Formaldehyde-purification-stage wood floor

A wooden floor and aldehyde-removing technology, which is applied in lignin coatings, coatings, buildings, etc., can solve problems affecting the health of residents and achieve the effect of improving the effect of aldehyde removal, improving the effect of aldehyde removal, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

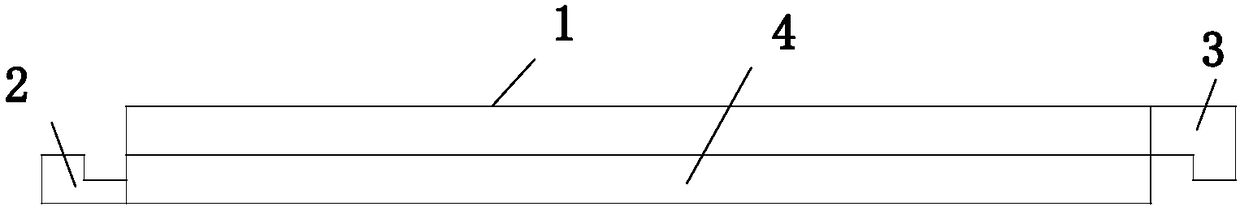

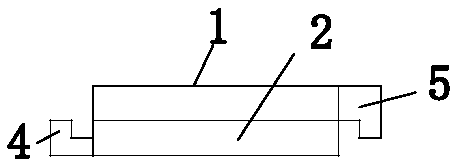

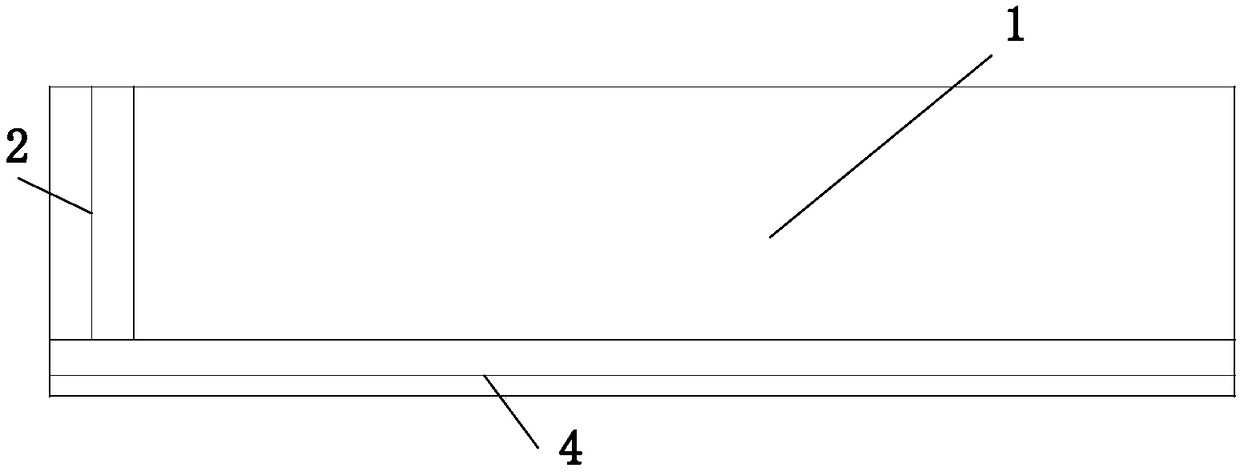

[0020] Example 1. A net aldehyde grade wooden floor, constituted as Figure 1 to Figure 4 As shown, including the floor body 1, the front of the floor body 1 is coated with primer, topcoat and net aldehyde paint in sequence; the two short sides of the floor body 1 are respectively provided with a fastening tenon groove 2 and a fastening tenon that cooperate with each other. 3. The two long sides of the floor body 1 are respectively provided with engaging tenons 4 and engaging tenons 5 corresponding to each other.

[0021] The net aldehyde paint includes the following raw materials in parts by weight: rosin resin, 5-6 parts; water, 2-3 parts; lignin, 15-20 parts; ultrafine bamboo charcoal powder, 10-12 parts; , 23-26 parts; metal porphyrin complexes, 1-3 parts; paraffin, 4-6 parts. Preferably: rosin resin, 6 parts; water, 2 parts; lignin, 18 parts; superfine bamboo charcoal powder, 11 parts; nano-titanium dioxide, 24 parts; metal porphyrin complex, 2 parts; paraffin, 5 parts....

Embodiment 2

[0023] Example 2. A net aldehyde grade wooden floor, constituted as Figure 5 to Figure 7 As mentioned above, the floor body 1 is included, and the front of the floor body 1 is coated with primer, topcoat and net aldehyde paint in turn; the two short sides of the floor body 1 are respectively provided with a fastening tenon groove 2 and a fastening tenon that cooperate with each other. 3. The two long sides of the floor body 1 are respectively provided with engaging tenons 4 and engaging tenons 5 corresponding to each other.

[0024] A plurality of positioning holes 201 are evenly arranged on the fastening tenon and groove 2, and a positioning seat 202 of a hollow structure is arranged in the positioning hole 201, and a compression spring 203, an iron seat 204 and an annular collar 205 are arranged in the positioning seat 202; The inlet end in the positioning seat 202 described above is a conical structure 206, and the middle part of the conical structure 206 is provided with...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com