Car leather cutting equipment

A leather and equipment technology, which is applied in the field of automobile leather cutting equipment, can solve the problems of high labor intensity of operators, low production efficiency of manual operation, low precision of manual pulling and cutting, etc., and achieves the effect of improving labor efficiency and reducing labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

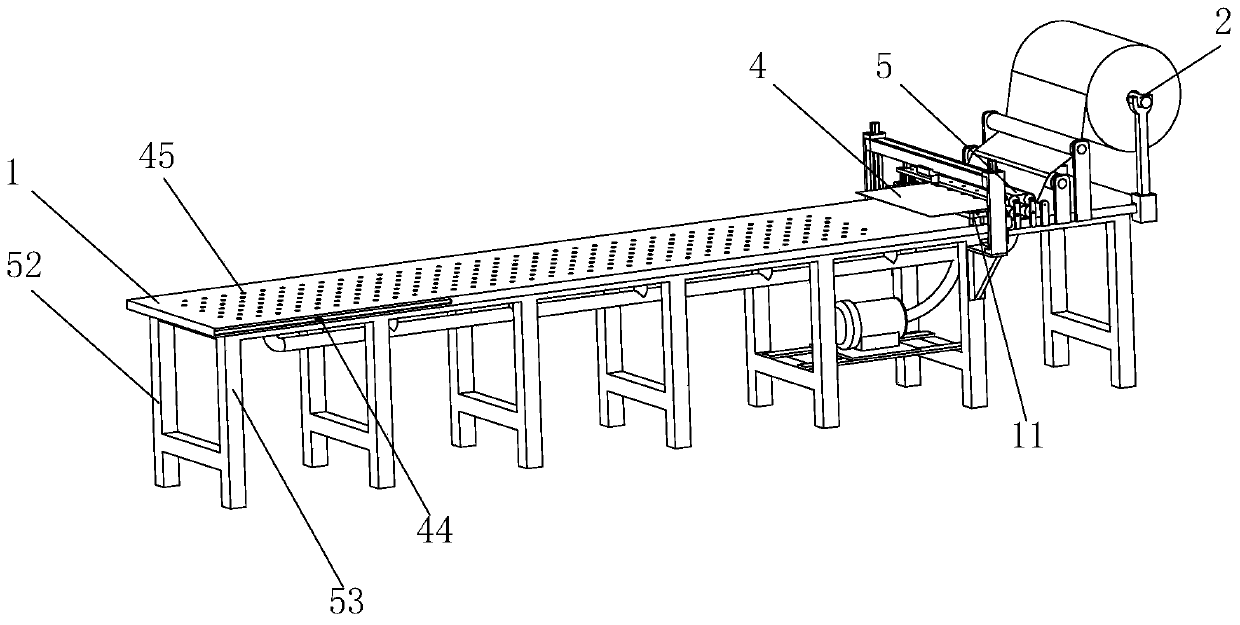

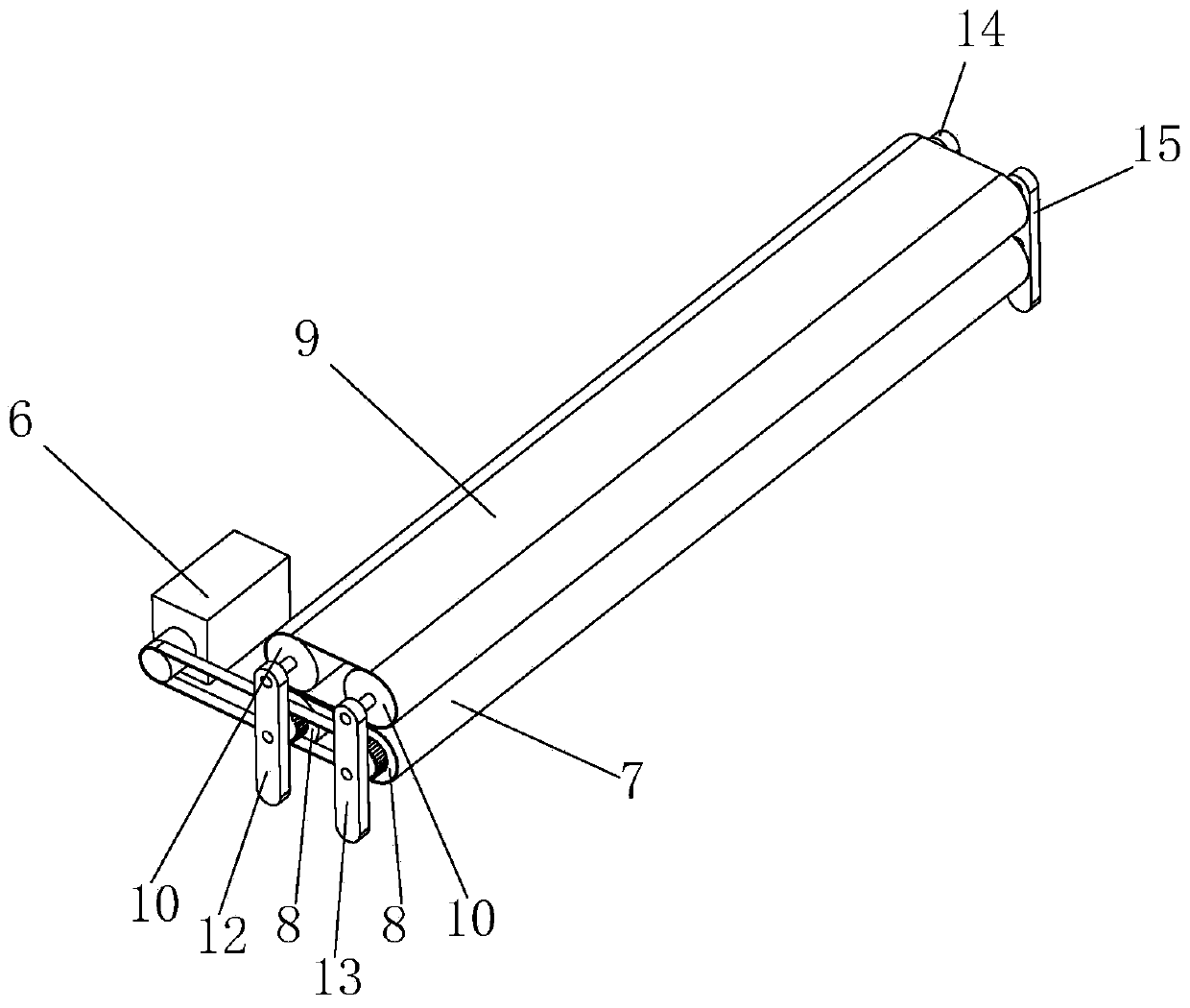

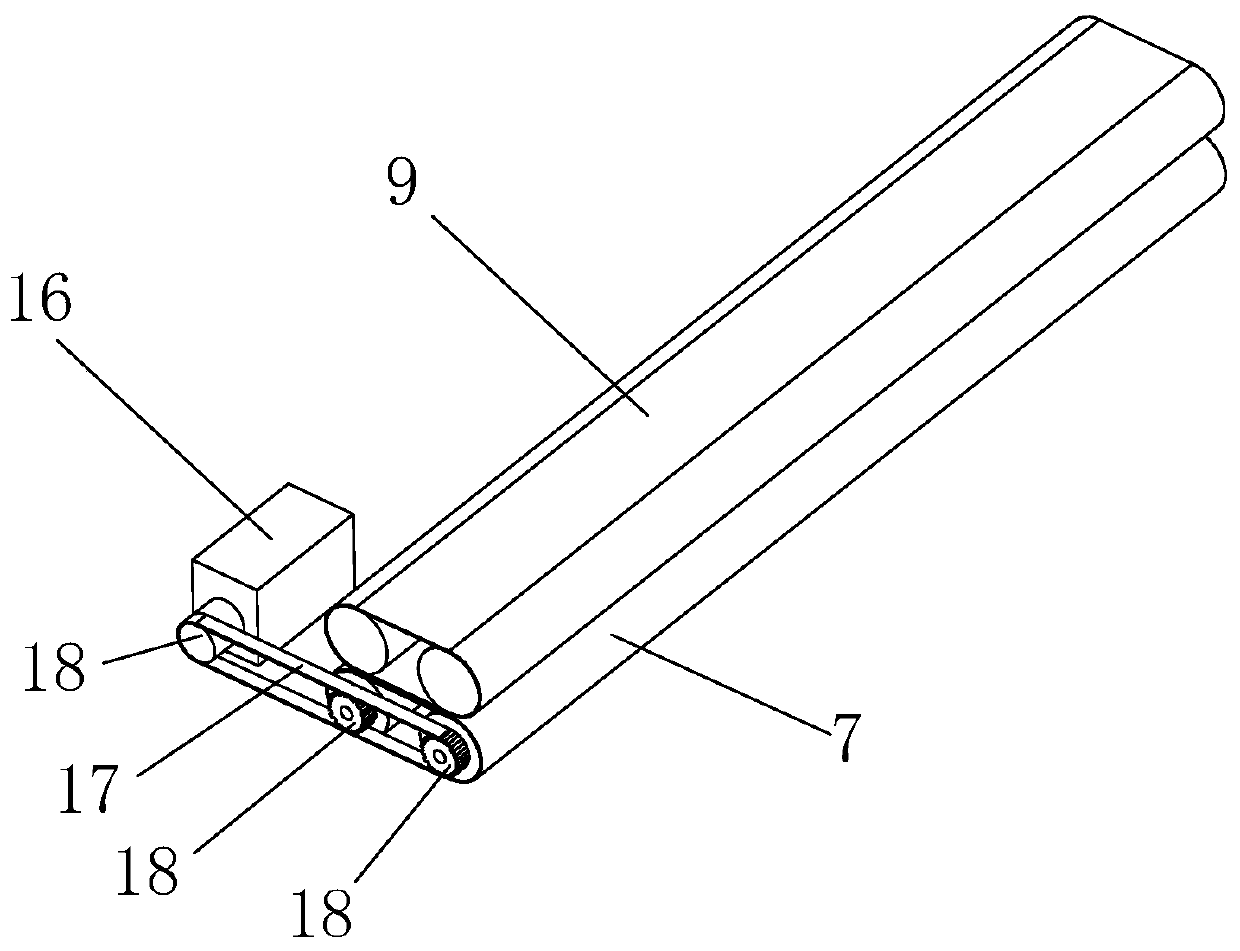

[0057] like Figure 1-8 As shown, the invention discloses a kind of automobile leather cutting equipment, comprising a base 1;

[0058] The base 1 is provided with a leather conveying device, a laser cutting device and a leather dragging device, and the leather conveying device, the laser cutting device and the leather dragging device are sequentially arranged along the length direction of the base 1;

[0059] The leather conveying device includes a stocking assembly and a conveying assembly 5, and the stocking assembly and the conveying assembly 5 are arranged above the base 1;

[0060] The storage assembly includes a storage shaft 2, a left support rod 3 and a right support rod, the leather 4 is wound on the storage shaft 2, the left support rod 3 is arranged on the left side of the base 1, and the right support rod is arranged on the base 1 On the right side, the two ends of the storage shaft 2 are in one-to-one correspondence with the left support rod 3 and the right supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com