Equipment for mixing granular drug

A granular and mixing technology, applied in the field of medicine, can solve the problems of inconvenient material processing, inability to directly transport, low production efficiency, etc., and achieve the effect of improving efficiency, reducing time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

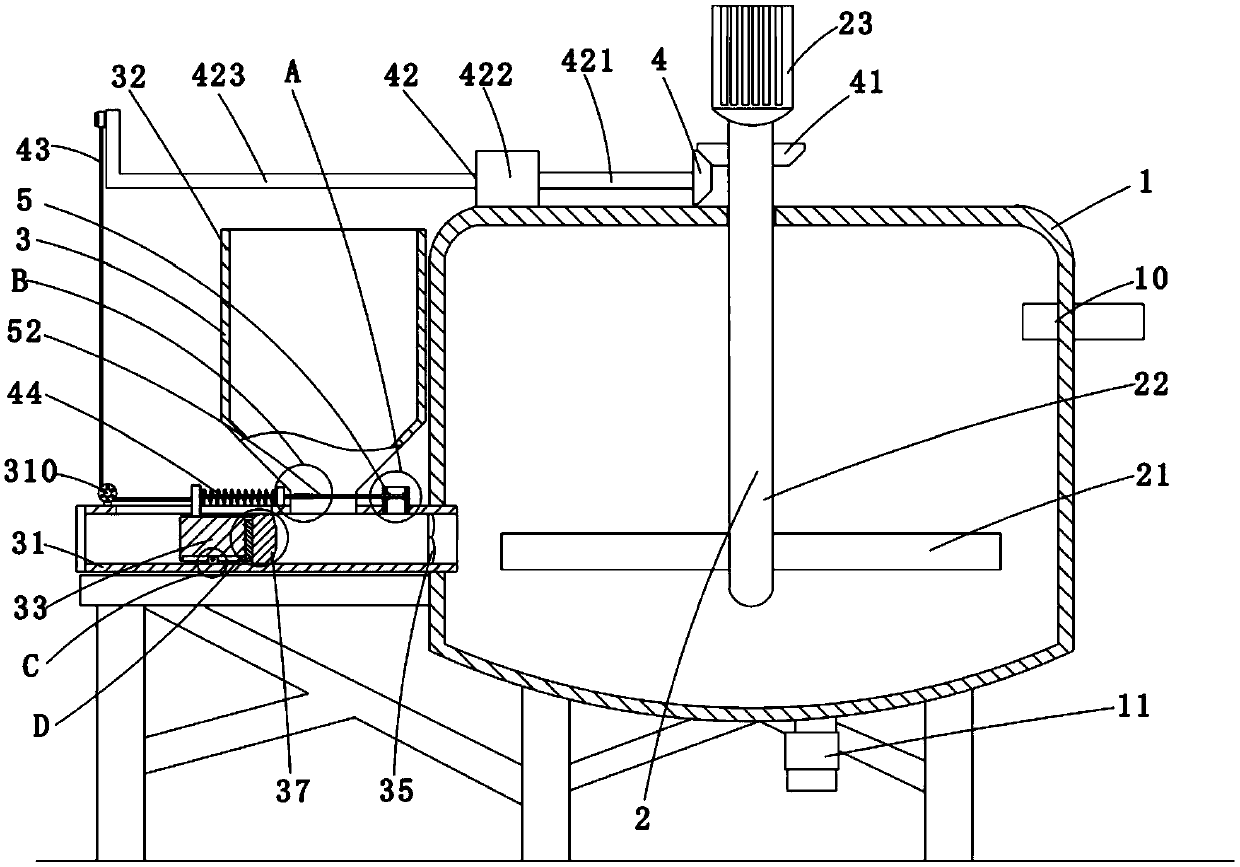

Method used

Image

Examples

Embodiment 2

[0039] Such as Figure 7-8 As shown, the difference between this embodiment and Embodiment 1 is that the shape of the stirring paddle 21 in the stirring member 2 is different, and a wear-resistant plate is added; specifically, the stirring member 2 includes a stirring paddle 21, a stirring shaft 22 and Driver 23; the stirring paddle 21 is a U-shaped metal paddle, the stirring shaft 22 is a metal shaft, the driving member 23 is a motor, and the stirring shaft 22 is connected with the driving member 23, so that the driving member 23 drives the stirring shaft 22 to rotate; the stirring paddle 21 is connected with the stirring shaft 22, so that the stirring paddle 21 rotates with the stirring shaft 22; and the stirring paddle 21 is connected with a wear-resistant The plate part 25, the wear-resistant plate part 25 is a plastic plate made of wear-resistant plastic.

[0040] Specifically, the elastic structure 6 includes a locking groove 61, a fixing piece 62 and an extruding sprin...

Embodiment 3

[0043] Such as Figure 9-11 As shown, the difference between this embodiment and Embodiment 1 is that a pumping part 9 is added to cooperate with the mixing kettle 1 to extract the material in the mixing kettle 1. Specifically, the pumping part 9 includes a pumping Pipeline 91, fan 92 and deflector 93, described fan 92 is existing fan on the market; The feed pipe 91 is provided with a branch pipe 911, which is a metal pipe perpendicular to the pumping pipe 91, and the branch pipe 911 communicates with the pumping pipe 911; the branch pipe 911 is connected with the fan 92 .

[0044] Further, the deflector 93 is an L-shaped metal plate with a transverse cross-section, and the deflector 93 is arranged below the branch pipe 911, so that the wind blown by the fan 92 is blown on the deflector 93 Its direction will change when it happens, and the wind blows out along the length direction of the material extraction pipe 91; there is a material gap 94 between the deflector 93 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com