Method of packaging electronic devices

A technology of electronic devices and plastic films, which is applied in the field of packaging electronic devices, and can solve problems such as packaging bag collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below by means of specific embodiments:

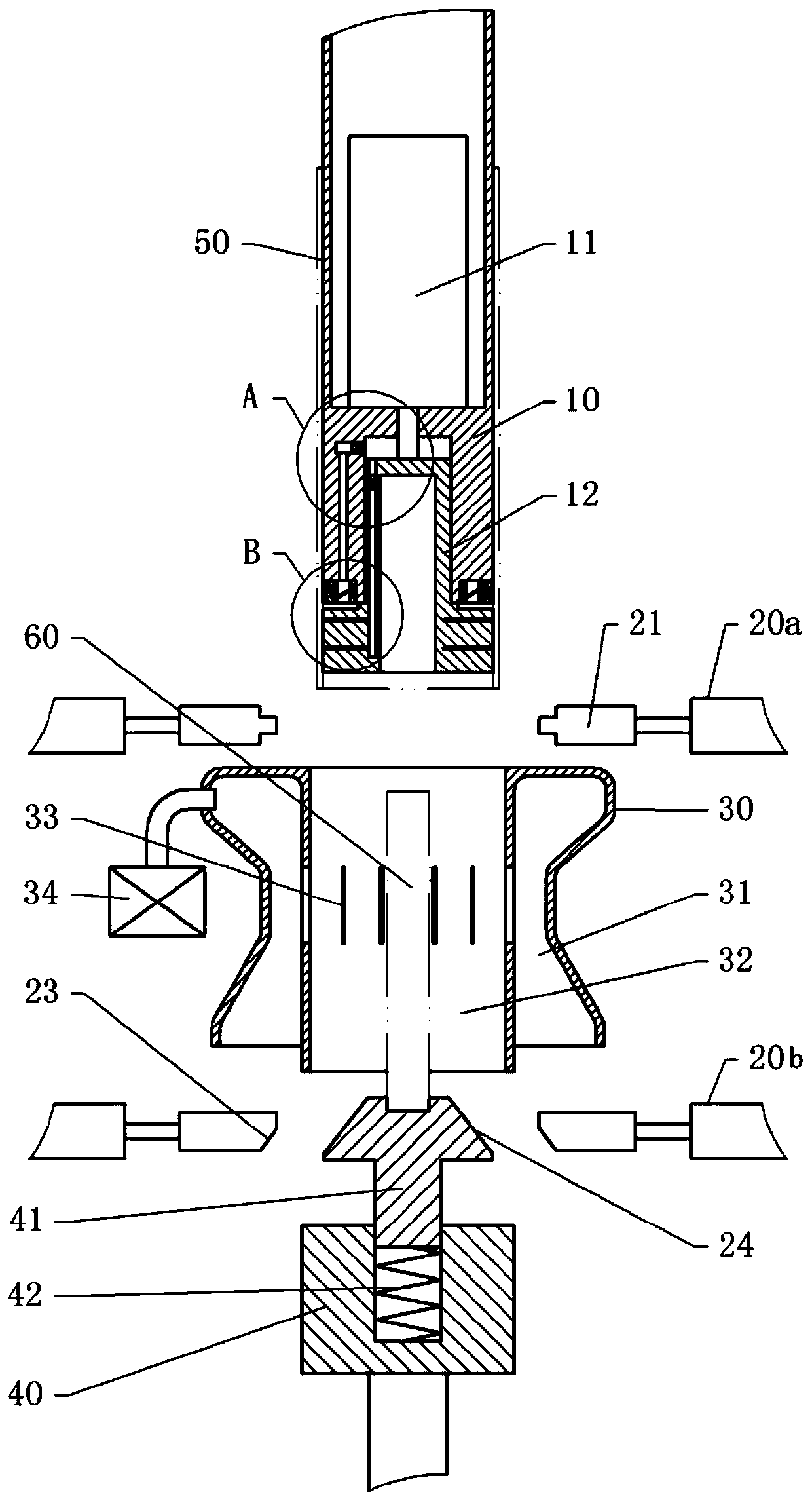

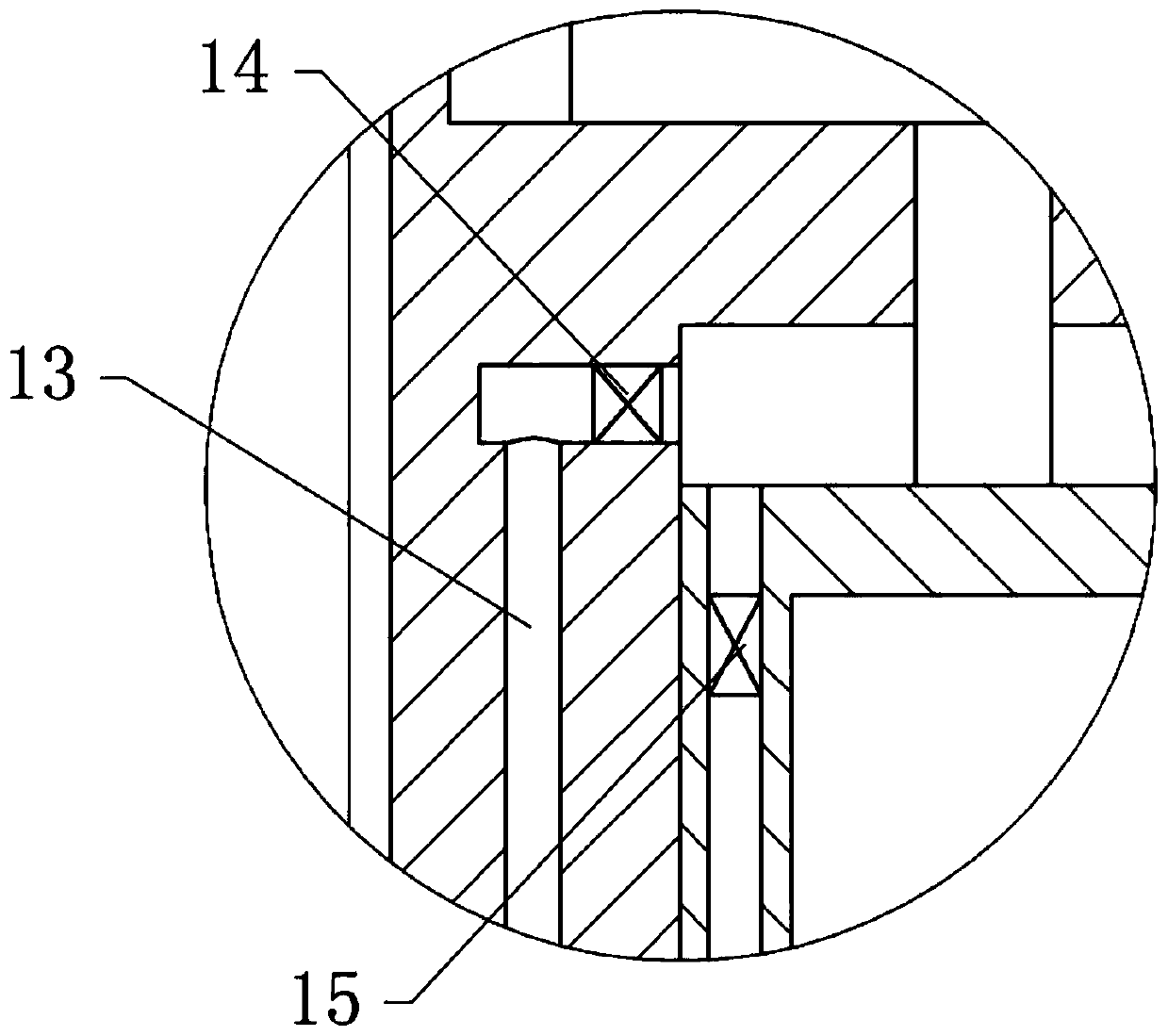

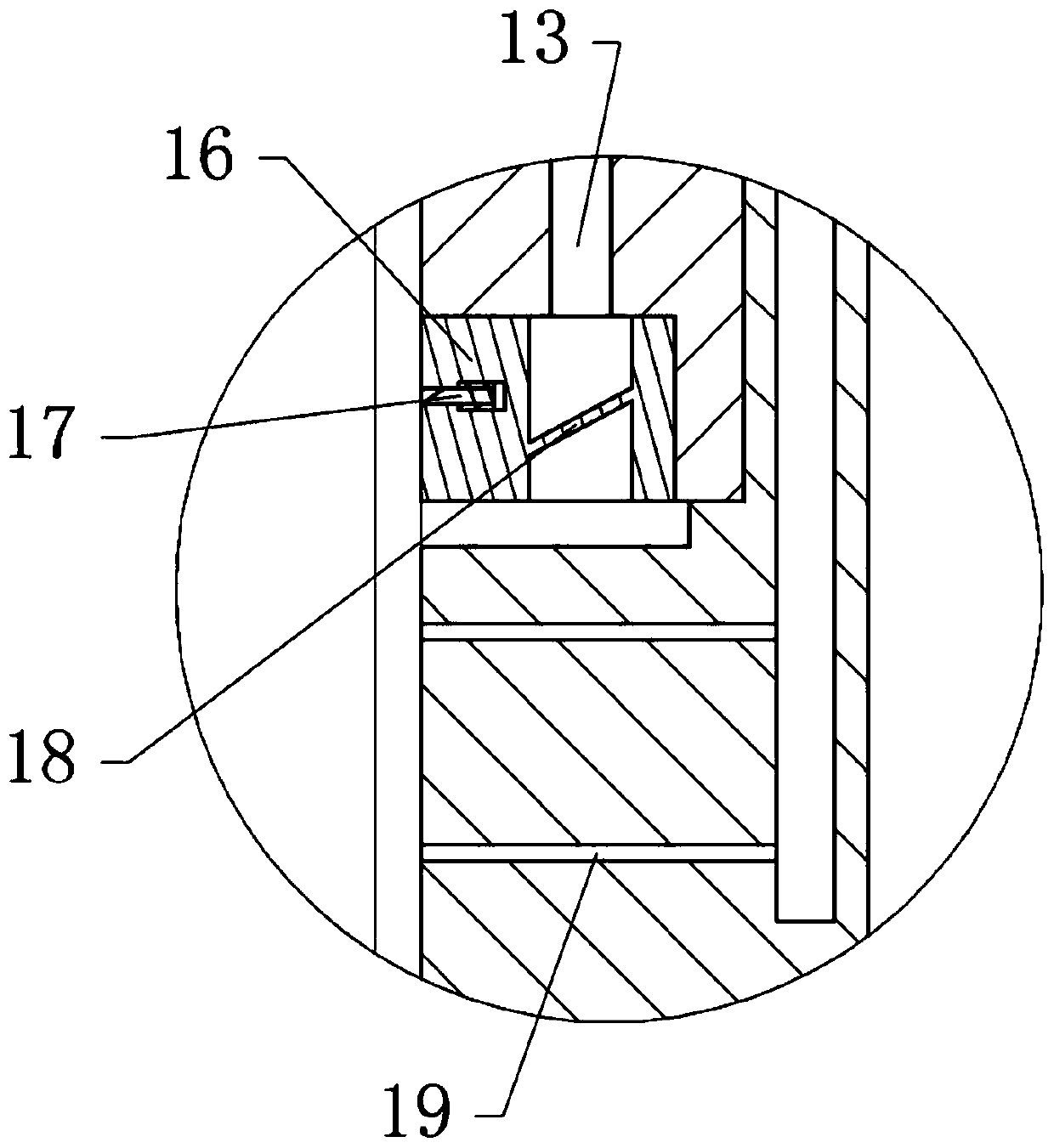

[0030] The reference signs in the accompanying drawings of the specification include: cylinder 10, first cylinder 11, adsorption body 12, first channel 13, first check valve 14, second check valve 15, ring body 16, blade 17, guide Air piece 18, air hole 19, upper sealing part 20a, lower sealing part 20b, hot pressing block 21, second wedge surface 23, first wedge surface 24, adsorption part 30, air duct 31, dust removal pipe 32, strip slit 33. Fan 34, seat body 40, workpiece table 41, pressure spring 42, plastic packaging film 50, electronic device 60

[0031] The method for packaging the electronic device 60 in this embodiment uses a packaging device for the electronic device 60 . Such as figure 1 , figure 2 and image 3As shown, the applied electronic device 60 packaging device includes a feeding part, an adsorption part 30 and a placing part in order from top to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com