Making method and processing system of peanut protein oily skin

A technology of peanut protein and production method, applied in the field of food processing, can solve the problems of high content of indigestible sugar, easy residual accumulation of materials, difficult digestion and absorption, etc., and achieves the effect of light and mellow flavor, easy digestion and absorption, and elimination of foam.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

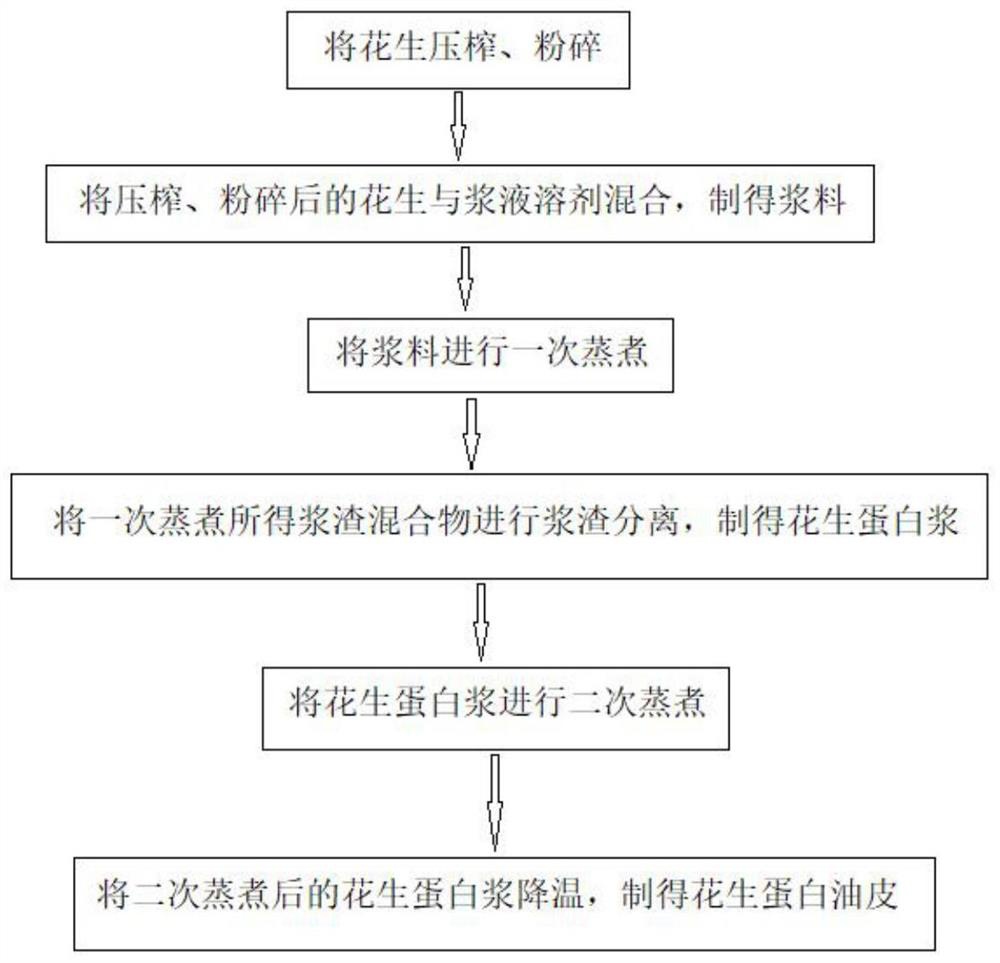

[0034] Such as figure 1 Shown, a kind of preparation method of peanut protein oil skin comprises the following steps,

[0035] Squeeze and crush peanuts;

[0036] Mixing the crushed and crushed peanuts with a slurry solvent to obtain a slurry;

[0037] Carrying out the slurry cooking once;

[0038] Separating the pulp and residue mixture obtained from the primary cooking to obtain peanut protein slurry;

[0039] The peanut protein slurry is subjected to secondary cooking;

[0040] The peanut protein slurry after secondary cooking is cooled to obtain peanut protein oil skin.

[0041] Such as image 3 As shown, a processing system of peanut protein oil skin is used to realize the preparation method of the peanut protein oil skin of the present embodiment, including an oil press 1, a cooking system pot 2, a separator 3 and a peeling system; The peeling system includes a secondary cooking pot 4; the oil press 1 is used to squeeze the peanuts; the primary cooking pot 2 of the...

Embodiment 2

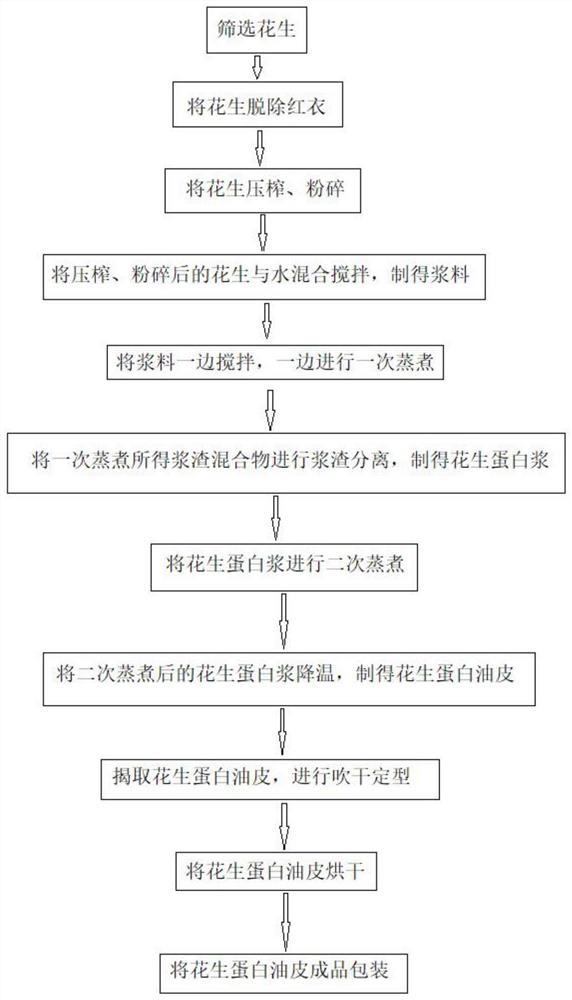

[0043] Such as figure 2As shown, the preparation method of the peanut protein oil skin in Example 1 can also be specifically described as the above-mentioned preparation method of the peanut protein oil skin, before the peanuts are pressed and crushed, the peanuts are first removed from the red coat. When removing the red coat from the peanut, the red coat can be removed by roasting the peanut; and the red coat can be removed by roasting the peanut at a low temperature, and the roasting temperature can be 65-72°C.

[0044] In addition, in the above method for making peanut protein oil skin, the peanuts are first screened before removing the red coat from the peanuts. Specifically, it is to screen peanut kernels. For example, screening peanut kernels of Baisha series varieties. Another example is the specification of screening peanut kernels with a particle size of 35-40. Among them, the graded peanut kernels are graded according to the size of the grains, that is, the numb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com