Grinder for tread cleaning device for high-speed motor car and preparation process

A grinding wheel and high-speed train technology, applied in vehicle cleaning, vehicle maintenance, transportation and packaging, etc., can solve problems such as easy oxidation, achieve good deflation and hot pressing, reduce deflation operation procedures, and avoid failure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

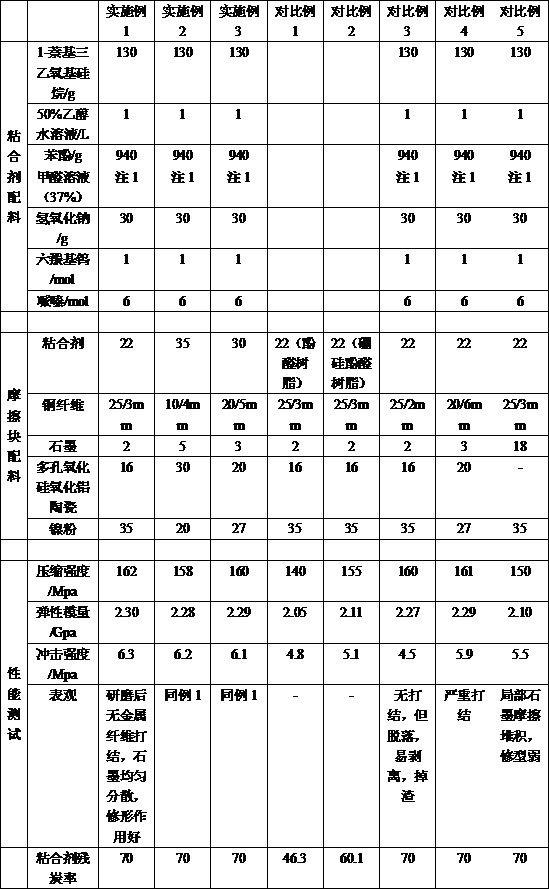

Examples

Embodiment 1

[0033] Process A prepares the adhesive tungsten silicon phenolic resin:

[0034] 1) Add 130g of 1-naphthyltriethoxysilane into 1L of 50% ethanol aqueous solution, add hydrochloric acid to adjust the pH value to 5, and hydrolyze it at a temperature of 35°C for 5 hours to obtain solution I;

[0035] 2) Prepare a tungsten-piperazine complex by reacting 1 mol of tungsten hexacarbonyl with 6 mol of piperazine, which is designated as product II;

[0036] 3) Dissolve 30g of catalyst sodium hydroxide in 37% formaldehyde solution, then mix it with 940g of melted phenol in the reactor (the molar ratio of phenol to formaldehyde is 1:1), and react at 65°C for 2 hours; After vacuum dehydration, add solution I and product II, and react for 2.5 hours to obtain tungsten-silicon double-modified phenolic resin, and tungsten, silicon and phenolic formaldehyde form chemical bonds;

[0037] Process B: Preparation of modified graphite:

[0038] Based on the total weight of the friction block, a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com