External wall aluminum strip back adhesive smearing and cutting integrated device for building construction

A technology for building construction and aluminum strips, which is applied in the field of an integrated device for coating and cutting aluminum strips on exterior walls for building construction, and can solve problems such as inability to adapt, high cost, and waste of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

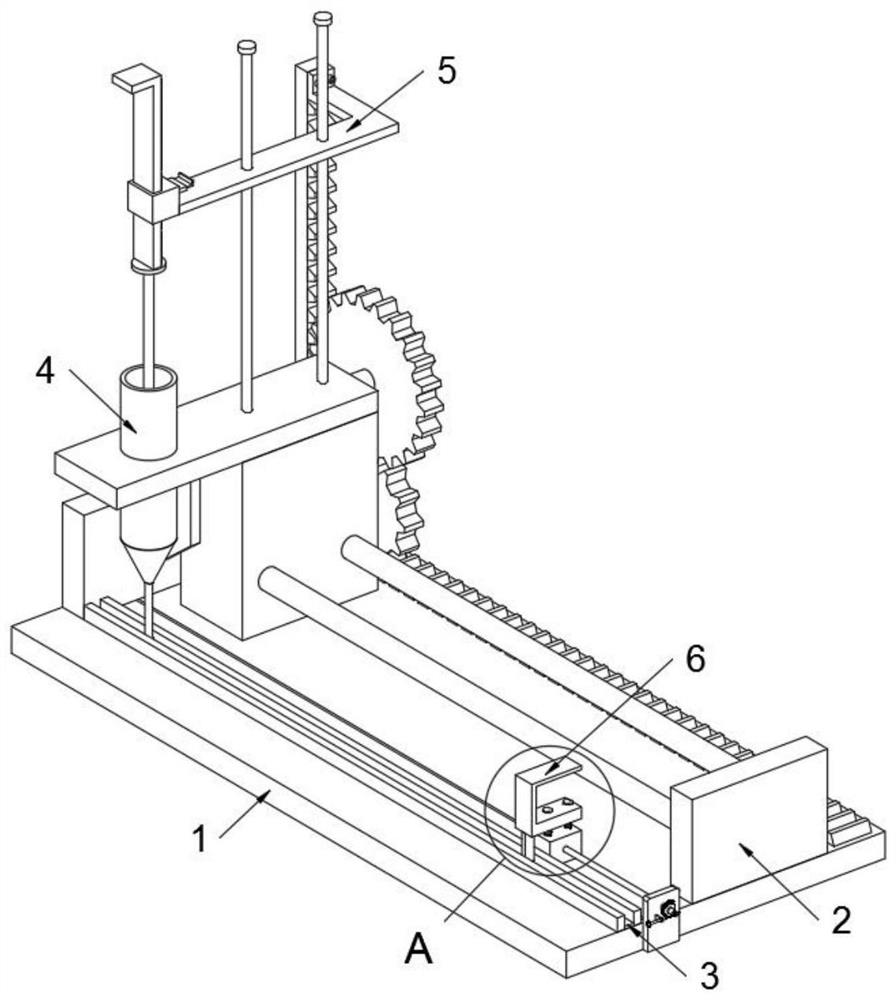

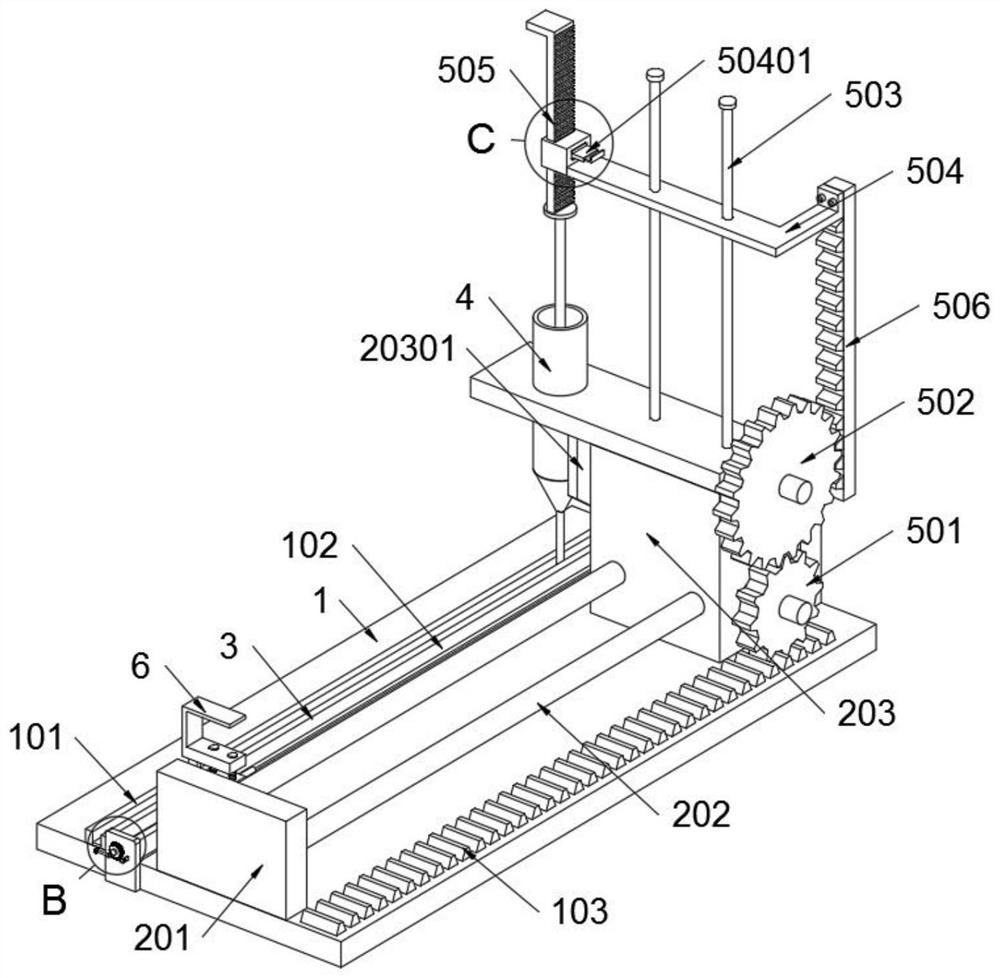

[0036] as attached figure 1 to attach Figure 8 Shown:

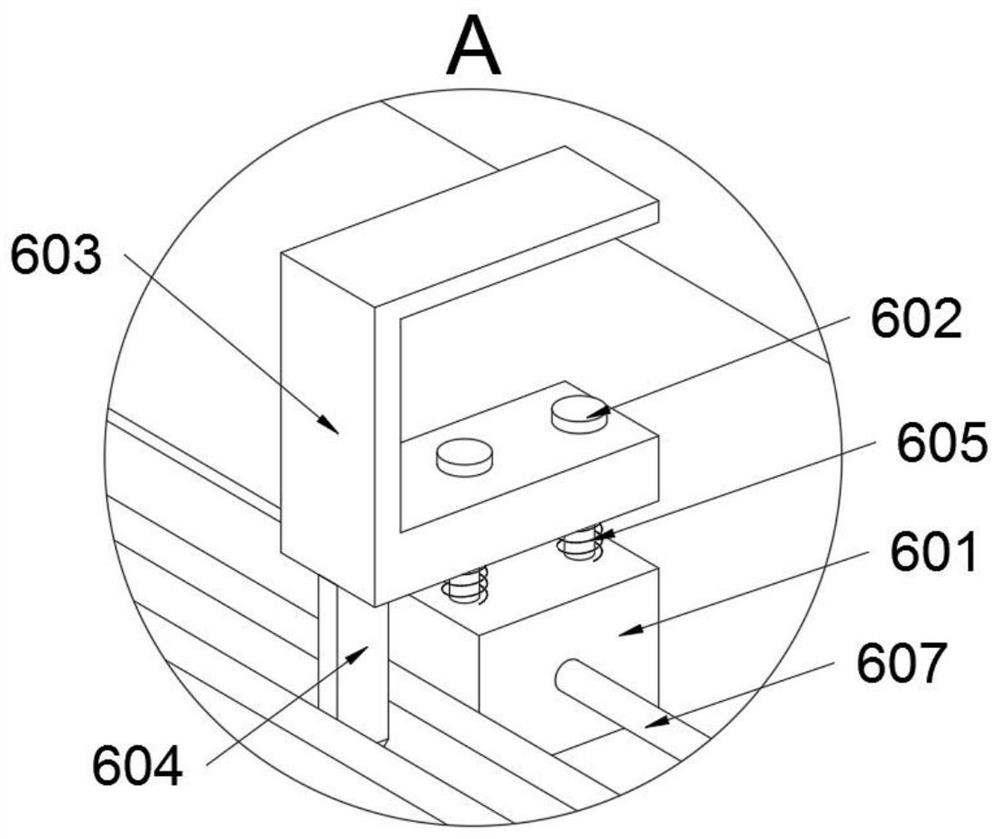

[0037] The invention provides an integrated device for smearing and cutting aluminum strips on exterior walls for building construction, comprising a main body plate 1, a sliding block 203 and a sliding seat 504; a sliding structure 2 is welded on the main body plate 1, and placed on the main body plate 1 There is an aluminum strip 3, and a rubber tube 4 is installed on the sliding structure 2; an extrusion structure 5 is installed on the sliding structure 2; a cutting structure 6 is installed on the main board 1; refer to as image 3 , the sliding block 203 includes a toggle block 20301, the toggle block 20301 is welded on the slide block 203, and contacts with the cutter seat 603 when the toggle block 20301 slides with the slide block 203, and the bottom end surface of the toggle block 20301 is inclined structure, so that the cutting of the aluminum strip 3 can also be realized when the sliding block 203 slides to ap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com