Polyethylene film winding and cutting mechanism

A polyethylene film and film cutting technology, which is applied in the direction of winding strips, thin material processing, and sending objects, can solve the problems affecting the normal progress of winding, achieve adjustability, increase friction, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

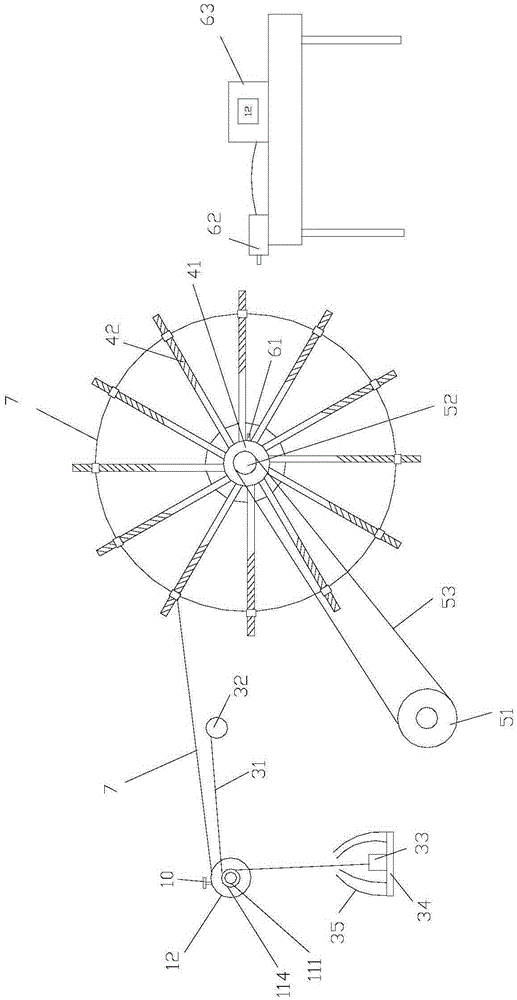

[0044] Such as Figure 1-2 As shown, the present embodiment includes a feeding device, a deceleration mechanism, a fixed-length winding device, and a driving device. The feeding device is arranged in front of the fixed-length winding device for feeding the film 7 to the fixed-length winding device, and the output of the driving device is connected to the fixed-length winding device.

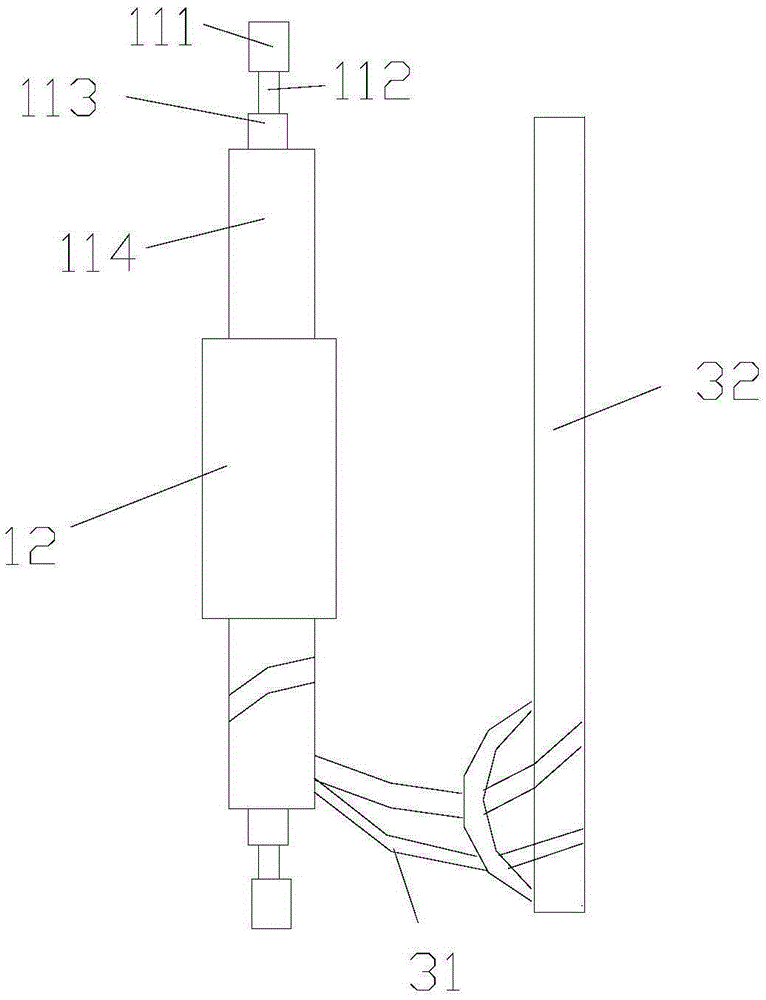

[0045] The feeding device includes a long shaft and a feeding cylinder 12. The long shaft includes a first shaft body 111, a second shaft body 112, a third shaft body 113, and a fourth shaft body 114 from the end to the middle area. The first shaft body 111 is the same as the outer diameter of the third shaft body 113 and is larger than the outer diameter of the second shaft body 112 and smaller than the outer diameter of the fourth shaft body 114; the feeding cylinder 12 is sleeved on the fourth shaft body 114, and the feeding cylinder 12 is provided with bolt 10 mounting holes.

[0046] Such as...

Embodiment 2

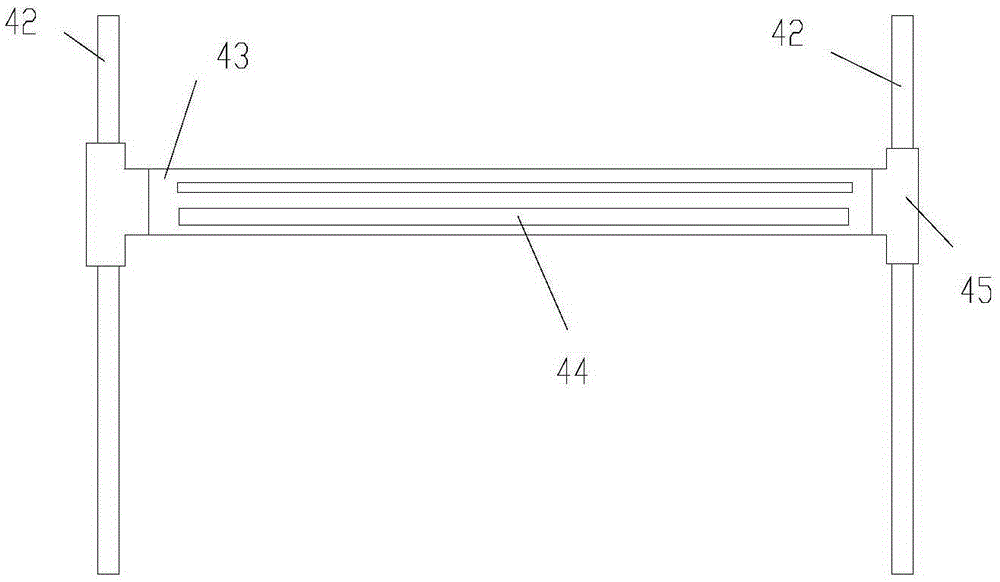

[0066] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the support rod 42 is provided with external threads, and the two ends of the cross bar 43 are sleeved on the corresponding support rods 42 respectively. Both upper and lower sides are provided with first nuts 47 , and the first nuts 47 are screwed on the corresponding support rods 42 .

[0067] The position of the cross bar 43 is adjusted by turning the first nut 47 .

Embodiment 3

[0069] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the lower end of the support rod 42 is provided with a positioning block 410, the positioning block 410 is provided with a spring sleeve 49, the upper end of the support rod 42 is spun with a second nut 48, and the cross bar The two ends of 43 are sleeved on the corresponding support rod 42 and located between the corresponding spring sleeve 49 and the second nut 48 .

[0070] By turning the second nut 48 and compressing the spring sleeve 49, the position of the cross bar 43 is adjusted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com