Solid plastic rubber wheel and manufacturing process thereof

A manufacturing process and technology of rubber wheels, applied in special tires, tire parts, transportation and packaging, etc., can solve problems such as damage to connecting parts and shortening of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with the examples, the specific implementation of the present invention will be further described in detail. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

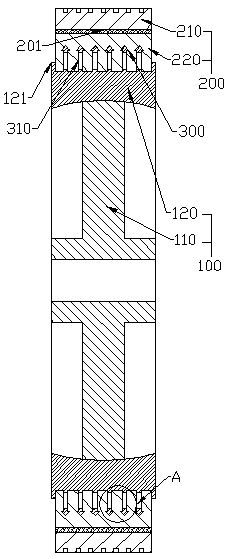

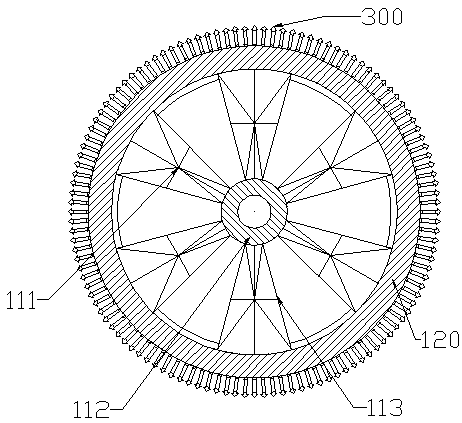

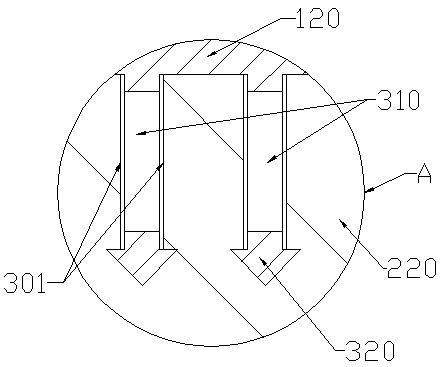

[0034] Such as figure 1 As shown, a solid plastic rubber wheel includes a hub part 100 and a tire part 200, wherein the tire part 200 is wrapped around the outside of the hub part 100, and the inner side of the tire part 200 and the outer side of the hub part 100 are embedded in each other, and the specific hub part 100 includes a supporting part 110 and the heat insulating ring part 120, the outer side of the support part 110 is integrally formed to connect the inner side of the heat insulating ring part 120, the hub part 100 and the heat insulating ring part 120 are embedded and fixed with each other, and the center of the tire part 200 is wrapped with a layer of metal mesh 201.

[0035] Such as Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com