Device for hot-rolled strip steel production line to achieve uncoiling of steel coils in small batches

A hot-rolled strip and production line technology, applied in the field of steelmaking industry, can solve the problems of low utilization rate of inspection line equipment, reduced product yield, loss of individual customers, etc., and achieves improved strip product yield and inspection line equipment. Use rate, improve product yield, and reduce product manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

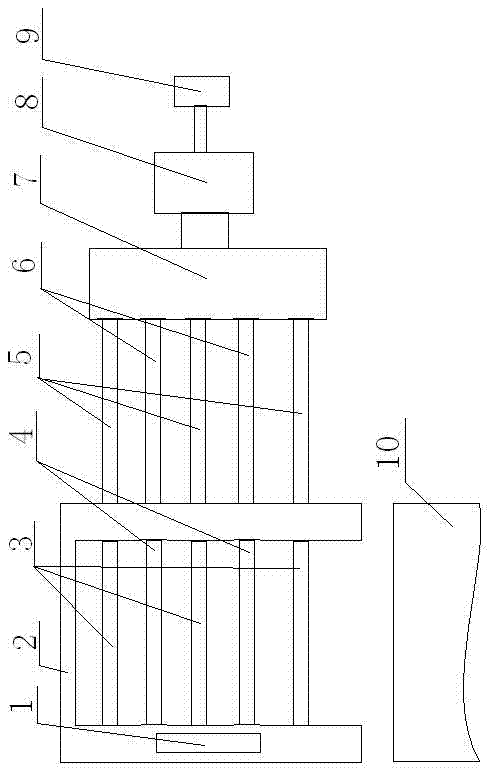

[0007] In the present invention, a pinch roll rolling device is correspondingly installed after the strip steel inspection line 10 after the final output of hot strip steel, and the structure of the pinch roll rolling device is: an upper roll 4 and a lower roll are installed on the frame 2 3. The distance between the upper roll 4 and the lower roll 3 is the same as the thickness of the steel strip, which is convenient for leveling the strip head or scattered steel strips. There is an adjustment mechanism 1 for adjusting the distance between the upper roll 4 and the lower roll 3 on the frame 2. The upper roll The distance between 4 and the lower roller 3 is adjusted according to the thickness of the steel strip, which is convenient for rolling. The upper roll 4 is connected with the upper universal joint shaft 6, the lower roll 3 is connected with the lower universal joint shaft 5, and the upper universal joint shaft 6 and the lower universal joint shaft 5 are connected with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com