Hot pressing device for plate surface sheet hot pressing processing and processing method thereof

A technology of a hot pressing device and a processing method, which is applied in the field of hot pressing devices for hot pressing processing of sheet surface layers, can solve the problems of degumming, poor flatness of sheet surface, surface warpage and deformation, etc. The effect of pressing use and improving the quality of hot pressing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

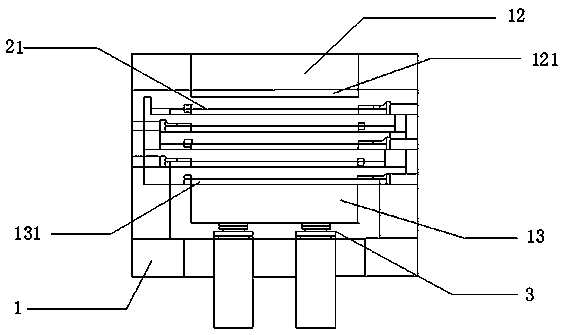

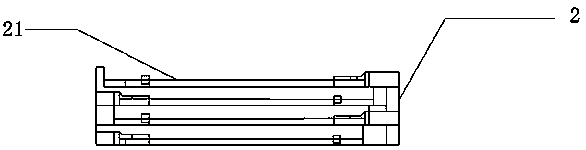

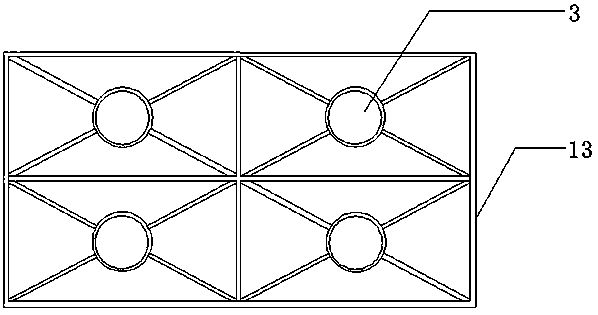

[0024] A hot-pressing device for hot-pressing processing of thin plates on the surface of boards, comprising a hot-pressing frame 1, an upper supporting plate 12, a lower supporting plate 13, a hot-pressing plate group 2, and a plunger cylinder assembly, the upper supporting plate 12 is located at the upper part, the lower supporting plate 13 is located at the lower part, and the hot pressing plate group 2 includes at least two hot pressing plates 21, and the hot pressing plates 21 are respectively located at the lower part of the upper supporting plate 12 and the upper part of the lower supporting plate 13, so The plunger cylinder assembly is located at the lower part of the lower support plate 13 , and the upper end of the plunger cylinder assembly passes through the lower support plate 13 and is fixedly installed with the second buffer plate 131 .

[0025] According to the above structure, the present invention utilizes the plunger oil cylinder 3 to drive the lower supportin...

Embodiment 2

[0032] A hot-pressing processing method for the surface layer of a sheet, characterized in that: preheating, heating the hot-pressing plate 21 in the hot-pressing frame 1 to a specified temperature, the temperature of the hot-pressing plate 21 is 90°C to 100°C, and the preheating time is Not less than 5 minutes; select the surface hot pressing pressure corresponding to the process specification requirements of the base material to be hot pressed, and the surface hot pressing pressure is , where Pg is the surface hot pressing pressure set in the hot pressing process of the substrate, S is the surface area of one side of the hot pressing processed substrate, Pd is the unit pressure, D is the diameter of the plunger cylinder of the hot press, and X is the diameter of the hot press The number of plunger cylinders 3, A is the pressure loss coefficient; set the hot pressing time, the hot pressing time is 280s~320s.

[0033] Further, the unit pressure in this embodiment is 0.5 MPa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com