Flute membrane cutter with flute membrane adhesive

A technology of Dimo glue and Dimo, applied in metal processing, sending objects, thin material processing, etc., can solve the problems of low convenience, cumbersome operation, rupture and damage, etc., and achieve the effect of convenient replacement, simple operation and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings.

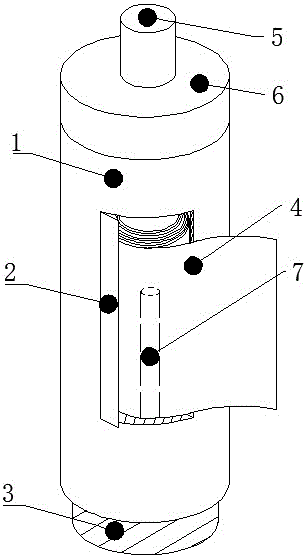

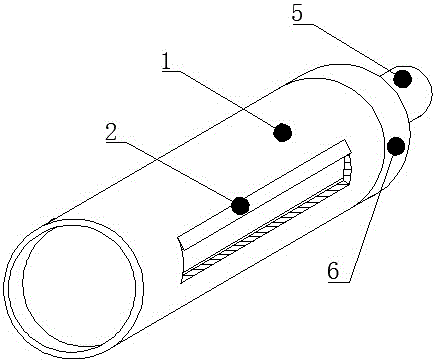

[0017] like figure 1 , 2 Shown is the structure of each part of the present invention, including Dimo container 1, thin blade 2, Dimo glue 3, Dimo 4, rotating shaft 5, screw cap 6, and fixed shaft 7. Structurally, the thin blade 2 is fixed on the edge of the outlet groove in the Dimo container 1; the Dimo glue 3 is inserted into the groove at the bottom of the Dimo container 1; , leaving the tail end; the thin shaft at the upper end of the rotating shaft 5 passes through the central round hole of the screw cap 6, and at the same time the fixed shaft 7 on the bottom surface of the dimo container 1 is inserted into the hollow part of the thick shaft at the lower end of the rotating shaft 5, and the screw cap 6 is rotated and fixed Cover the mouth on the upper end of Dimo container 1.

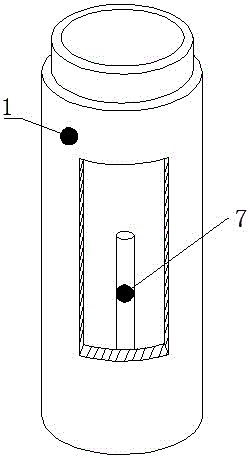

[0018] like image 3 Shown is the connection structure between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com