An anti-icing water conservancy engineering gate

A technology for water conservancy projects and gates, which is applied in the field of anti-icing water conservancy project gates. It can solve the problems of improving utilization efficiency, difficulty in gate power supply, and decline in gate life, so as to reduce utilization and conversion, optimize water flow utilization, and reduce rotation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

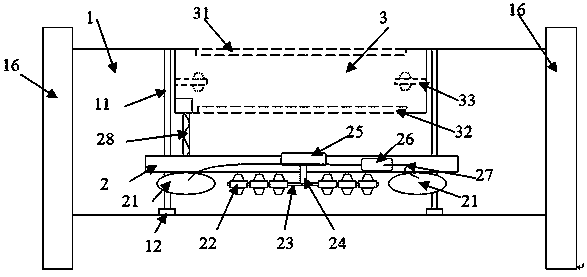

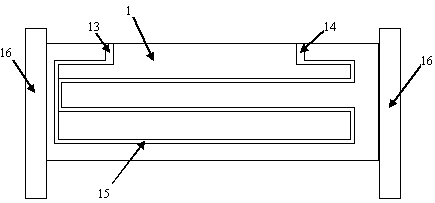

[0029] Such as figure 1 as shown,

[0030] An anti-icing water conservancy engineering gate comprises a gate plate, a column, a power generation device and a water storage device arranged on the water surface behind the gate plate, and a circulating water pipe arranged on the water surface of the gate plate.

[0031] The column is arranged on both sides of the gate plate, and is used for fixing the gate plate and realizing the rising and falling of the gate plate through the slideway.

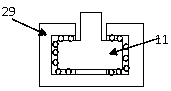

[0032] The power generation device is arranged on the backwater surface of the gate, and includes two vertical slide rails, a power generation device bracket, an air bag, water wheel blades, a water wheel shaft, a power conversion shaft, a generator set, an air pump, an inflation pipeline, and a wire channel; The straight slide rails are parallel to the uprights, and are respectively fixed on the two ends of the uprights on the backwater surface of the gate. One end of the fastening slider is...

Embodiment 2

[0047] An anti-icing water conservancy engineering gate comprises a gate plate, a column, a power generation device and a water storage device arranged on the water surface behind the gate plate, and a circulating water pipe arranged on the water surface of the gate plate.

[0048] The column is arranged on both sides of the gate plate, and is used for fixing the gate plate and realizing the rising and falling of the gate plate through the slideway.

[0049] The power generation device is arranged on the backwater surface of the gate, and includes two vertical slide rails, a power generation device bracket, an air bag, water wheel blades, a water wheel shaft, a power conversion shaft, a generator set, an air pump, an inflation pipeline, and a wire channel; The straight slide rails are parallel to the uprights, and are respectively fixed on the two ends of the uprights on the backwater surface of the gate. One end of the fastening slider is fixed on the power generation device ...

Embodiment 3

[0060] An anti-icing water conservancy engineering gate comprises a gate plate, a column, a power generation device and a water storage device arranged on the water surface behind the gate plate, and a circulating water pipe arranged on the water surface of the gate plate.

[0061] The column is arranged on both sides of the gate plate, and is used for fixing the gate plate and realizing the rising and falling of the gate plate through the slideway.

[0062] The power generation device is arranged on the backwater surface of the gate, and includes two vertical slide rails, a power generation device bracket, an air bag, water wheel blades, a water wheel shaft, a power conversion shaft, a generator set, an air pump, an inflation pipeline, and a wire channel; The straight slide rails are parallel to the uprights, and are respectively fixed on the two ends of the uprights on the backwater surface of the gate. One end of the fastening slider is fixed on the power generation device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com