Traceless bra machine

A bra machine and bra technology, applied in bras, clothing, bras, etc., can solve the problems of mechanical equipment affecting processing efficiency, reducing labor costs, and disadvantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

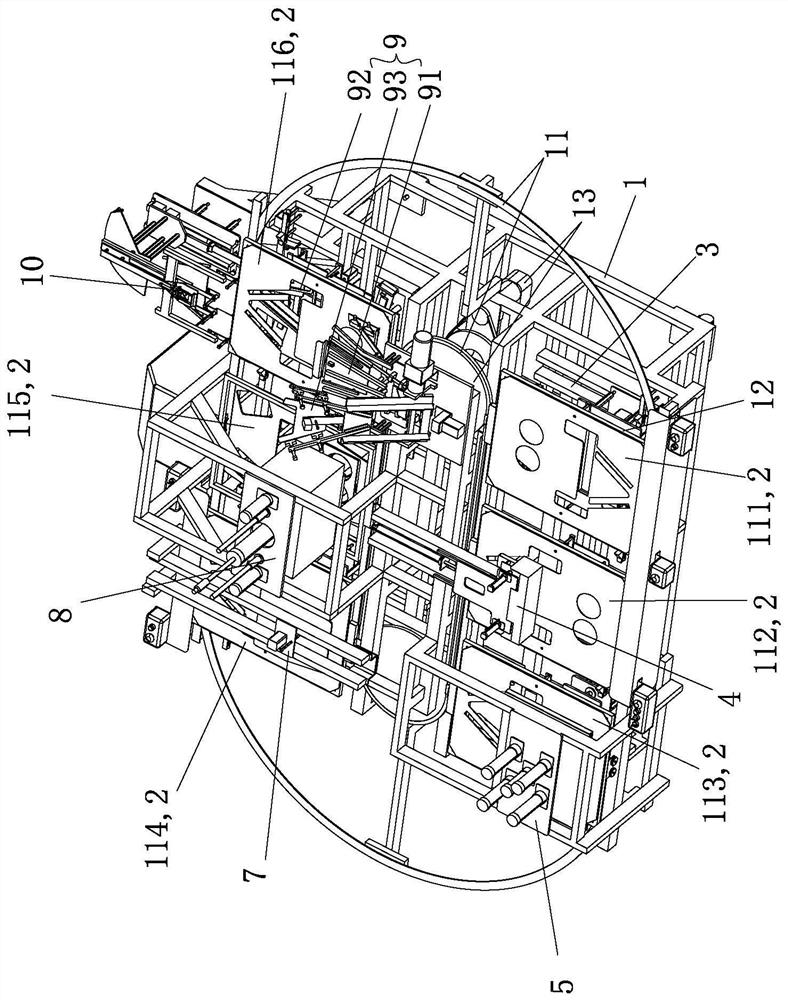

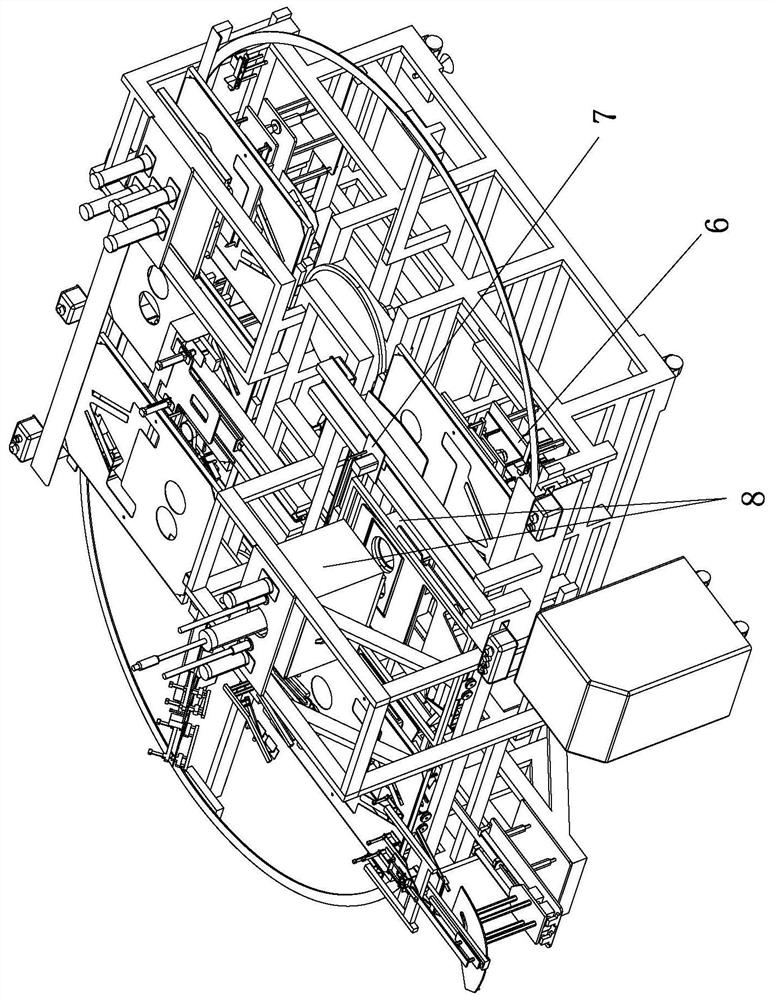

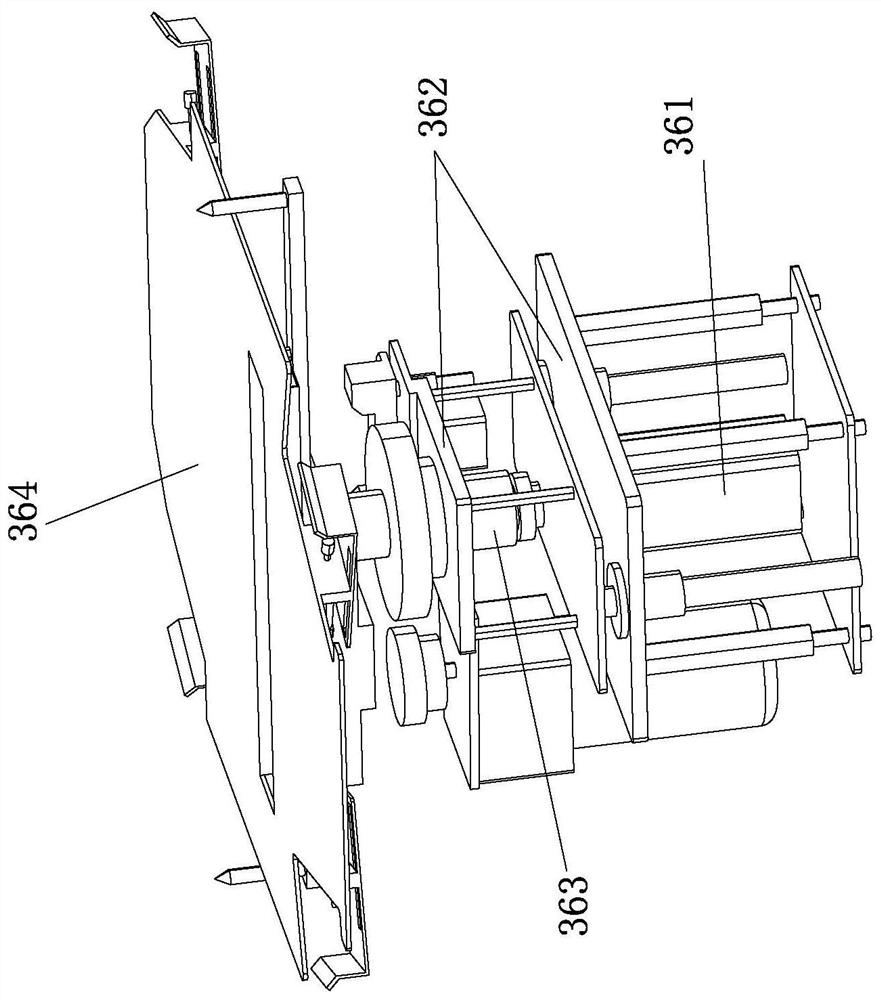

[0033] Such as Figure 1 to Figure 12 As shown, a layout structure of a seamless bra machine includes a frame 1, and the frame 1 is provided with a circulating station line 11, and a carrier plate for moving on the circulating station line 11 is hollowed out. Seat 12, and a power mechanism 13 for driving the carrier board to place the hollow seat 12 to move on the cycle station line 11, and the carrier board to place the hollow seat 12 for providing a number of avoidance holes / slots The cloth carrier plate 2 is positioned and placed on it, and the circulation station line 11 is successively provided with a first station 111, a second station 112, a third station 113, a fourth station 114, a fifth station 115, The sixth station 116, the first station 111 is provided with a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com