallyachieved, and manual editing is not needed any more; full-automatic swerving data filtering and clipping are achieved; manual intervention is not needed; and data processing efficiency is greatly improved.

Owner:GUIYANG BUREAU OF CHINA SOUTHERN POWER GRID CO LTD EHV TRANSMISSION CO +1

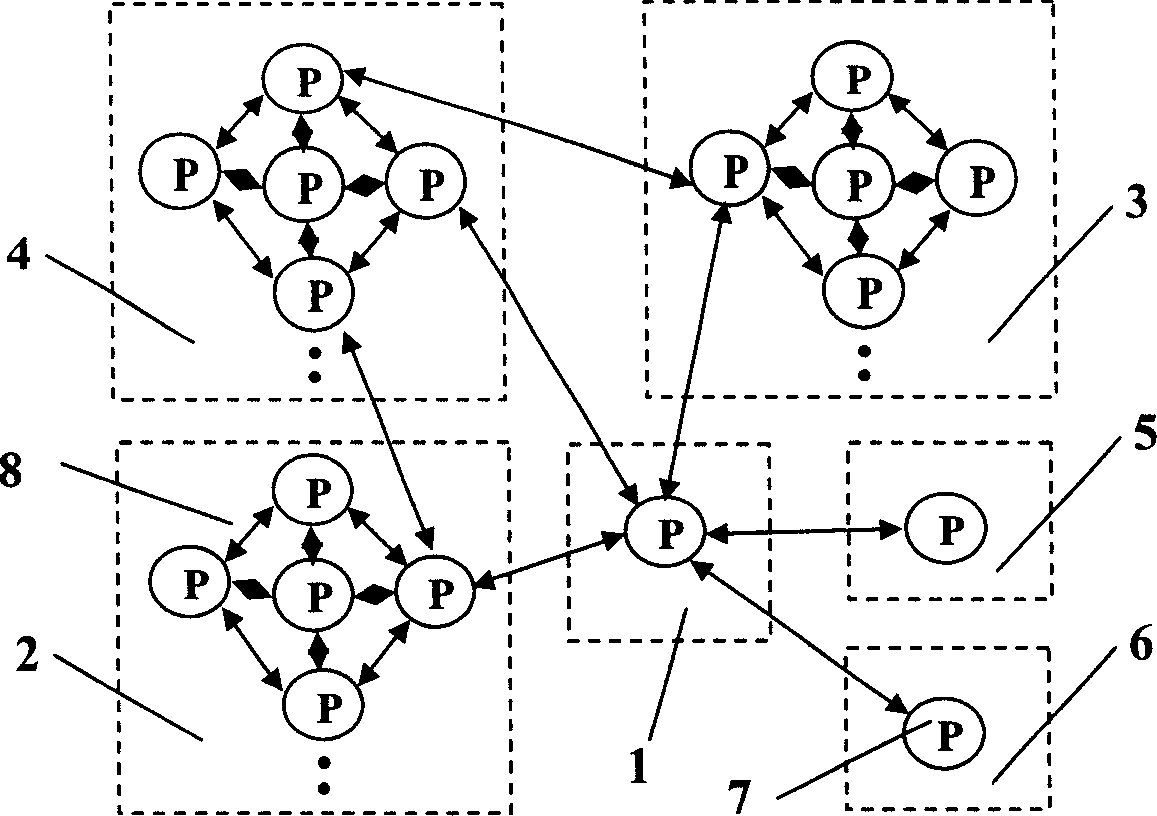

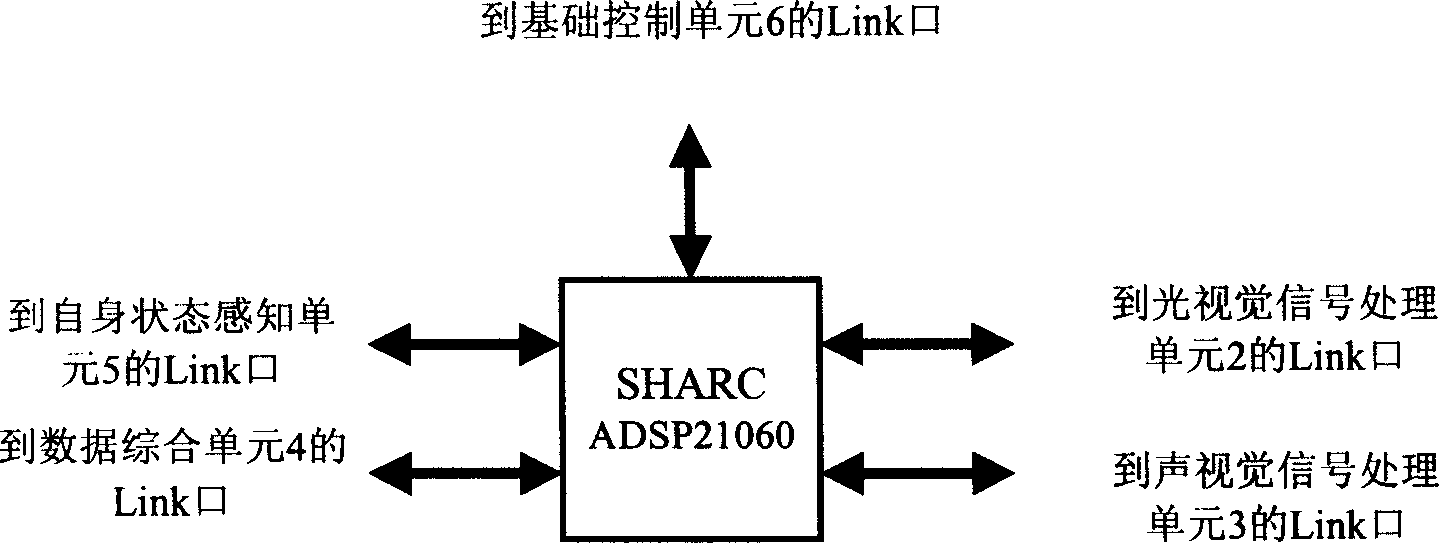

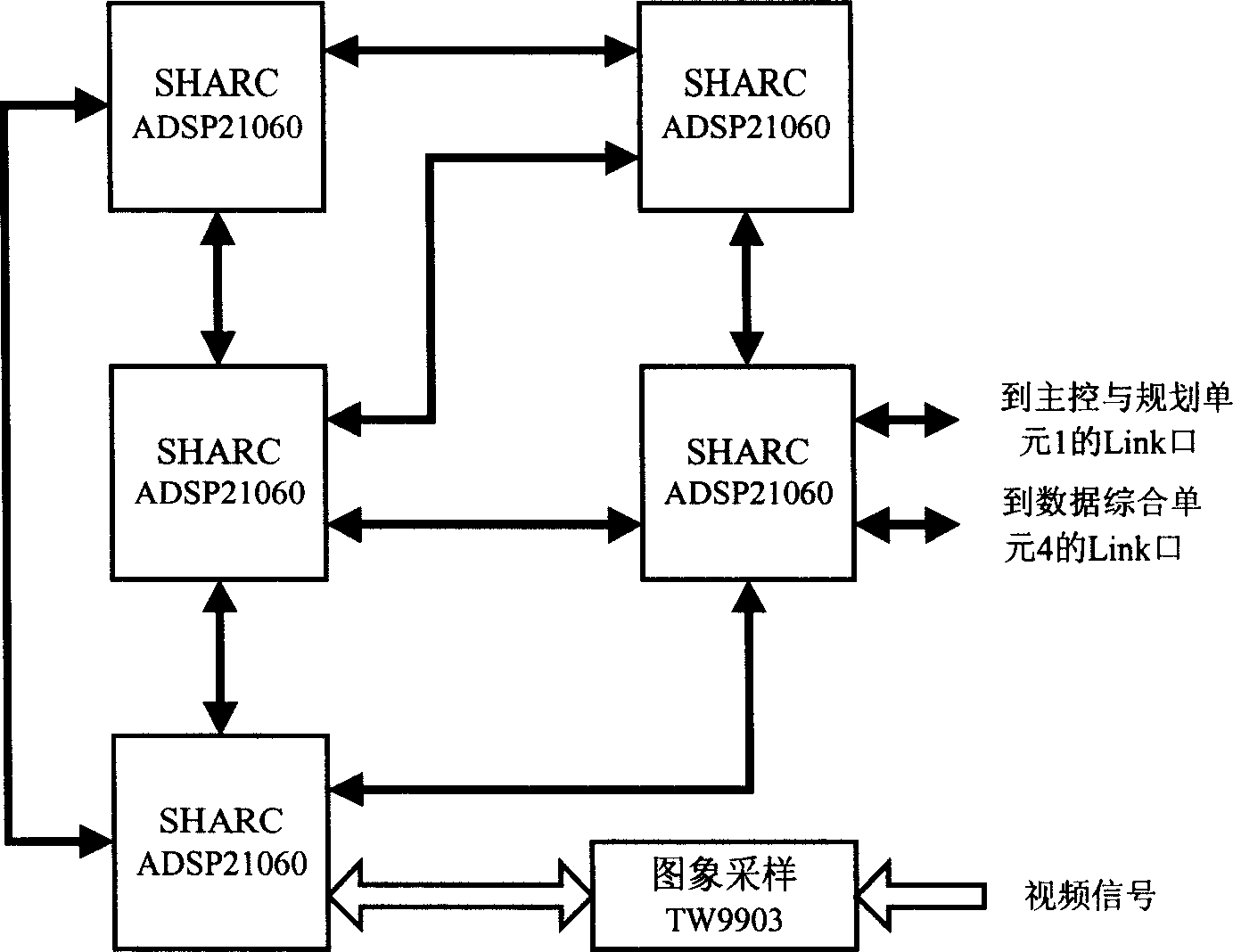

High performance intelligent controlling computer system for underwater robot

InactiveCN1724225ASimple structureImprove reliabilityManipulatorIntelligent control systemEngineering

An intelligent control computer system for high-performance underwater robot is composed of master control and plan unit, optical visual signal processing unit, audio visual signal processing unit, data integrating unit, auto-geneous state sensing unit and basic control unit. It features that each unit has a signal processor with high-speed multi-channel Link port for interconnection between units.

Owner:NO 709 RES INST OF CHINA SHIPBUILDING IND CORP

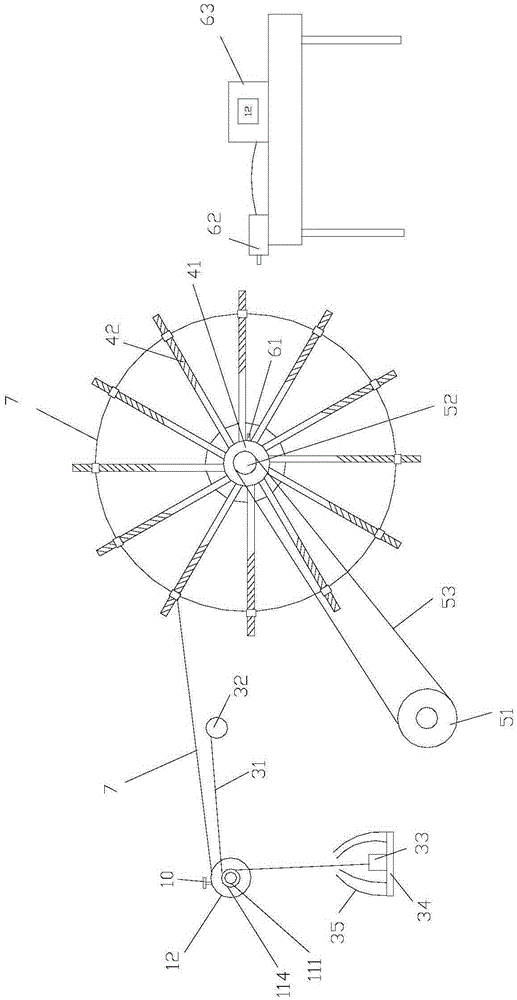

Fast lead automatic production process

ActiveCN110480278AQuick and automatic transport awayRapid automated productionOther angling devicesMetal working apparatusFishingMechanical engineering

The invention discloses a fast lead automatic production process and belongs to the technical field of fishing equipment. The fast lead automatic production process includes the following steps that firstly, a lead leather base is automatically fed; secondly, the surface of the lead leather base is roughened, specifically, a rotating disk rotates to a lead leather base roughening station, a lead leather base roughening device is used for performing roughening operation on the lead leather base on a material rolling device, so that the surface of the lead leather base is roughened, and the combining force between lead leather and the lead leather base is improved; thirdly, the lead leather is fed, rolled and cut, specifically, the rotating disk rotates to a lead leather feeding station anda material rolling station, and the lead leather is automatically wound, cut and pulled through cooperation of a lead leather feeding device and the material rolling device; fourthly, fast lead wherethe lead leather is wound is chamfered, specifically, the rotating disk rotates to a grinding station, and due to cooperation of a grinding device and the material rolling device, the upper and lowerends of the fast lead after the lead leather is wound are subjected to chamfering operation; and fifthly, automatic discharging is performed. The process is ingenious in design, connection between themechanisms is smooth, and compared with the process for making fast lead manually, the efficiency is improved by ten times or above.

Owner:威海怡隆渔具有限公司

Cloth tailoring device with measuring function for garment producing and processing

InactiveCN109281150AWith measurement functionAvoid scratchesSevering textilesEngineeringMechanical engineering

The invention discloses a cloth tailoring device with a measuring function for garment producing and processing. The cloth tailoring device comprises a side plate, cloth, a fixed shaft and a cutting head, fixed plates are welded to the front end and the rear end of the right side of the side plate, the fixed plates are connected through a movable plate, and the front side and the rear side of themovable plate are fixed to the fixed plates through rotary connectors respectively. The cloth is arranged above the movable plate, limiting plates are fixed above the front end and the rear end of thecloth, the upper portions of the limiting plates are rotationally connected with movable shafts, sliding blocks are fixed to the front end and the rear end of the fixed shaft, the outer sides of thesliding blocks are connected with pointers, scale marks are arranged below the pointers, the upper portion of the cutting head is connected with a movable part through a sleeve, and the movable part is in sliding connection with the fixed shaft through a second sliding groove. According to the cloth tailoring device with the measuring function for garment producing and processing, the cloth can bemeasured firstly before the cloth is tailored, and the precision of the device is improved.

Owner:嘉兴珠韵服装有限公司

Clothes tailoring device

The invention discloses a clothes tailoring device comprising a work table and a mobile table; the surface of the work table is provided with a groove and a first slide slot; a linear motor is arranged on the end face of the work table; the top of a support is provided with a horizontally arranged cutter; the surface of the housing is provided with a third slide slot; a tailor rack slides and is clamped in the third slide slot through a pulley in the bottom; the pulley is connected with a rotary shaft of a motor arranged on the side face of the housing; the clothes tailoring device uses the linear motor to drive the rack to move; the rack is connected with the mobile table; the structure can simultaneously move the rack and the mobile table, so the clothes can be easily cut; the rack is provided with the cutter having a cutting blade; the cutting blade can be driven by the motor to move, thus tailoring the clothes; the clothes tailoring device can vertically move the clothes, and the cutting blade can transversely move, thus automatically tailoring the clothes, improving tailoring efficiency, and reducing people work intensity.

Owner:华巧波

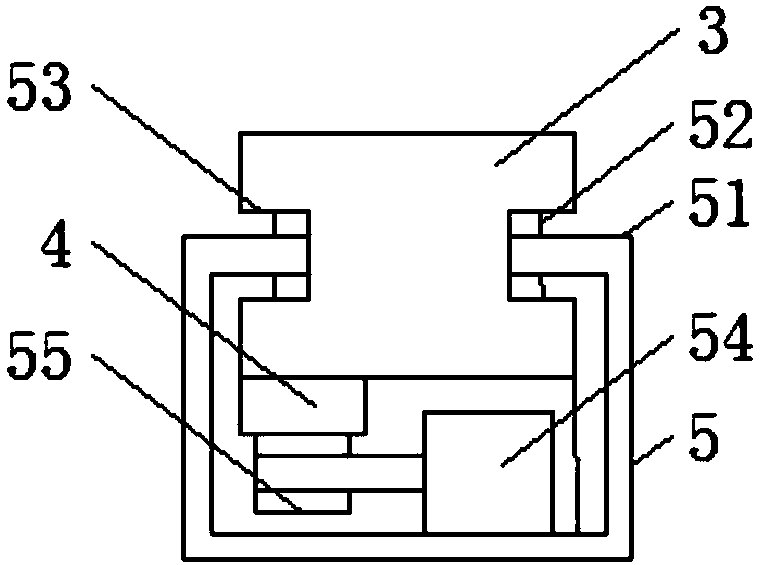

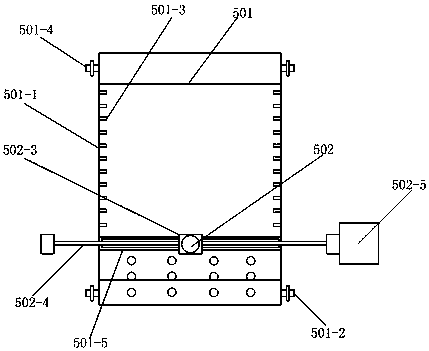

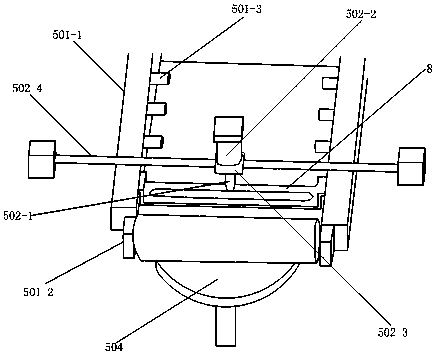

Automatic assembling equipment for spinneret assembly

PendingCN107553126AReduce labor intensityImprove assembly pass rateAssembly machinesMetal working apparatusElectrical controlElectric control

The invention discloses automatic assembling equipment for spinneret assembly. The automatic assembling equipment comprises a conveying line which is provided with a spinneret nut feeding system and an automatic discharging system, wherein a spinneret filling station, a filter cloth mounting station, a sealing ring filling station and a detection station are sequentially arranged at the positions,between the spinneret nut feeding system and the automatic discharging system, on the conveying line; and the spinneret filling station is provided with a spinneret feeding system, the filter cloth mounting station is provided with a filter cloth feeding system, the sealing ring filling station is provided with a sealing ring feeding system, and the detection station is provided with an automaticdetection system. According to the automatic assembling equipment, the installation steps of all parts in the existing spinneret assembling process are decomposed and can be completed on all the stations of the conveying line, the conveying line is used for sequentially conveying all the parts to the designated stations to complete automatic assembly of the spinneret, automatic electric control is realized in the whole process, and therefore the labor intensity of workers can be reduced, and the qualification rate of assembly can be improved; and the conveying line is provided with the automatic detection system, so that the spinning quality is ensured.

Owner:YIBIN HIEST FIBER +1

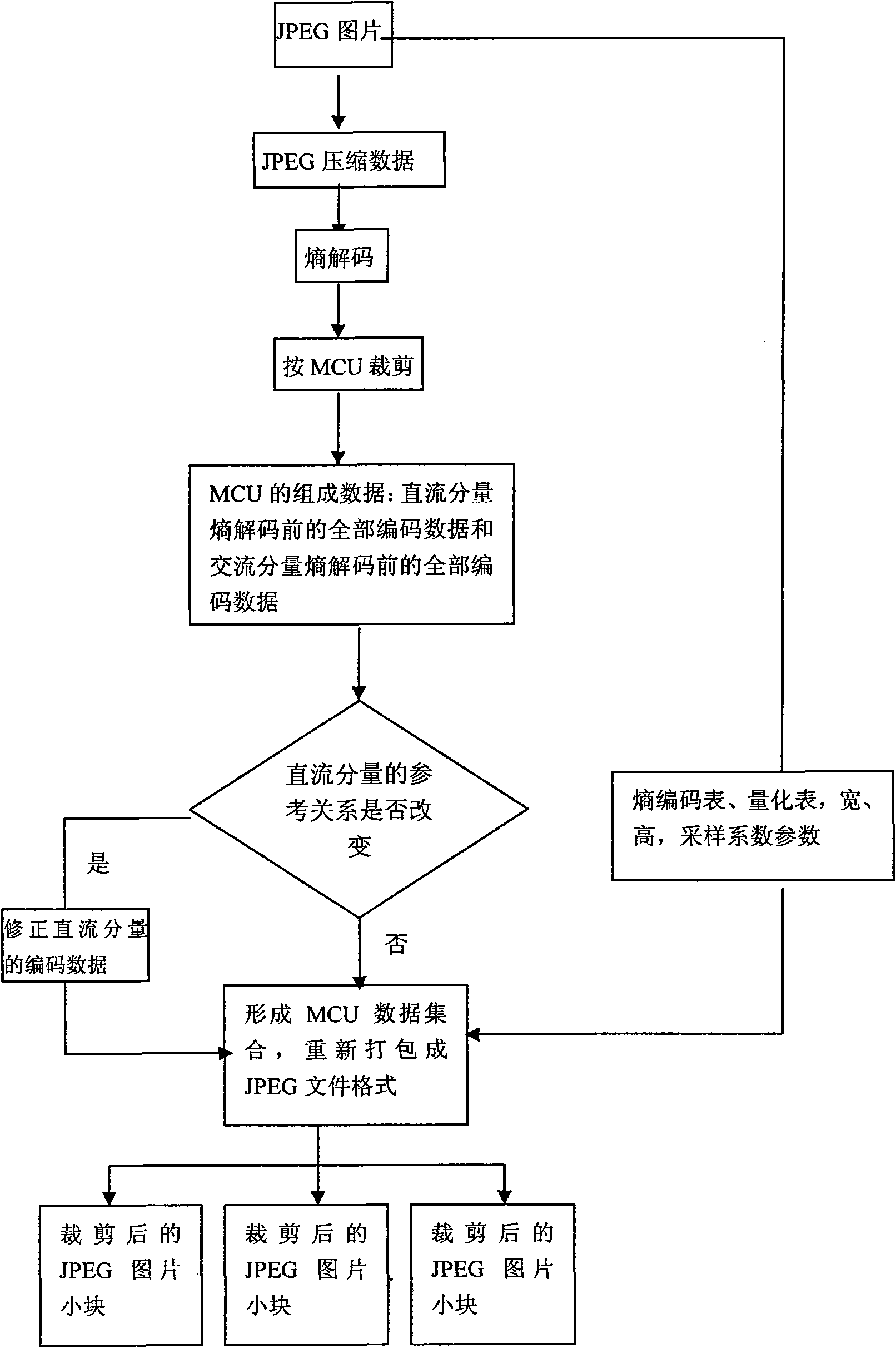

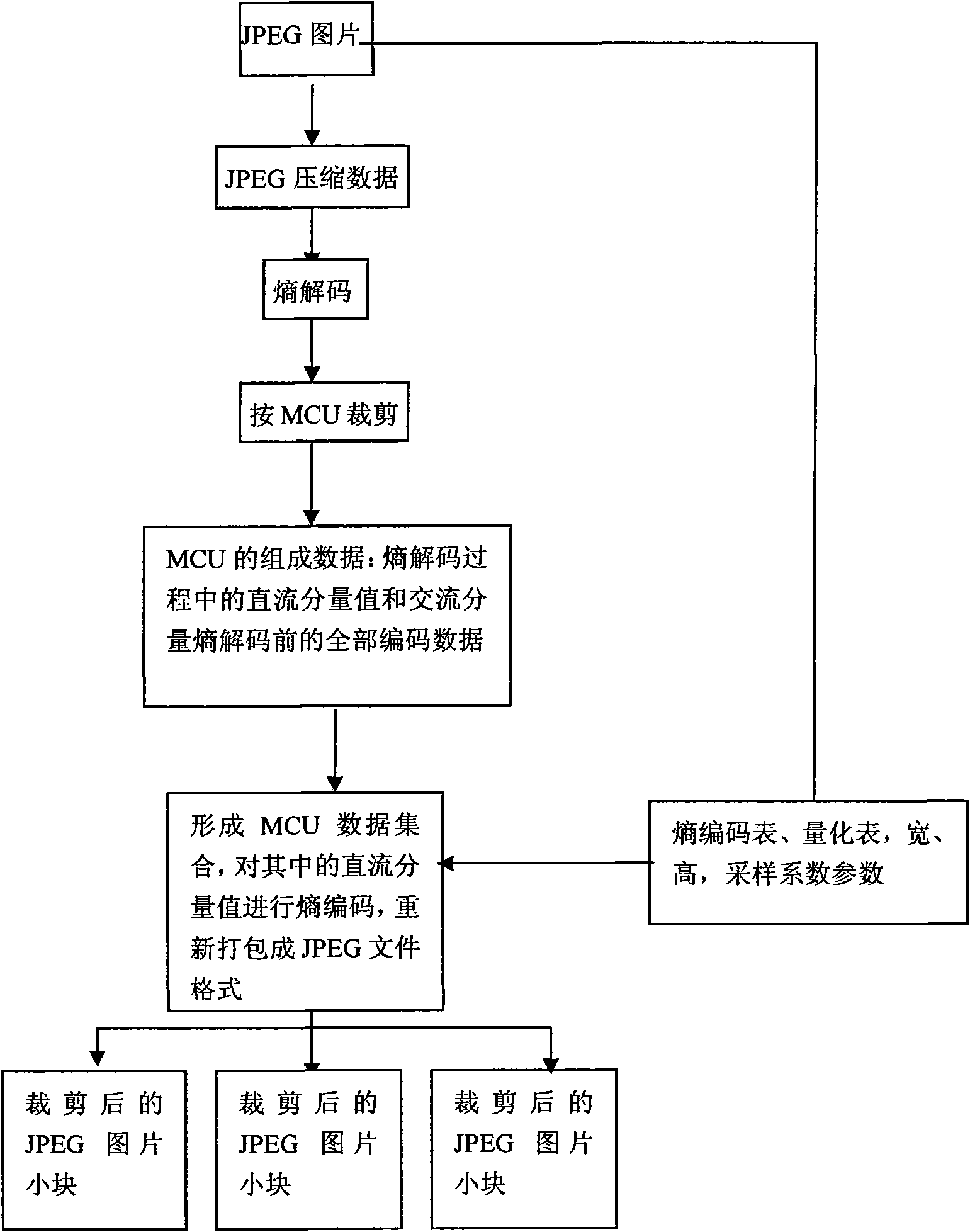

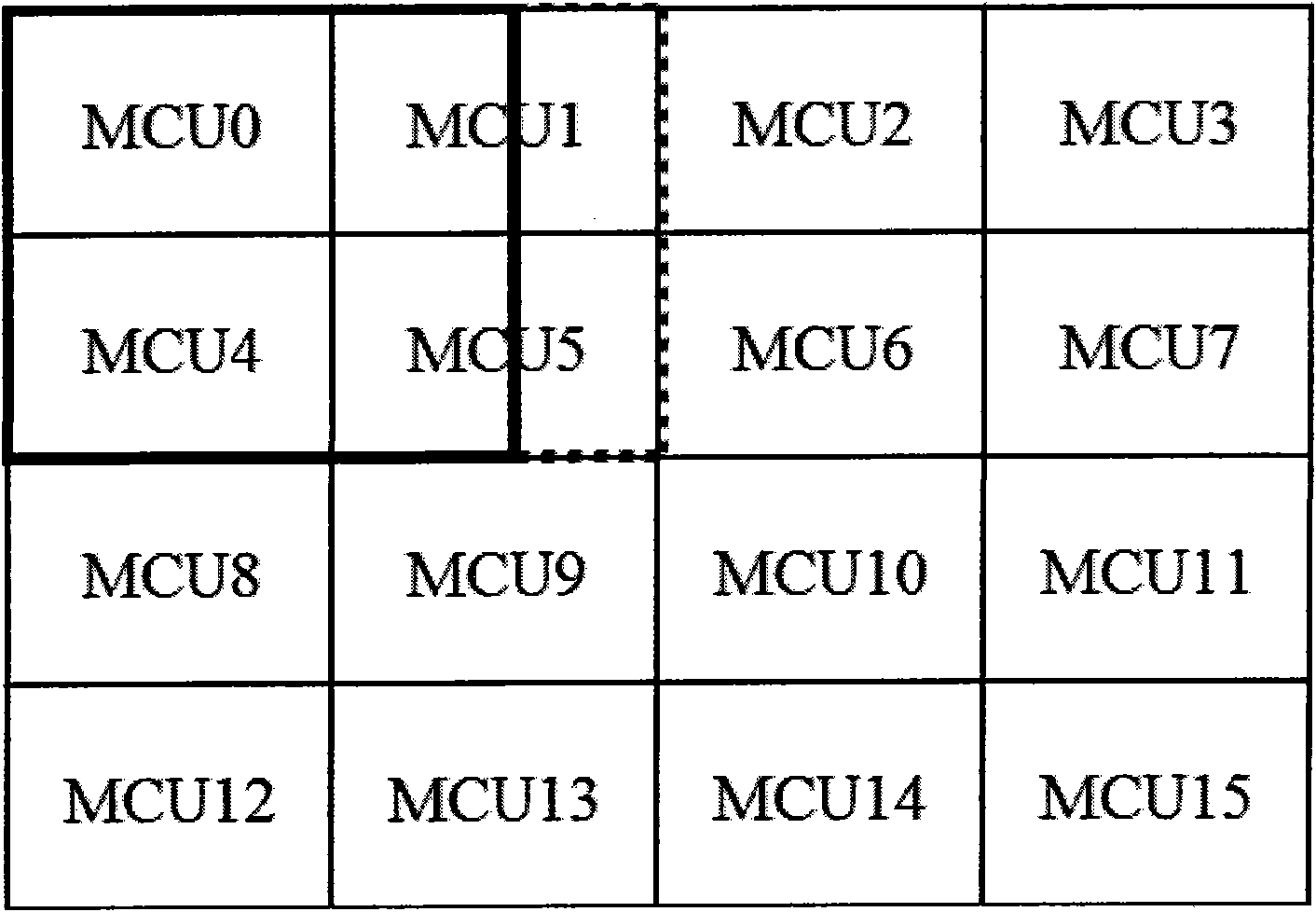

Method for cutting JPEG picture

The invention discloses a method for cutting a JPEG picture, which comprises the following steps: (1) loading a cut JPEG picture and reading the compressed data of an image and picture information necessary for decoding; (2) carrying out entropy decoding on the compressed data of the picture to obtain the combination data of each MCU; (3) cutting the picture, confirming the MCU contained in the cut picture according to the position of the cut picture in the original picture and leading the combination data of the MCU to form an MCU data set; and (4) writing into a new file according to the MCUdata set of the step (3), the picture information of the step (1) and a file format of the JPEG picture to obtain the cut picture. The invention adopts the MCU as the minimal processing unit to justcarry out entropy decoding on the decoding process of the JPEG picture without carrying out the complete JPEG decoding and recoding process, simply and easily realizes the cutting of the JPEG pictureand improves the efficiency.

Owner:GUANGDONG VTRON TECH CO LTD

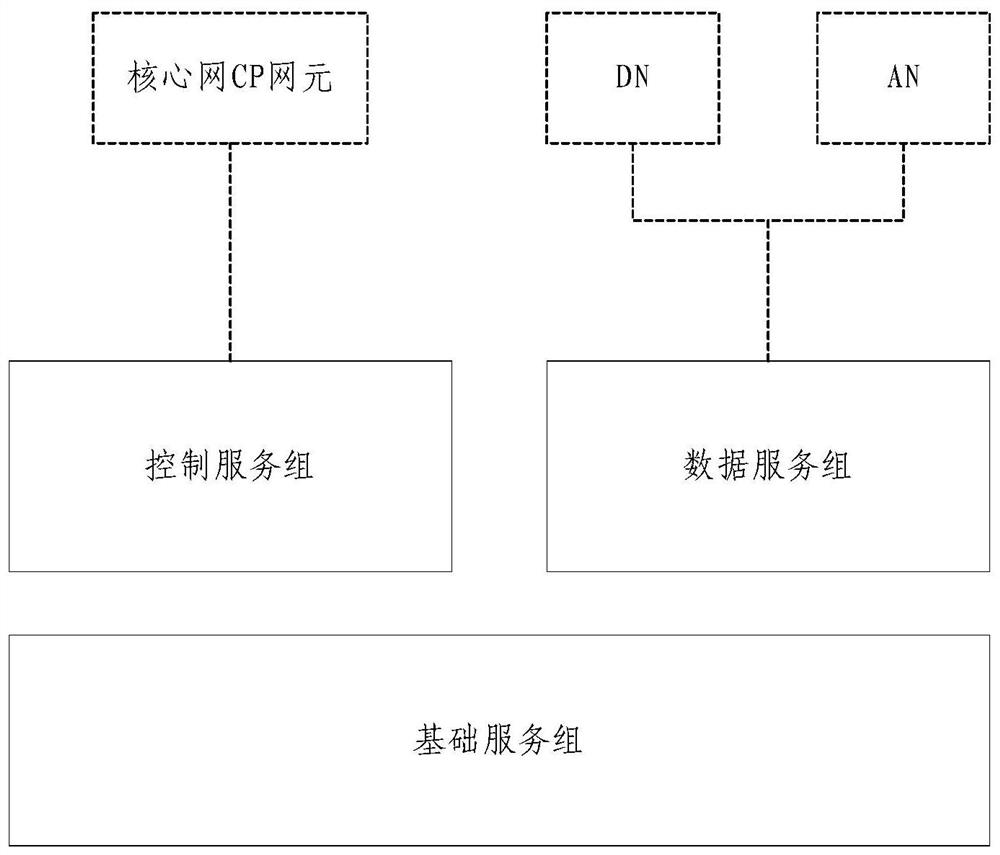

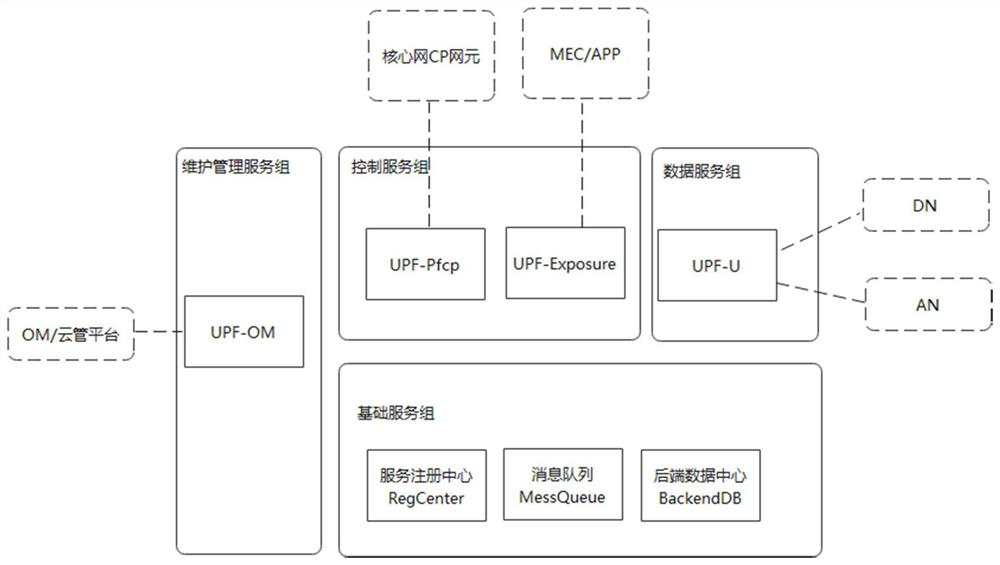

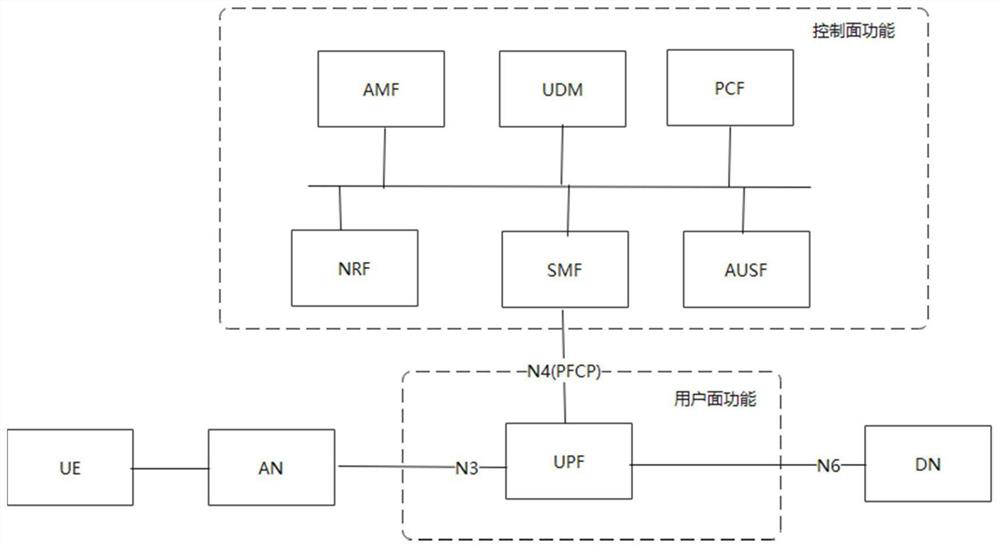

Cloud-oriented native user plane function micro-service system

PendingCN113852939AAchieve scalabilityAchieve croppingService provisioningNetwork traffic/resource managementAccess networkEngineering

The invention provides a cloud-oriented native user plane function micro-service system, which comprises a basic service group used for service registration and discovery; a control service group which is used for interacting with a core network control plane function and calling services through the basic service group; and a data service group which is used for communicating with an access network AN and a data network DN and calling services through the basic service group. According to the cloud-oriented native user plane function micro-service system, service functions are grouped, that is, the basic service group provides registration and discovery of services, the control service group realizes function interaction with the core network control plane, and the data service group communicates with the access network AN and the data network DN, so that in the micro-service system, each service is neutralized and loosely coupled, and a basis is provided for independent upgrading and capacity expansion of each service. Meanwhile, through service calling, elastic and dynamic cloud arrangement of network element functions can be realized, and a basic user plane function platform is provided for promotion of a cloud native idea.

Owner:INSPUR COMM TECH CO LTD

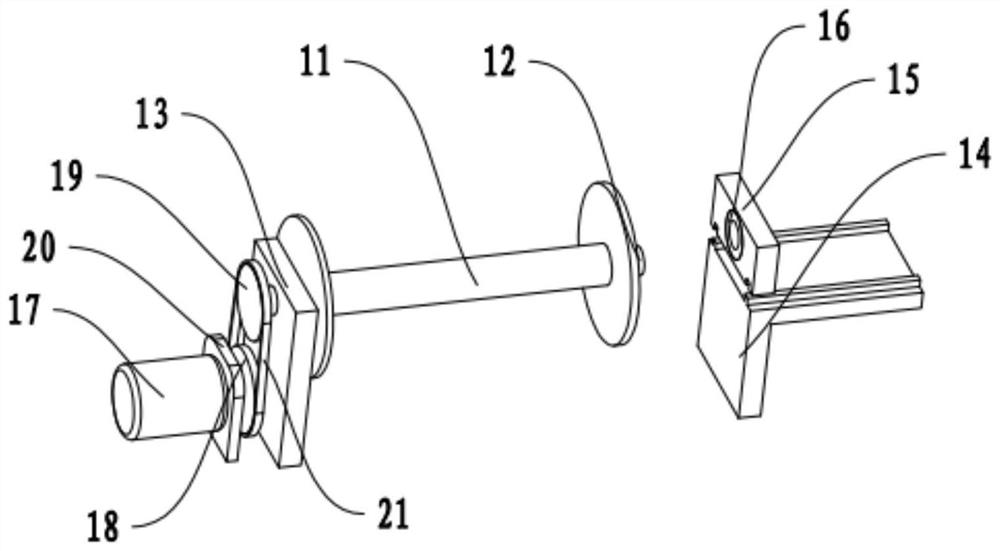

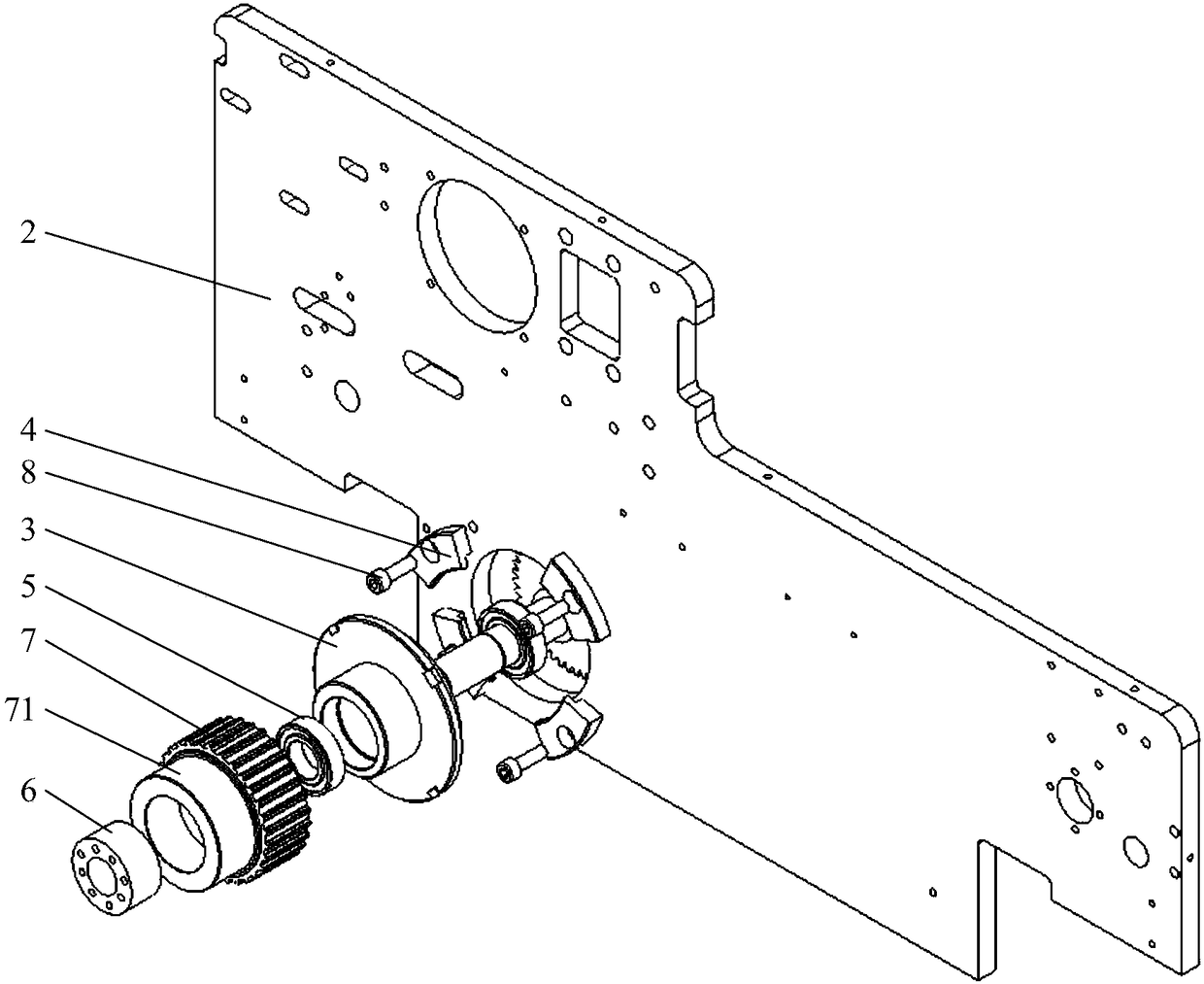

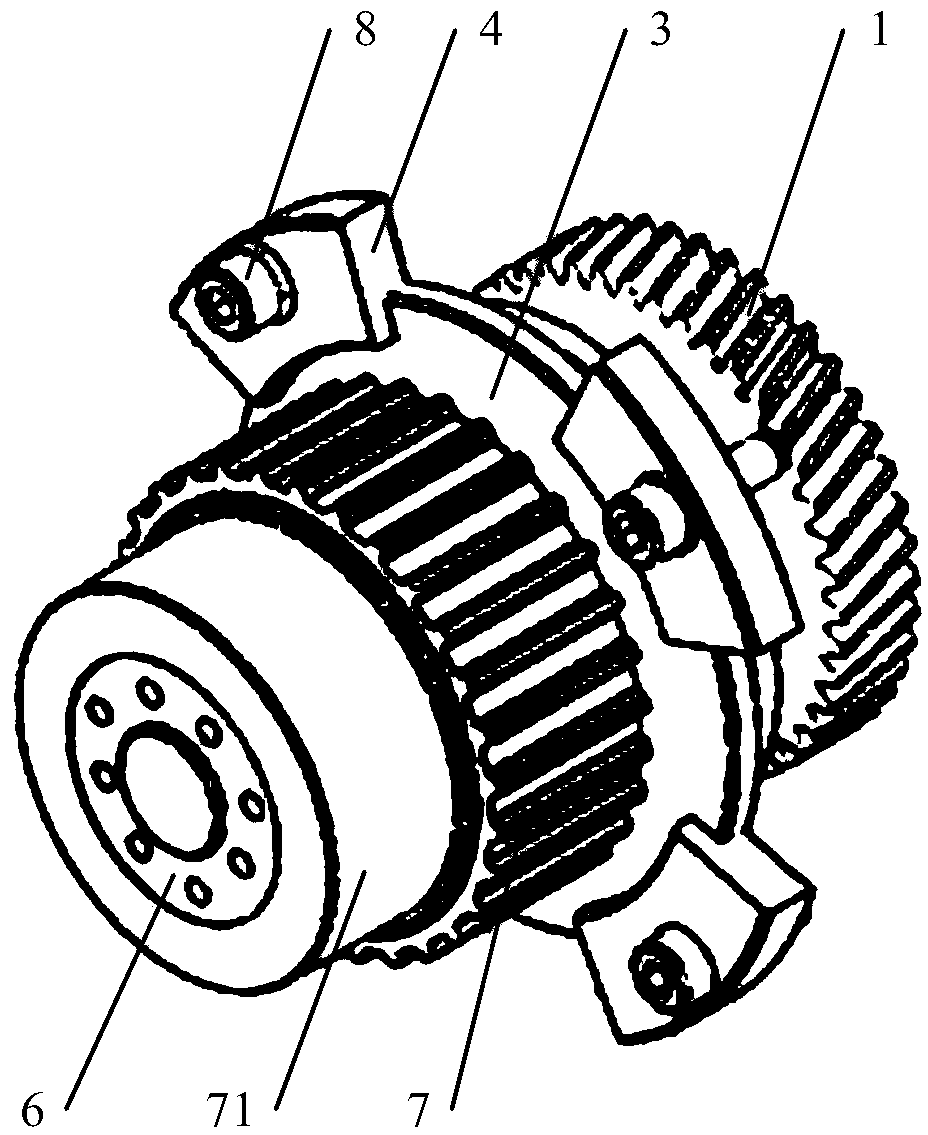

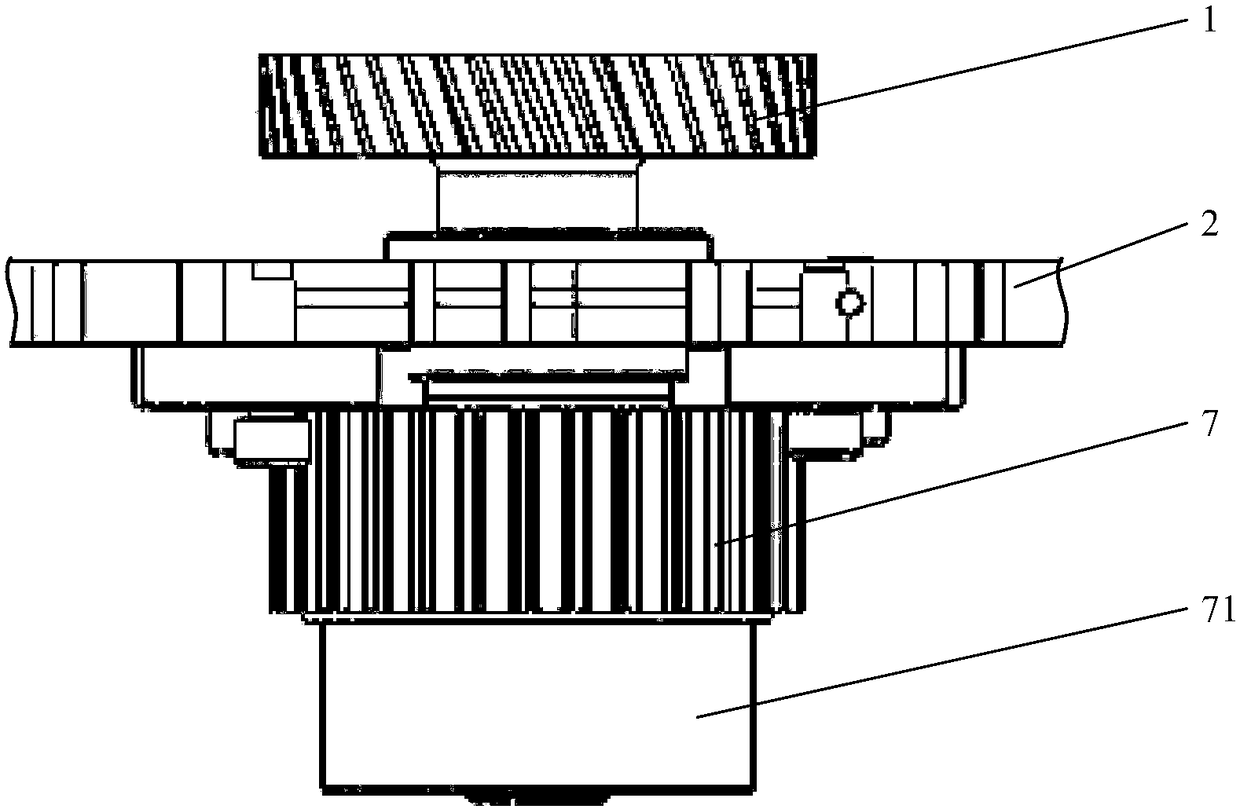

Gear adjusting device for cutting machine and cutting machine

The invention discloses a gear adjusting device for a cutting machine. The device comprises a gear for engaged transmission with a rack on the cutting machine, a machine wall for arranging a cutting part, and an eccentric flange for connecting the gear with the machine wall; the eccentric flange is provided with an eccentric hole whole axis is deviated from a center shaft of the eccentric flange;the eccentric flange is connected with the gear through a connecting shaft inserted in the eccentric hole; and the eccentric flange is mounted on the machine wall in a manner of rotating around the center shaft. The invention further discloses the cutting machine comprising the gear adjusting device. When the eccentric flange is rotated around the center shaft, the eccentric hole eccentrically moves around the center shaft, so that the axis position of the connecting shaft can be changed, the center position of the gear connected with the connecting shaft is changed, the purpose of adjusting the cooperating gap between the gear and the rack of the cutting machine can be achieved, and the adjustment of the cooperating gap between the gear and the rack on the cutting machine is simple and convenient, and saves both time and labors.

Owner:BULLMER ELECTROMECHANICAL TECH

External wall aluminum strip back adhesive smearing and cutting integrated device for building construction

InactiveCN111992814ARealize automatic lockingAchieve regulationLiquid surface applicatorsCoatingsArchitectural engineeringExternal cladding

The invention provides an external wall aluminum strip back adhesive smearing and cutting integrated device for building construction and relates to the technical field of building construction tools.The external wall aluminum strip back adhesive smearing and cutting integrated device for building construction solves the problems that in the prior art, by the adoption of an existing manner of conducting manual cutting and then conducting manual adhesive smearing, time is wasted as a whole, the smearing position is prone to deviate, and when a mechanical device is adopted to conduct automaticadhesive smearing, the mechanical device is expensive in manufacturing cost, inconvenient to carry and not adaptable to small-scale building construction. The external wall aluminum strip back adhesive smearing and cutting integrated device for building construction comprises a body plate, a sliding block and a sliding seat. A sliding structure is welded to the body plate. Since the sliding seat is provided with an elastic bayonet pin, and the elastic bayonet pin and a rack B are connected in an inserted manner and are locked, the head end of the elastic bayonet pin is of an inclined structure, the gravity of the rack B is larger than the elastic force of the elastic bayonet pin, and meanwhile when the sliding seat moves upwards, the position of the rack B is not changed, continuous smearing is achieved.

Owner:孔德强

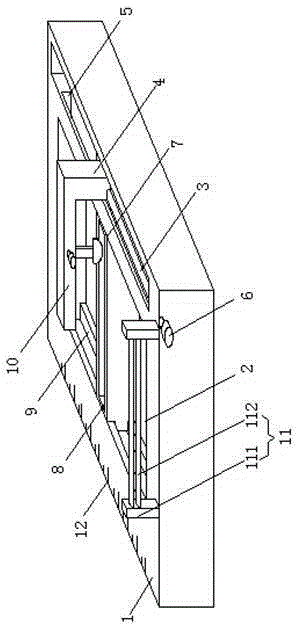

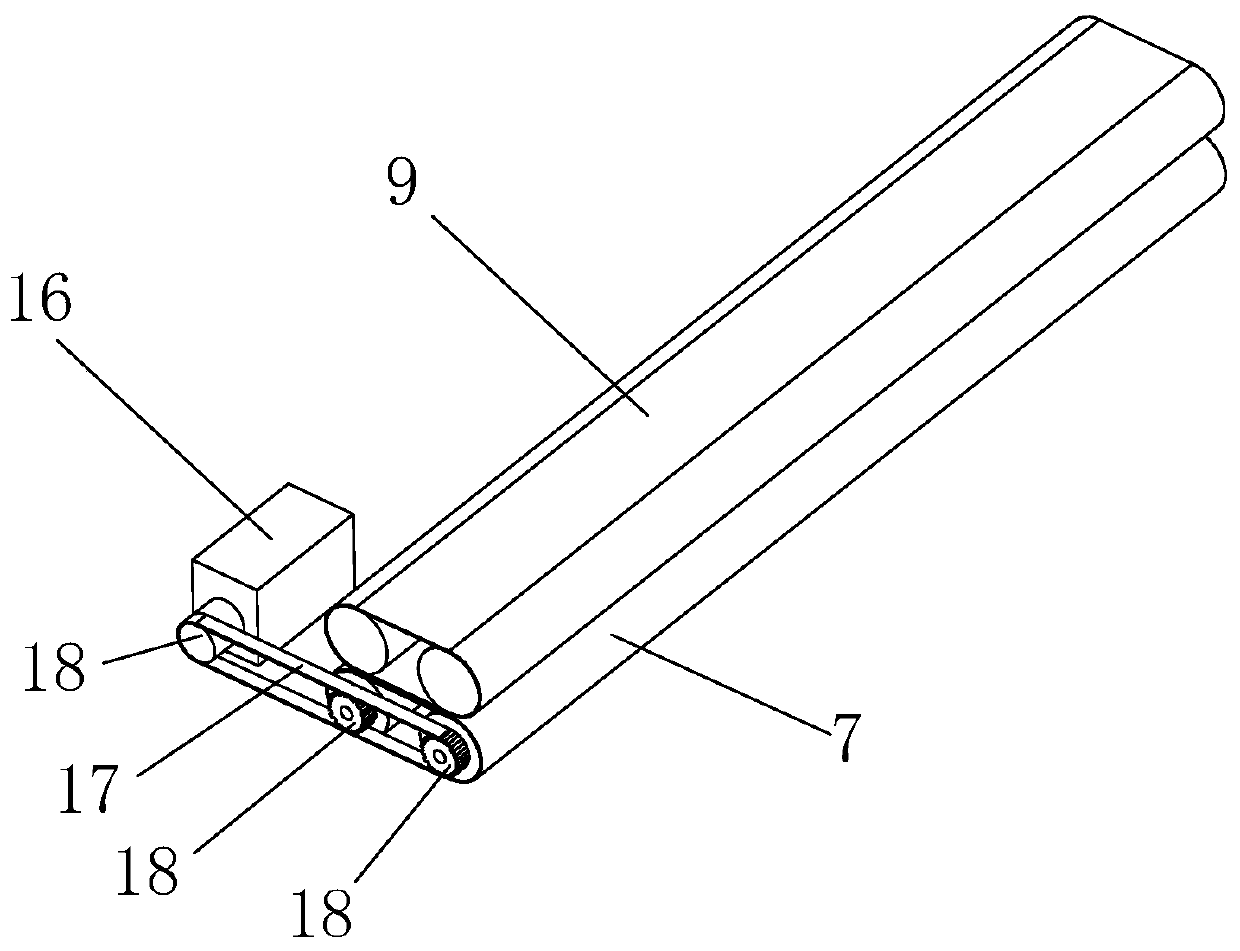

Polyethylene film winding and cutting mechanism

InactiveCN105417253AReduce rotation rateIncrease frictionArticle deliveryWebs handlingThin membraneConductor Coil

The invention discloses a polyethylene film winding and cutting mechanism which comprises a feeding device, a fixed-length winding device and a driving device, wherein the feeding device is arranged in front of the fixed-length winding device, and is used for feeding a film into the fixed-length winding device; the driving device is in output connection with the fixed-length winding device; a film cutting structure is arranged on the fixed-length winding device, and comprises a retarding mechanism; the retarding mechanism comprises an annular elastic band, a fixed rod and a weight; the fixed rod is parallel to the feeding device; one end of the annular elastic band is knotted on the fixed rod; the other end of the annular elastic band bypasses the feeding device; and the weight is suspended at the other end of the annular elastic band. The polyethylene film winding and cutting mechanism has the advantages that the structure is simple, the film length adjusting flexibility is high, the deviation of the feeding device is prevented, the abrasion of the feeding device is alleviated, and the film winding efficiency is improved.

Owner:ANQING XINSHUN PLASTIC CO LTD

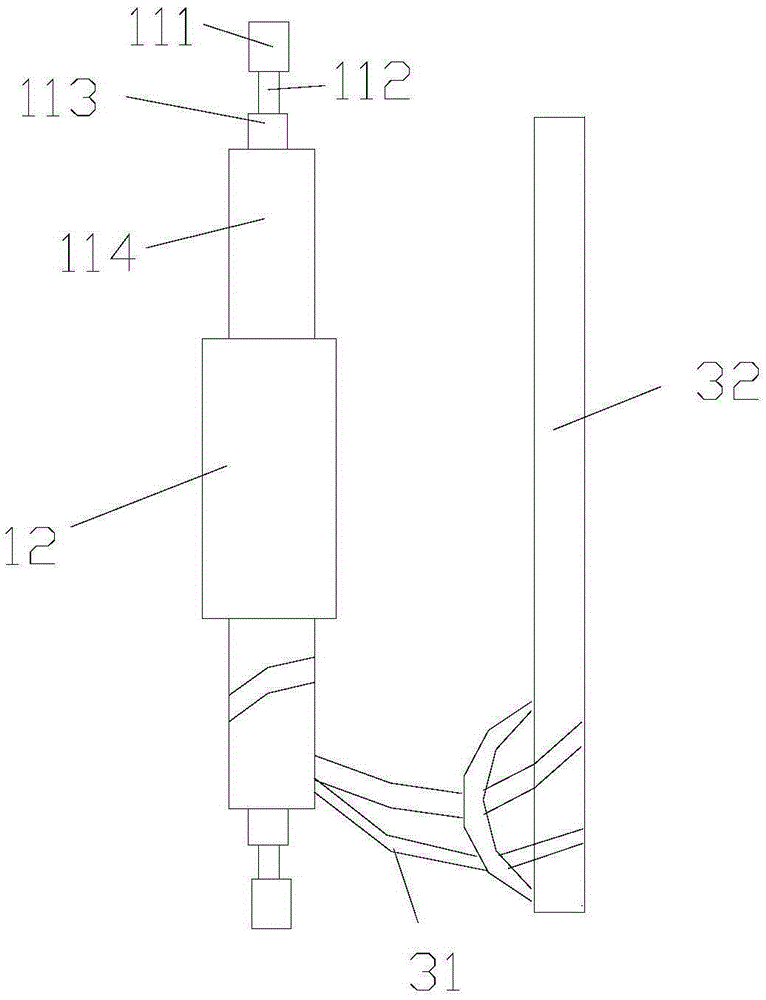

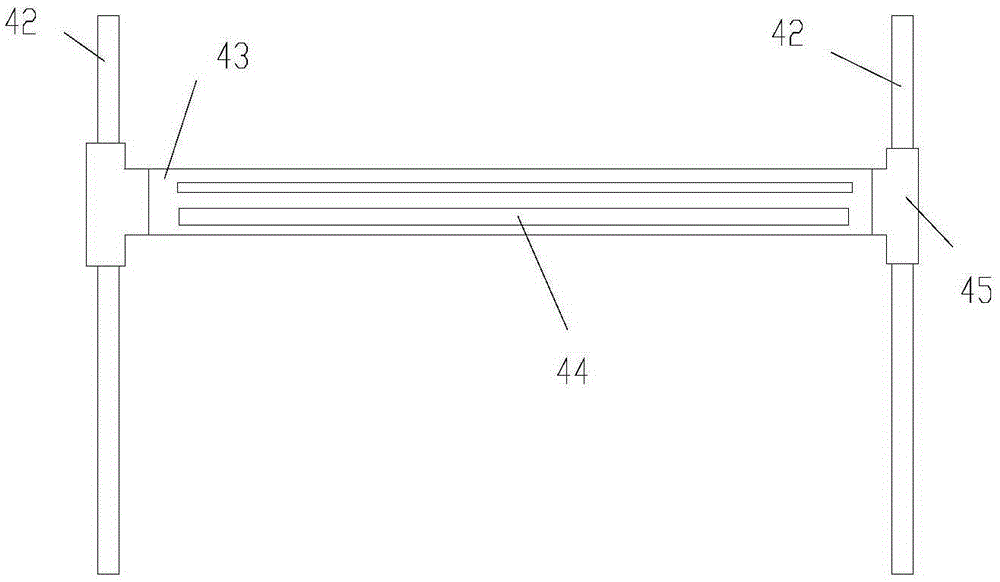

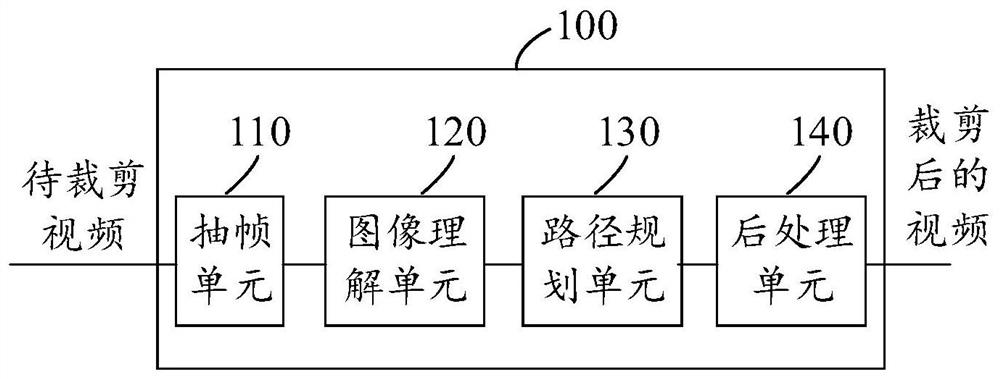

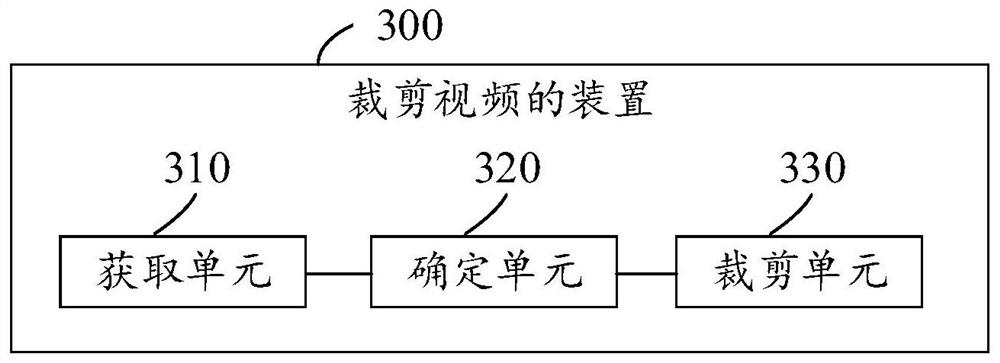

Video cropping method and device, equipment and storage medium

ActiveCN112188283AAchieve croppingIncrease flexibilitySelective content distributionImage enhancementAgricultural engineeringEngineering

The invention provides a video cropping method and device, equipment and a storage medium. The method comprises the following steps: acquiring at least one detection box of a first image frame; determining the cost of the detection box according to at least one selected from the importance score, the coverage area and the smooth distance of any detection box in the at least one detection box; determining the first detection box with the lowest cost in the at least one detection box as a cropping box; and cropping a first image frame based on the cropping frame. Based on the cost of each detection frame, the first detection frame with the minimum cost in the at least one detection frame is determined as the cropping frame so as to crop the first image frame, thereby improving the flexibility of video cropping and enhancing the cropping effect under the condition of ensuring the simplification of a video cropping process.

Owner:BEIJING BYTEDANCE NETWORK TECH CO LTD

Car leather cutting equipment

PendingCN109777899ARealize automatic skinningAchieve croppingLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusEngineeringLaser cutting

The invention discloses car leather cutting equipment. The car leather cutting equipment comprises a base, and the base is provided with a leather conveying device, a laser cutting device and a leather dragging device. The leather conveying device, the laser cutting device and the leather dragging device are sequentially arranged in the length direction of the base. The leather conveying device comprises a storage assembly and a conveying assembly, and the storage assembly and the conveying assembly are arranged above the base. The storage assembly comprises a storage shaft, leather is wound around the storage shaft, the laser cutting device comprises a cutter seat, and the cutter seat is arranged above the base. One end of the leather wound around the storage shaft is conveyed to the cutter seat through the conveying assembly, the leather dragging device is used for moving the leather conveyed to the cutter seat by one stroke again in the length direction of the base. The leather located on the cutter seat is cut by a laser cutting head on the laser cutting device. The car leather cutting equipment can achieve automatic leather dragging, cutting and stacking.

Owner:广州合驰汽车部件有限公司

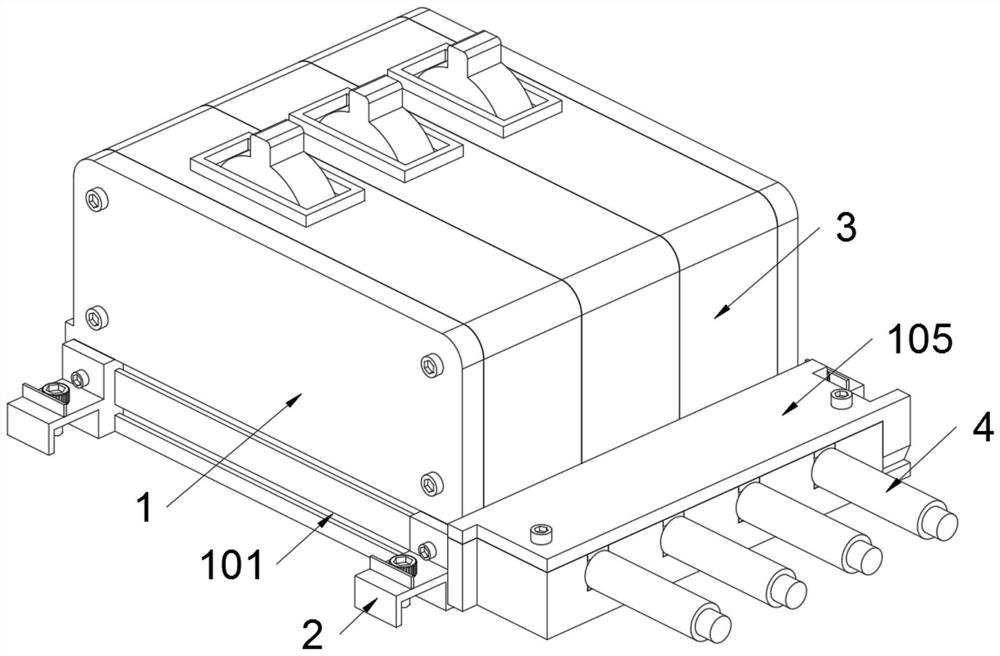

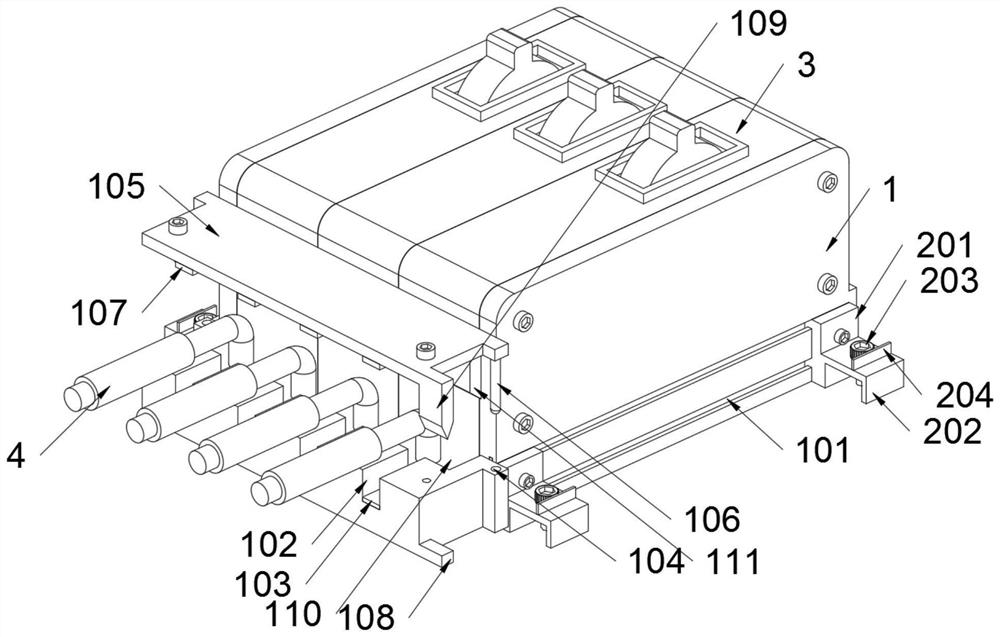

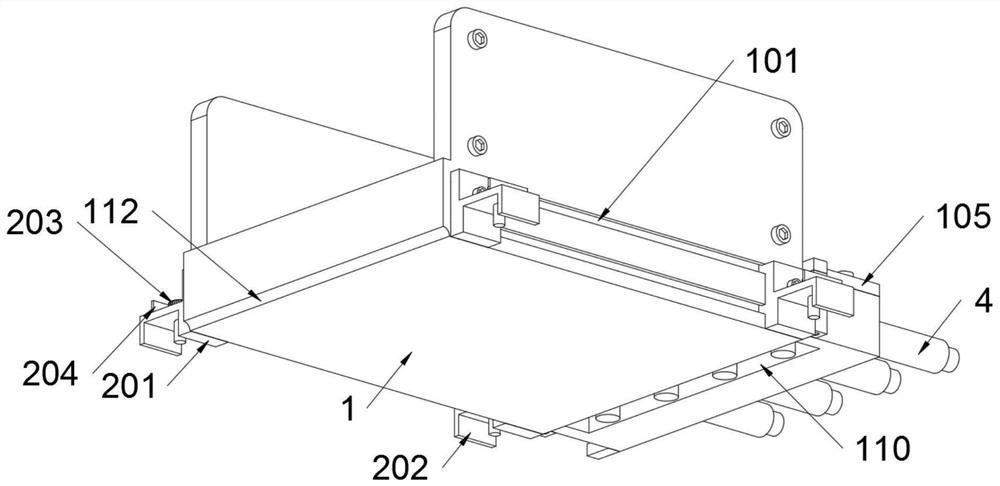

Switching mechanism with cable peeling and cutting functions

InactiveCN112614708AImprove convenienceEnhanced fasteningApparatus for cutting/splicing cablesContact electric connectionStructural engineeringMechanical engineering

The invention provides a switching mechanism with cable peeling and cutting functions, relates to the technical field of electric appliance accessories, and solves the problems that the flexible adjustment of a fixed position cannot be realized, the elastic looseness prevention of a fixed bolt cannot be realized, the drainage of water drops cannot be realized and the like. Auxiliary bending and pressing of the cable cannot be realized through structural improvement. The invention discloses a switching mechanism with cable peeling and cutting functions. The switching mechanism comprises a base body, four fixing structures are installed on the base body, a switch main body is further installed on the base body, and four cables are connected to the switch main body. The head end of the auxiliary block is of an inclined structure, and the auxiliary block and the rectangular hole jointly form a bending structure of the cable, so that the cable can be bent after the cover plate is fixed, and the fixing and fastening degree of the cable is further enhanced.

Owner:华睿企业管理咨询(衢州)有限公司

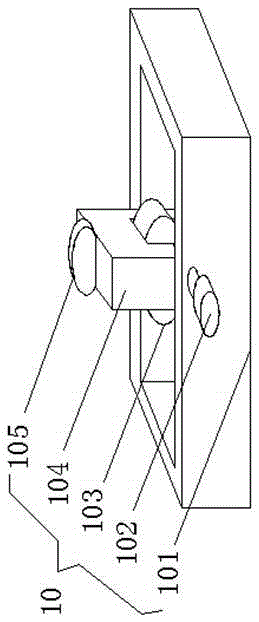

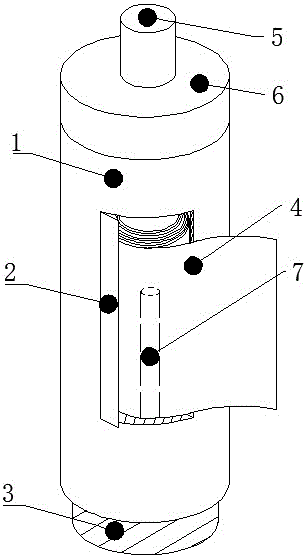

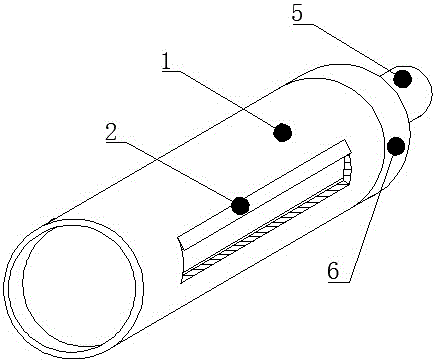

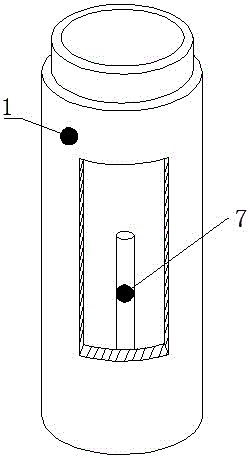

Flute membrane cutter with flute membrane adhesive

InactiveCN106826944AAchieve croppingReduce volumeMetal working apparatusArticle deliveryAdhesiveEngineering

The invention discloses a flute membrane cutter with a flute membrane adhesive. The flute membrane cutter comprises flute membrane container 1, a fine blade 2, a flute membrane adhesive 3, a flute membrane 4, a rotating shaft 5, a screw cap 6 and a fixed shaft 7, wherein the fine blade 2 is fixed on the edge of an outlet slot in the flute membrane container 1; the flute membrane adhesive 3 is inserted into a groove in the bottom of the flute membrane container 1; a head end of the flute membrane 4 is adhered to the surface of a thick shaft at the lower end of the rotating shaft 5 and then is wound and a tail end is reserved; a thin shaft at the upper end of the rotating shaft 5 penetrates outside from a round hole in the center of the screw cap 6; and meanwhile, the fixed shaft 7 on the bottom surface of the flute membrane container 1 is inserted into the hollow part of the thick shaft at the lower end of the rotating shaft 5; and the screw cap 6 is rotationally fixed on a cap opening in the upper end of the flute membrane container 1.

Owner:陈肇熙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com