Seamless wave bottom of underpants and technology for compounding wave bottom and hot melting adhesive tape

A seamless wave bottom, hot melt adhesive technology, applied in underwear, clothing, lamination devices and other directions, can solve the problems of high production cost, leakage of glue, uneven glue strip, etc., to improve production capacity and save electricity costs , to avoid the effect of high temperature injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

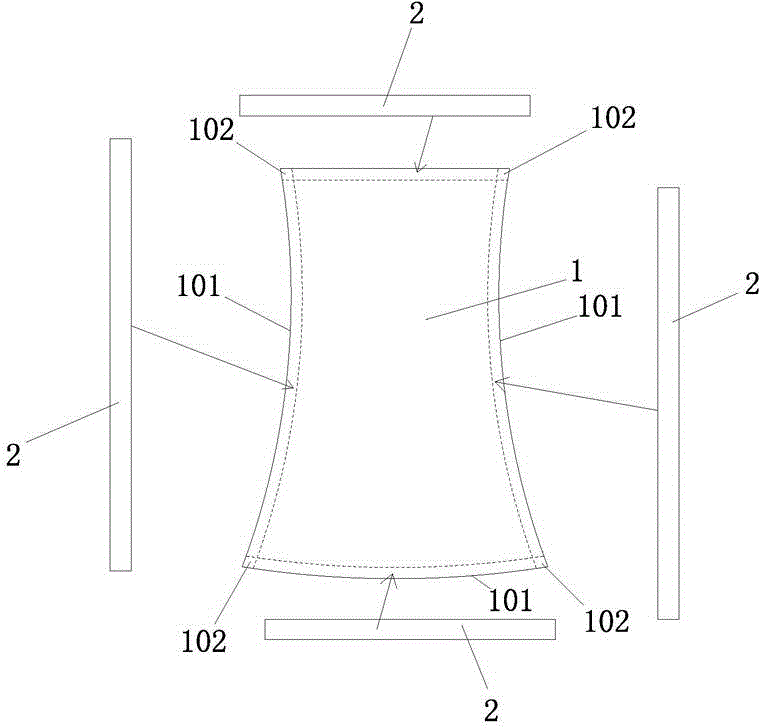

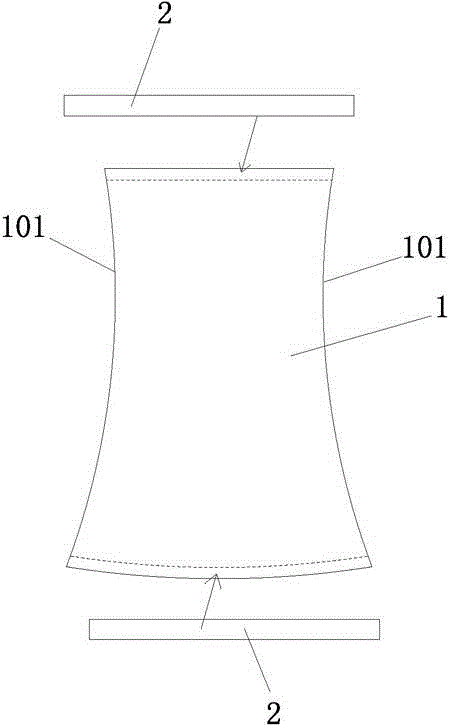

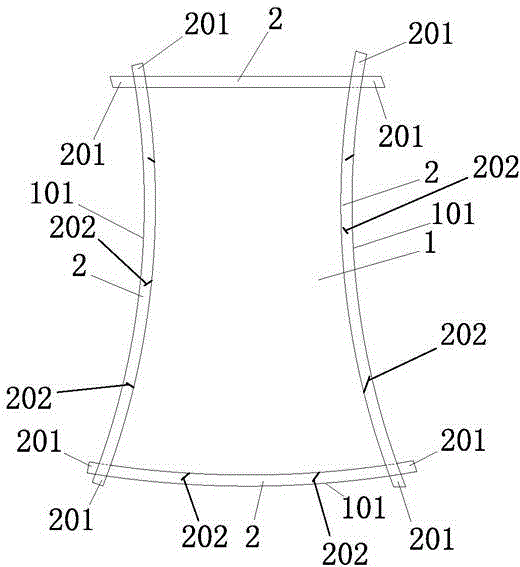

[0047] Such as Figure 6 to Figure 12 As shown, a seamless wave bottom of underwear includes a wave bottom fixing area 101 arranged on the underwear main body 1, and a wave bottom 2 is seamlessly pressed on the wave bottom fixing area 101. A hot-melt adhesive strip 3 with a width of L is provided on the wave bottom 2, and the hot-melt adhesive strip 3 is integrated to extend along the contour edge 201 of the wave bottom 2, and the wave bottom 2 is bonded to the wave bottom by hot-melt adhesive strip 2 On the fixed area 101.

[0048] The L is 5-9mm (the best range value is 6-8mm, and the best value is 8mm).

[0049] A technique for compounding wave bottoms and hot-melt adhesive strips is characterized in that it comprises the following steps:

[0050] (1) Slitting hot melt adhesive film and wave bottom fabric

[0051] First prepare roll-shaped hot melt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com