Patents

Literature

40results about How to "Easy to heat press" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

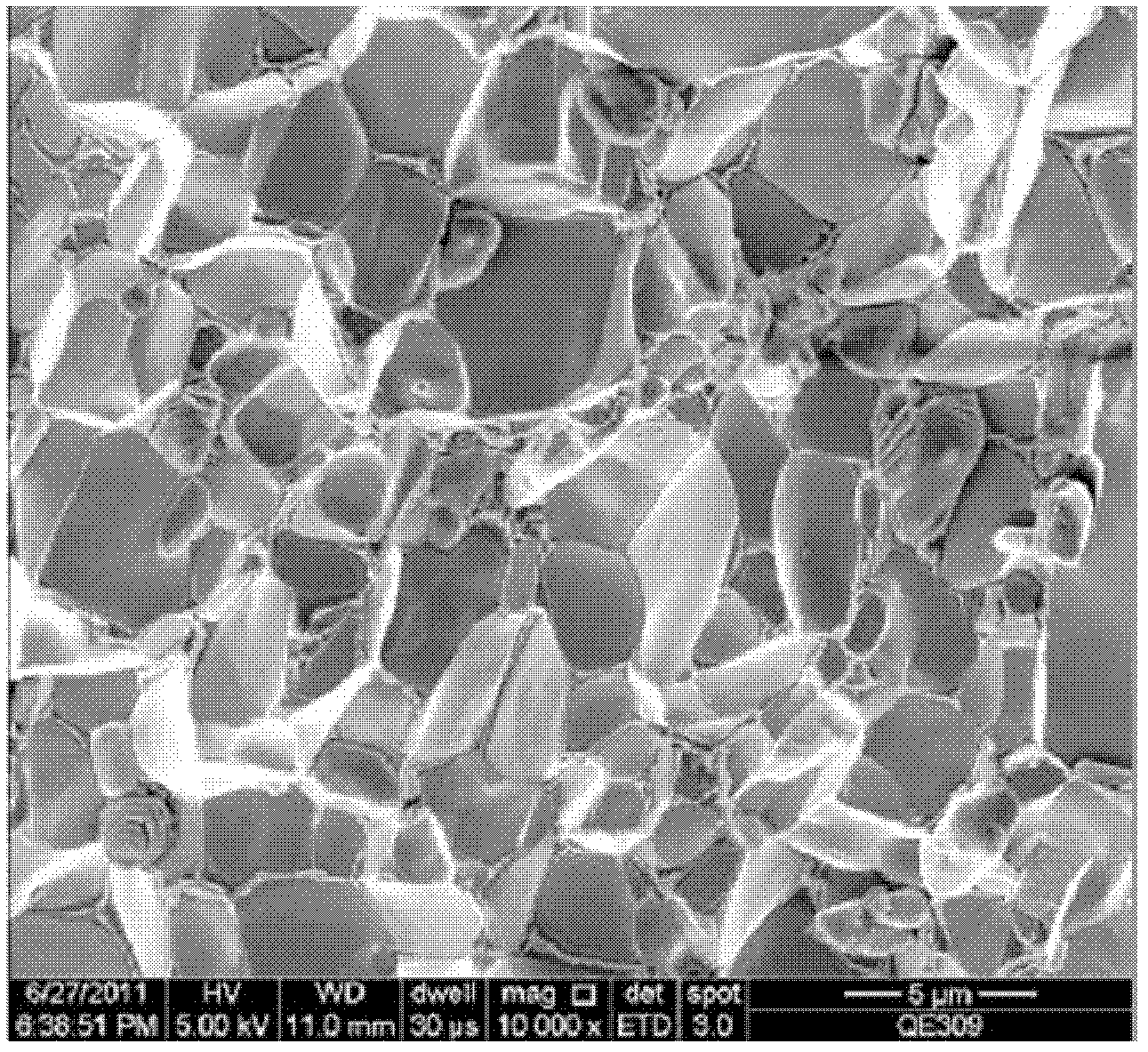

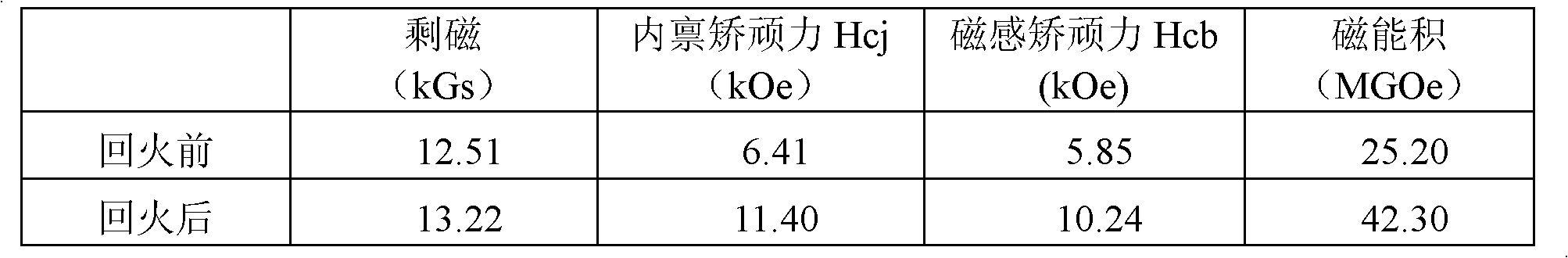

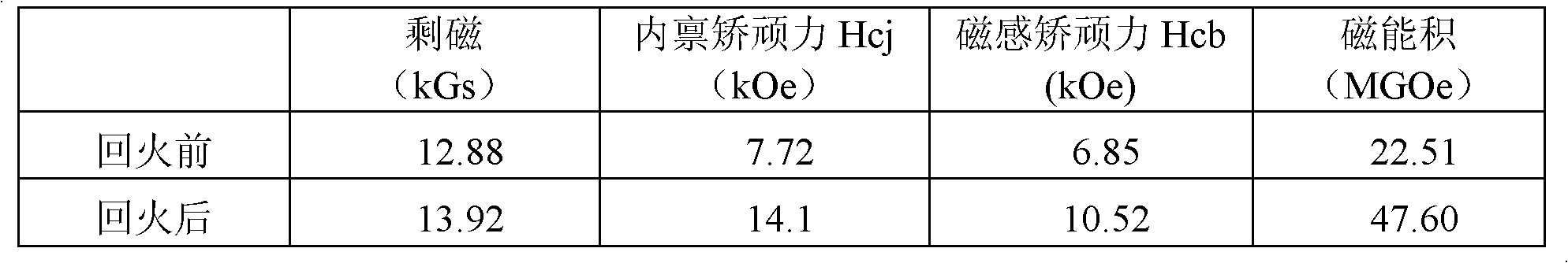

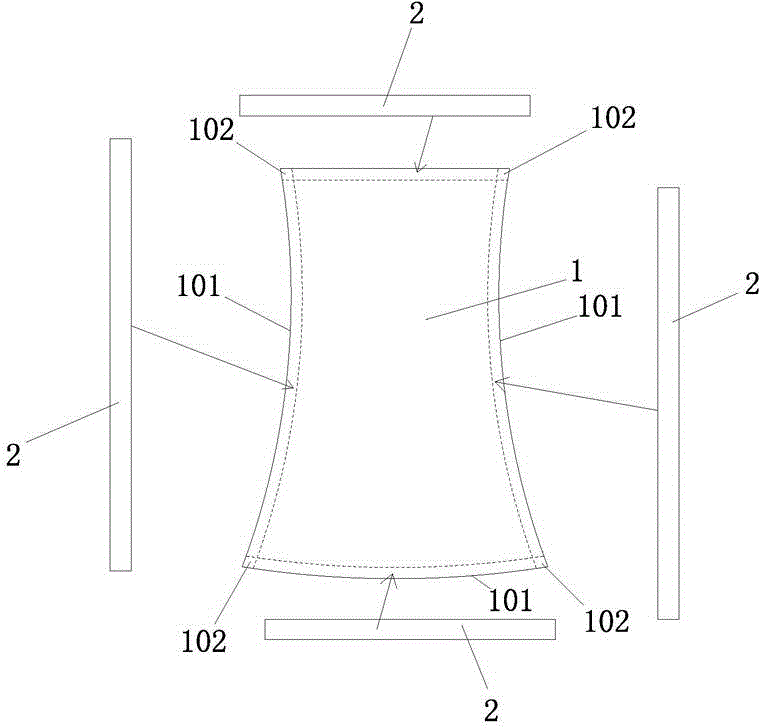

Preparation method for fine grain anisotropy densified neodymium iron boron permanent magnet

ActiveCN103123843ASmall sizeNo grain growth occurredPermanent magnetsInductances/transformers/magnets manufactureHydrogenGranularity

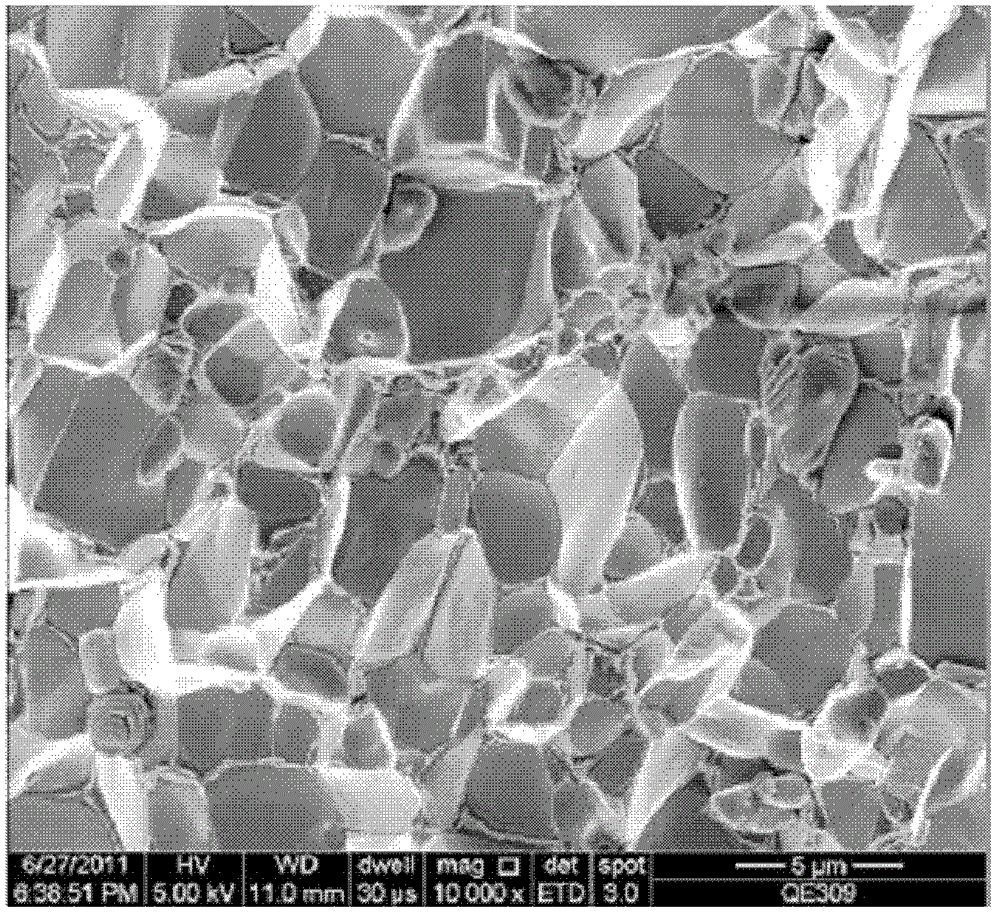

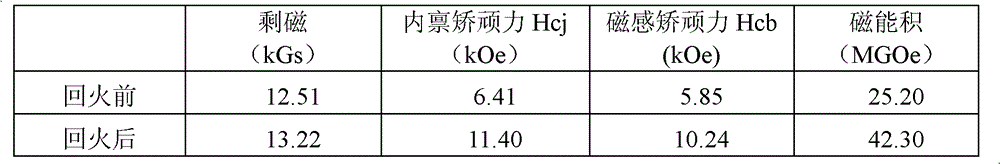

The invention relates to a preparation method for a fine grain anisotropy densified neodymium iron boron permanent magnet. The preparation method comprises the steps: traditional firing neodymium iron boron technology is adopted; a magnetic blank with small grains and loose texture is obtained by means of low-temperature presintering after rapid hardening, hydrogen breaking, air-stream milling and orientation forming; then the blank is hot-pressed and densified; and the anisotropy neodymium iron boron magnet with the small grains and densified is obtained after tempering is performed to the blank. According to the method, the grains in sintering process of magnet can be prevented from being larger effectively, the prepared magnet has a fine grain structure and is high in densification and the grain size of the fine grain anisotropy densified neodymium iron boron permanent magnet is close to air-stream milling powder granularity.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

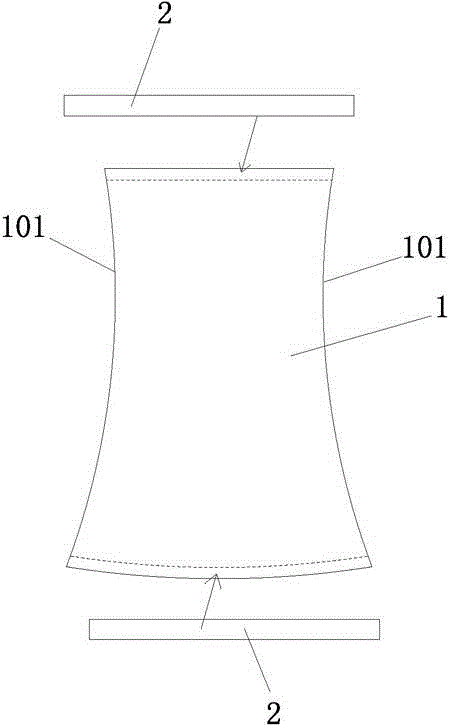

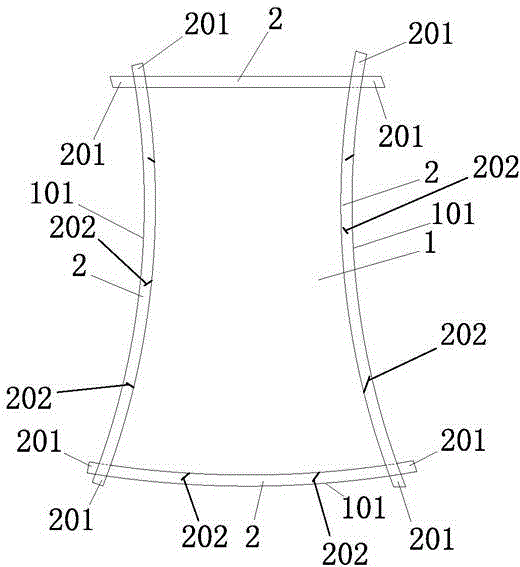

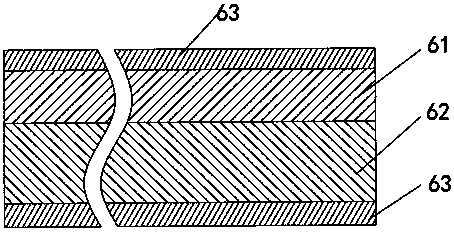

Seamless wave bottom of underpants and technology for compounding wave bottom and hot melting adhesive tape

InactiveCN106263047ANo archingReduce individually cut fabricsLamination ancillary operationsLaminationPhysicsHot pressing

The invention relates to a seamless wave bottom of underpants and a technology for compounding the wave bottom and a hot melting adhesive tape. The seamless wave bottom comprises a wave bottom fixing area arranged on an underpants main body, and the wave bottom is formed on the wave bottom fixing area through seamless pressure pasting; the seamless wave bottom is characterized in that the hot melting adhesive tape with the width being L is arranged on the wave bottom close to the contour edge, the hot melting adhesive tape is arranged in a manner of integrally extending along the contour edge of the wave bottom, and the wave bottom is formed on the wave bottom fixing area through hot-pressing laminating by adopting the hot melting adhesive tape. The technology for compounding the wave bottom and the hot melting adhesive tape comprises the following steps: (1) slitting a hot melting adhesive film and a fabric of the wave bottom; (2) punching a positioning hole and an inner frame hole; (3) carrying out thermal compounding on the hot melting adhesive film and the fabric; and (4) forming the wave bottom finished product through die cutting and integrated blanking. The process is simple and reasonable, the processing efficiency is high, the operation is safe and reliable, the technology is energy-saving and environmentally friendly, and the production cost is greatly reduced.

Owner:佛山市真北工业技术材料有限公司

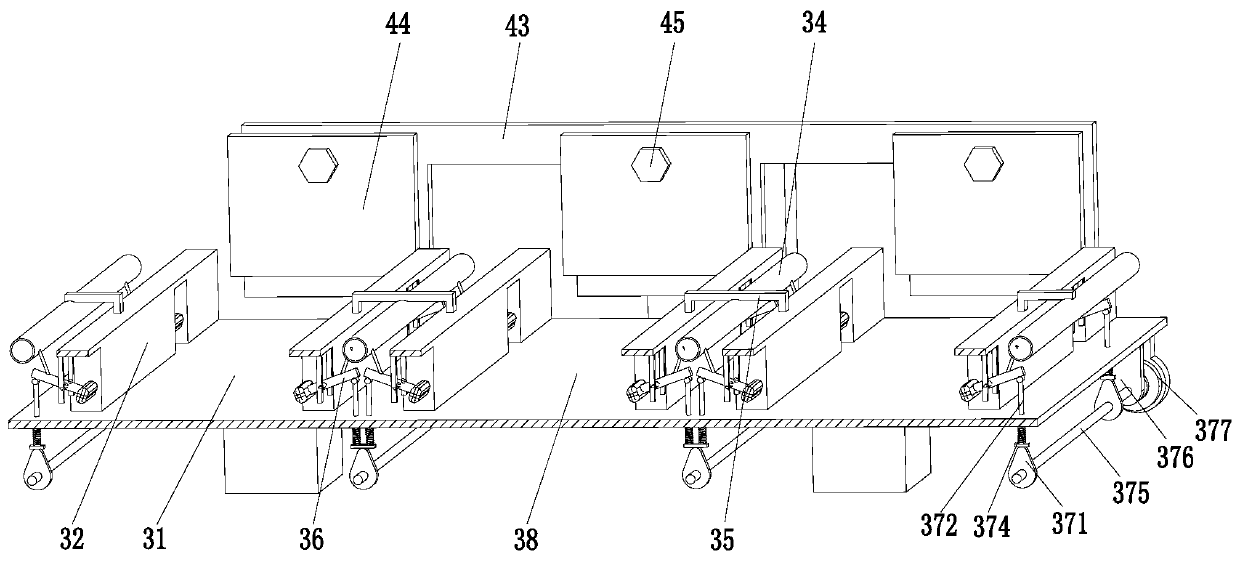

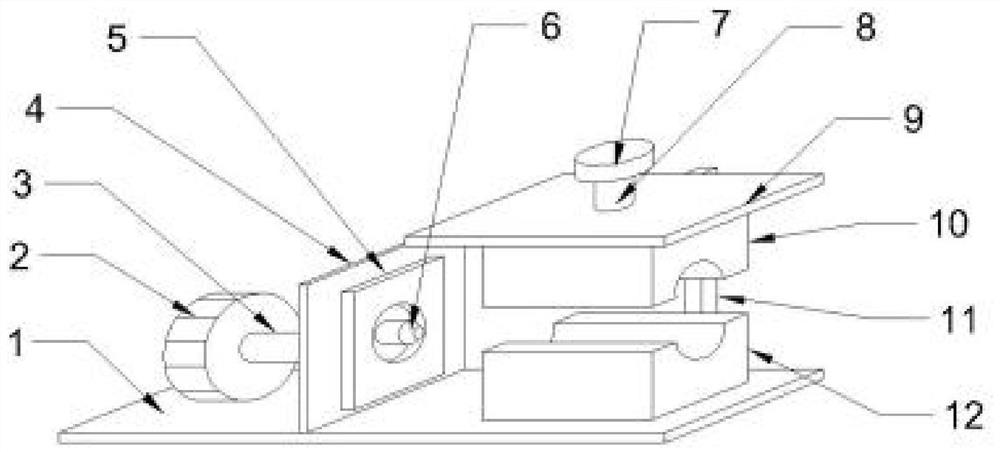

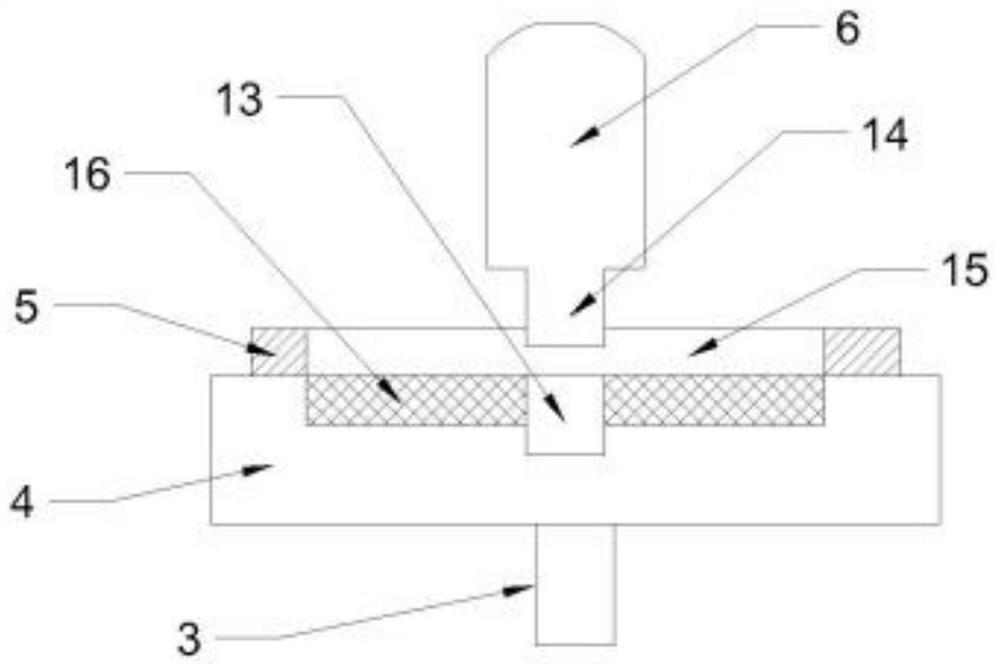

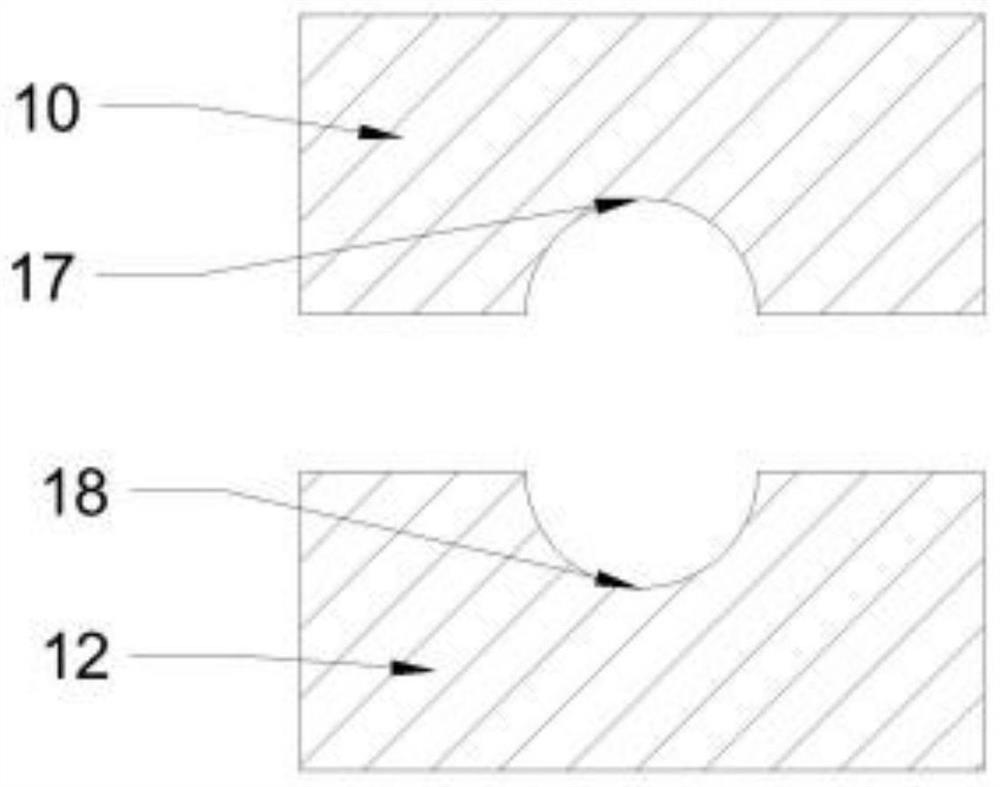

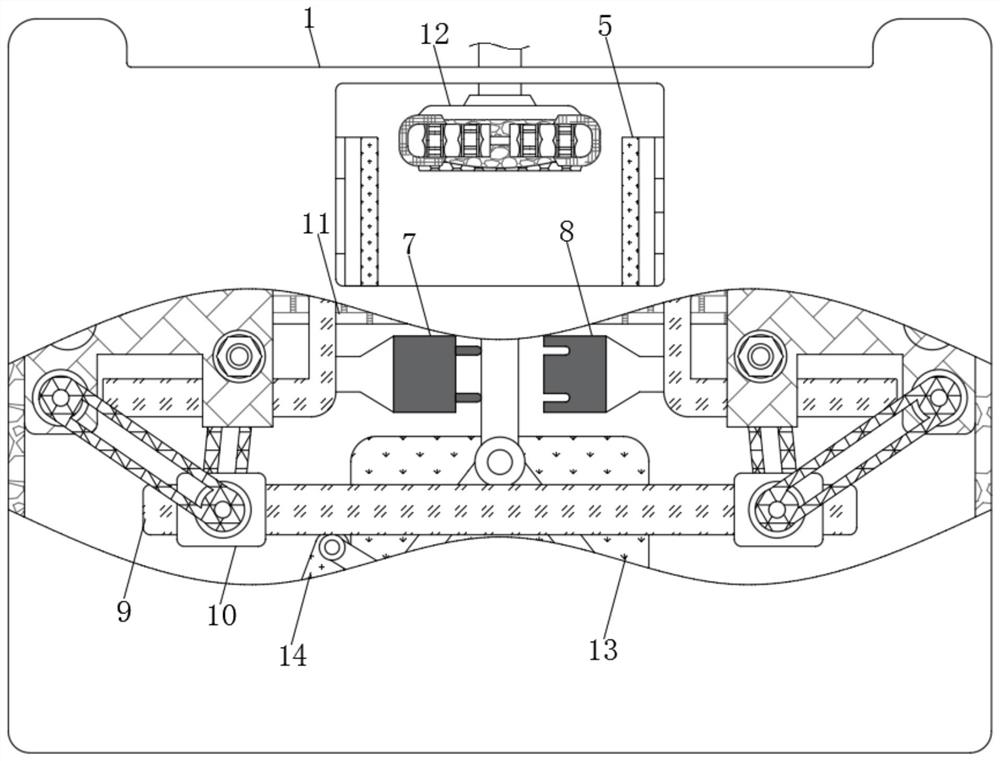

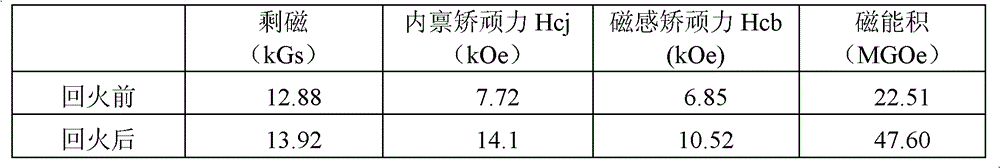

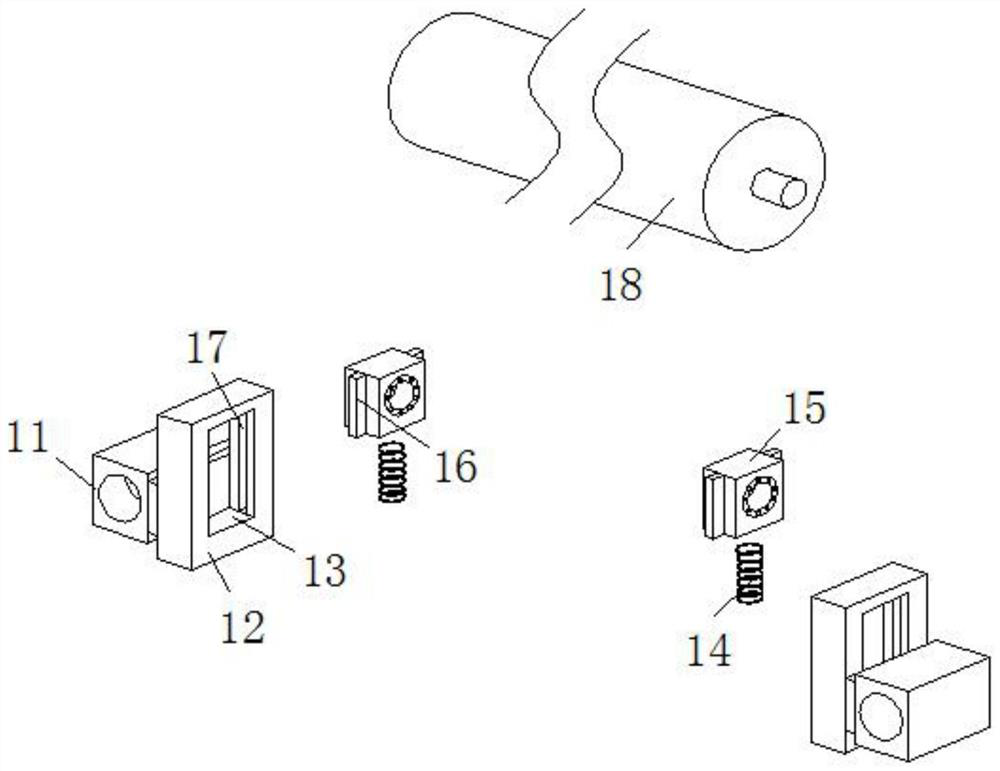

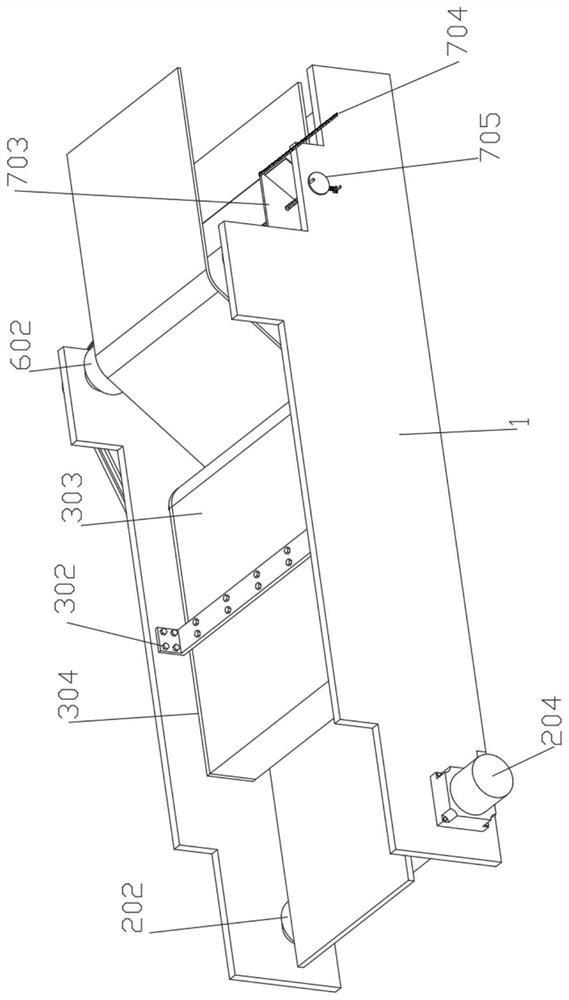

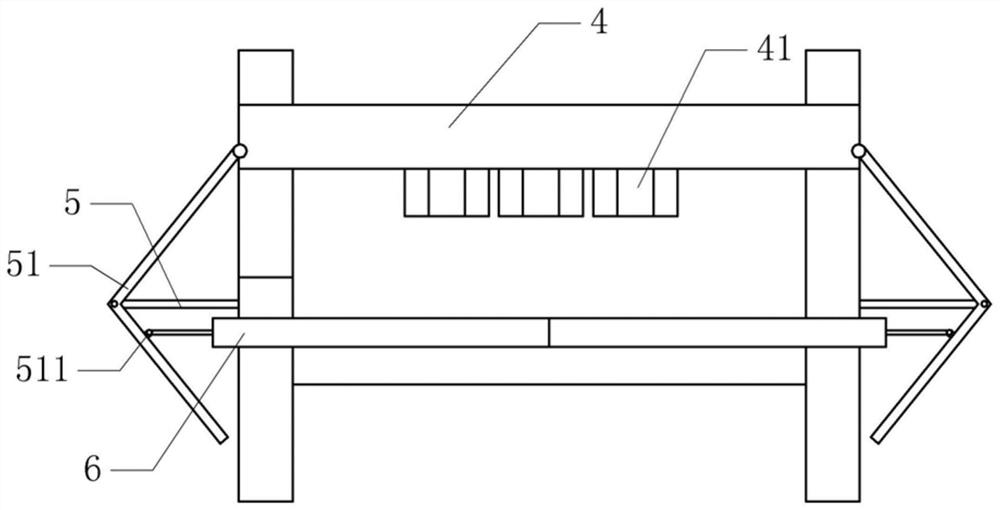

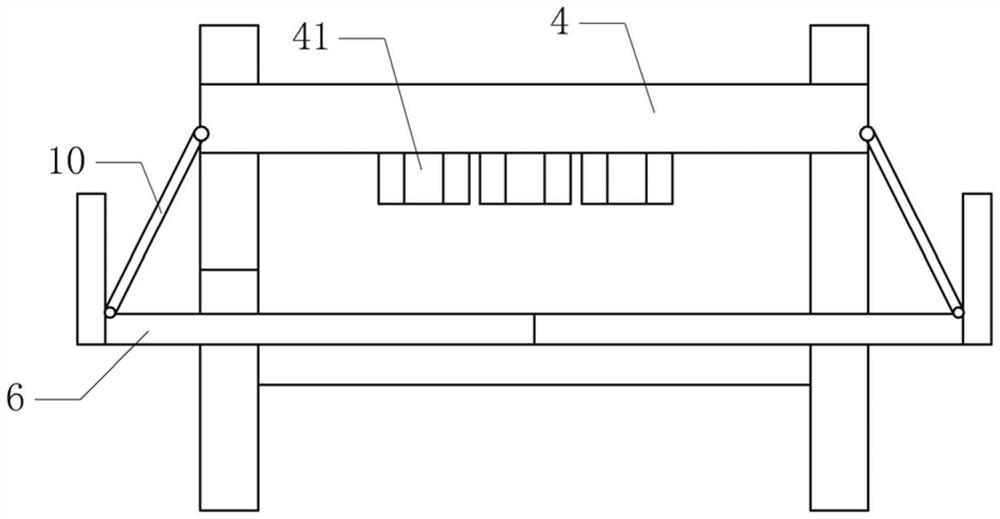

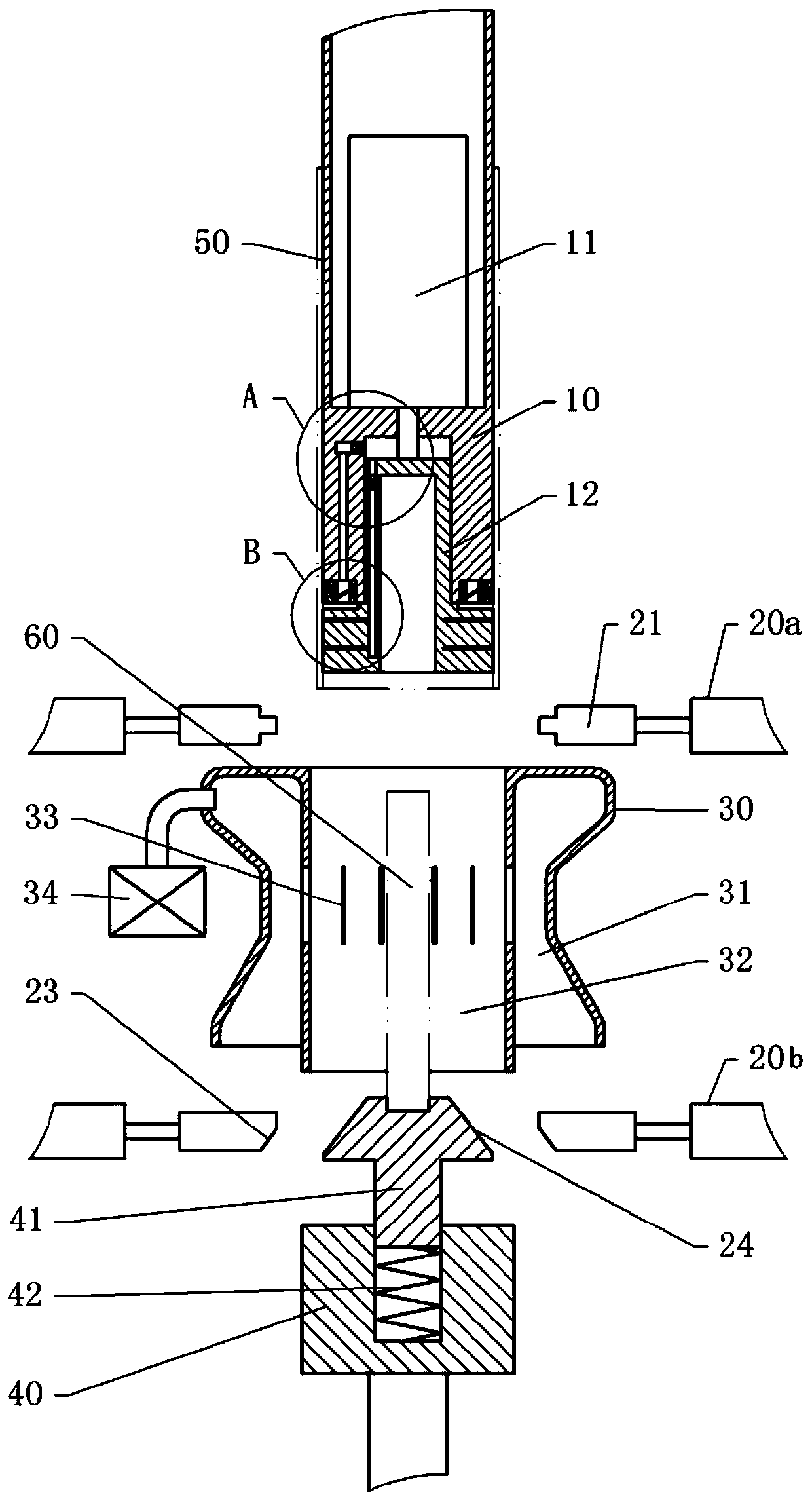

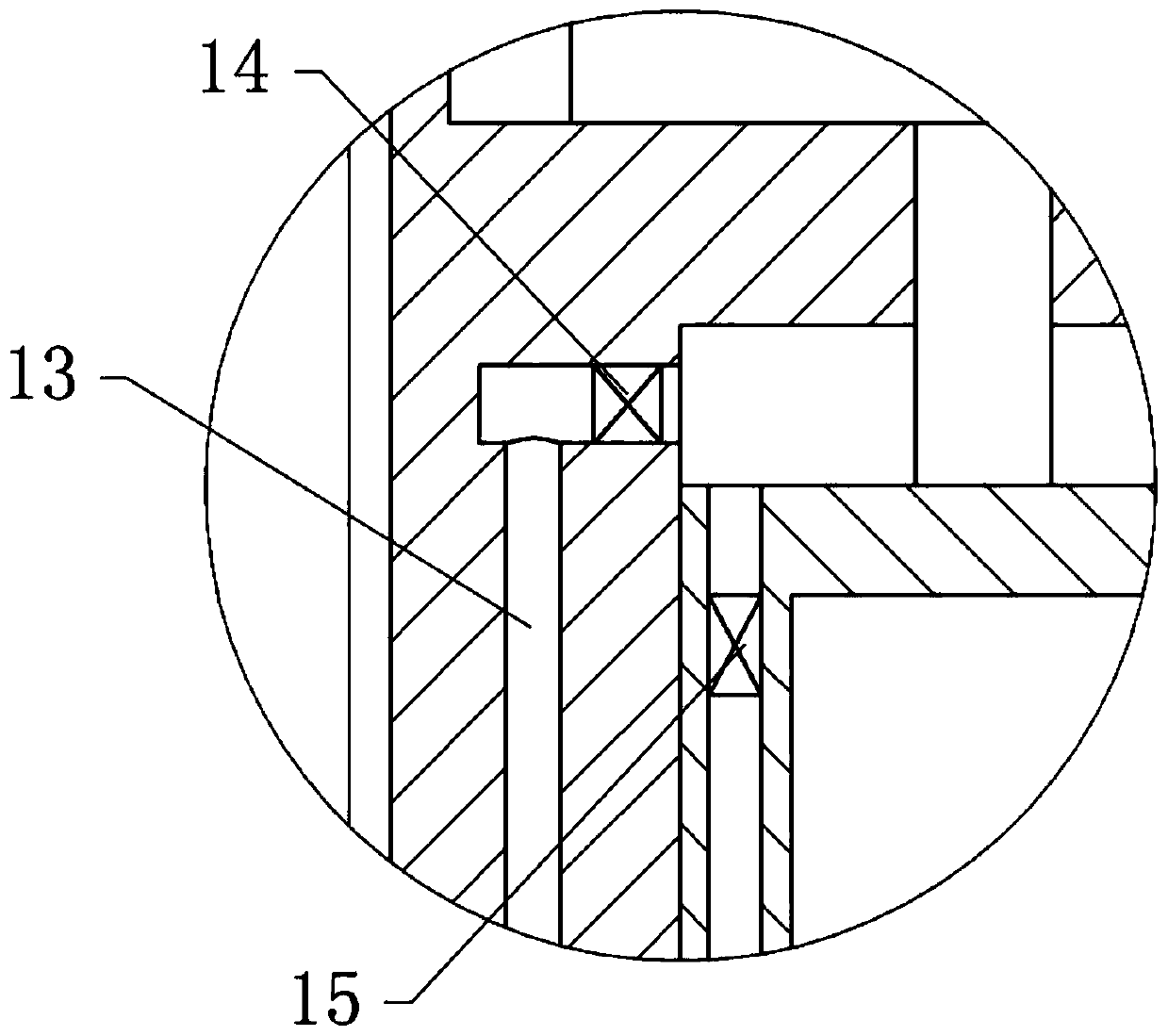

Hot pressing setting device and hot pressing setting method for ribbon fabric

InactiveCN110820191AEasy ironingImprove the effect of hot pressingHeating/cooling textile fabricsTextile treatment by spraying/projectingEngineeringMechanical engineering

The invention relates to a hot pressing setting device and hot pressing setting method for ribbon fabric. The hot pressing setting device for ribbon fabric comprises a bottom plate, a top plate, a hotsteaming device, leveling mechanisms, a pressing-down mechanism and an ironing mechanism; the top plate is arranged on a fixed surface, such as a wall surface, and the hot steaming device is arrangedabove the bottom plate; the bottom end of the hot steaming device is arranged in the middle of the top end of the bottom plate; the leveling mechanisms are symmetrically arranged on the left side andright side of the hot steaming device; the bottoms of the leveling mechanisms are mounted on the top end of the bottom plate; the top end of the pressing-down mechanism is mounted in the middle of the bottom end of the top plate and arranged on the upper left side of the bottom plate; the ironing mechanism is positioned below the pressing-down mechanism; the top end of the ironing mechanism is fitted on the bottom end of the pressing-down mechanism. The invention can solve the problems that, for instance, a ribbon cane not fully wetted by manual spraying wetting, and an iron easily scorches the part of the ribbon not fully wetted, so that product quality of the ribbon is affected, and that manual ironing of the ribbon has low production efficiency, so that the manual ironing is unable toadapt to large-scale production.

Owner:汪永超

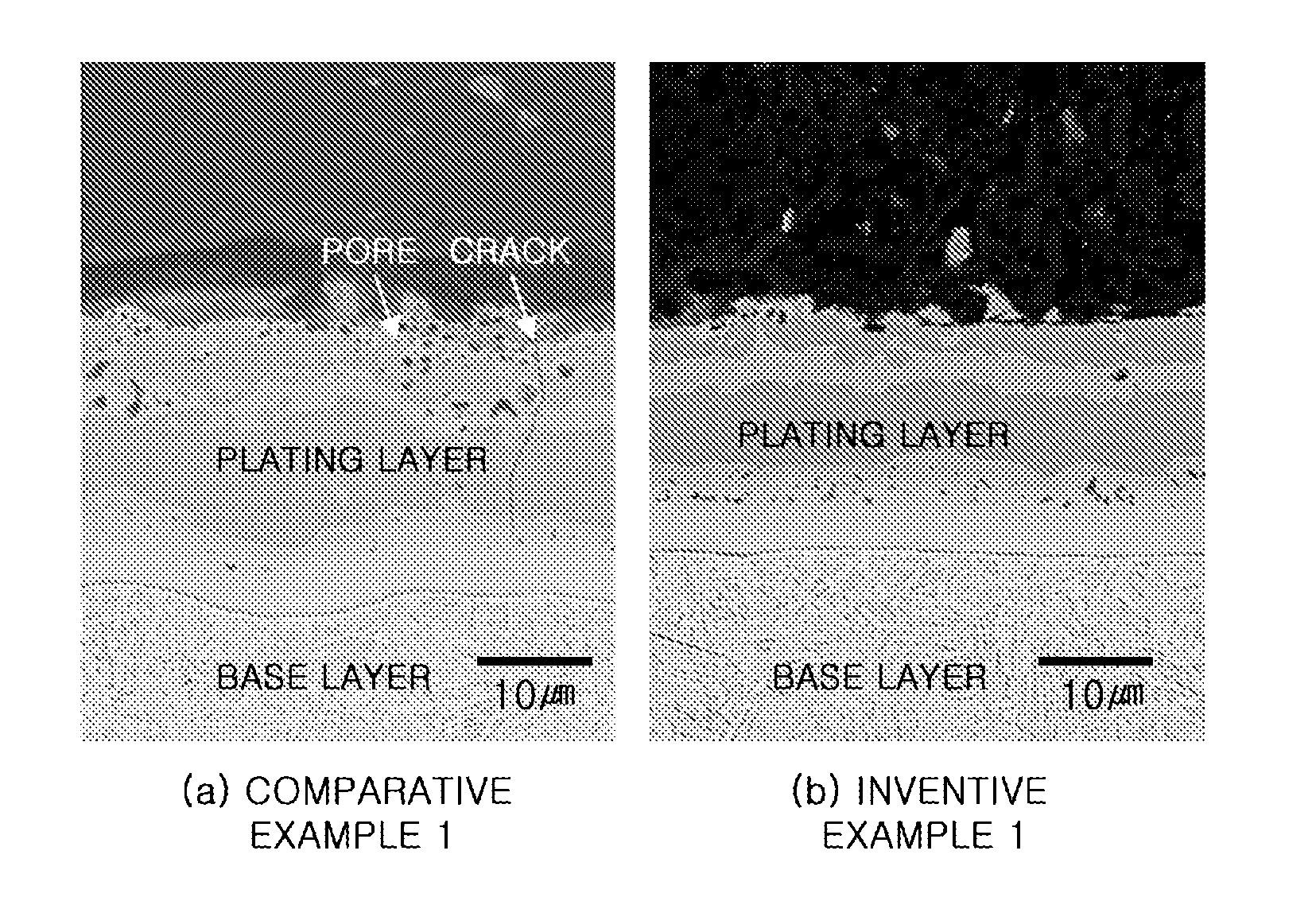

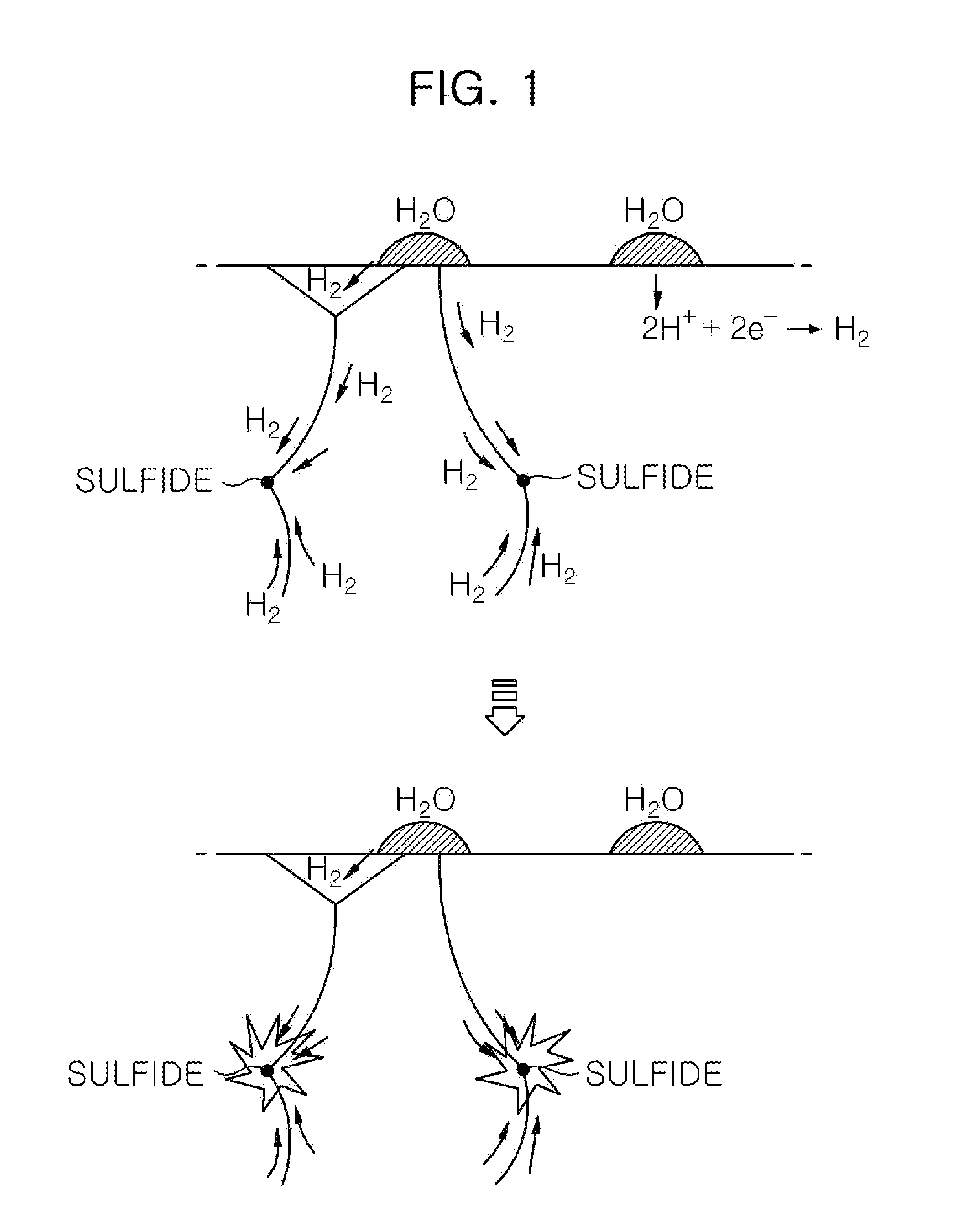

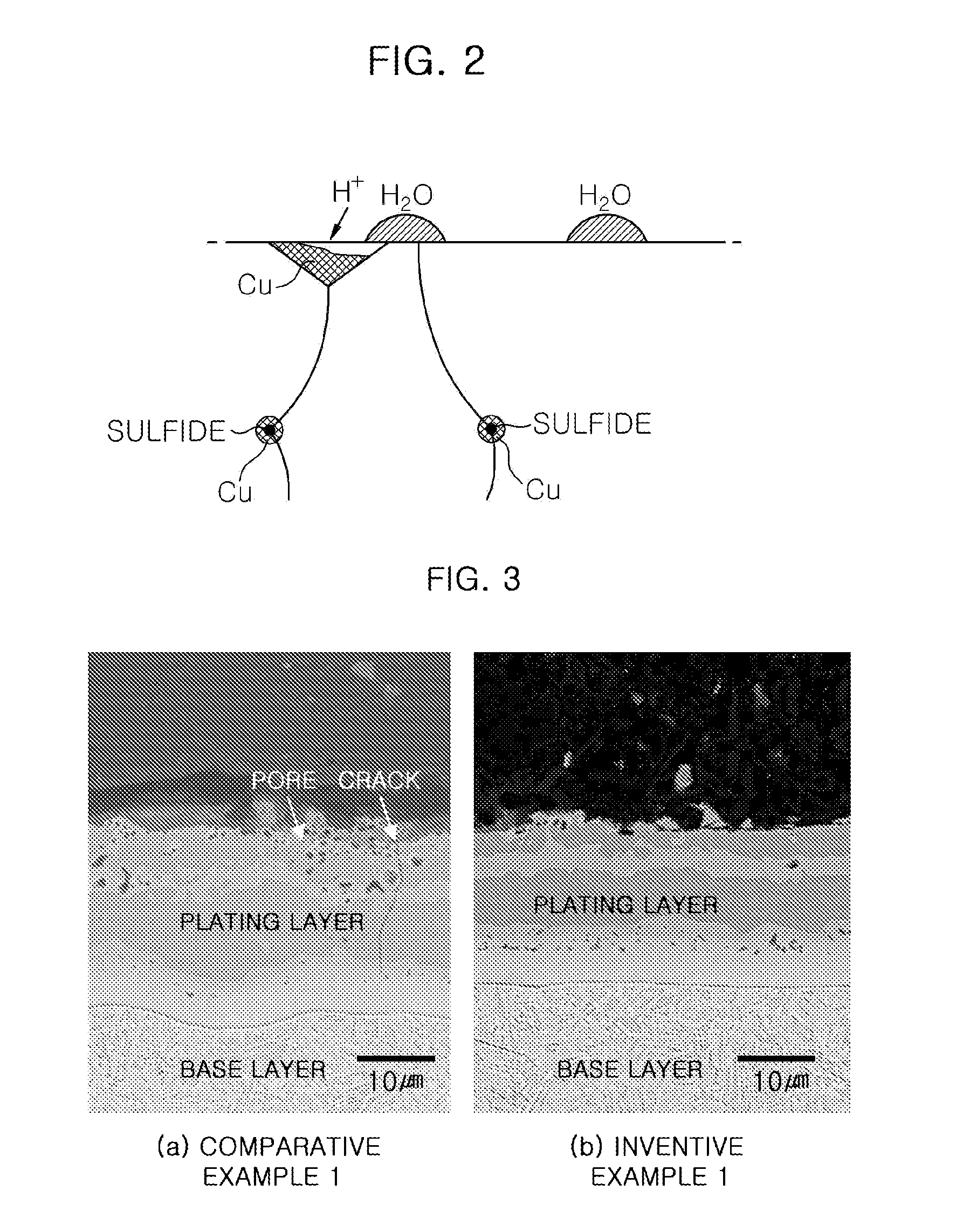

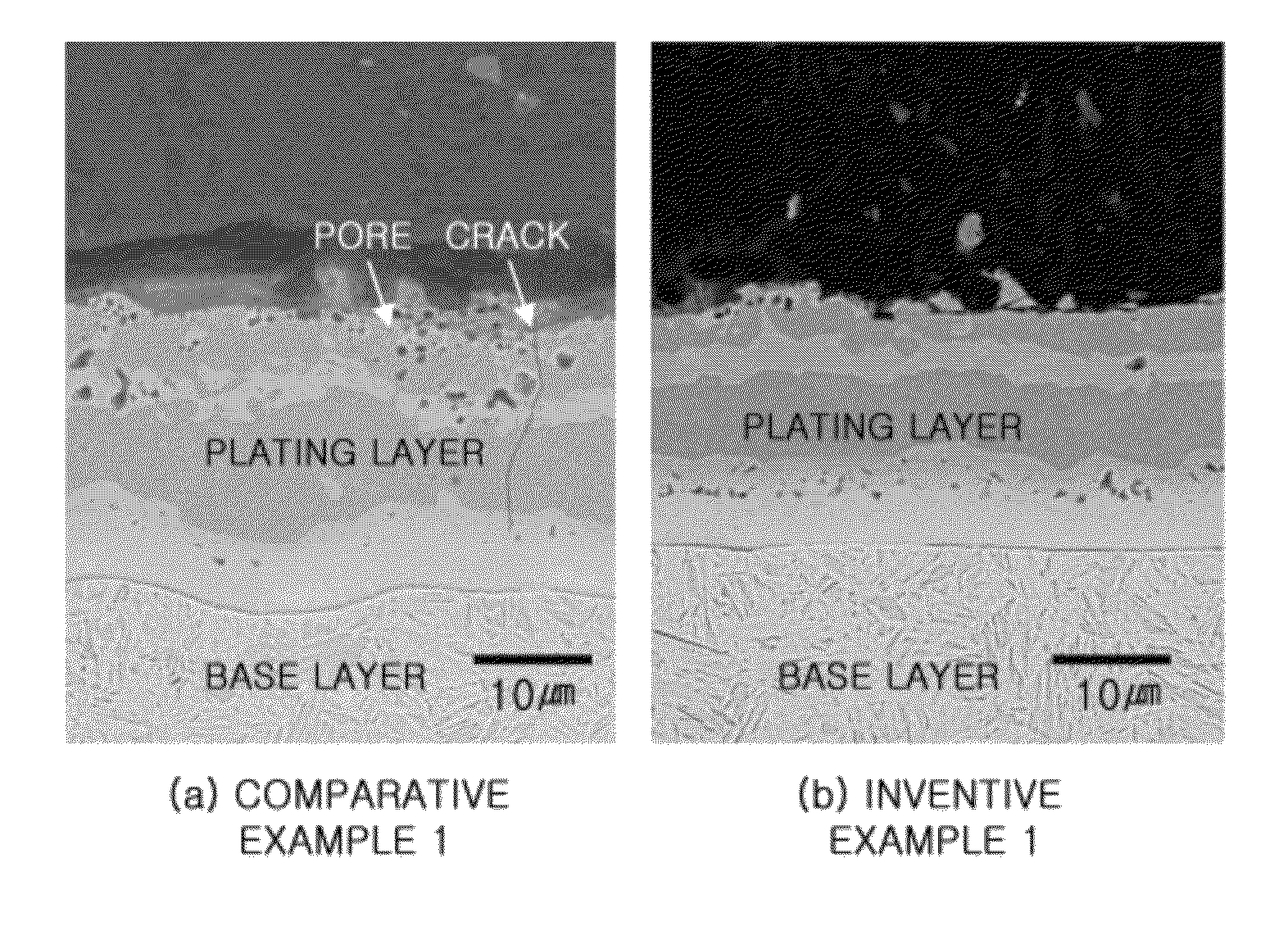

Quenchable steel sheet having high hot press workability and method of manufacturing the same

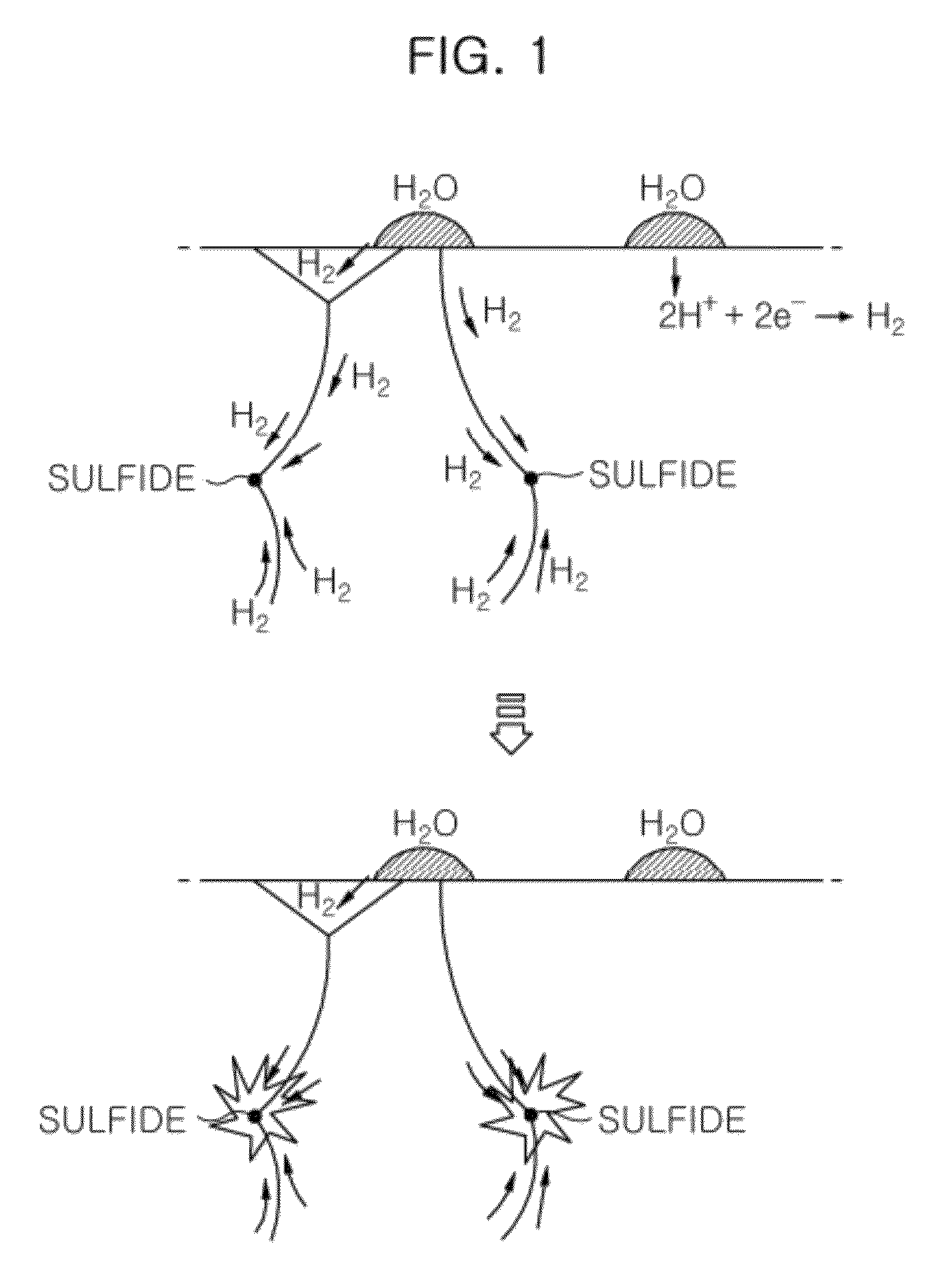

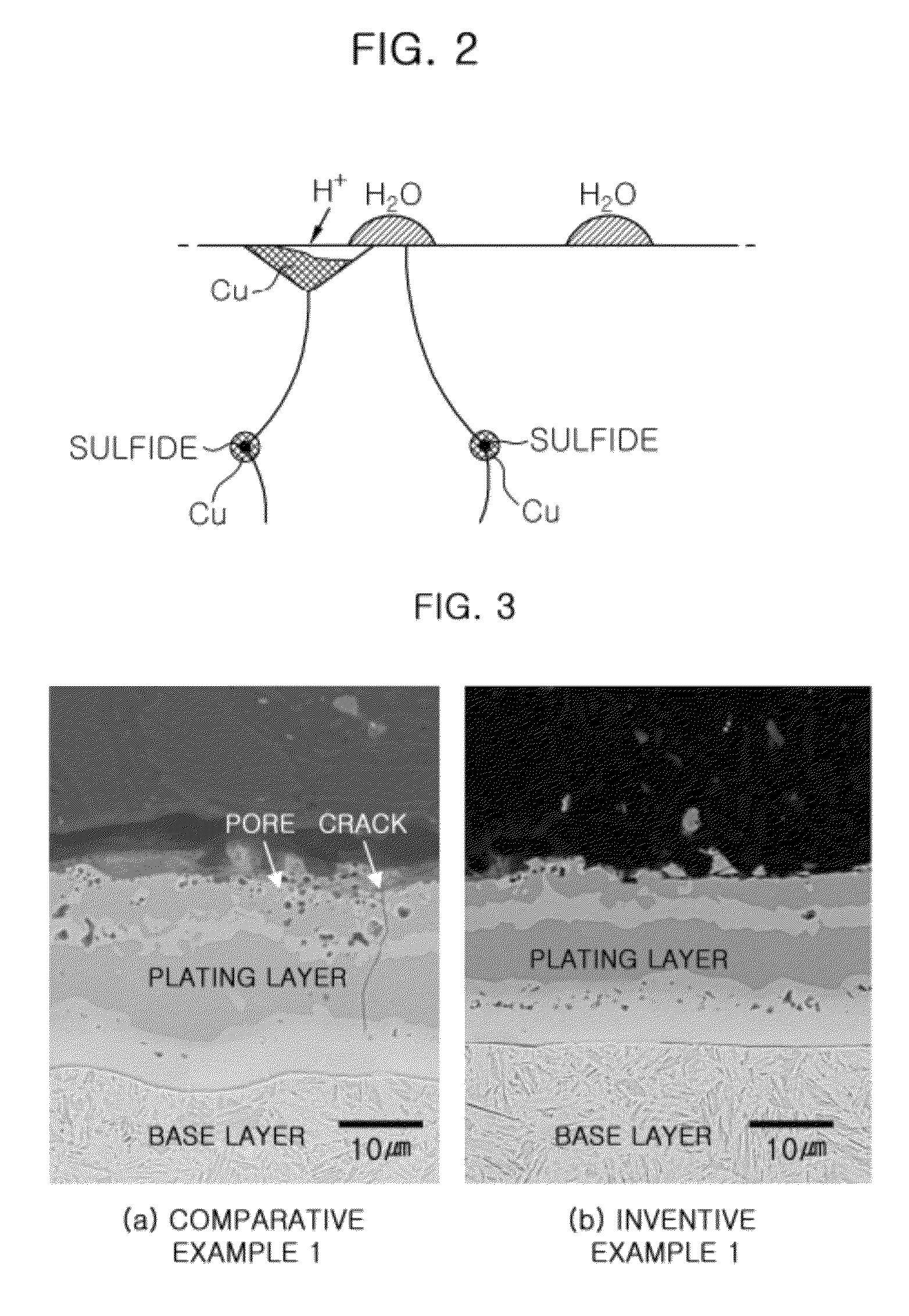

ActiveUS20110159314A1Improve corrosion resistanceMaximize economic benefitsHot-dipping/immersion processesThin material handlingAlloy elementHot press

The quenchable steel sheet has an alloy composition including carbon (C) in an amount of 0.15˜0.30 wt %, silicon (Si) in an amount of 0.05˜0.5 wt %, manganese (Mn) in an amount of 1.0˜2.0 wt %, boron (B) in an amount of 0.0005˜0.0040 wt %, sulfur (S) in an amount of 0.003 wt % or less, phosphorus (P) in an amount of 0.012 wt % or less, one or more selected from among calcium (Ca) in an amount of 0.0010˜0.0040 wt % and copper (Cu) in an amount of 0.05˜1.0 wt %, two or more selected from among cobalt (Co), zirconium (Zr) and antimony (Sb), and iron (Fe). Alloy elements are controlled to increasing hot ductility and enabling pressing at 600˜900° C. so that a tensile strength of 1400 MPa or more and an elongation of 8% or more are obtained after pressing.

Owner:HYUNDAE STEEL CO LTD

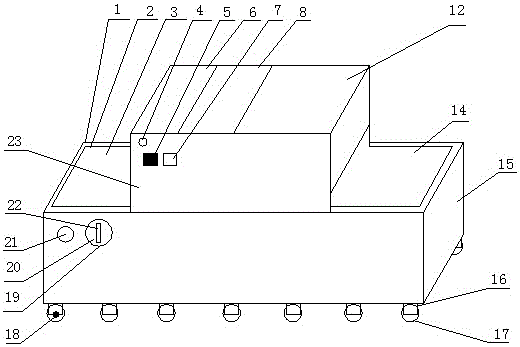

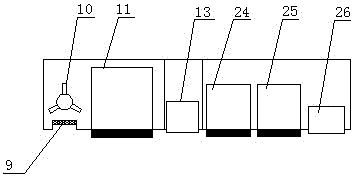

Hot press

InactiveCN110239190ASticky and firmEasy to heat pressLaminationLamination apparatusSupport planeHot press

The invention discloses a hot press. According to the technical scheme, the hot press comprises a base; the base is connected with a supporting frame; an upper die base and a lifting mechanism for driving the upper die base to move up and down are arranged on the supporting frame; a lower die base is arranged on the base; the upper die base comprises a heating plate and a pressing plate connected with the heating plate; the lower die base comprises a supporting block and a containing plate which is arranged corresponding to the pressing plate; a cavity is formed in the containing plate; the cavity is connected with a plurality of vent holes communicating with the surface of the containing plate; and the cavity is connected with a negative pressure device. The scheme provided by the invention can prevent a fabric from being misplaced and deformed.

Owner:成工业制衣(苏州)有限公司

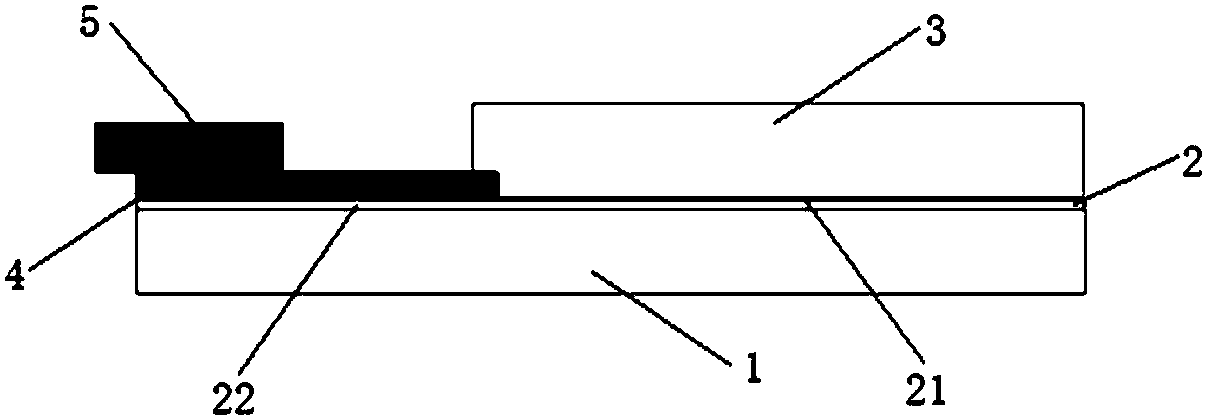

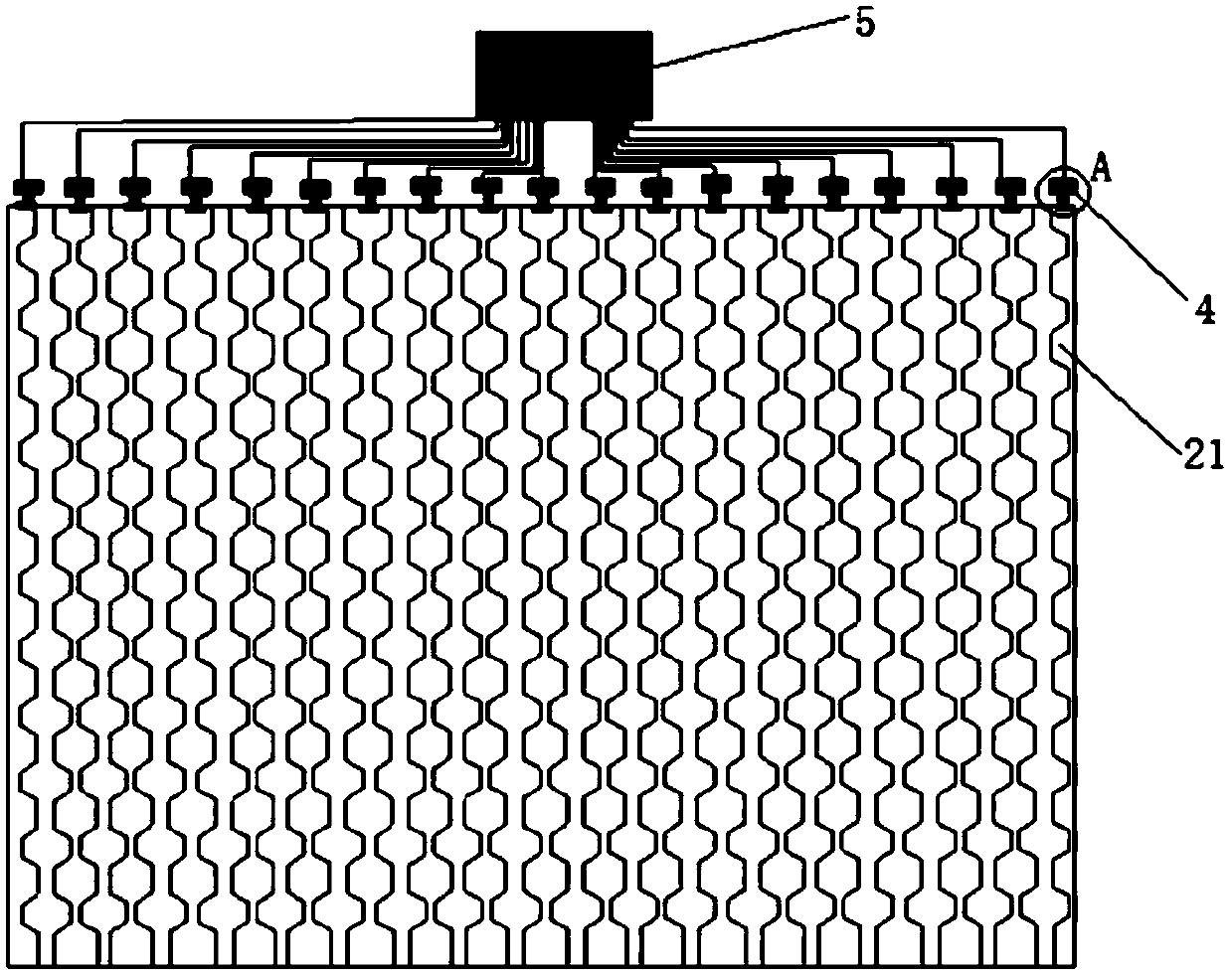

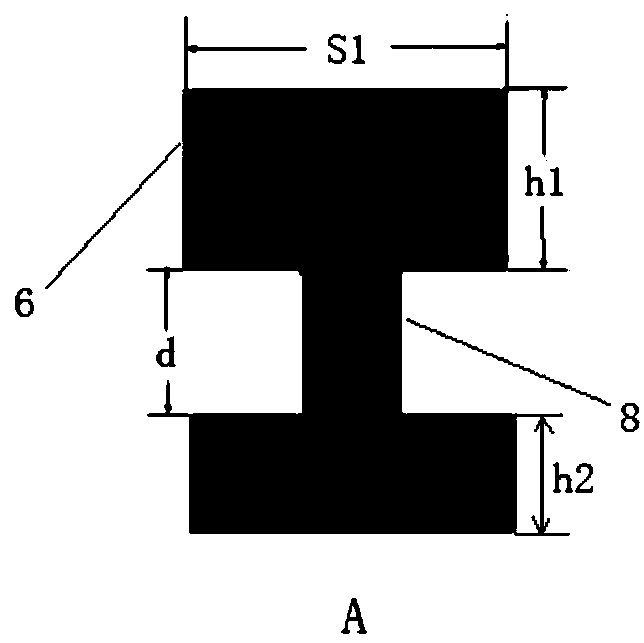

A capacitive touch screen and terminal equipment

PendingCN109683752AAvoid damage to silver nanowiresImprove protectionMaterial nanotechnologyConductive layers on insulating-supportsSilver pasteLaser etching

The invention relates to the field of touch screens, in particular to a capacitive touch screen. The capacitive touch screen comprises a base material and a silver nanowire conducting layer coated onthe base material, wherein the silver nanowire conducting layer comprises a visible area and a binding area, OCA optical cement is attached to the visible area, a connecting circuit is printed from the inner edge of the visible area to the binding area, and the silver nanowire conducting layer is connected with the flexible circuit board through the connecting circuit. According to the invention,the silver nanowires are used as the conductive layer, and the connection line is printed in the conductive layer binding area, so that the connection between the conductive layer and the flexible circuit board is realized, and the phenomenon that the silver nanowires are damaged due to the direct binding between the flexible circuit board and the conductive layer is avoided; And the printed silver paste does not need to be etched, so that the problem of environmental pollution caused by destructive particles generated by laser etching or acid-base etching is avoided. And by printing a connecting circuit, the protection of the silver nanowires from the conductive layer binding region to the visible region can be realized.

Owner:SHENZHEN HUAKE COMM TECH CO LTD

Efficient film laminating machine

The invention belongs to the technical field of film laminating machine equipment, and discloses an efficient film laminating machine. The efficient film laminating machine comprises a film laminating machine body. The film laminating machine body comprises a work room and a machine base. The work room is fixedly connected with the machine base and provided with a master opening key. One side of the master opening key is provided with a master closing key. One side of the work room is provided with a power source indicating lamp. The work room is provided with a film laminating room. A drying room is fixedly connected with one side of the film laminating room. A hot-pressing room is arranged on one side of the drying room. The machine base is provided with a conveying belt and a conveying switch. One side of the conveying switch is provided with a rotating speed adjuster. The rotating speed adjuster is provided with a rotating speed dial plate. The rotating speed dial plate is provided with a rotating speed adjusting rotary knob. One side of the machine base is provided with a feeding table. The other side of the machine base is provided with a discharging table. A foundation of the machine base is provided with multiple supporting feet. One side of each supporting foot is fixedly connected with a rolling wheel. By means of the rolling wheels at the bottom of the machine base, the device can be easily moved.

Owner:王剑

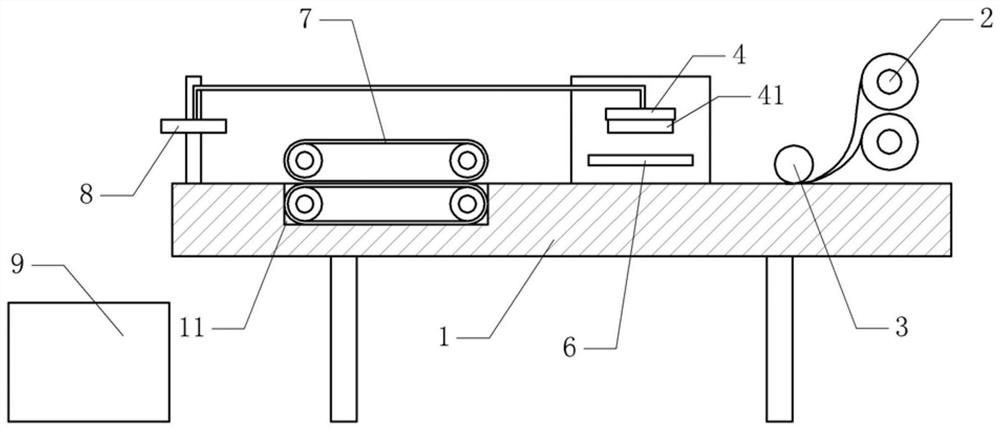

Film laminating device

InactiveCN107933087AReduce processing costsEasy to operateLayered productsLaminationPulp and paper industryCam

The invention belongs to the technical field of printed matter machining, in particular to a film laminating device comprising a paper feeding mechanism, a hot-pressing mechanism, a film conveying mechanism and a collecting mechanism. The paper feeding mechanism, the film conveying mechanism, the hot-pressing mechanism and the collecting mechanism are sequentially arranged in the conveying direction of the paper. The hot-pressing mechanism comprises a communication column, a downward-pressing plunger and an upward-pressing plunger. Hydraulic oil and a heating device are arranged in the communicating column. The downward-pressing plunger and the upward-pressing plunger are connected to the upper portion and the lower portion of the communicating column in a sliding manner. The downward-pressing plunger is provided with a cutter. The surface of the upward-pressing plunger is provided with a groove. A jacking column is fixed into the lower portion of the communicating column. The jackingcolumn penetrates through the upward-pressing plunger. The collecting mechanism comprises a cam, a power motor and a collecting cylinder. The collecting cylinder communicates with the communicating column. A piston is connected into the collecting cylinder in a sliding manner. The cam is rotationally connected into the communicating column. The cam drives the piston to move in a reciprocating manner along the collection cylinder. By the adoption of the film laminating device, after film laminating, paper cutting can be completed, and the cut paper can also be collected and piled in order.

Owner:重庆渝州印务厂

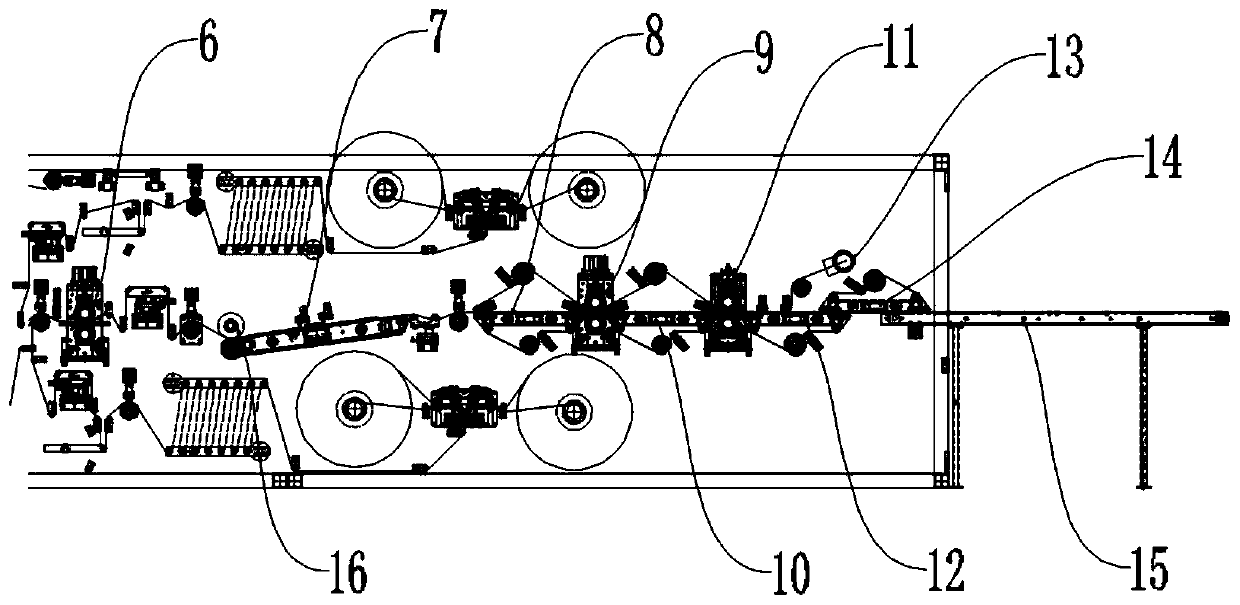

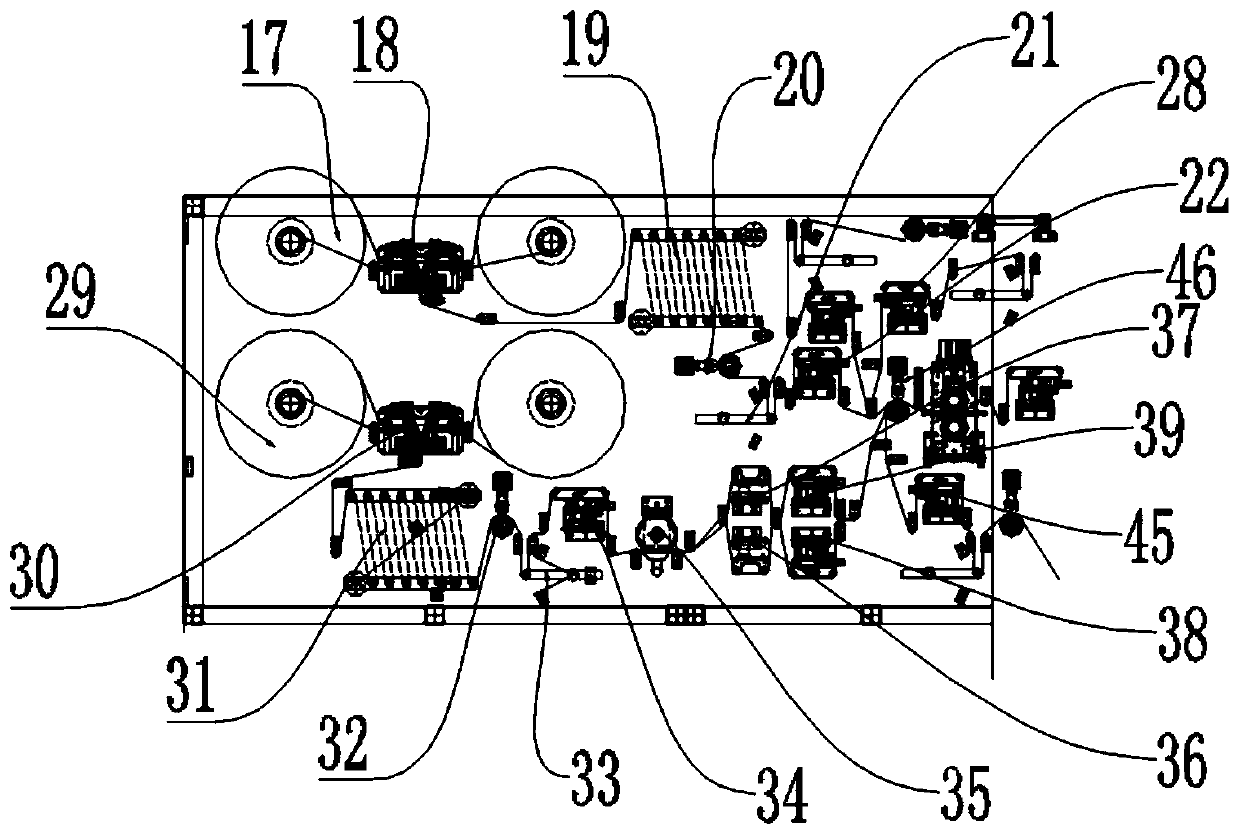

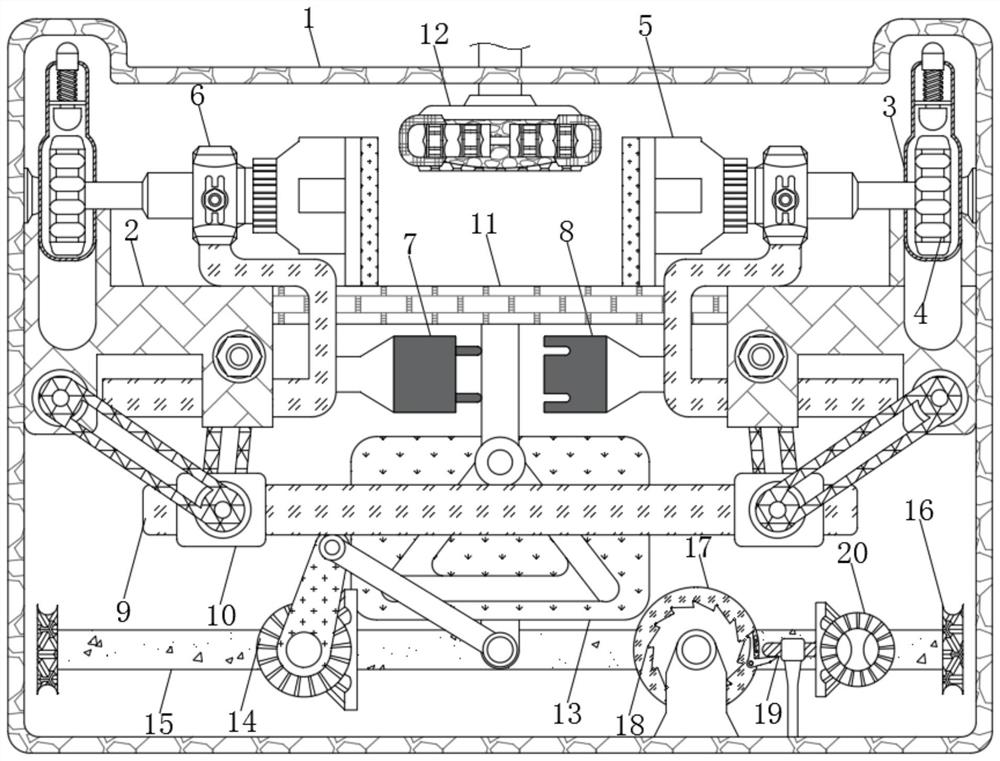

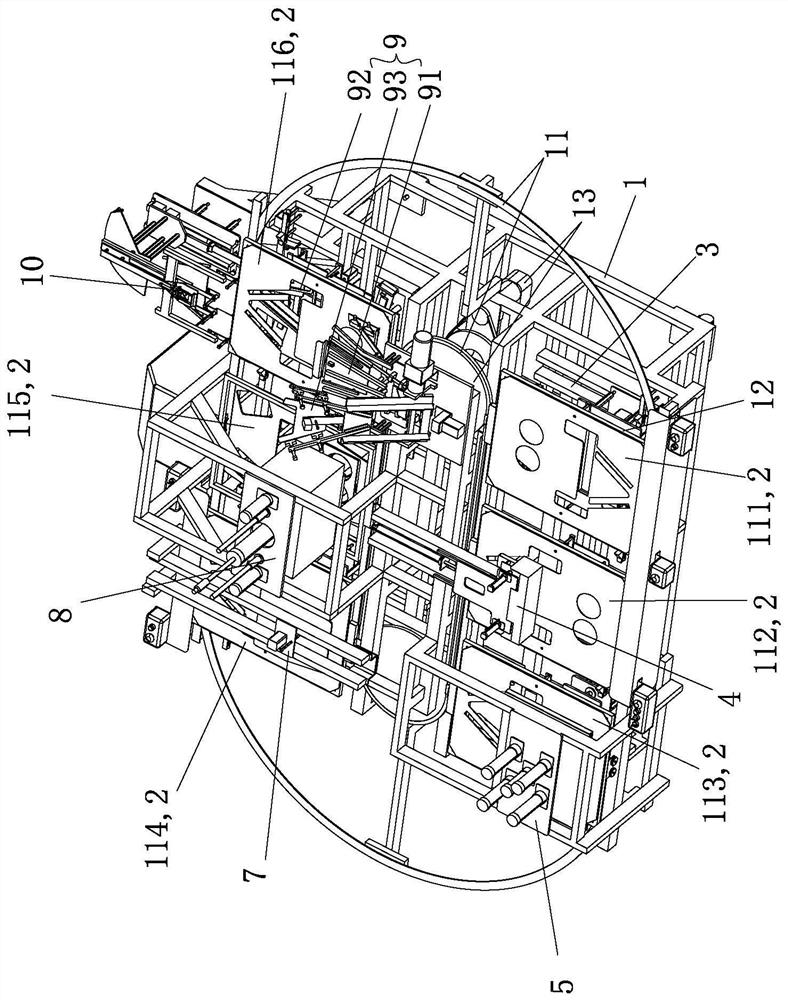

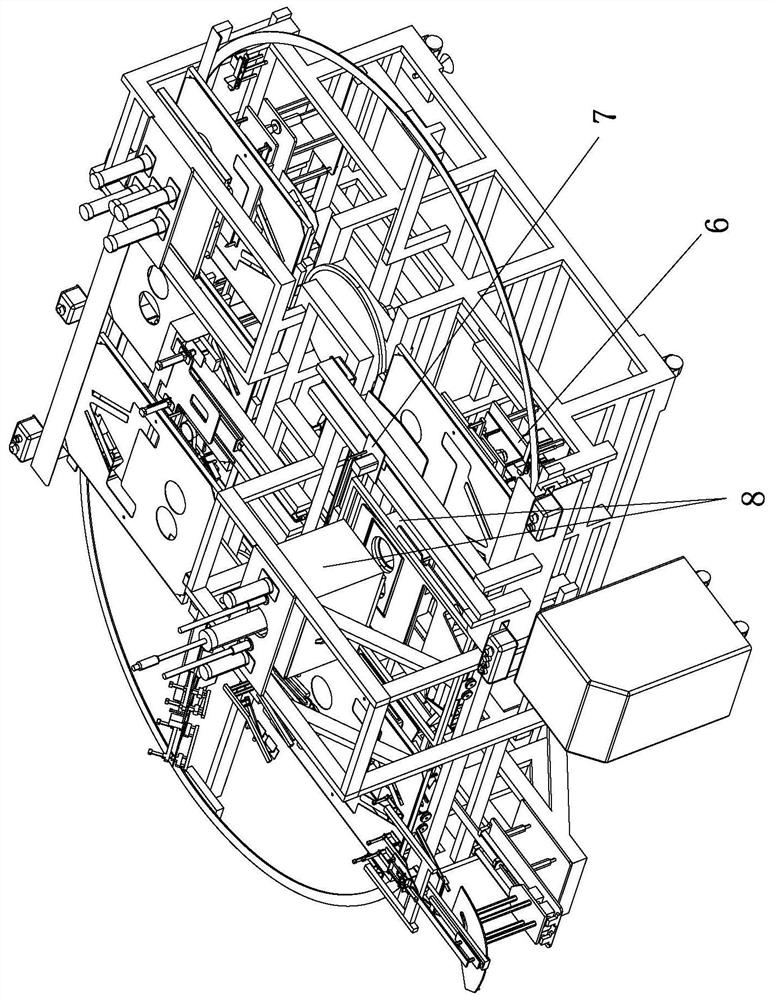

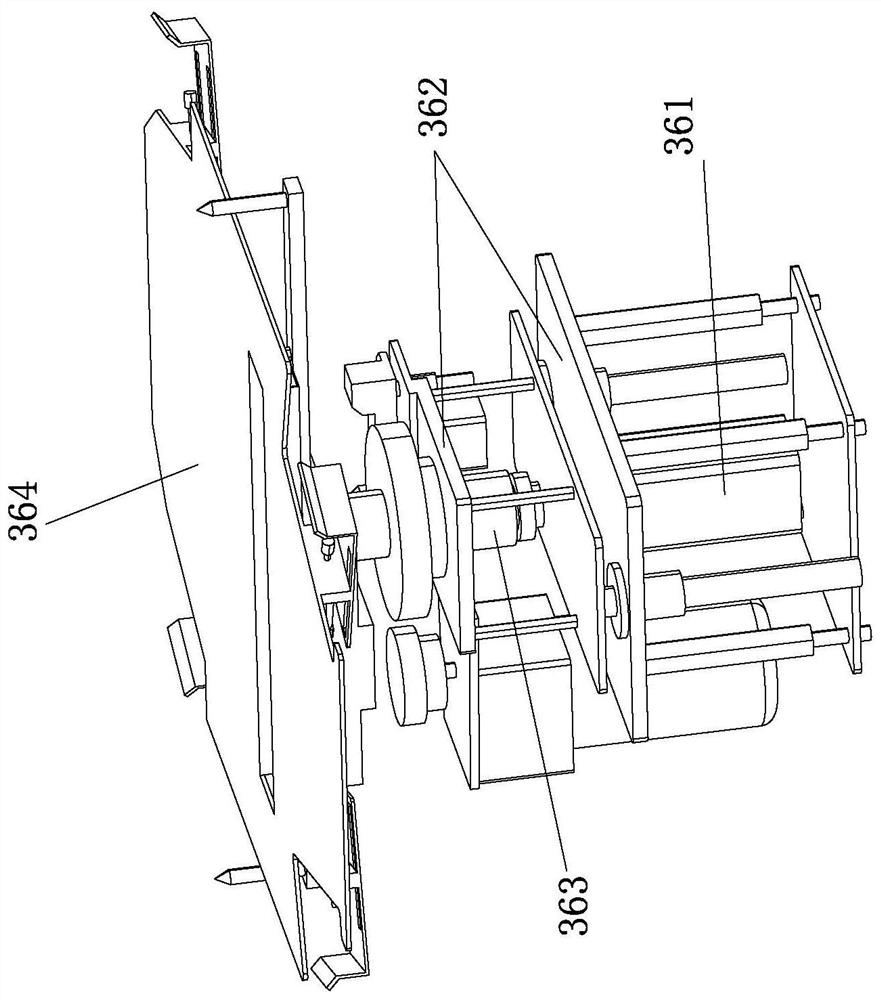

Full-automatic multifunctional mask machine

PendingCN111449332AEasy to shapeImprove molding qualityFolding thin materialsProtective garmentMechanical engineeringIndustrial engineering

The invention discloses a full-automatic multifunctional mask machine. The mask machine comprises a melt-blown cloth conveying mechanism, a lining material conveying mechanism, an inner-layer materialconveying mechanism, an outer-layer material conveying mechanism, a standby material conveying mechanism, a leveling mechanism, a folding mechanism, an air scoop assembly, an ultrasonic hot-pressingmechanism, a circumferential cutting mechanism and a rim charge collecting mechanism. Through the arrangement of the mechanisms, automation and intelligentizing of mask production are achieved, the mask machine can complete manufacturing of masks made of three-layer materials, four-layer materials or even five-layer materials, meanwhile, the production speed is high, the production efficiency is high, and the heavy demand of the market can be met.

Owner:诸暨市兴江密封件有限公司

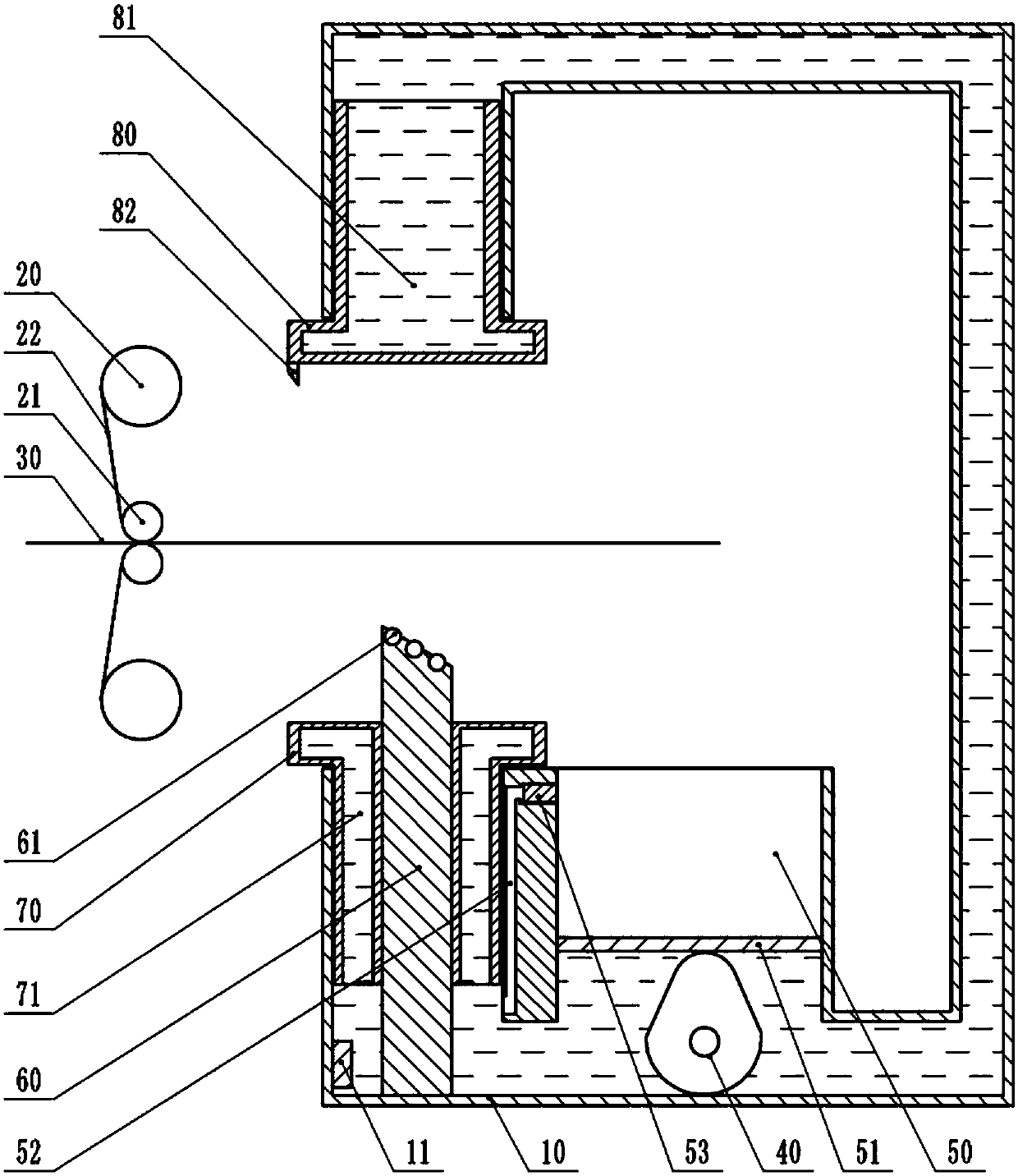

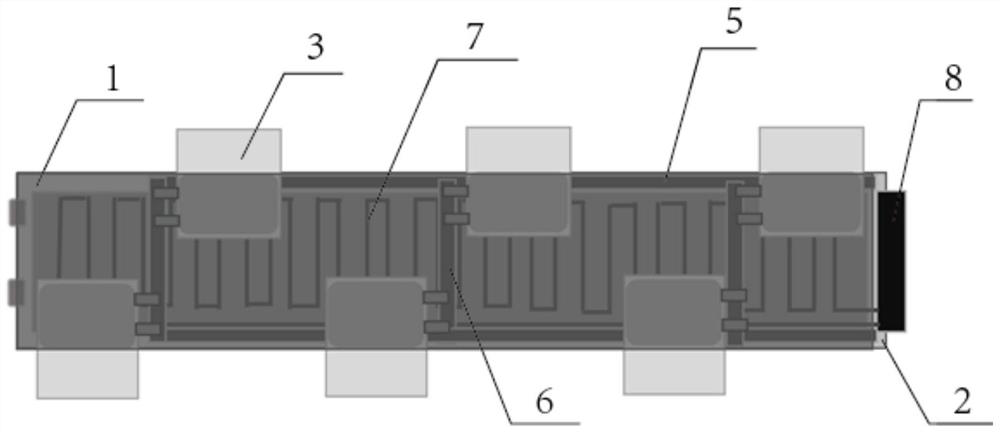

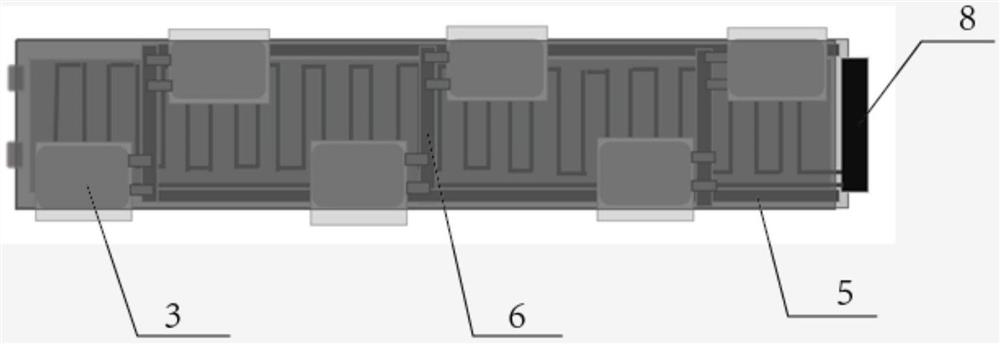

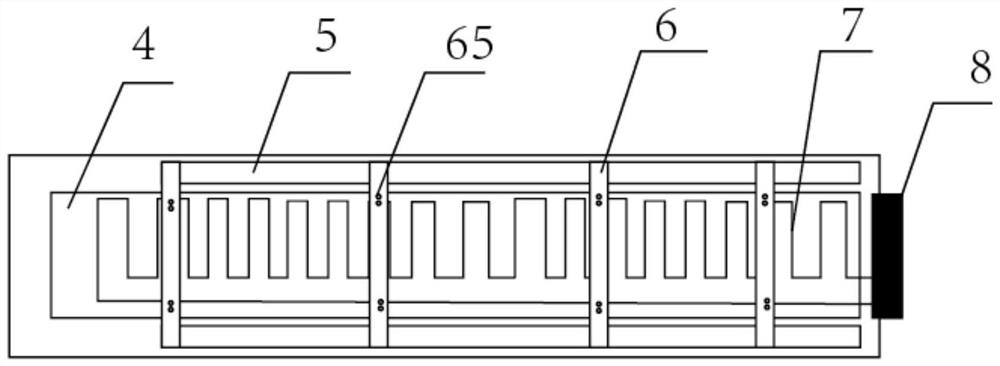

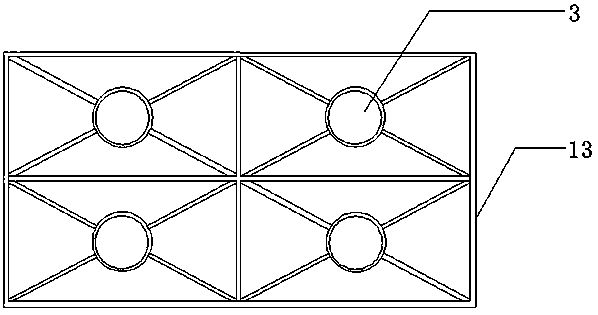

Formation and capacity grading conjoined plate of soft package battery and formation and capacity grading method thereof

PendingCN111864288AConvenient shaping and trimmingEasy to heat pressFinal product manufactureElectrical testingElectrical batteryStructural engineering

The invention discloses a formation and capacity grading conjoined plate of a soft package battery and a formation and capacity grading method thereof. The formation and capacity grading conjoined plate comprises a lower plate body, an upper gland plate and a wiring port, and the upper gland plate is rotationally connected with one end of the lower plate body; the wiring port is fixedly connectedwith the other end of the lower plate body; a battery accommodating groove is formed in the center of the lower plate body; resistance heating wires are distributed at the bottom of the battery accommodating groove; two ends of the resistance heating wire are electrically connected with the wiring port; wiring grooves are respectively formed in two sides of the battery accommodating groove; a plurality of tab positioning groove bodies which are parallel to one another are connected between the wiring grooves in the two sides; two groups of tab connecting poles are arranged at the bottom in thetab positioning groove body, tab abdicating openings are formed in two sides of the tab positioning groove body, tabs of the soft package battery penetrate through the abdicating openings to be electrically contacted with the tab connecting poles, the tab connecting poles are connected with leads, and the leads are led out from the wiring groove. Formation, shaping and capacity grading are integrated, frequent battery loading and unloading are not needed, the production process is greatly simplified, and cooperation with automatic assembly line operation is facilitated.

Owner:GUANGZHOU RONGCHENG LITHIUM BATTERY

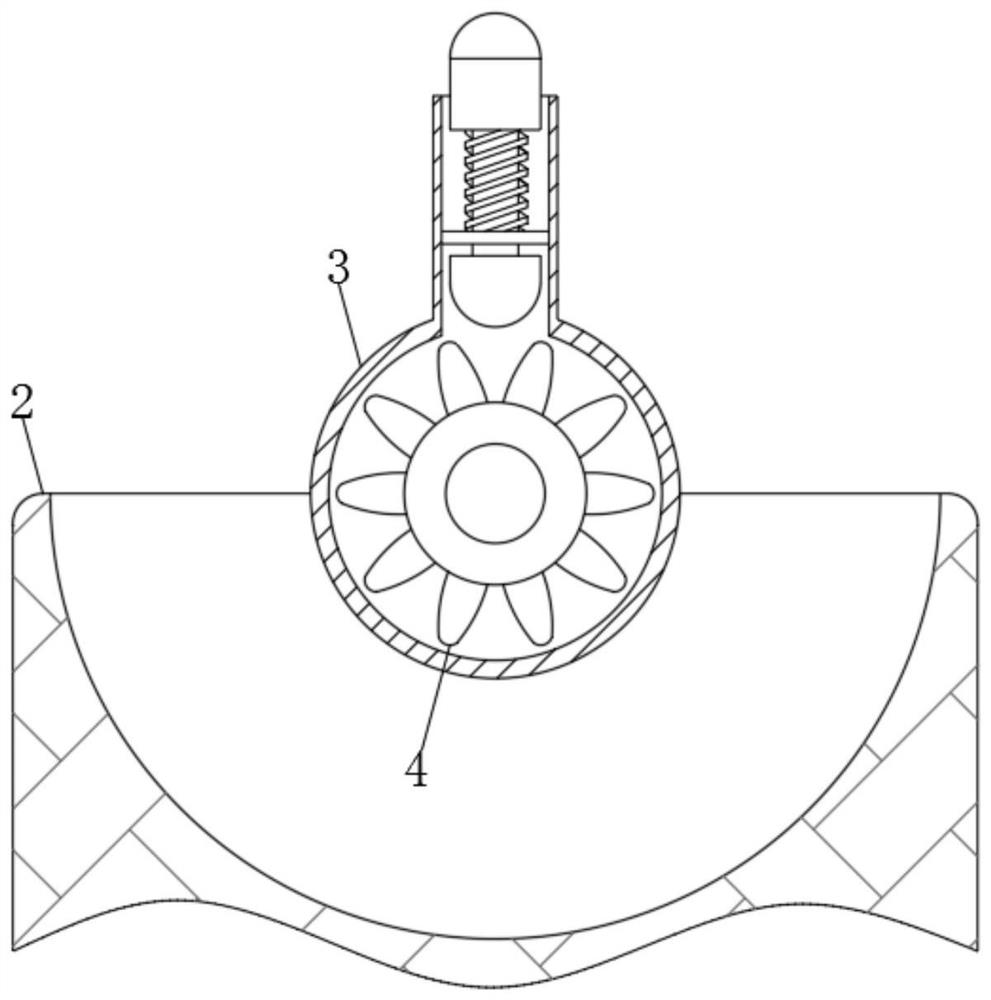

Polytetrafluoroethylene pipe flanging and hot-pressing device

The invention belongs to the technical field of polytetrafluoroethylene pipe flanging, and particularly relates to a polytetrafluoroethylene pipe flanging hot-pressing device. The device comprises a base, a telescopic machine is arranged at the upper end of the base, a telescopic rod is connected to one end of the telescopic machine, a hot-pressing die is connected to one end of the telescopic rod, a limiting annular plate is arranged on one side of the hot-pressing die, a positioning column is arranged at the axis of the limiting annular plate, the back of the base is provided with a connecting bracket, a top plate is connected to one end of the connecting bracket, a connecting rod penetrating to the bottom end is arranged at the top of the top plate, a hydraulic telescopic machine is arranged at one end of the connecting rod, an upper fixing plate is arranged at the lower end of the top plate, and a lower fixing plate is arranged at the lower end of the upper fixing plate. By arranging the fixing plates, pipelines can be well fixed, operation becomes simple, and the pipelines with different lengths can be subjected to flanging treatment; and meanwhile, positioning column is arranged, the positioning column can be replaced according to the pipelines with different diameters, and therefore the equipment is multipurpose, and the flanging treatment effect is good.

Owner:江苏亿豪塑业股份有限公司

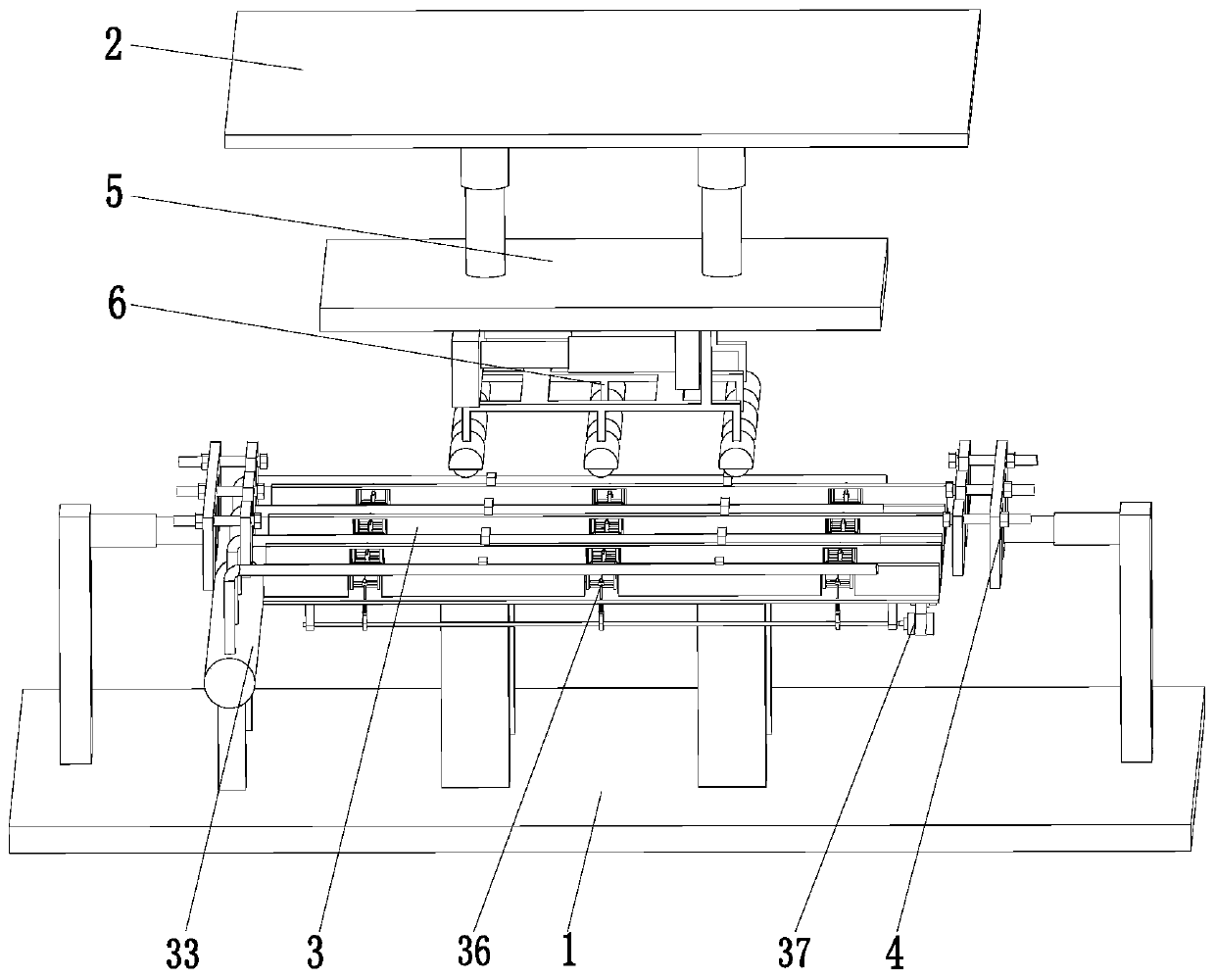

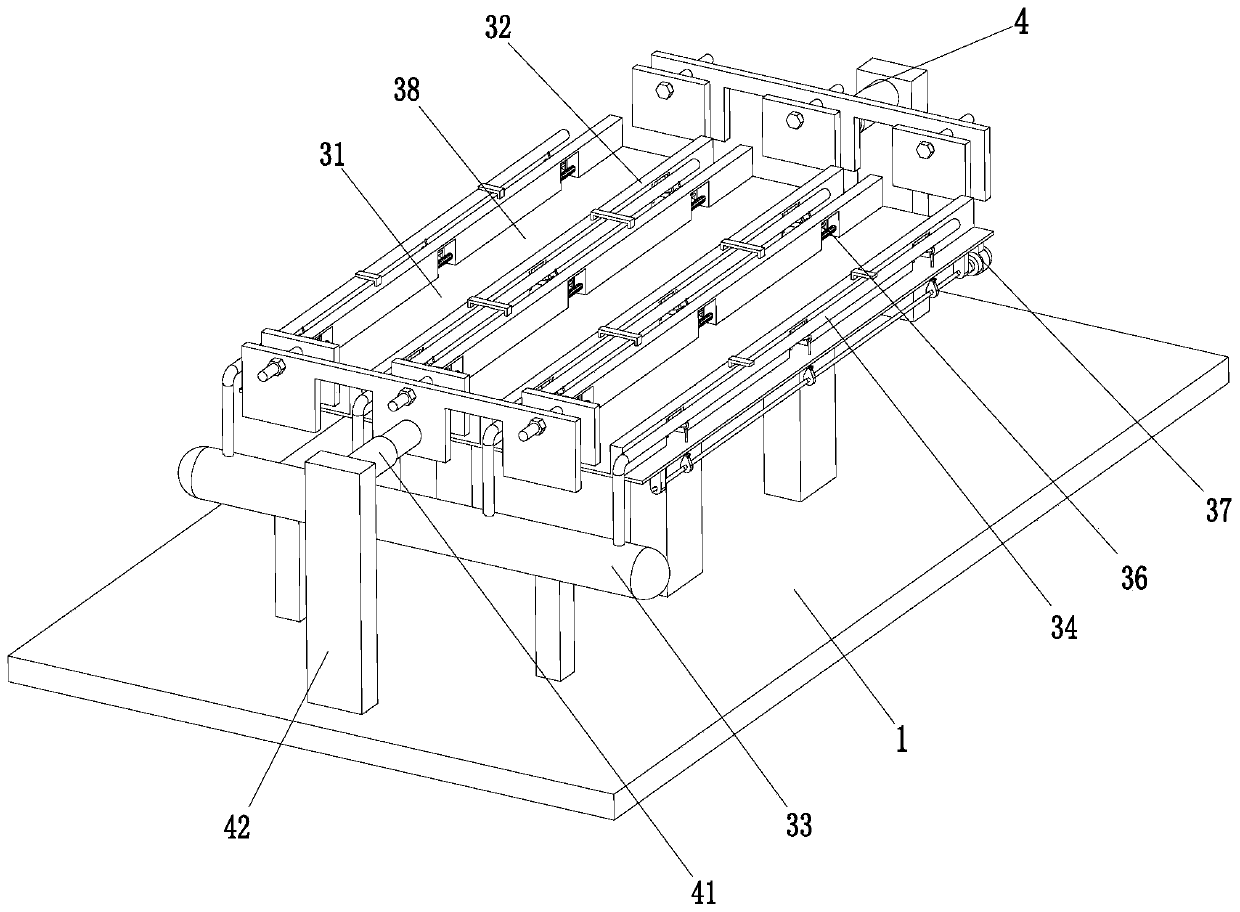

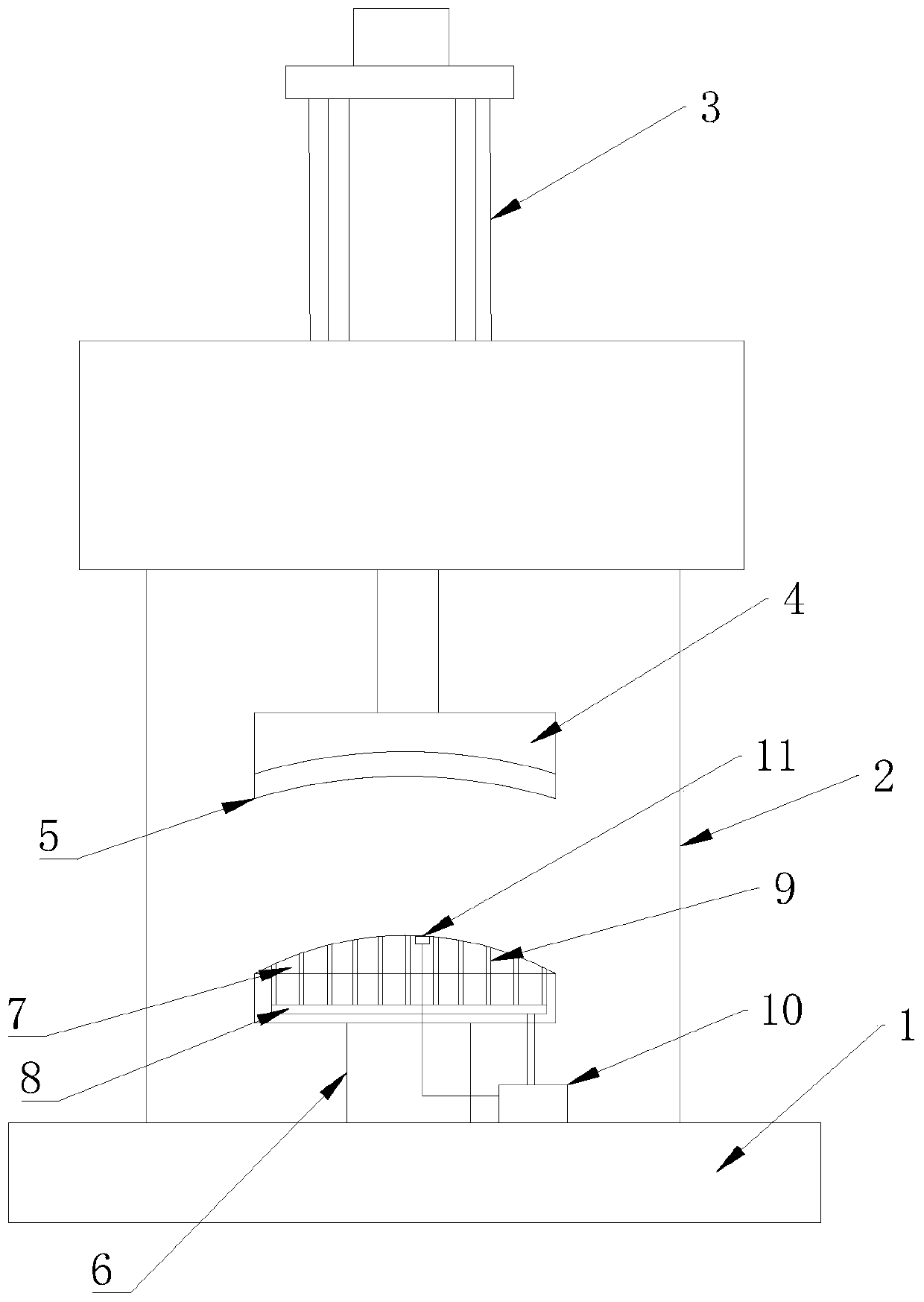

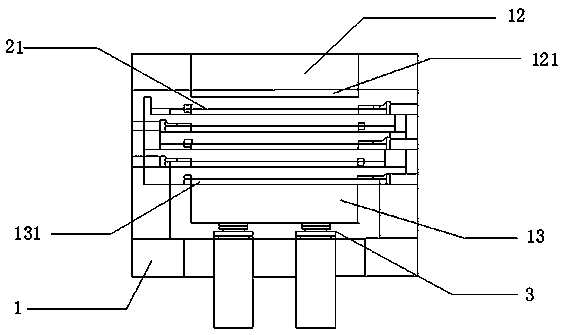

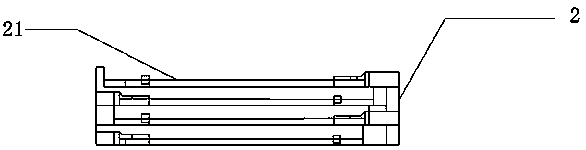

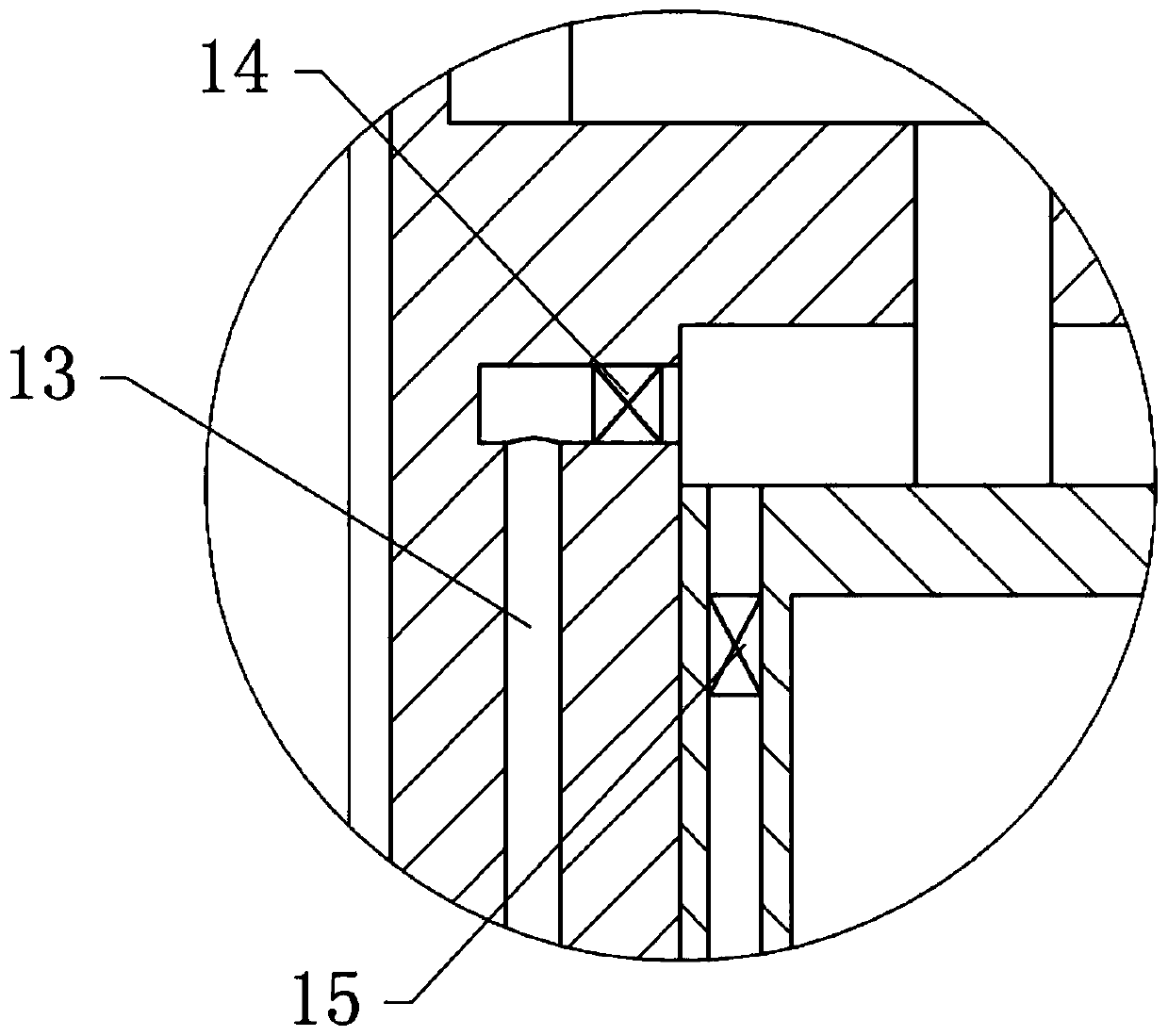

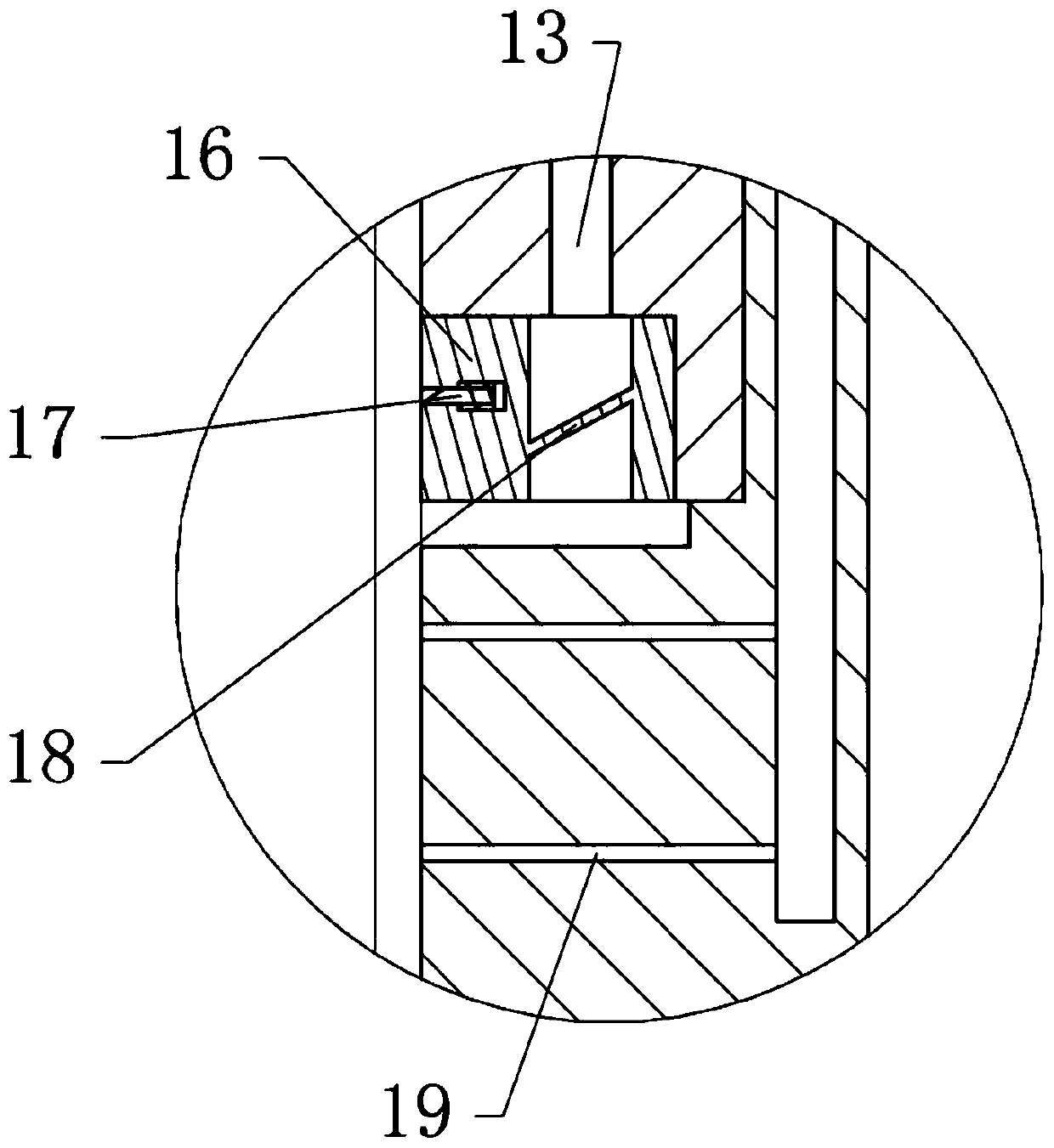

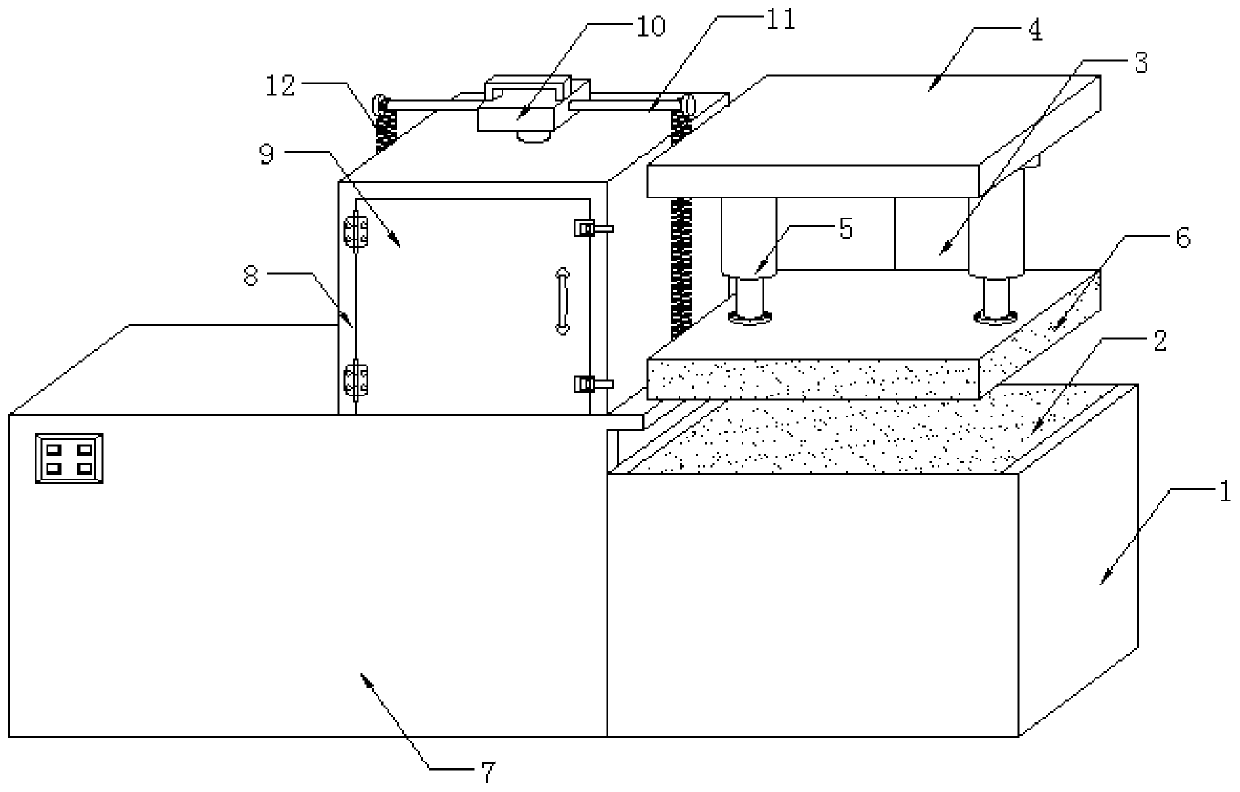

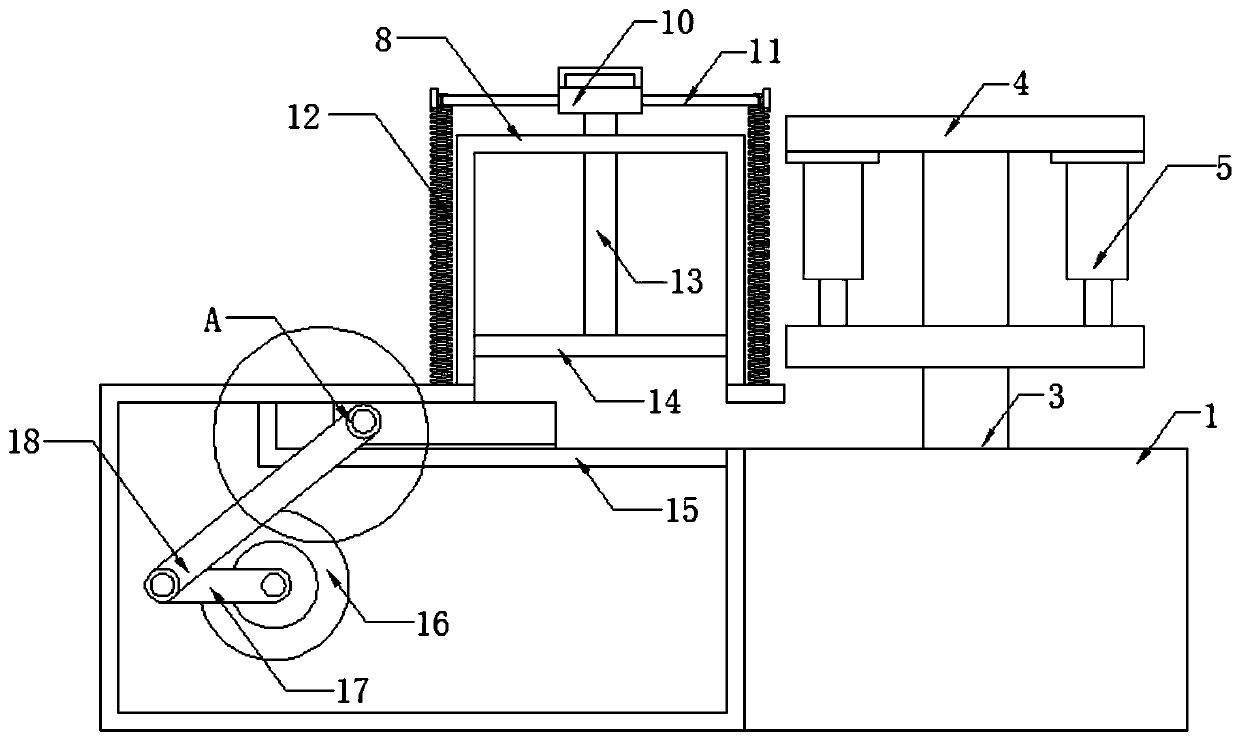

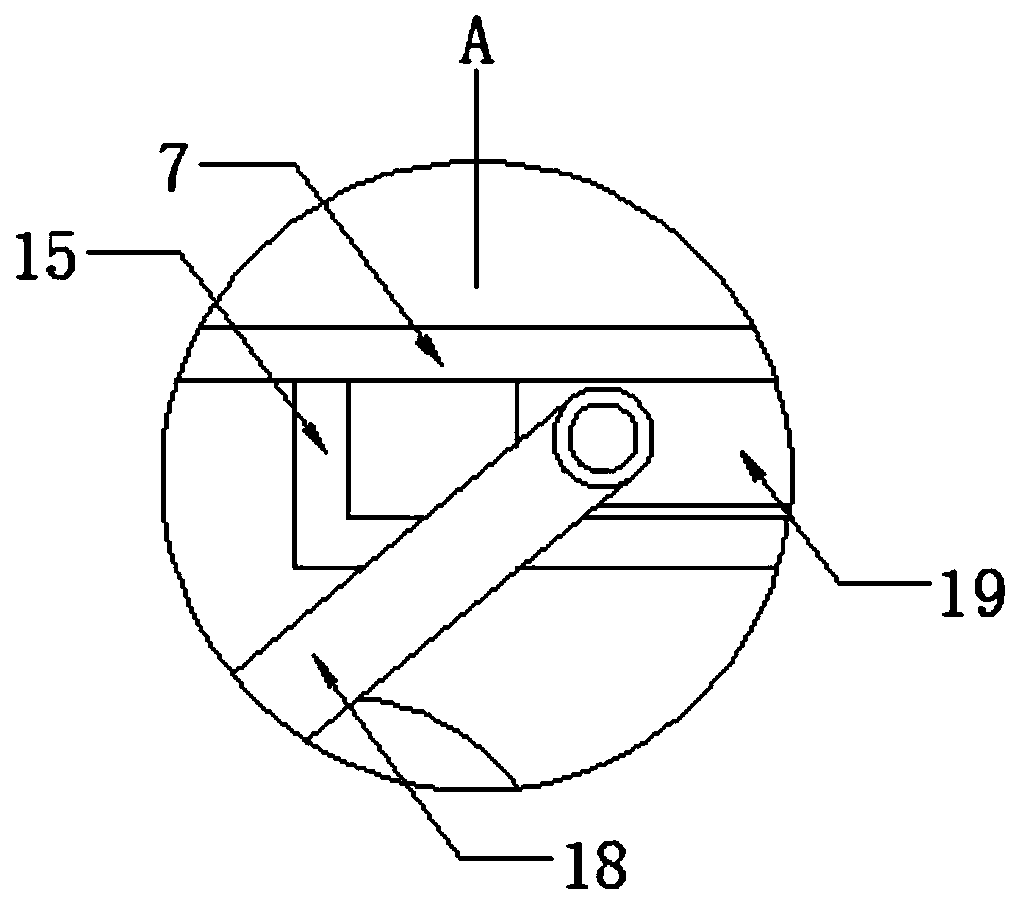

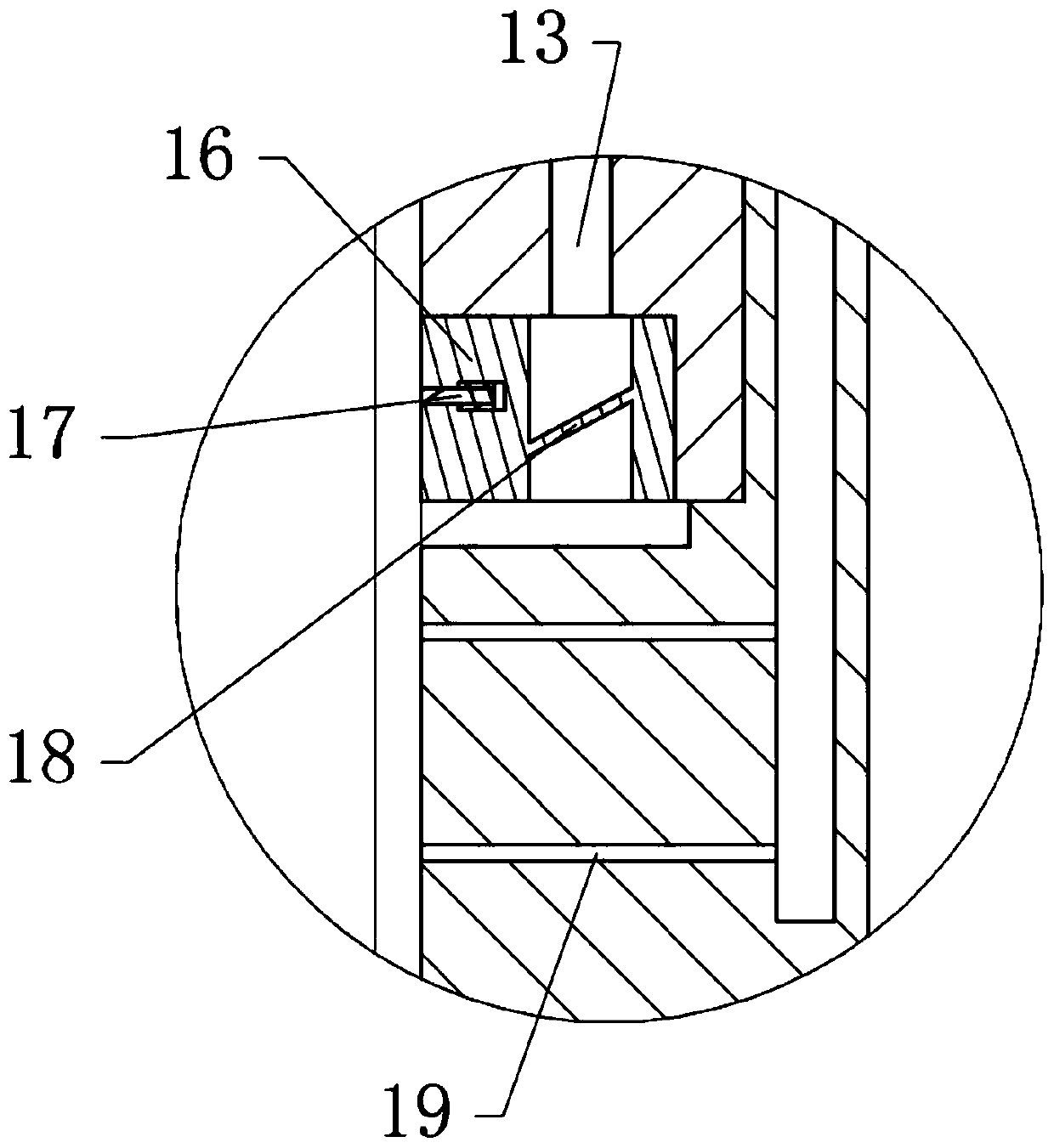

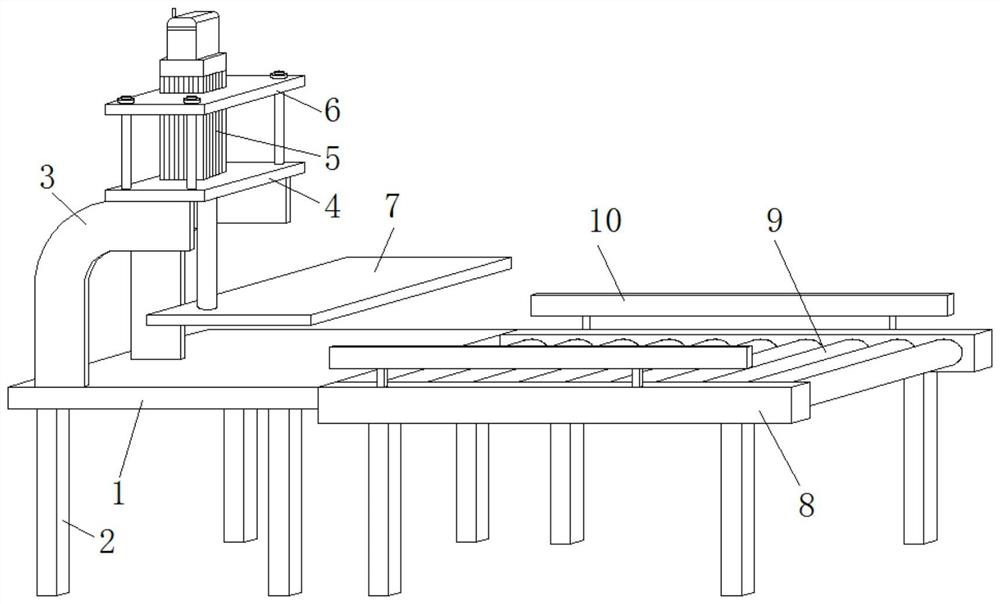

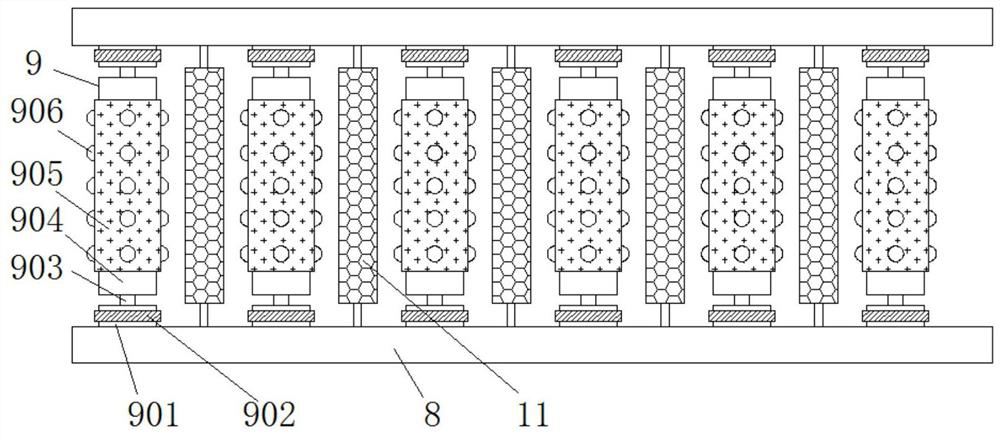

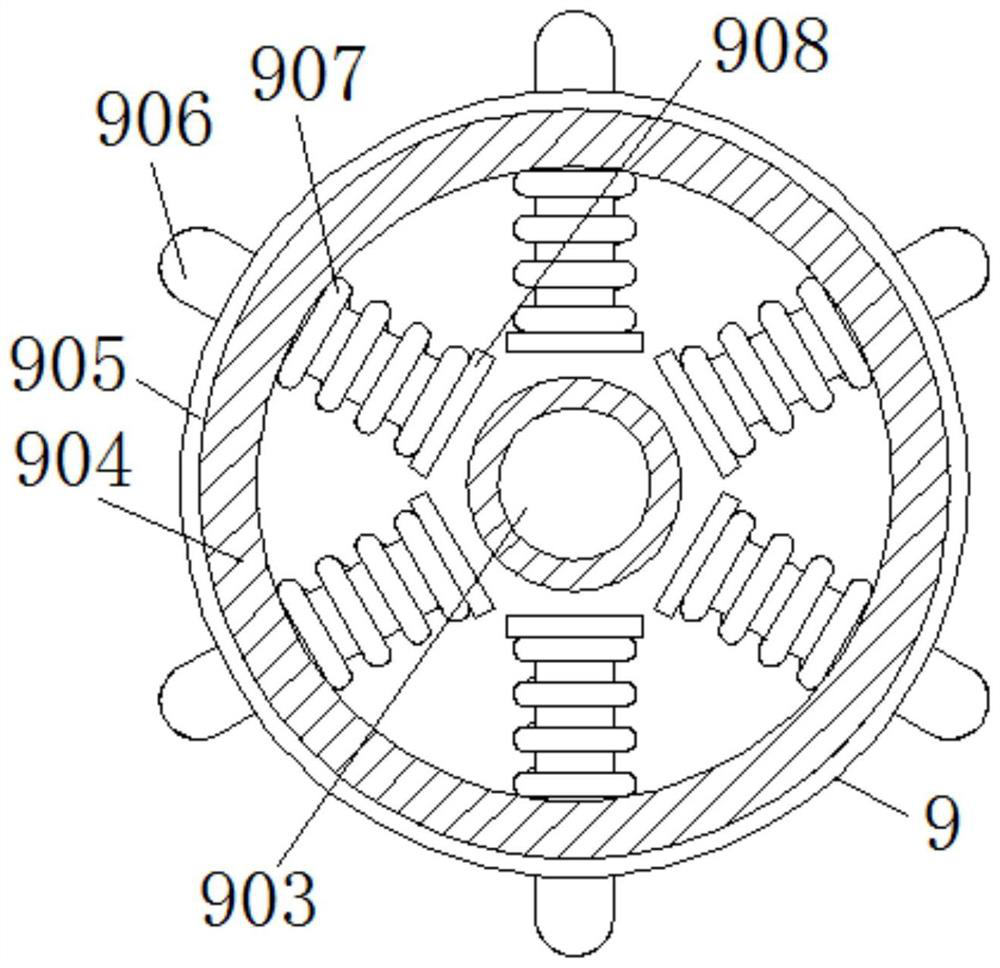

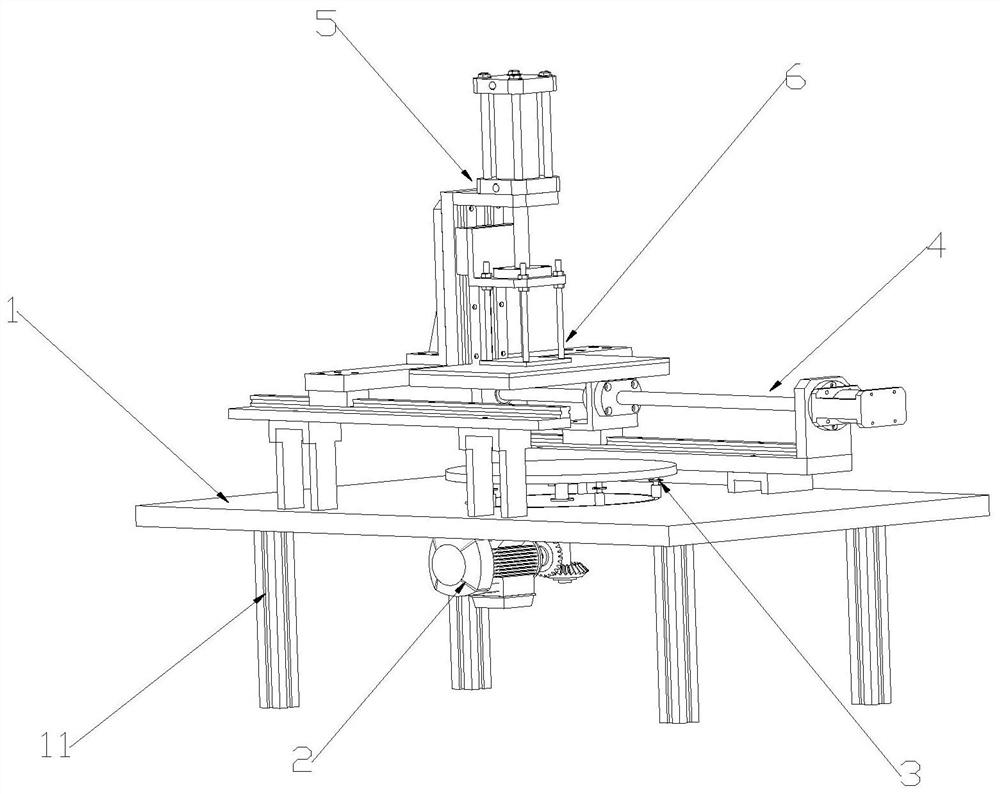

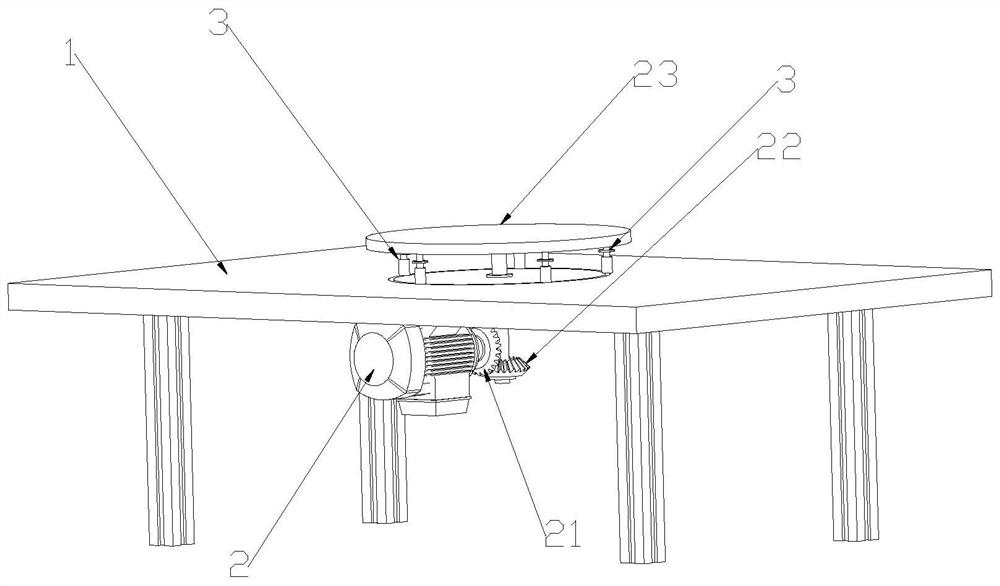

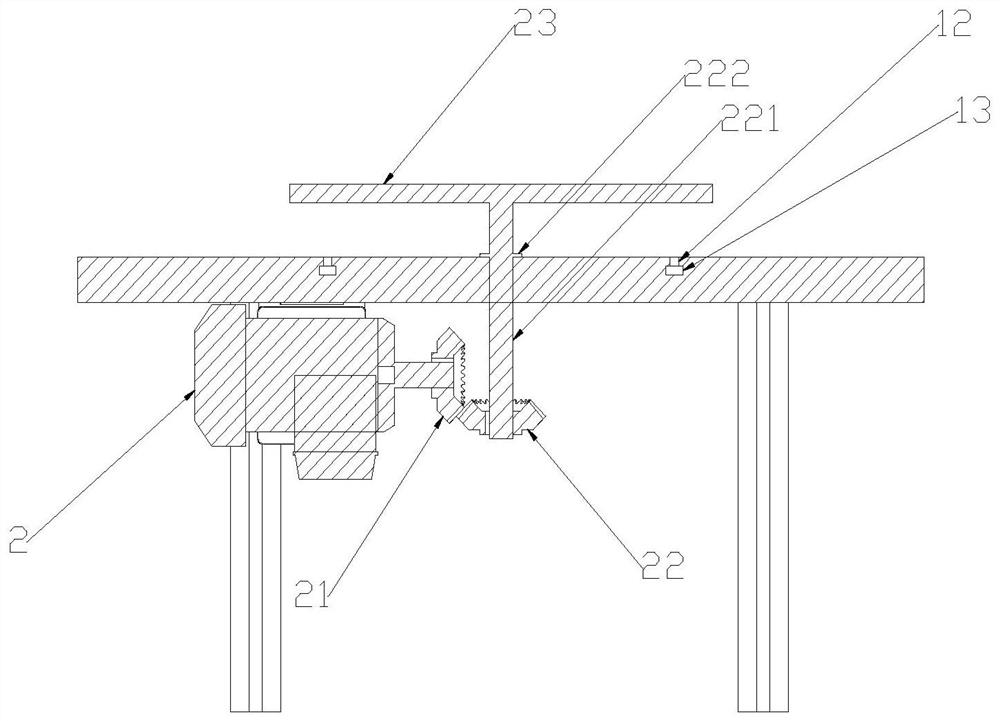

Hot pressing device for plate surface sheet hot pressing processing and processing method thereof

InactiveCN109079934AOptimizing hot pressing processEasy to heat pressPlywood pressesVeneer pressesHeating timeHigh surface

The invention discloses a hot pressing device for plate surface sheet hot pressing processing and a processing method thereof. The device comprises a hot pressing machine frame, and further comprise an upper supporting plate, a lower supporting plate, a hot pressing plate assembly, and a plunger oil cylinder assembly. The upper supporting plate is located on the upper portion. The lower supportingplate is located on the lower portion. The hot pressing plate assembly comprises at least two hot pressing plates. The hot pressing plates are respectively located on the lower portion of the upper supporting plate and the upper portion of the lower supporting plate. The plunger oil cylinder assembly is located on the lower portion of the lower supporting plate. The upper end of the plunger oil cylinder assembly penetrates through the lower supporting plate and is fixedly mounted at the hot pressing plates. The processing method comprises the following steps that pre-heating is conducted, thetemperature of the hot pressing plates in a hot pressing machine is raised to the set temperature, the temperature of the hot pressing plates is 90-98DEG C, and the pre-heating time is not less than5min; and the surface hot pressing pressure of substrate to be hot pressed and corresponding to technology specification requirements is selected, and hot pressing processing is completed. The designis optimized, the hot pressing quality is improved, plates are ensured to have characteristics of excellent sheet pasting, high surface flatness and excellent quality stability sequentially.

Owner:湖州奇士堂工业设计有限公司

Double-single-face PI copper-clad plate pressing and bonding device

PendingCN113085330AEasy to operateImprove work efficiencyLaminationLamination apparatusEngineeringHot press

The invention relates to the technical field of copper-clad plates, and discloses a double-single-face PI copper-clad plate pressing and bonding device. The device comprises a shell, and the interior of the shell is fixedly connected with a fixing seat. Copper-clad plates are automatically fixed, the positions of the copper-clad plates are adjusted so that the copper-clad plates are placed in order, manual operation is omitted, the operation is convenient and fast, and the working efficiency is effectively improved. Follow-up overturning operation is triggered by means of position adjusting operation, linkage between structures is improved, and the automation degree is high. According to actual machining requirements, the placement position of a supporting plate is controlled, so that the supporting plate has a supporting effect on the copper-clad plates and facilitate hot pressing operation when being located at the highest point, and when the supporting plate is located at the lowest point, overturning operation is facilitated, the copper-clad plates are overturned by 180 degrees in a fixed state, and hot pressing on the other sides of the copper-clad plates is facilitated. Therefore, a double-side machining effect is achieved, various machining requirements can be met, and actual use conditions are better met.

Owner:SHENZHEN CITY THREE GOLDS PRECISE CIRCUIT TECH

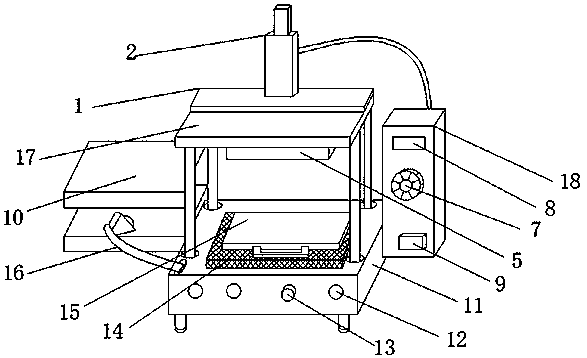

Rapid-heating leather hot-pressing machine

InactiveCN107815879AHeating up fastSave time waiting for heating upLeather surface mechanical treatmentTextiles and paperTemperature controlSlide plate

The invention discloses a rapid-heating leather hot-pressing machine which comprises a leather hot-pressing machine main body and a hot-pressing machine working table, wherein a temperature control box is arranged on one side of the leather hot-pressing machine main body; a leather holding plate is arranged on the other side of the leather hot-pressing machine main body; indication lamps are arranged on the outer surface of the hot-pressing machine working table; leather hot-pressing machine operation keys are arranged on one side of the indication lamps; a sliding plate is arranged at the upper end of the hot-pressing machine working table; and an adjustable LED lamp is fixedly mounted on one side of the hot-pressing machine working table. Due to adoption of a heat conduction copper plate, an electric heating furnace, the leather holding plate, the sliding plate and the adjustable LED lamp, the rapid-heating leather hot-pressing machine disclosed by the invention is capable of rapidlyheating, leather can be conveniently taken and placed by operators, in addition, the operators can operate at night conveniently, the leather can be hot-pressed and taken down rapidly, then the production efficiency is improved, and the machine is applicable to different working situations and has relatively good application prospects.

Owner:江苏华驰机械有限公司

A kind of preparation method of fine-grained anisotropic densified NdFeB permanent magnet

ActiveCN103123843BSmall sizeNo grain growth occurredPermanent magnetsInductances/transformers/magnets manufactureHydrogenGranularity

The invention relates to a preparation method for a fine grain anisotropy densified neodymium iron boron permanent magnet. The preparation method comprises the steps: traditional firing neodymium iron boron technology is adopted; a magnetic blank with small grains and loose texture is obtained by means of low-temperature presintering after rapid hardening, hydrogen breaking, air-stream milling and orientation forming; then the blank is hot-pressed and densified; and the anisotropy neodymium iron boron magnet with the small grains and densified is obtained after tempering is performed to the blank. According to the method, the grains in sintering process of magnet can be prevented from being larger effectively, the prepared magnet has a fine grain structure and is high in densification and the grain size of the fine grain anisotropy densified neodymium iron boron permanent magnet is close to air-stream milling powder granularity.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

An electronic device packaging device

InactiveCN108177829BAvoid residueEasy to heat pressWrappingWrapper twisting/gatheringMechanical engineeringHot pressing

The invention relates to the technical field of packaging, and specifically discloses a packaging device for an electronic device. The packaging device comprises a feeding part, an adsorption part anda placement part, wherein the feeding part comprises a cylinder body, a first cylinder and an adsorption body, a gas cavity with an opening in the bottom is formed in the lower end of the cylinder body, the upper part of the adsorption body is inserted into the gas cavity, the first cylinder is installed in the cylinder body, the first cylinder is capable of driving the adsorption body to stretchout of or retreat back into the gas cavity, a gas hole communicating with the gas cavity is formed in the sidewall of the lower part of the adsorption body; the adsorption part comprises a dust removal pipe, a fan and an air pipe, an air channel is formed between the dust removal pipe and the air pipe, the middle part of the air pipe is sunken inwards, the upper part of the air channel communicates with the fan, and strip-shaped slits are formed in the sidewall of the dust removal pipe; sealing parts are arranged above and below the adsorption part separately, and each sealing part comprisestwo oppositely-arranged second cylinders and two oppositely-arranged hot-pressing blocks; and the placement part comprises a seat body and a workbench, the workbench is slidably connected to the seatbody, and a pressure spring is arranged below the workbench. The electronic device can be subjected to dust removal while being packaged, and the packaged bag body is enabled to be bulged.

Owner:深圳市钰铭烽科技有限公司

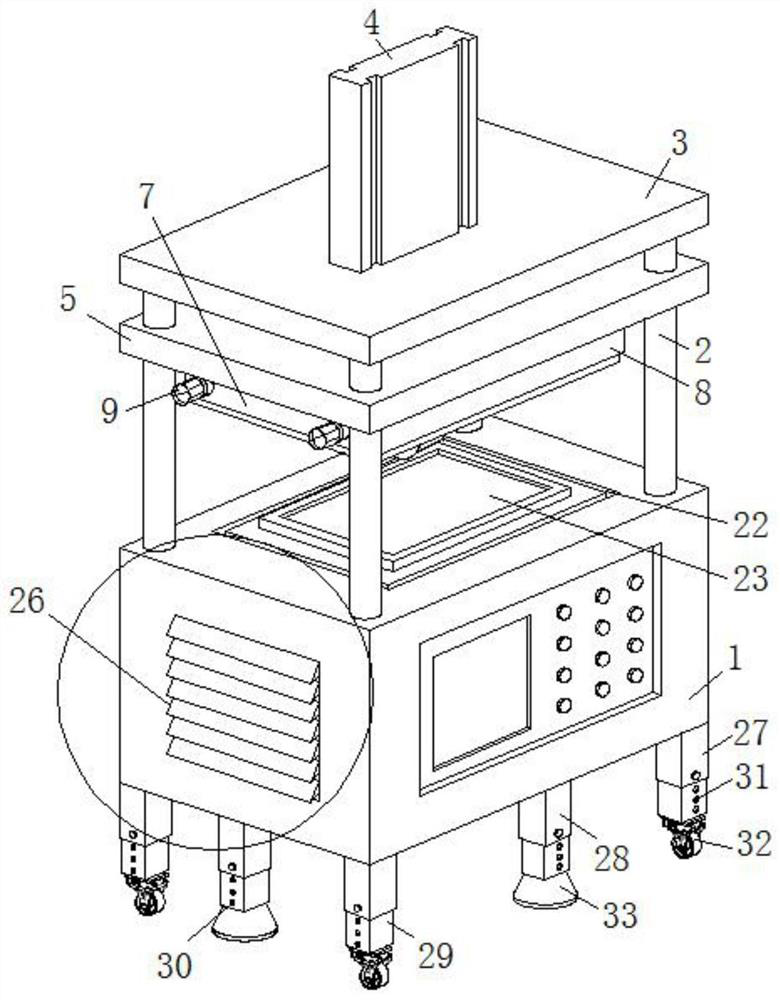

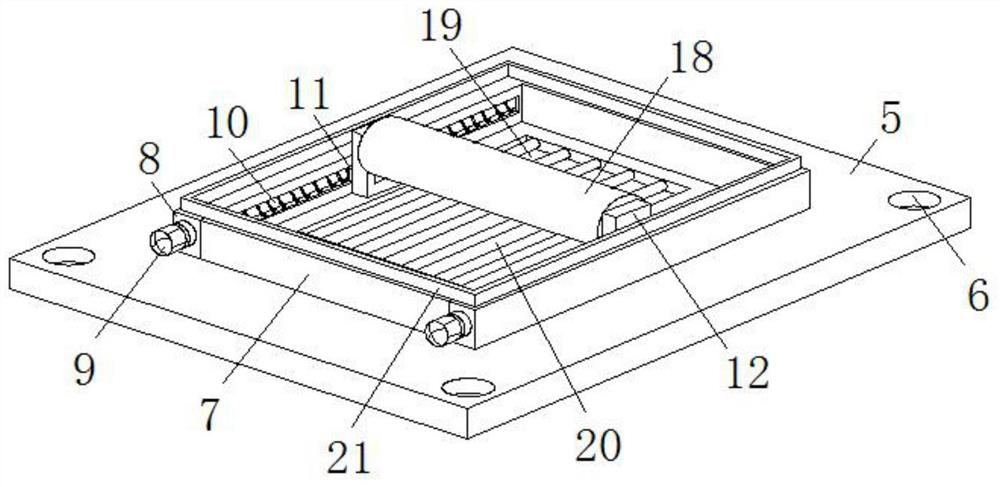

Constant-temperature reciprocating type hot press for touch screen machining

The invention discloses a constant-temperature reciprocating type hot press for touch screen machining. The constant-temperature reciprocating type hot press for touch screen machining comprises a hot press body, the upper end of the hot press body is fixedly connected with a connecting rod, the lower end of the hot press body is fixedly connected with an adjusting supporting leg, the adjusting supporting leg internally comprises a sleeve, the sleeve is internally and movably connected with a movable rod, a fixed screw hole is formed in the interior of the movable rod, a fixed screw is detachably connected to the interior of the sleeve, the fixed screw penetrates through the outer side of the sleeve to be matched with the fixed screw hole in a clamped mode, and the lower end of the adjusting supporting leg is fixedly connected with a fixed supporting leg and a universal trundle in sequence from inside to outside. According to the constant-temperature reciprocating type hot press for touch screen machining, overall resource consumption is reduced, and therefore overall hot pressing is facilitated, a lead screw sliding block drives a hot pressing roller in the interior of an automatic adjusting frame to carry out repeated hot pressing on a touch screen, the overall hot pressing effect is improved, meanwhile, overall moving and fixing are facilitated, and the overall practicability is improved.

Owner:李福生

Bamboo hot press processing equipment

InactiveCN111231032AEasy to heat pressEasy to transportPlywood pressesCane mechanical workingHydraulic cylinderEngineering

The invention discloses bamboo hot press processing equipment. The equipment comprises a first box. A first hot press plate is embedded in the top end of the first box. A vertical plate is fixedly mounted on one side of the top end of the first box. A supporting plate is fixedly mounted at the top end of the vertical plate. Hydraulic cylinders are fixedly mounted on the two sides of the bottom endof the supporting plate and are in series connection. A second hot press plate is arranged at the bottom of the supporting plate. Hydraulic rods of the two hydraulic cylinders are fixedly connected with the two sides of the top end of the second hot press plate correspondingly. A second box is fixedly mounted on one side of the first box. An L-shaped plate is fixedly mounted in the second box. The bamboo hot press processing equipment has the beneficial effects that through mutual cooperation among the first hot press plate, the second hot press plate and the hydraulic rods, the first hot press plate is made to rise and fall and is matched with the second hot press plate, accordingly, hot pressing is performed on bamboo plates conveniently, accordingly, the hot press effect is improved conveniently, and the hot press quality is improved.

Owner:赣州森贸文具有限公司

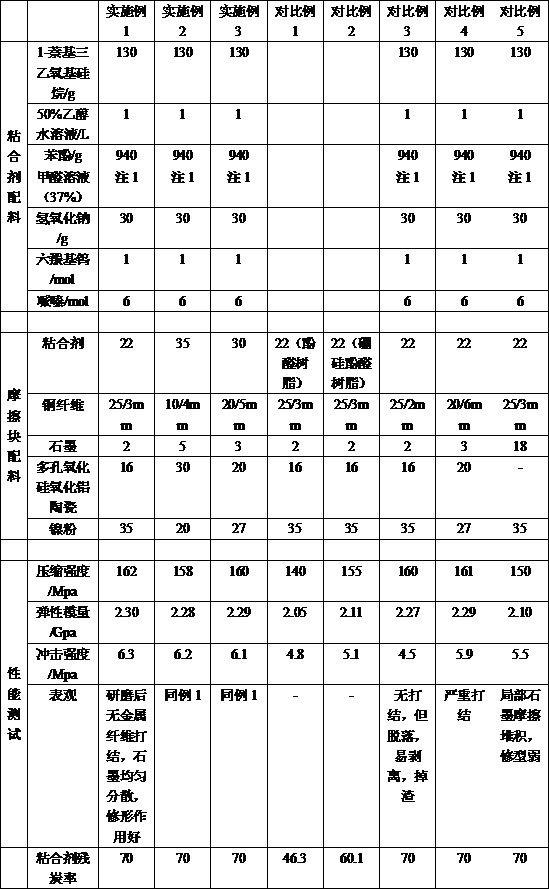

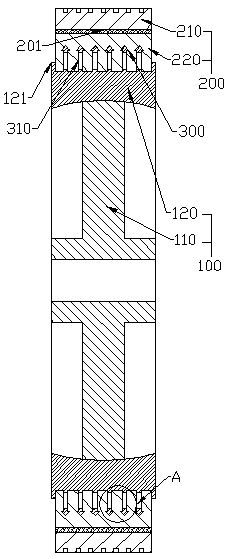

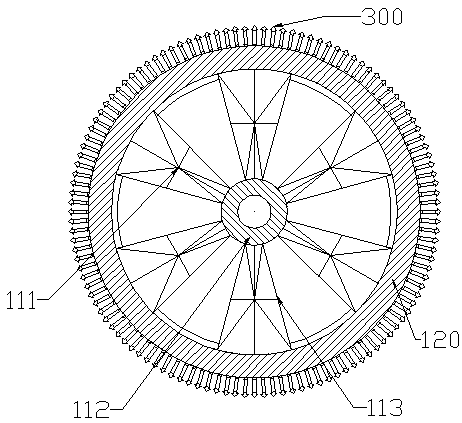

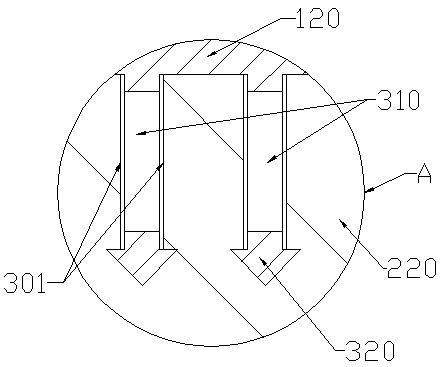

Grinder for tread cleaning device for high-speed motor car and preparation process

The invention relates to a grinder for a tread cleaning device for a high-speed motor vehicle and its preparation process, including a friction block and a back plate, the friction block is in contact with the back plate, and a connecting part embedded in the friction block is arranged on the back plate, and the connecting part is Barb-shaped, when preparing, put the back plate with barb-shaped connecting parts into the hot-pressing mold, use the hot-pressing device with 0.1-1mm exhaust micro-holes on the hot-pressing head, and inject the friction material components into the mold Thermoforming. Friction material components include 22-35wt% tungsten-silicon double-modified phenolic resin binder, 10-25%wt 3-5mm thermally conductive enhanced copper fiber, 20%-35% nickel powder, 2-5wt% graphite impregnated in 16 ‑30wt% of porous ceramic particles meet the application requirements of grinding sub-working conditions, have high thermal stability, no shedding and knotting, and have certain effects such as repairing.

Owner:上海国由复合材料科技有限公司

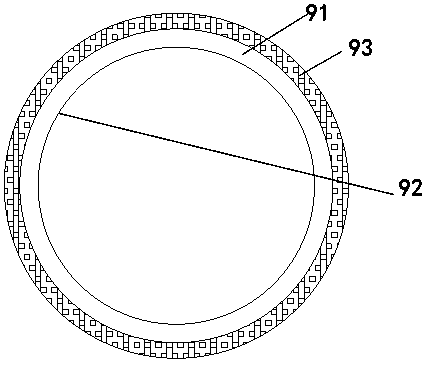

Solid plastic rubber wheel and manufacturing process thereof

PendingCN111196111AClosely connectedNot easy to looseSpecial tyresMechanical engineeringAutomotive engineering

The invention provides a solid plastic rubber wheel. The solid plastic rubber wheel comprises a hub part and a tire part; the tire part wraps the outer side of the hub part; the inner side of the tirepart and the outer side of the hub part are embedded into each other; the hub part comprises a supporting part and a heat insulation ring part; the outer side of the supporting part is connected withthe inner side of the heat insulation ring part; the hub part and the heat insulation ring part are embedded into each other and fixed to each other; and a layer of metal net wraps the center of thetire part. Since the inner side of the tire part and the outer side of the hub part are embedded into each other, so that the tire part and the hub part can be tightly connected together; being subjected to hot pressing, the tire part and the hub part cannot be separated and can be connected more tightly; and the tire part and the hub part are not easy to loosen and damage when being impacted.

Owner:嘉兴智悦橡塑股份有限公司

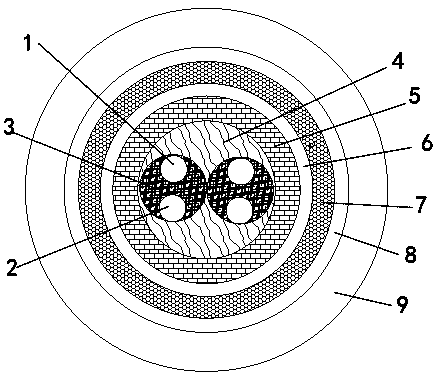

Heavy-type rubber jacketed flexible cable

PendingCN108550415AEnhanced tensile and torsional performanceImprove extrusion resistancePlastic/resin/waxes insulatorsClimate change adaptationFiberCopper conductor

The invention discloses a heavy-type rubber jacketed flexible cable, comprising insulating wire cores, wherein each insulating wire core is formed by longitudinally arranging tin-plated copper conductors and aluminum alloy conductors in parallel at intervals and then jointly extruding a high-elasticity silicone rubber insulating layer; the two insulating wire cores are closely and transversely arranged in parallel and then are wrapped together with metallized paper or semi-conductive tapes as an inner shielding layer, a copper tape outer shielding layer is woven outside the inner shielding layer, a waterproof film is wrapped outside the copper tape outer shielding layer, a ceramic fiber tape is wrapped outside the waterproof film, a low-smoke halogen-free flame-retardant polyolefin oxygenbarrier layer is extruded outside the ceramic fiber tape, and a rubber outer jacket is sleeved outside the low-smoke halogen-free flame-retardant polyolefin oxygen barrier layer. The heavy-type rubberjacketed flexible cable disclosed by the invention not only has excellent mechanical and physical properties, oil resistance, electrical properties, flame resistance and processing performance, but also has the characteristics of no halogen, low smoke volume and the like.

Owner:JIANGSU DONGFENG CABLE

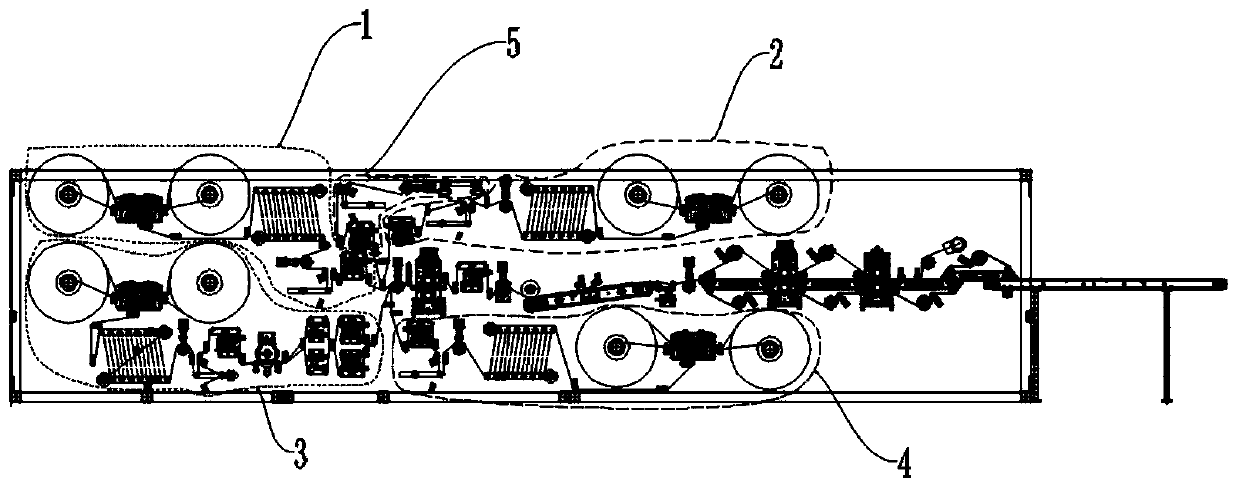

Traceless bra machine

PendingCN113384010AEasy to move aroundLow costBrassieresCorsetsProcess engineeringMechanical engineering

The invention discloses a traceless bra machine which is provided with six stations, traceless bra cloth placed on a cloth carrying plate can be conveniently processed into traceless bra finished products through procedures of hot pressing, cup punching, bonding and the like, the mechanical processing process is achieved, processing efficiency can be improved, practicability is good, only one person is needed for operation in the specific implementation process, personnel cost can be saved; besides, due to the arrangement of the circulating station line, under the action of the power mechanism, the carrier plate placement hollowed-out seat drives the cloth carrier plate to circularly move, so workers do not need to transfer the cloth carrier plate after the seamless bra is processed, and manpower is saved.

Owner:广东清溢德制衣有限公司

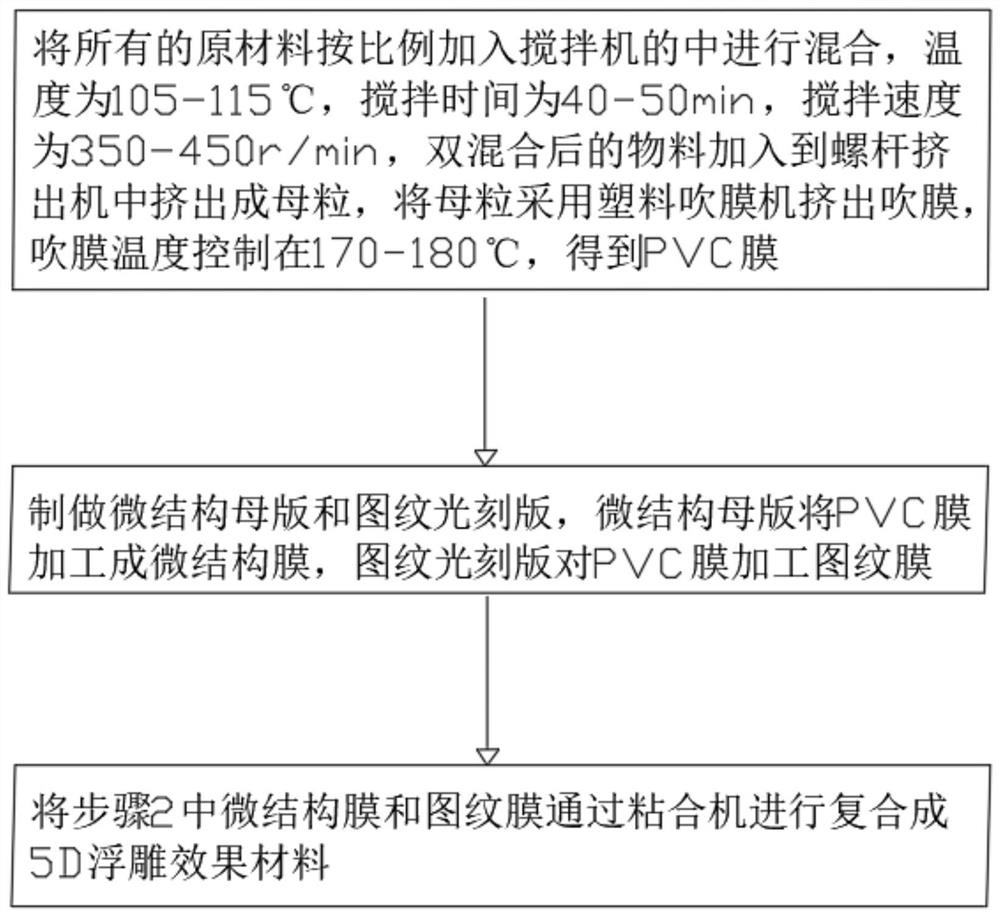

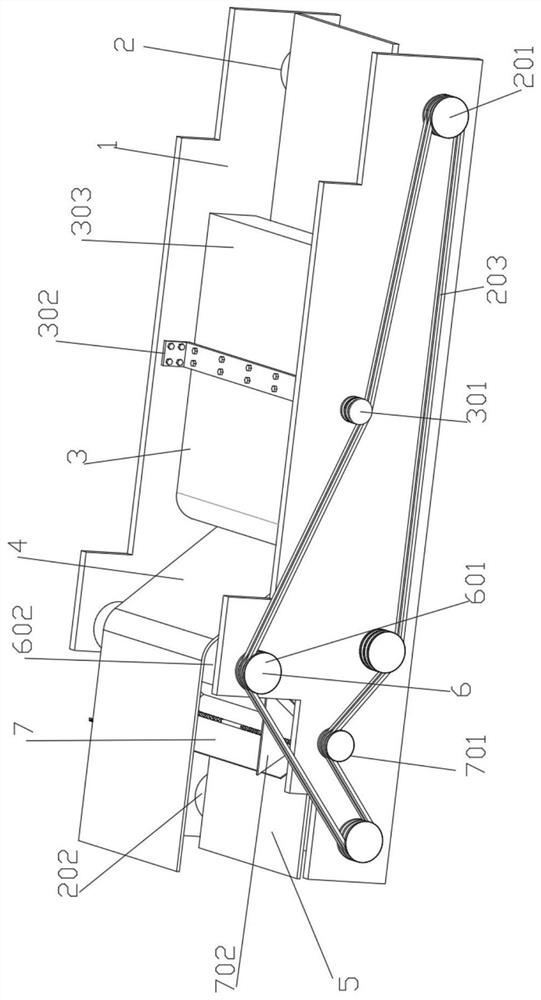

A 5D three-dimensional relief effect material and production process

ActiveCN113429699BEasy to moveApply evenlySynthetic resin layered productsLaminationMeth-Polymethyl methacrylate

The invention relates to the technical field of new materials, in particular to a 5D three-dimensional relief effect material and a production process. The 5D three-dimensional relief effect material is composed of the following components by weight: 65-82 parts of PVC resin, 35-45 parts of polyurethane, 28-35 parts of methyl methacrylate, 12-16 parts of phosphite, 5-15 parts of diethylene glycol dibenzoate, 1-4 parts of PVC stabilizer, 1-4 parts of non-toxic plasticizer, p- 1.1-1.5 parts of cyclohexyl methoxycinnamate, 1.2-1.5 parts of 4-methyl-6-methoxy coumarin; the present invention reduces the stress concentration phenomenon caused by agglomeration through the combination of various substances, thereby improving the The structural strength and tensile resistance of the PVC film, at the same time, through the cooperation of the microstructure master and the pattern lithography, it is beneficial to form a three-dimensional effect on the material surface. The 5D relief stereo effect is ideal, which is conducive to all-round display. At the same time, the pattern film And the microstructure mode facilitates synchronous movement.

Owner:SHISHI GUANXIN REFLECTIVE MATERIAL CO LTD

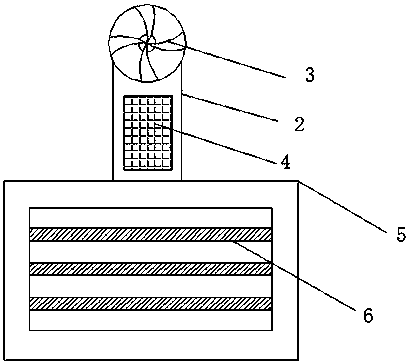

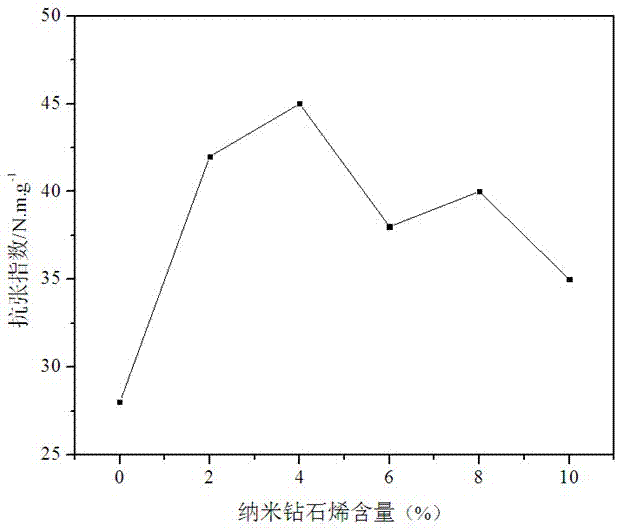

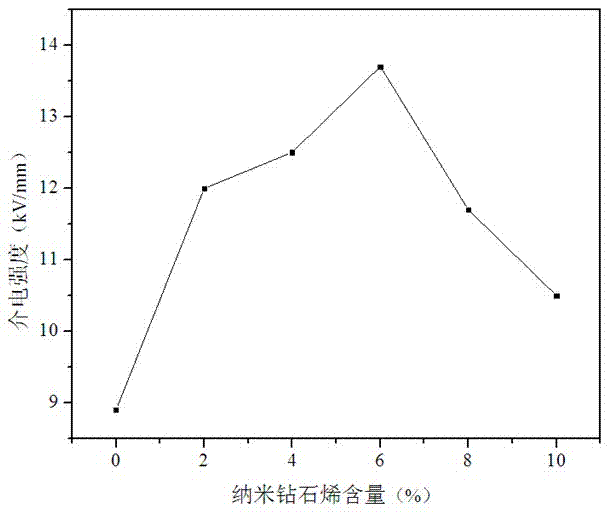

Meta-aramid paper containing nanometer diamondene, and making method thereof

InactiveCN107044072AChemically stableHigh hardnessSpecial paperPaper/cardboardTransformerTear resistance

A meta-aramid paper containing nanometer diamondene is mainly made of a basic raw material, polyoxyethylene and nanometer diamondene, the basic raw material is prepared from 30-60 parts by weight of meta-aramid chopped fibers and 40-70 parts by weight of meta-aramid pulp meal, the use amount of polyoxyethylene is 0.3-0.6% of the amount of the basic raw material, and the use amount of the nanometer diamondene is 2-10% of the amount of the basic raw material. The invention further discloses a making method of the meta-aramid paper containing nanometer diamondene. The meta-aramid paper made in the invention has the advantages of good tensile strength, excellent insulation property, good tear resistance and good wear resistance, and can be applied to the insulation fields of generators, motors, transformers and battery diaphragms, and non-main bearing parts of trains, ships, aircrafts.

Owner:ZHENGZHOU ARTIFICIAL DIAMOND & PROD ENG TECH RES CENT

Packaging bag forming and printing label all-in-one machine

ActiveCN110843260BRealize unwindingAchieve teleportationBag making operationsPaper-makingMarking outElectric machinery

The invention belongs to the technical field of marking equipment for packaging materials, and discloses a packaging bag forming and labeling integrated machine, which includes a workbench, on the workbench, an unwinding part, a hot-pressing part and a conveying part are sequentially arranged on the workbench, and the conveying part It includes two overlapping conveyor belts, the conveyor belts are driven by a motor, the worktable is provided with a placement slot, the bottom conveyor belt is located in the placement slot, and the upper surface of the bottom conveyor belt is coplanar with the upper surface of the worktable; The mounting frame on the table is vertically slidably connected with a plurality of heat-pressed blocks arranged side by side, and the adjacent heat-pressed blocks are fixed by connecting rods; The first cam that drives the push rod to move up and down; icons are set on the working surface of the hot pressing block. The invention solves the problem that an additional process needs to be added for label printing in the prior art, resulting in lower production efficiency of packaging bags.

Owner:重庆富美包装印务有限公司

Method of packaging electronic devices

The application relates to the technical field of packaging and particularly discloses a method of packaging an electronic device, comprising the steps of (1) sleeving a column above a suction portionwith plastic film in tubular shape; (2) activating a fan, and placing an electronic device to be packaged onto a workbench; (3) pulling down the plastic film until air holes in the lower portion of the suction portion are covered; (4) pushing down the suction portion so as to pull the plastic film into a dedusting barrel; (5) after the plastic film is sucked onto the inner wall of the dedusting barrel, pulling back the suction portion, and cutting the plastic film; (6) enabling two hot pressers of a sealing portion to move to each other, and separating the hot pressers after the plastic filmis press-fitted by the hot pressers; (7) taking out the packaged electronic device. During packaging of an electronic device by means of the method, the electronic device can be dedusted, and a post-packaging bag is bulged.

Owner:江门市富可鑫电子有限公司

A laminate heat pressing device with preheating function

ActiveCN112606131BSmall temperature differenceImprove product qualityPlywood pressesVeneer pressesFixed bearingEngineering

The invention discloses a laminate heat pressing device with a preheating function, comprising a workbench, a support column is fixedly installed at the bottom of the workbench, and a vertical plate is fixedly connected to the top of the workbench, the vertical plate A supporting plate is fixedly installed on the top. In the present invention, under the action of the transmission preheating mechanism, the rotating rod rotates inside the fixed bearing, so that the rotating rod drives the guide roller to rotate between the horizontal plates, so that the guide roller can transport the laminate on the surface , by setting multiple sets of heating rods inside the guide roller, under the elastic action of the first return spring, the heating rods are moved toward the outer wall of the guide roller, so that the heating rods are on the surface of the guide roller against the laminated plate The surface is heated and preheated, which is convenient to reduce the temperature difference of the laminate in the subsequent hot pressing, avoiding the distortion, depression, protrusion and other problems of the laminate due to excessive heating or concentrated heating, and improving the production quality of the laminate hot pressing device , reduce the scrap rate.

Owner:九江鑫星绝缘材料有限公司

A flat heat-pressing equipment for jackets

Owner:合肥英士博户外用品科技有限公司

Tread cleaning device grinder for high-speed bullet train and preparation process of tread cleaning device grinder

The invention relates to a tread cleaning device grinder for a high-speed bullet train and a preparation process of the tread cleaning device grinder. The tread cleaning device grinder comprises a friction block and a back plate, the friction block makes contact with the back plate, and a connecting part embedded into the friction block is arranged on the back plate; the connecting part is barb-shaped, and during preparation, the back plate with the barb-shaped connecting part is put into a hot pressing mold; and a 0.1-1 mm exhaust micropore hot-pressing device is arranged on a hot-pressing head, and friction material components are injected into a mold to be subjected to hot-pressing forming. The friction material comprises 22-35 wt% of a tungsten-silicon dual-modified phenolic resin adhesive, 10-25 wt% of 3-5 mm heat conduction reinforced copper fibers, 20%-35% of nickel powder and 2-5 wt% of graphite which are impregnated in 16-30 wt% of porous ceramic particles. The working condition application requirements of grinding can be met, the thermal stability is high, no shedding or knotting can be achieved, and certain modification and the like can be achieved.

Owner:上海国由复合材料科技有限公司

Quenchable steel sheet having high hot press workability and method of manufacturing the same

ActiveUS8293379B2Good stamping performanceImprove ductilityHot-dipping/immersion processesThin material handlingManganeseCobalt

The quenchable steel sheet has an alloy composition including carbon (C) in an amount of 0.15˜0.30 wt %, silicon (Si) in an amount of 0.05˜0.5 wt %, manganese (Mn) in an amount of 1.0˜2.0 wt %, boron (B) in an amount of 0.0005˜0.0040 wt %, sulfur (S) in an amount of 0.003 wt % or less, phosphorus (P) in an amount of 0.012 wt % or less, one or more selected from among calcium (Ca) in an amount of 0.0010˜0.0040 wt % and copper (Cu) in an amount of 0.05˜1.0 wt %, two or more selected from among cobalt (Co), zirconium (Zr) and antimony (Sb), and iron (Fe). Alloy elements are controlled to increasing hot ductility and enabling pressing at 600˜900° C. so that a tensile strength of 1400 MPa or more and an elongation of 8% or more are obtained after pressing.

Owner:HYUNDAE STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com