Packaging bag forming and printing label all-in-one machine

A packaging bag and all-in-one machine technology, applied in the field of marking equipment for packaging materials, can solve the problems of low production efficiency and additional addition of packaging bags, and achieve the effects of convenient hot pressing, short path, and fast sliding in and out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

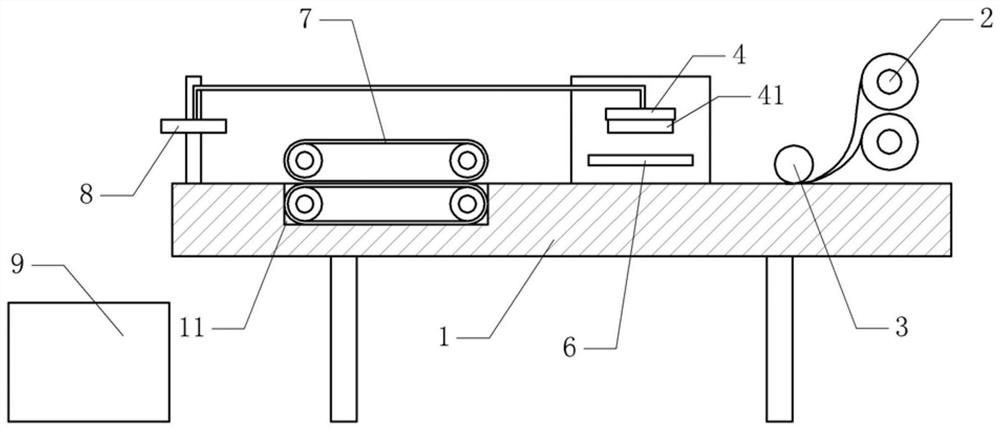

[0035] Packaging bag forming and labeling all-in-one machine, basically as attached figure 1 As shown, it includes a frame and a workbench 1 fixed on the frame. The workbench 1 is sequentially provided with an unwinding part, a hot pressing part, a conveying part and a cutting part from left to right. The unwinding part includes two vertical The unwinding rollers 2 overlapped in the vertical direction are provided with a support frame on the workbench 1, and the two unwinding rollers 2 are all rotatably connected on the support frame. The bottom of the support frame is also rotatably connected with a leveling roller 3, the leveling roller 3 is located below the unwinding roller 2, and is positioned on the right side of the unwinding roller 2, and the unwinding roller 2 sticks to the workbench 1 upper surface.

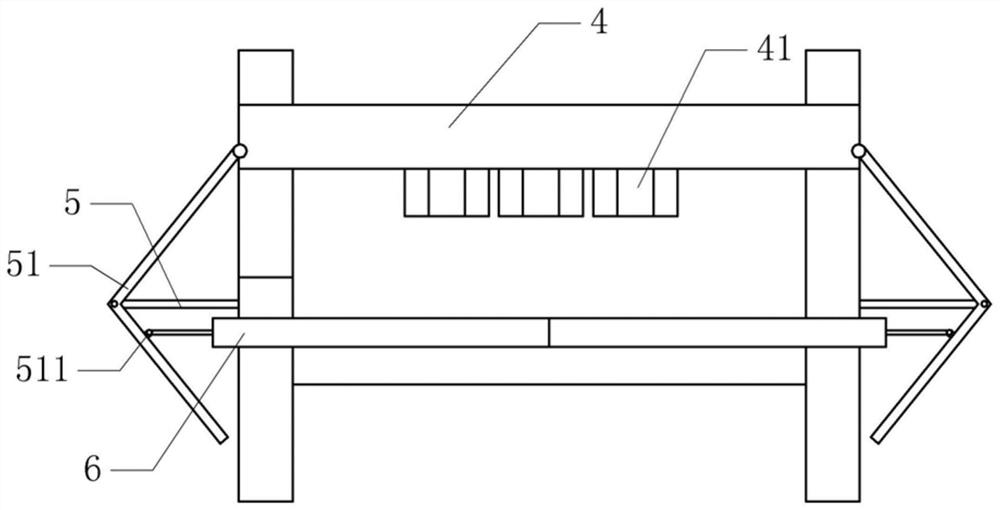

[0036] The hot pressing part includes a mounting frame fixed on the workbench 1, on which the fixed block 4 slides vertically, and the bottom of the fixed block 4 is fi...

Embodiment 2

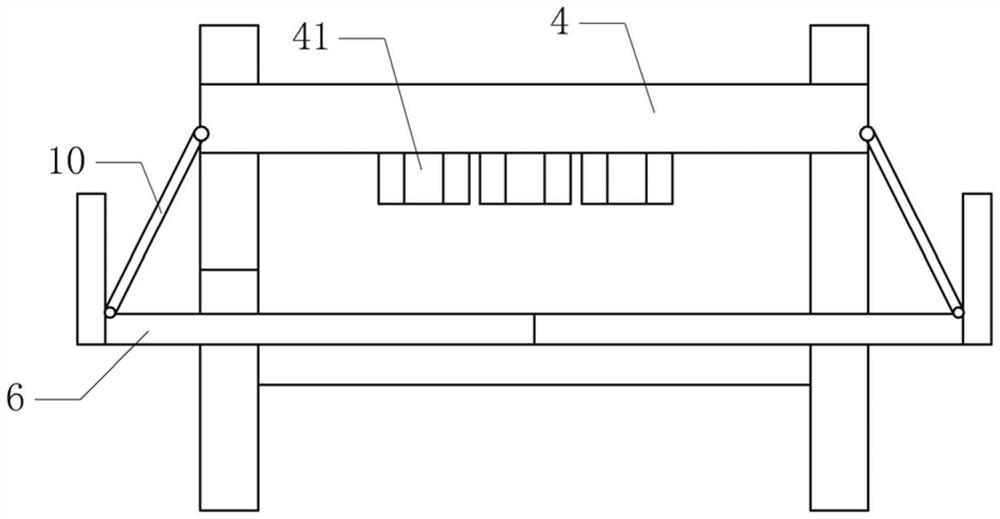

[0047] Embodiment 2 differs from Embodiment 1 only in that, as image 3 As shown, the driving member includes two push rods 10 hinged on the push rods, and the bottom ends of the two push rods 10 are respectively hinged on one end of the heat shield 6 outside the workbench 1 .

[0048] The specific implementation process is as follows:

[0049] When the cylinder drives the fixed block 4 to move down, the top of the push rod 10 moves down, and the length of the push rod 10 remains unchanged. In order to realize the downward movement of the top of the push rod 10, the bottom end of the push rod 10 will drive the heat shield 6 Move away from the direction of the workbench 1, and then realize the opening of the heat shield 6, which facilitates the hot pressing of the film. After the hot pressing is completed, the cylinder drives the fixed block 4 to move upward, thereby realizing the upward movement of the top of the push rod 10, and when the top of the push rod 10 moves upward, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com