Patents

Literature

173results about How to "Lower limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

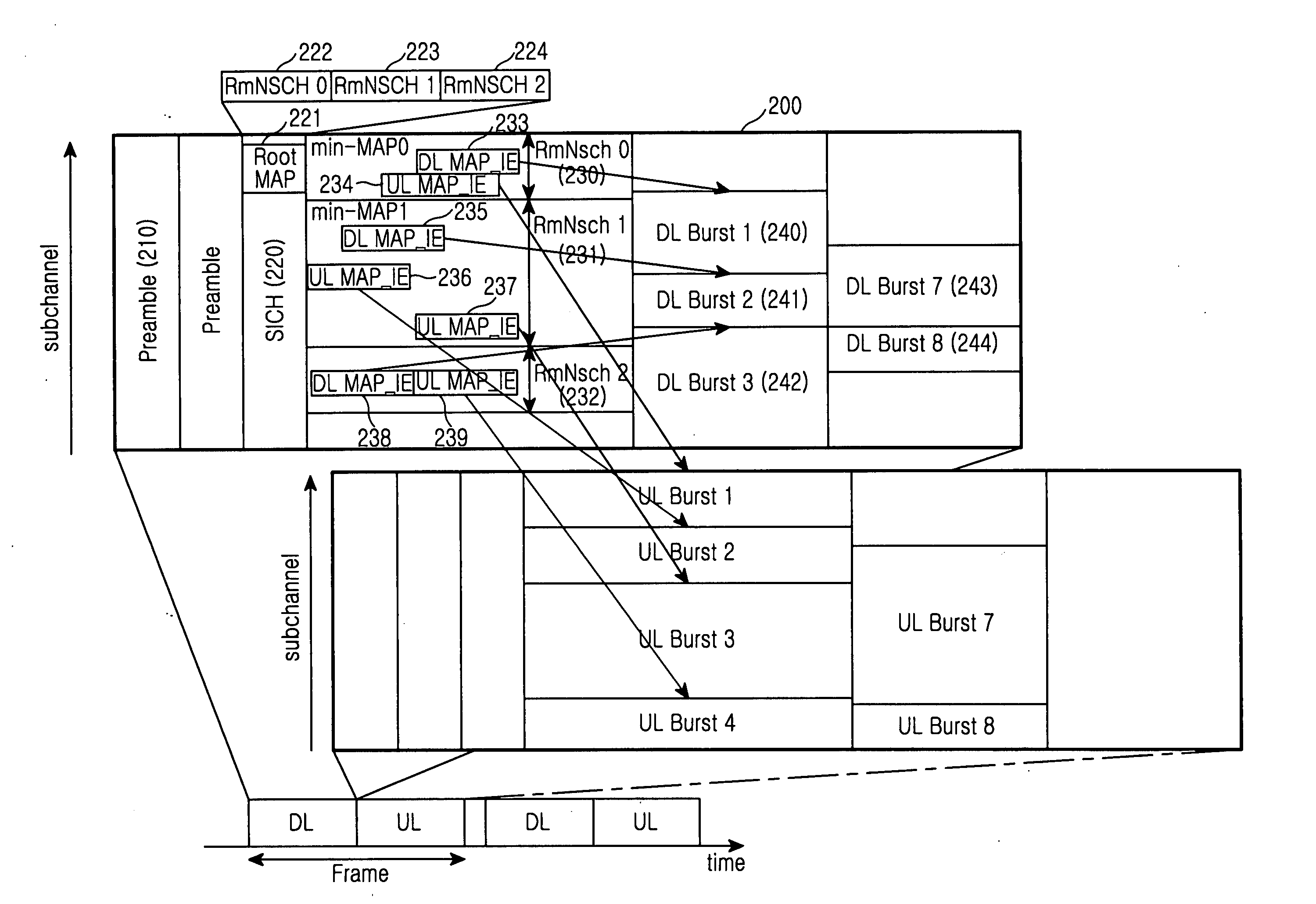

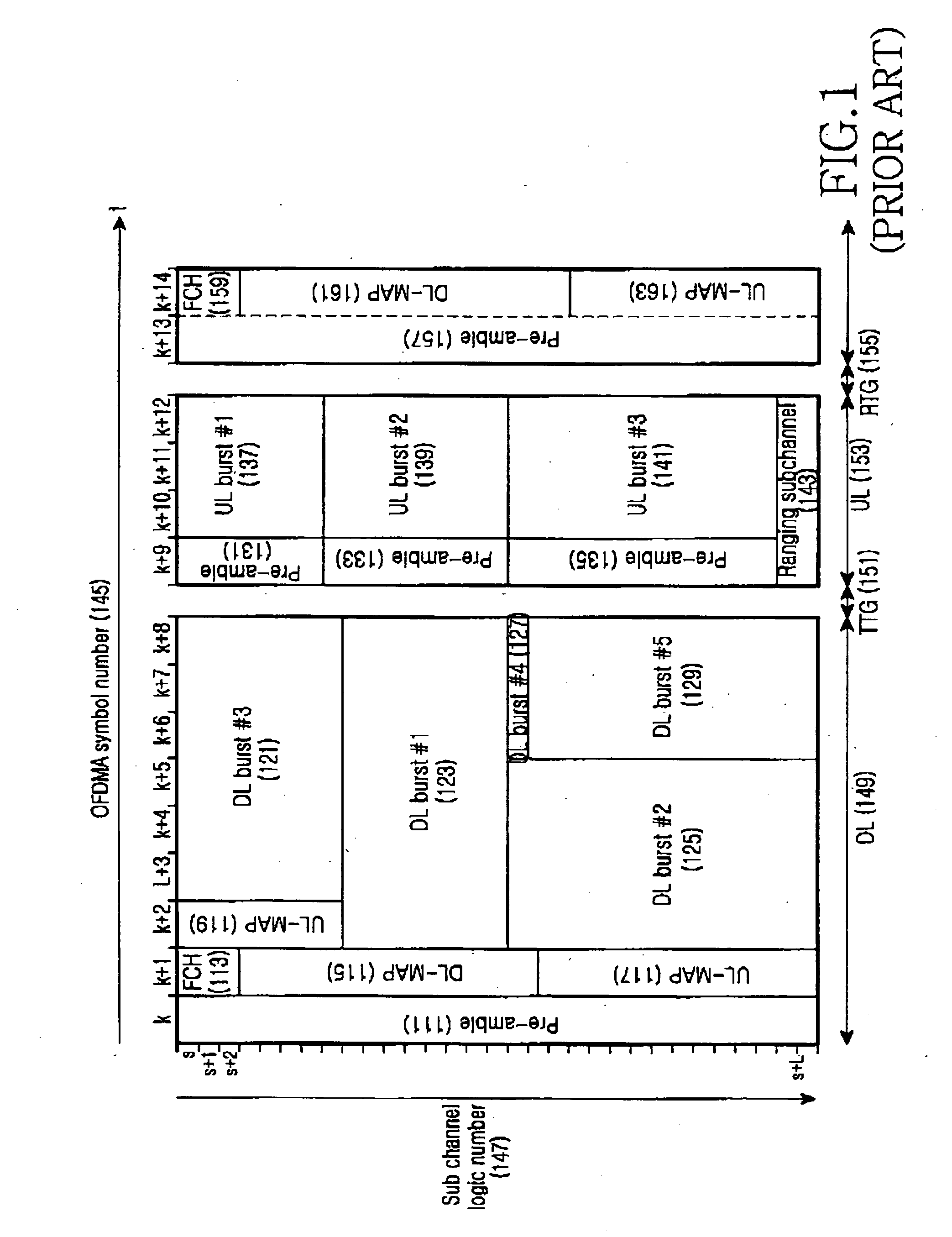

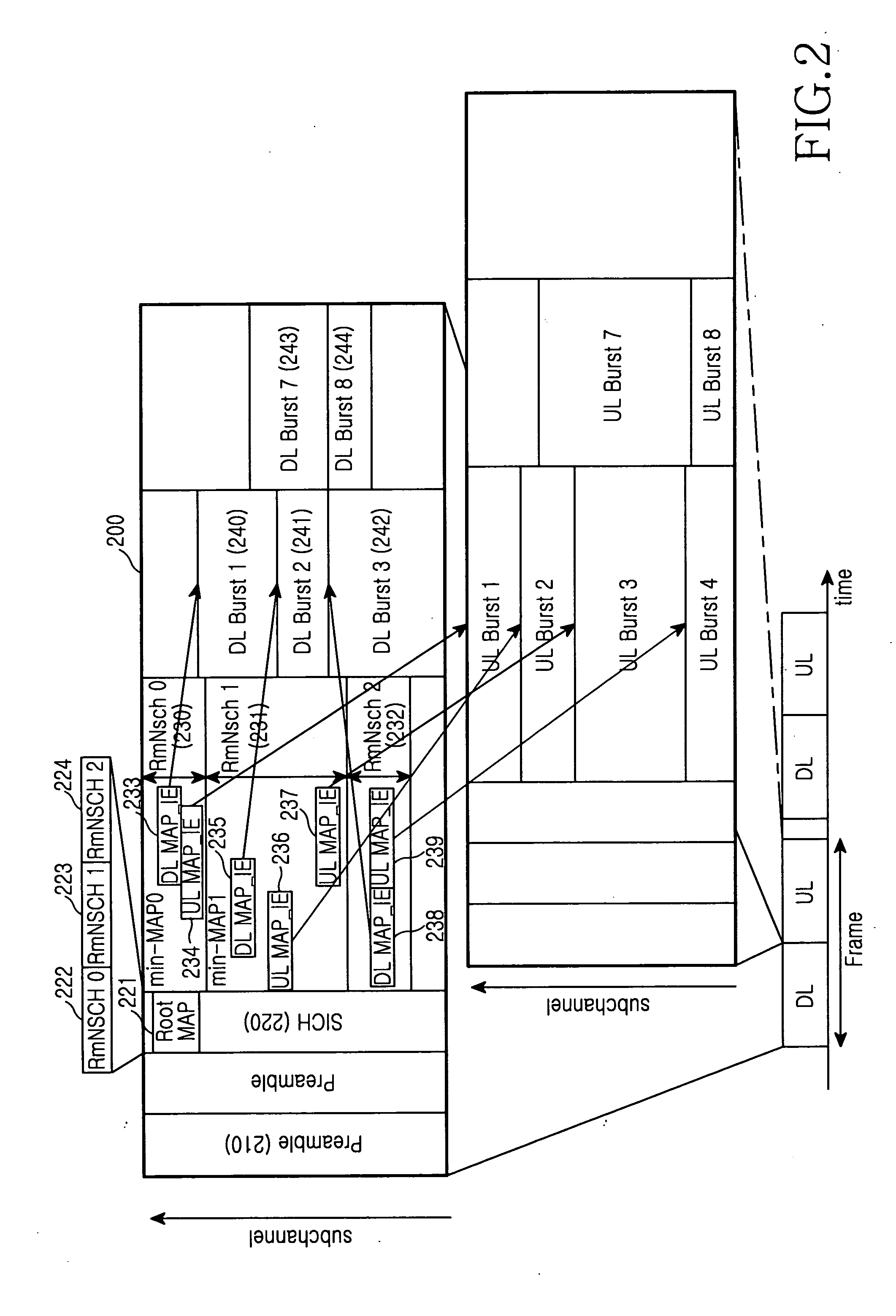

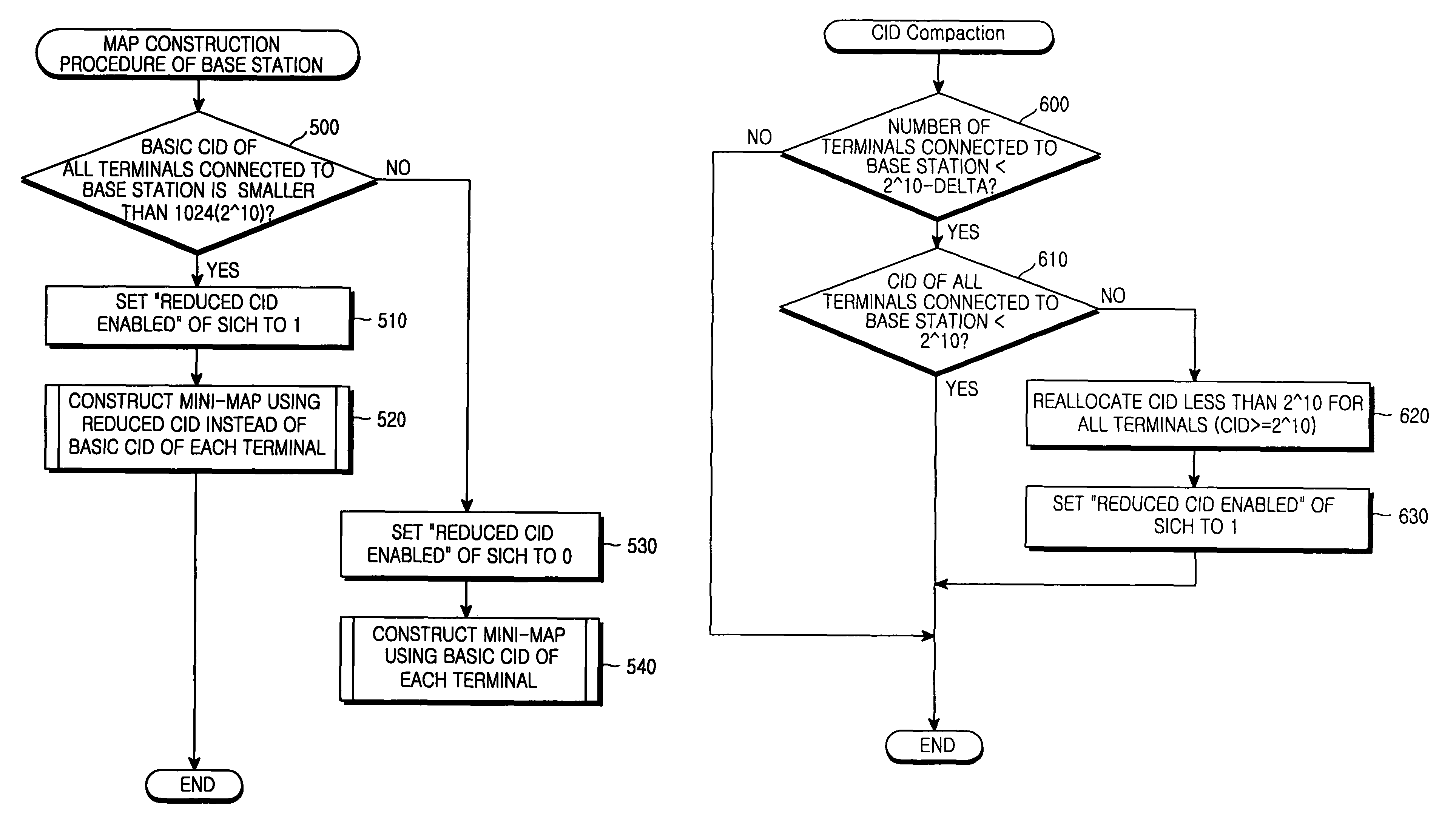

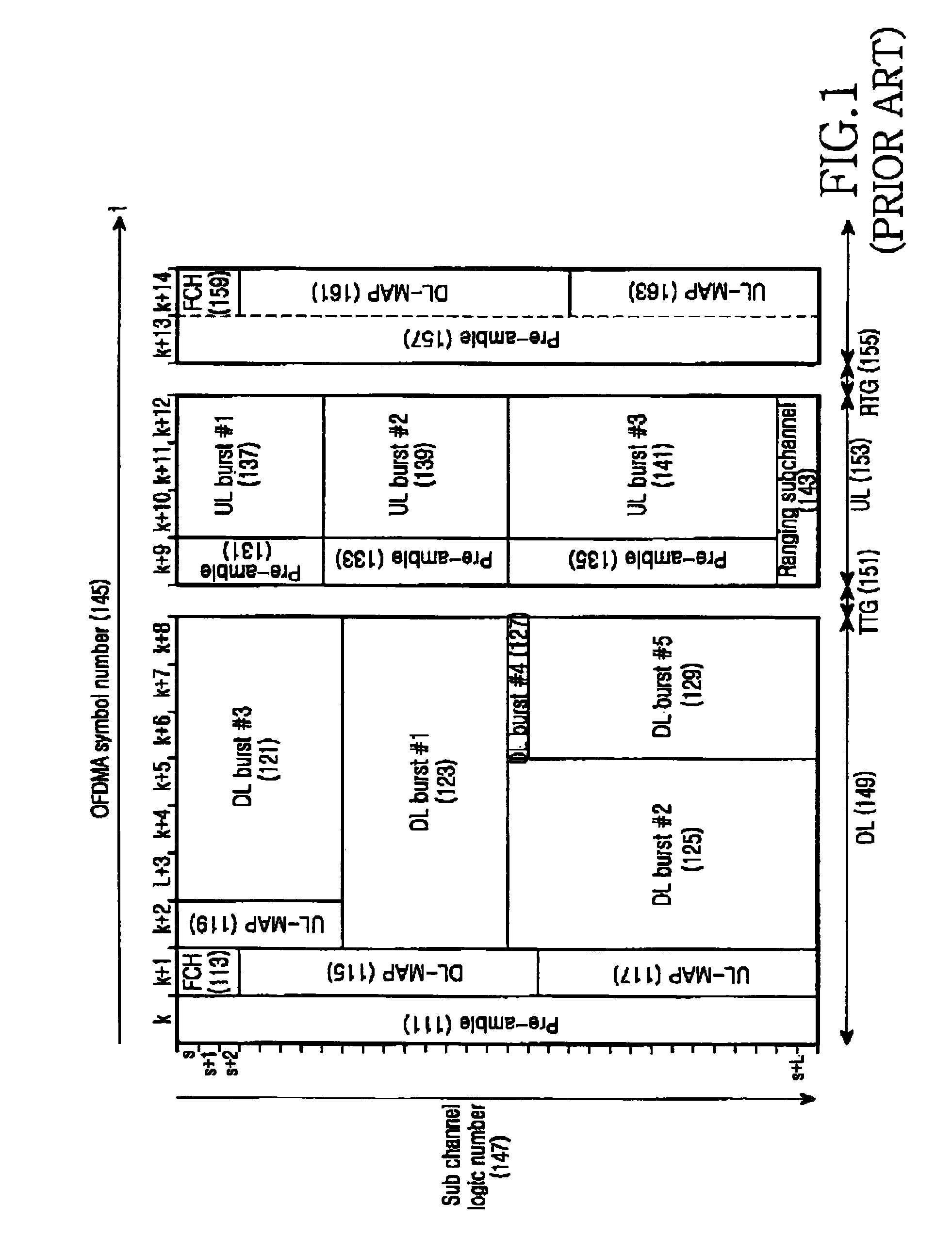

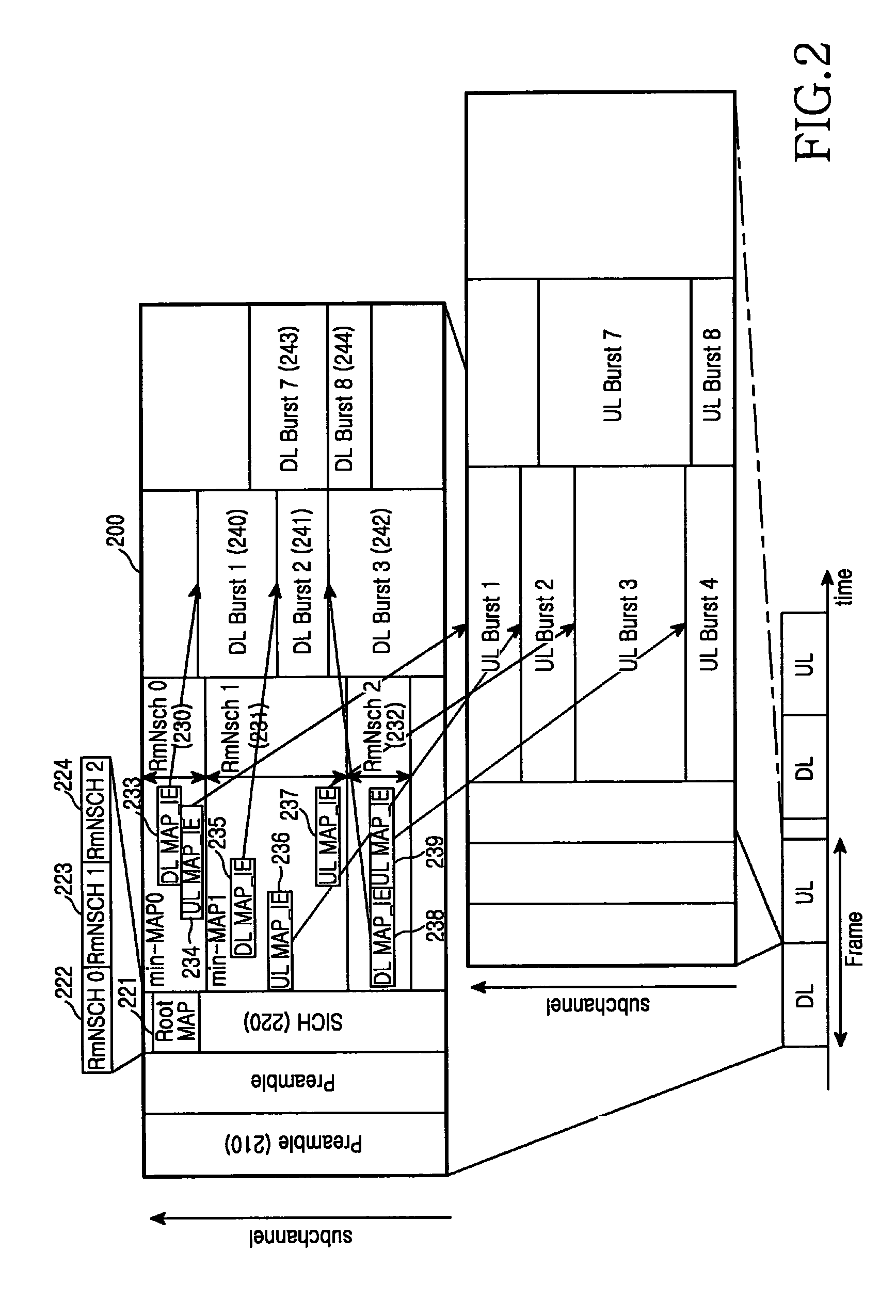

Method and apparatus for constructing MAP IE using reduced CID in broadband OFDMA systems

ActiveUS20050201269A1Reduce overheadReduce system overheadWith electric batteriesTime-division multiplexBroadbandComputer science

A method for transmitting burst allocation information by a base station in a broadband wireless communication system in which a transmitted frame includes symbols, and orthogonal subcarriers in a frequency axis constitute each of the symbols based on a predetermined time unit. The method includes the steps of generating a reduced connection identifier (CID) by reducing a basic CID of a mobile terminal connected to the base station when the basic CID exists within a preset range, and inserting an MAP, which includes an enabled field representing the reduced CID and one of use and non-use of the reduced CID, into the frame, and transmitting the frame to the mobile terminal.

Owner:SAMSUNG ELECTRONICS CO LTD

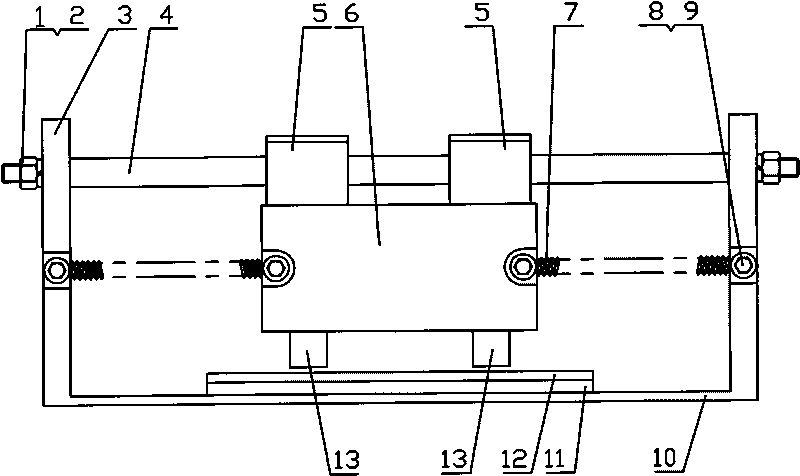

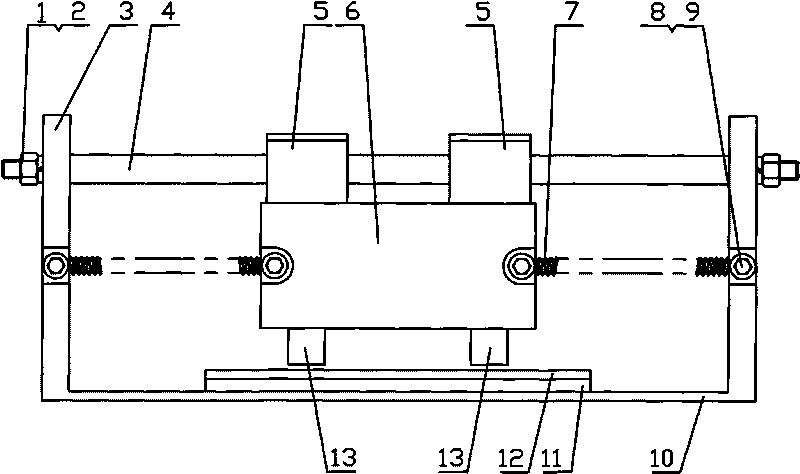

Permanent-magnet type eddy current tuned mass damper

ActiveCN101761146APrecise linear motionStructural damping dropBridge structural detailsTowersStress concentrationElectricity

The invention relates to a permanent-magnet type eddy current tuned mass damper which comprises a steel magnetic-conducting baseplate (10), wherein end plates (3) are respectively arranged at two ends of the baseplate (10). The permanent-magnet type eddy current tuned mass damper is characterized by also comprising a circular shaft (4) and a linear bearing seat (5), wherein two ends of the circular shaft (4) are respectively arranged on the corresponding end plates (3), and the linear bearing seat (5) is sleeved on the circular shaft (4) and can slide on the circular shaft (4); the lower part of the bearing seat (5) is connected with a mass block (6), and two ends of the mass block (6) are respectively connected with the corresponding end plates (3) through spiral springs (7); the lower part of the mass block (6) is connected with a permanent magnet (13), and a copper plate (12) is arranged below the permanent magnet (13) and connected with the baseplate (12) through a cushion block (11). By adopting an eddy current damping model with special design, the permanent-magnet type eddy current tuned mass damper realizes the damping adjustability of the damper in a larger range, realizes the complete separation between the system rigidity and the damper, and cancels the mechanical friction energy consumption and stress concentration elements, thereby avoiding the common TMD damage failure.

Owner:湖南省潇振工程科技有限公司 +1

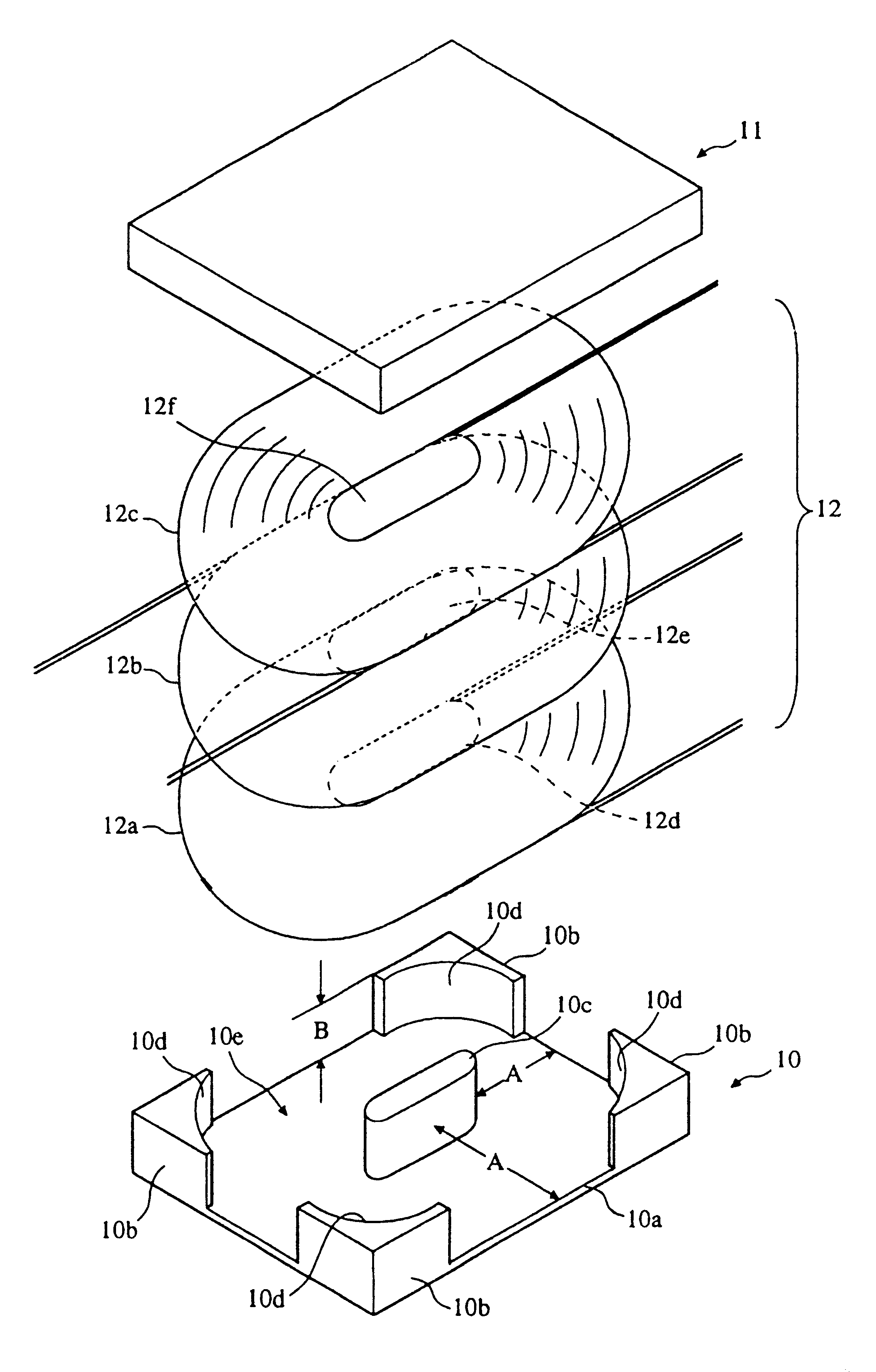

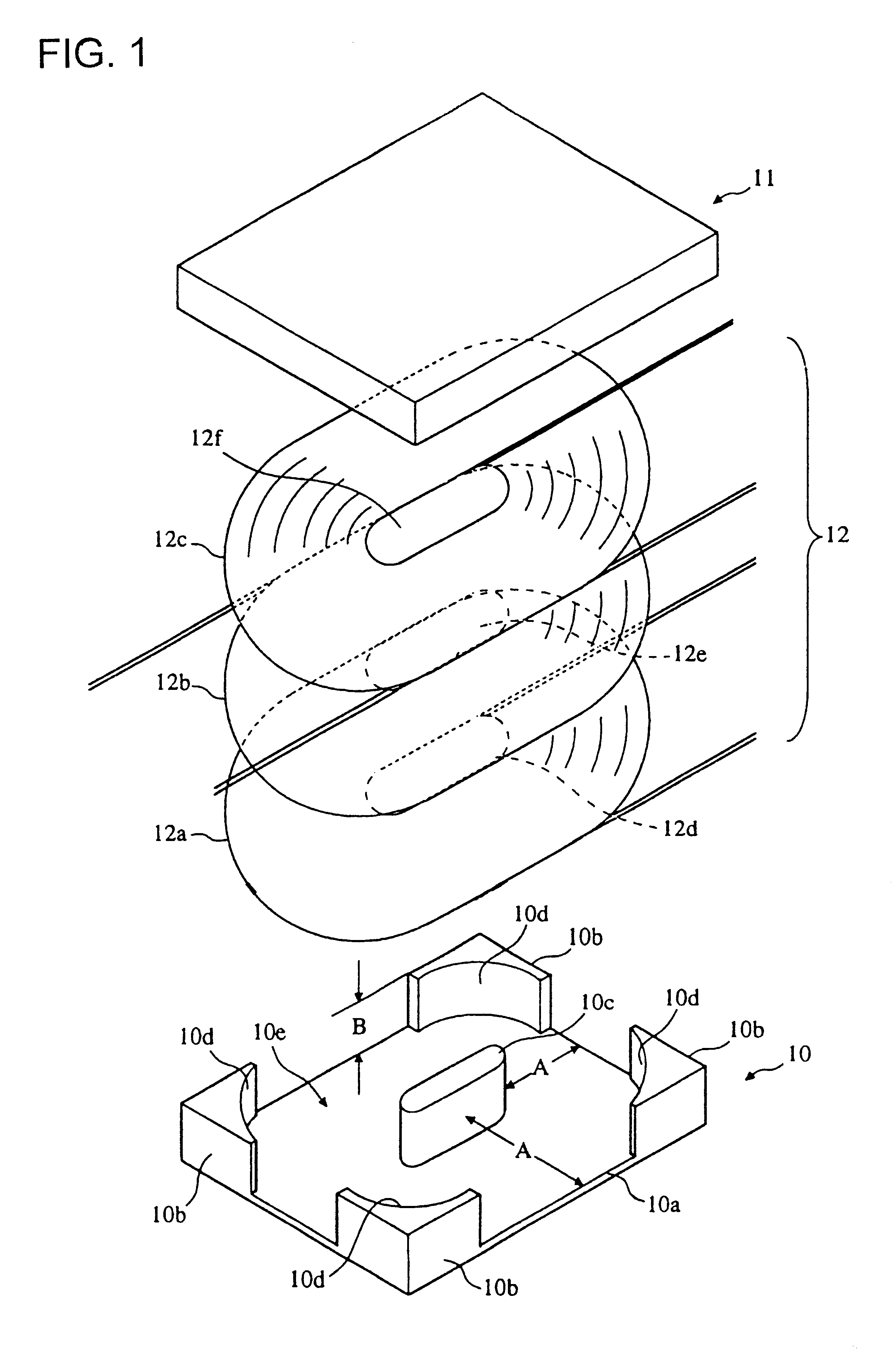

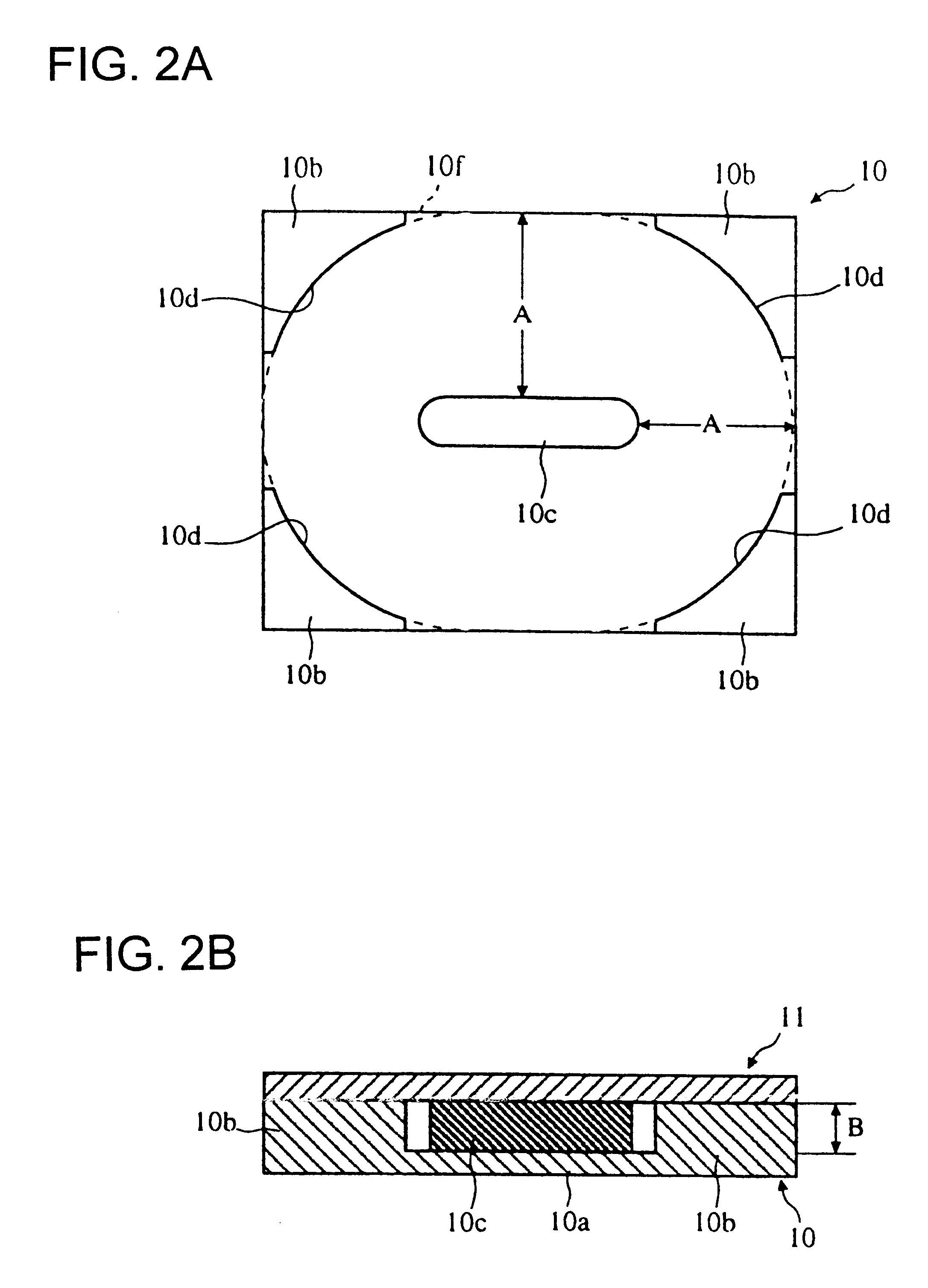

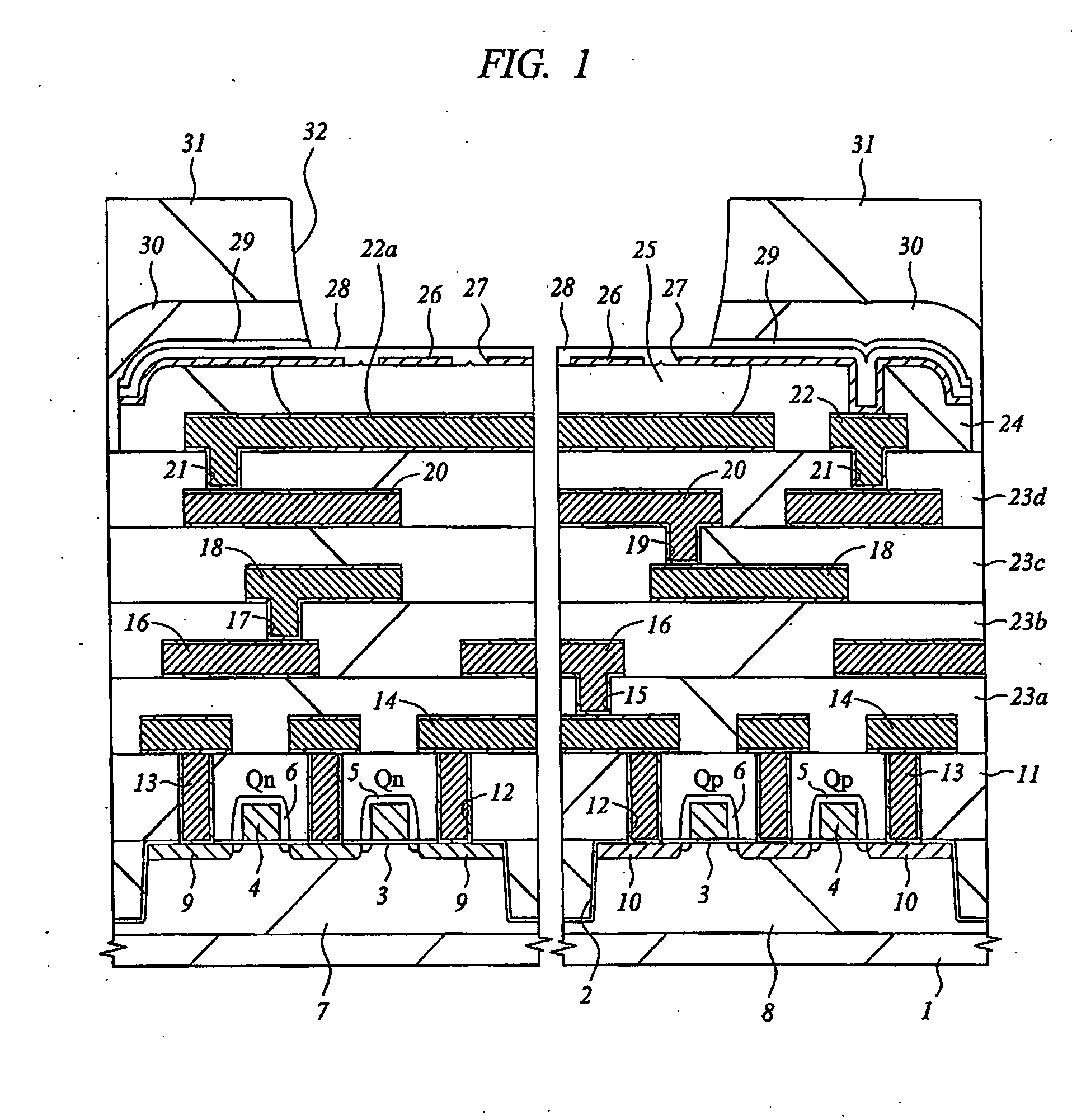

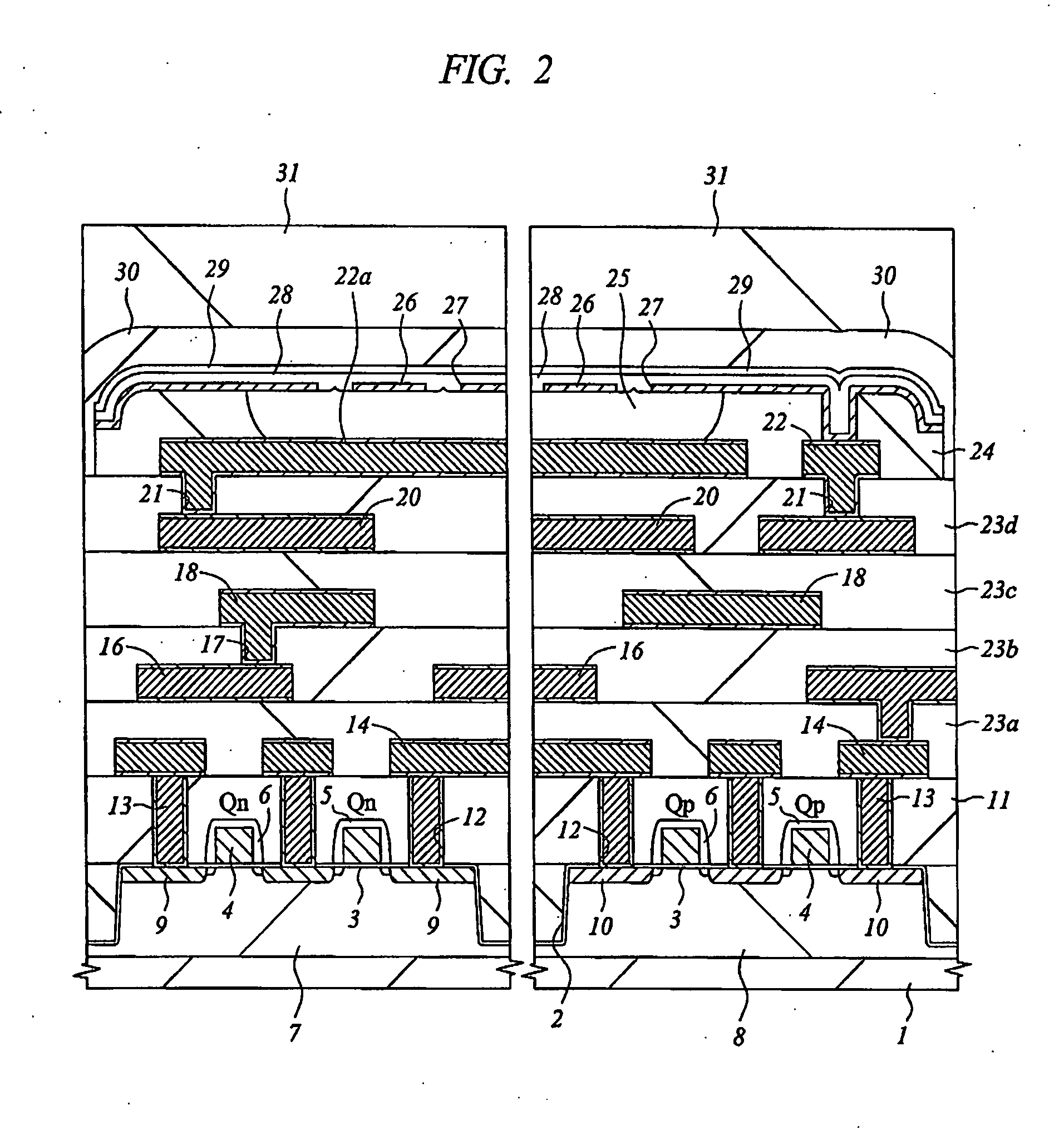

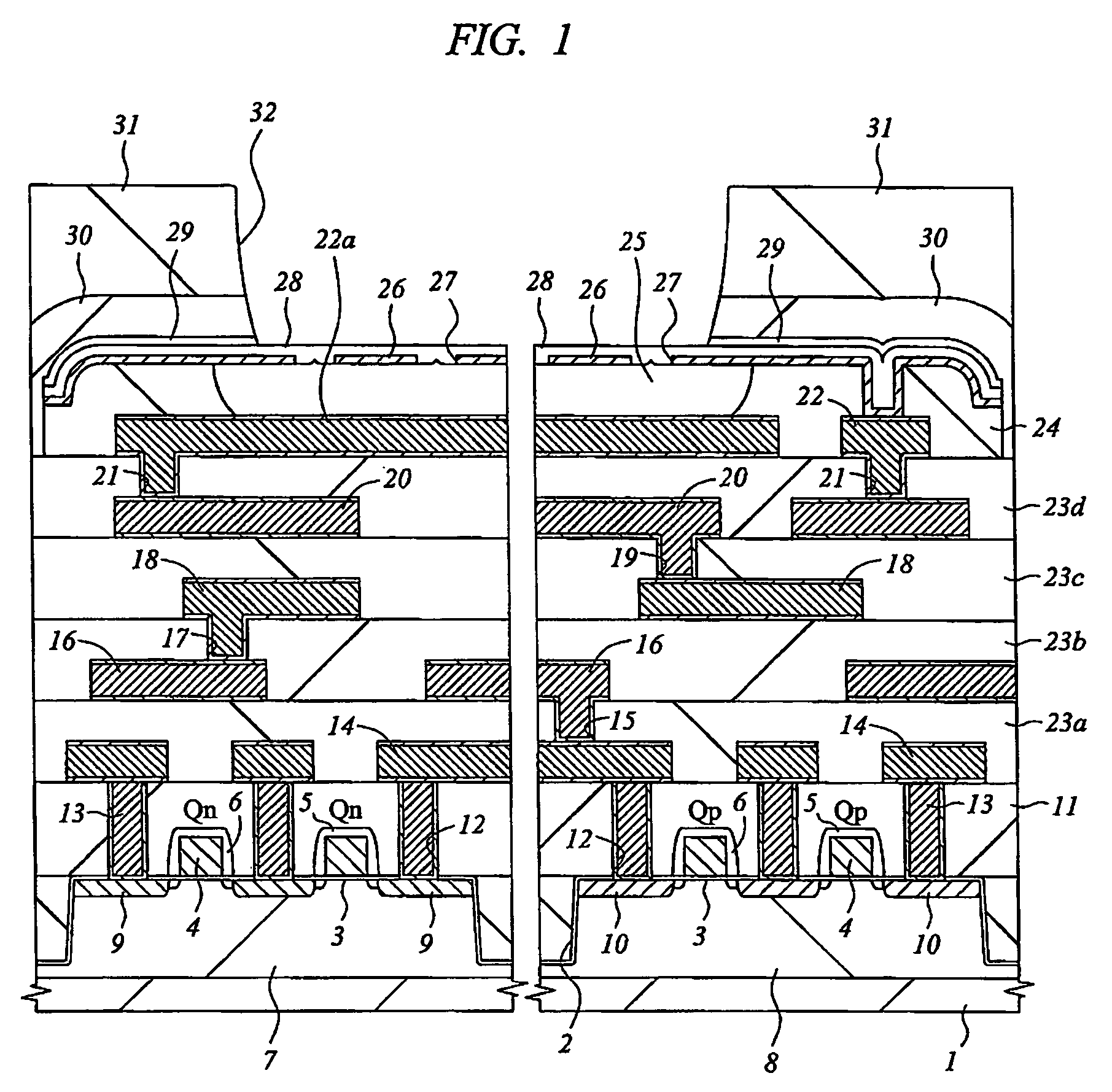

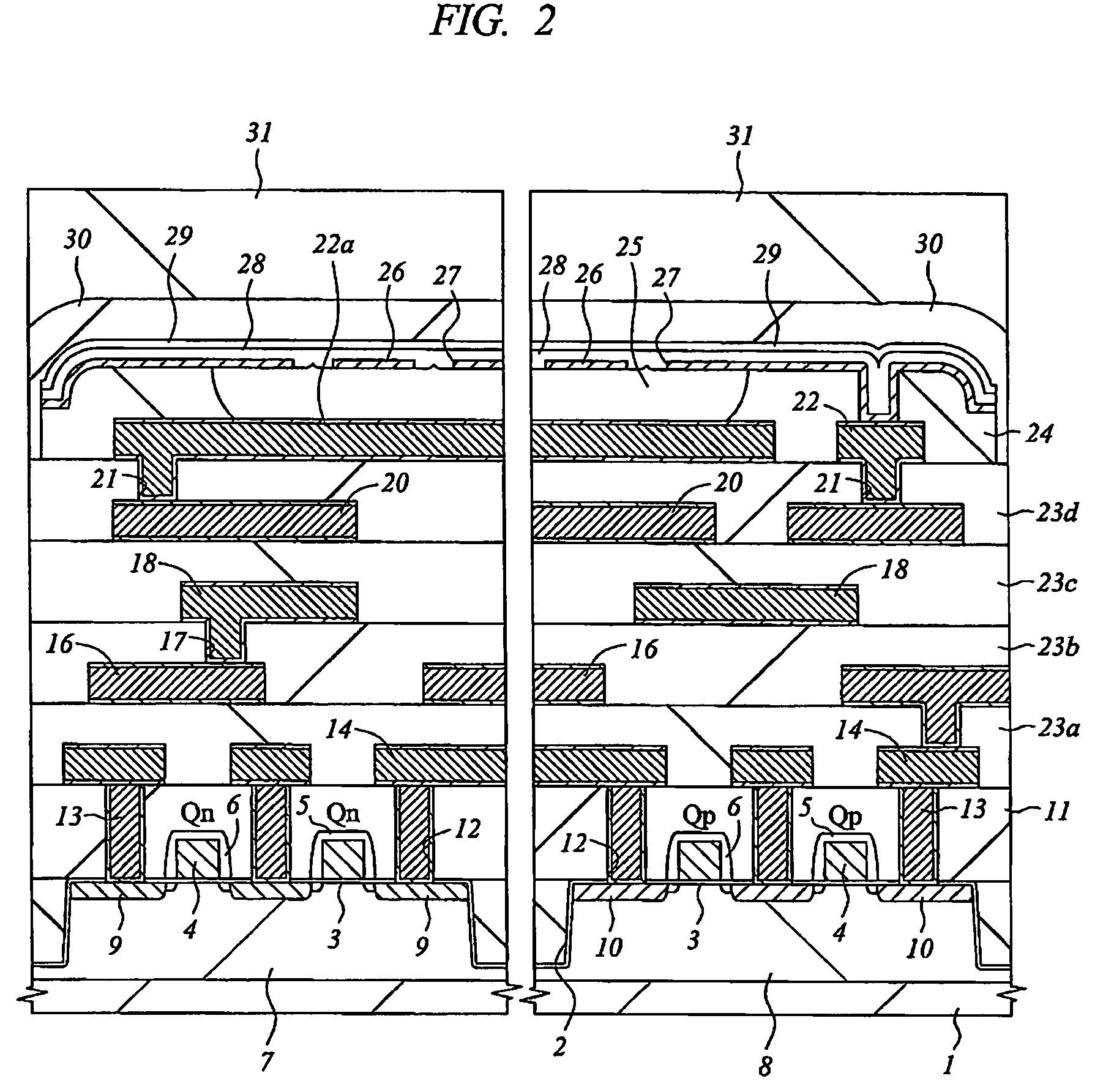

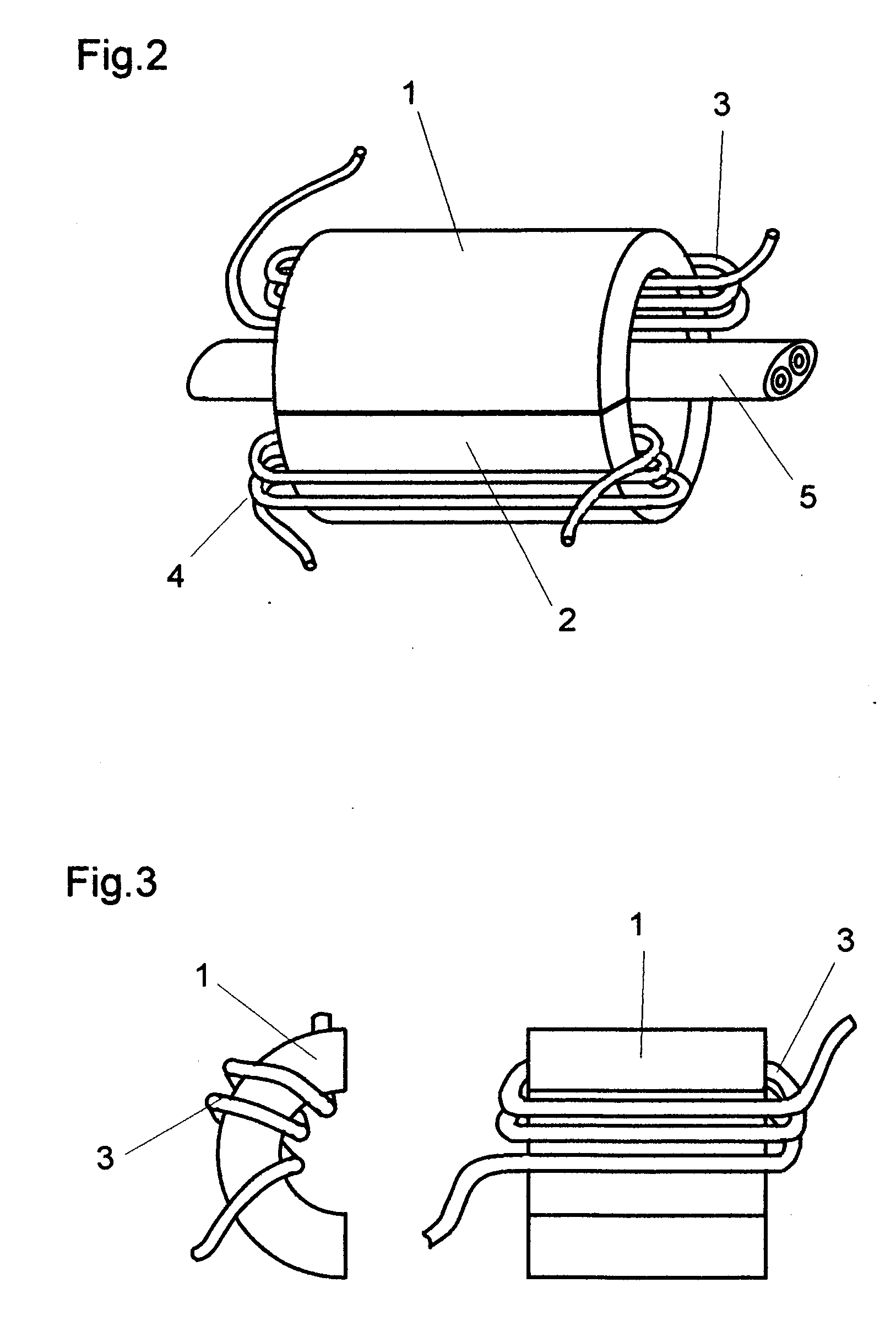

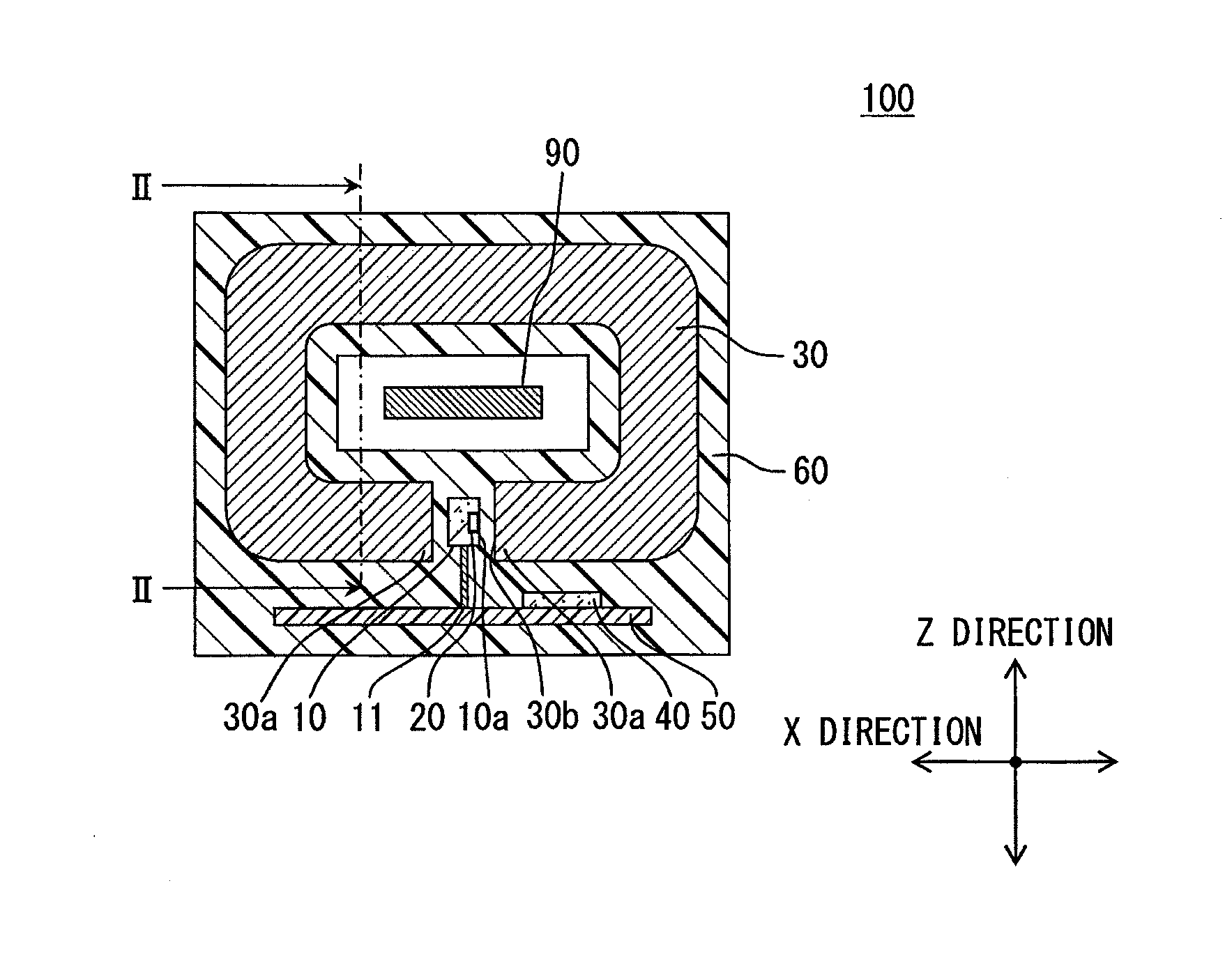

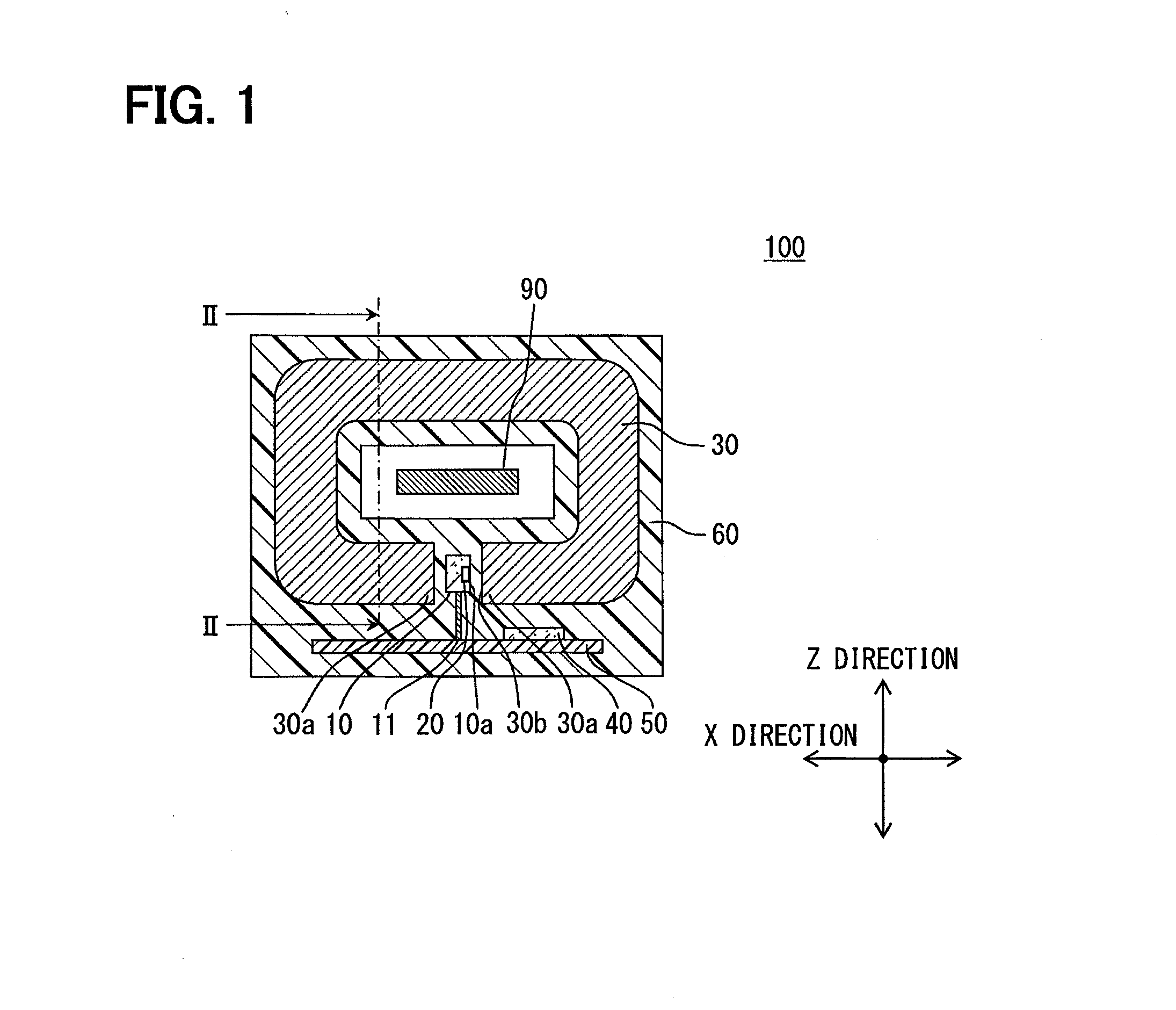

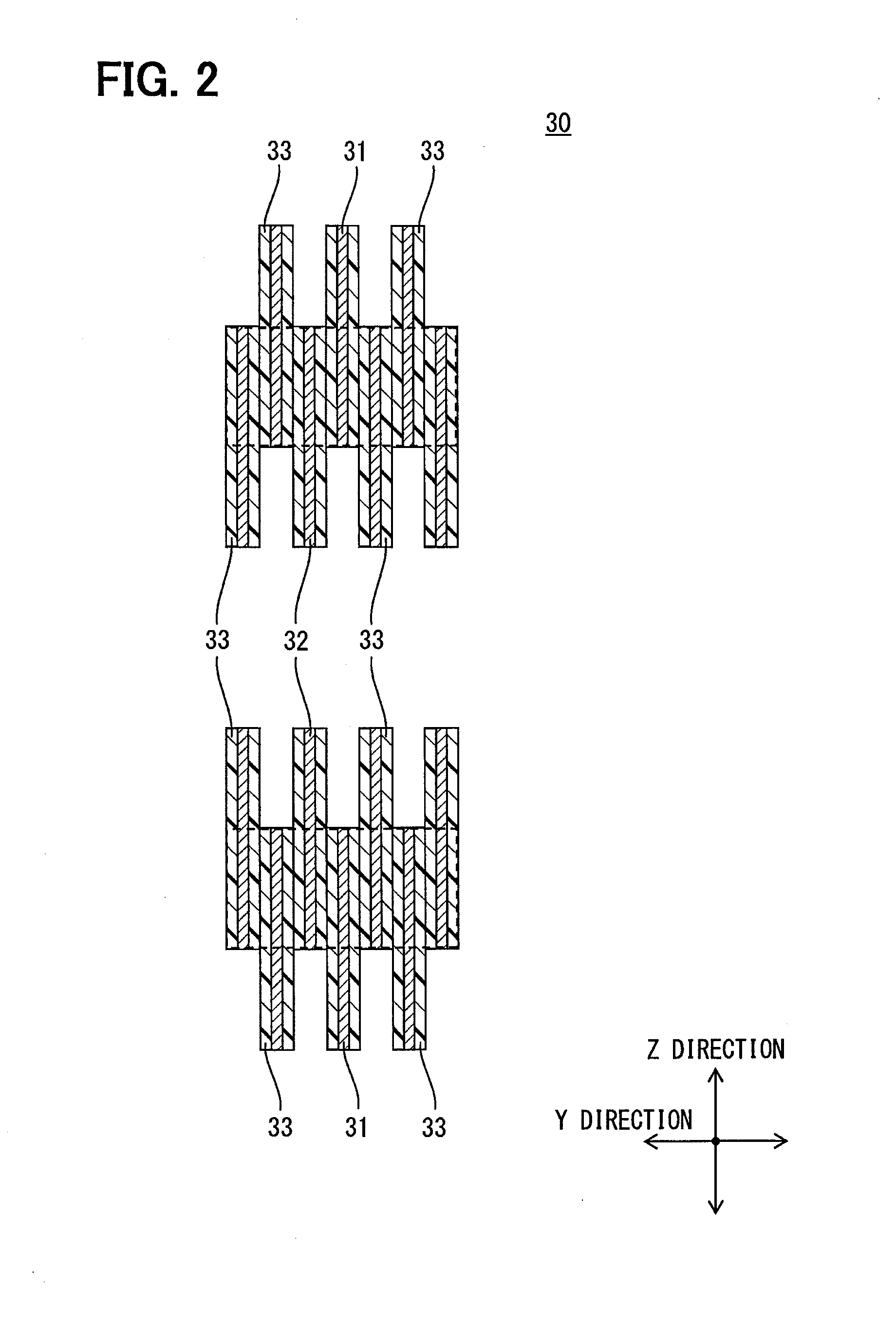

Transformer

InactiveUS6583697B2Reduce the amount requiredMinimized footprintTransformers/inductances casingsTransformers/inductances coils/windings/connectionsTransformerEngineering

A transformer including a first magnetic core and a second magnetic core having the shape of a flat plate. In the first magnetic core, a middle leg and substantially L-shaped outer legs whose inner sides are formed as circular-arc-shaped surfaces are provided in a standing manner at the central portion and at the comers of a rectangular flat plate, respectively. In addition, in the first magnetic core, a winding accommodating portion is formed between the circular-arc-shaped surfaces of the corresponding outer legs and an outer peripheral surface of the middle leg. Three coil portions, formed by spiral winding operations in level states, are placed upon each other, and are inserted into the winding accommodating portion of the first magnetic core. Then, from above the coil portions, the second magnetic core is placed thereon in order to form an integral structure. At this time, at the side portions of the flat plate, an external line of the flat plate and an external line of the winding accommodating portion coincide with each other. Therefore, the footprint of the transformer becomes small. Accordingly, in the invention, the transformer can be made smaller and thinner as a result of making the dead space that exists during the mounting of the coil to the magnetic core as small as possible.

Owner:MURATA MFG CO LTD

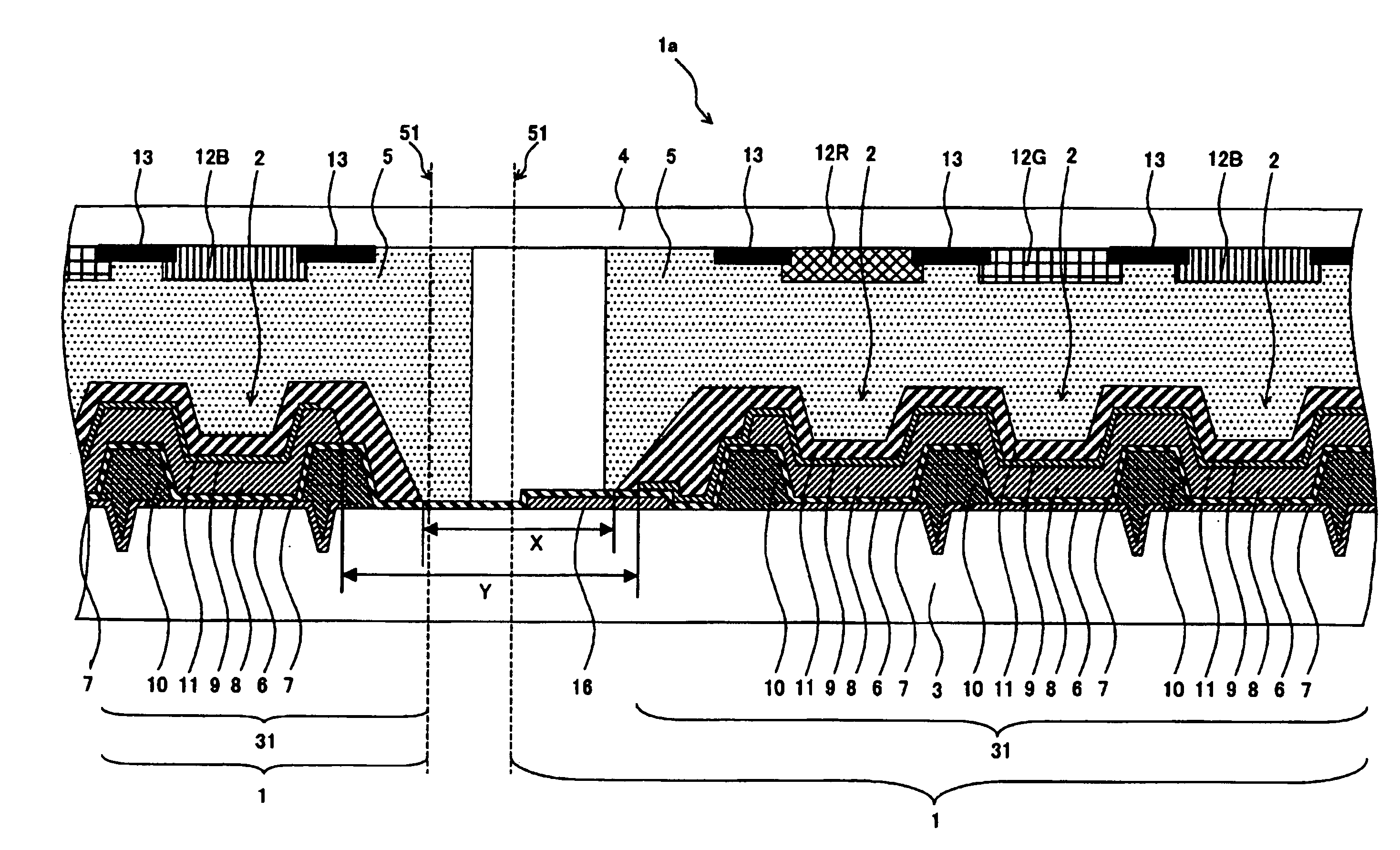

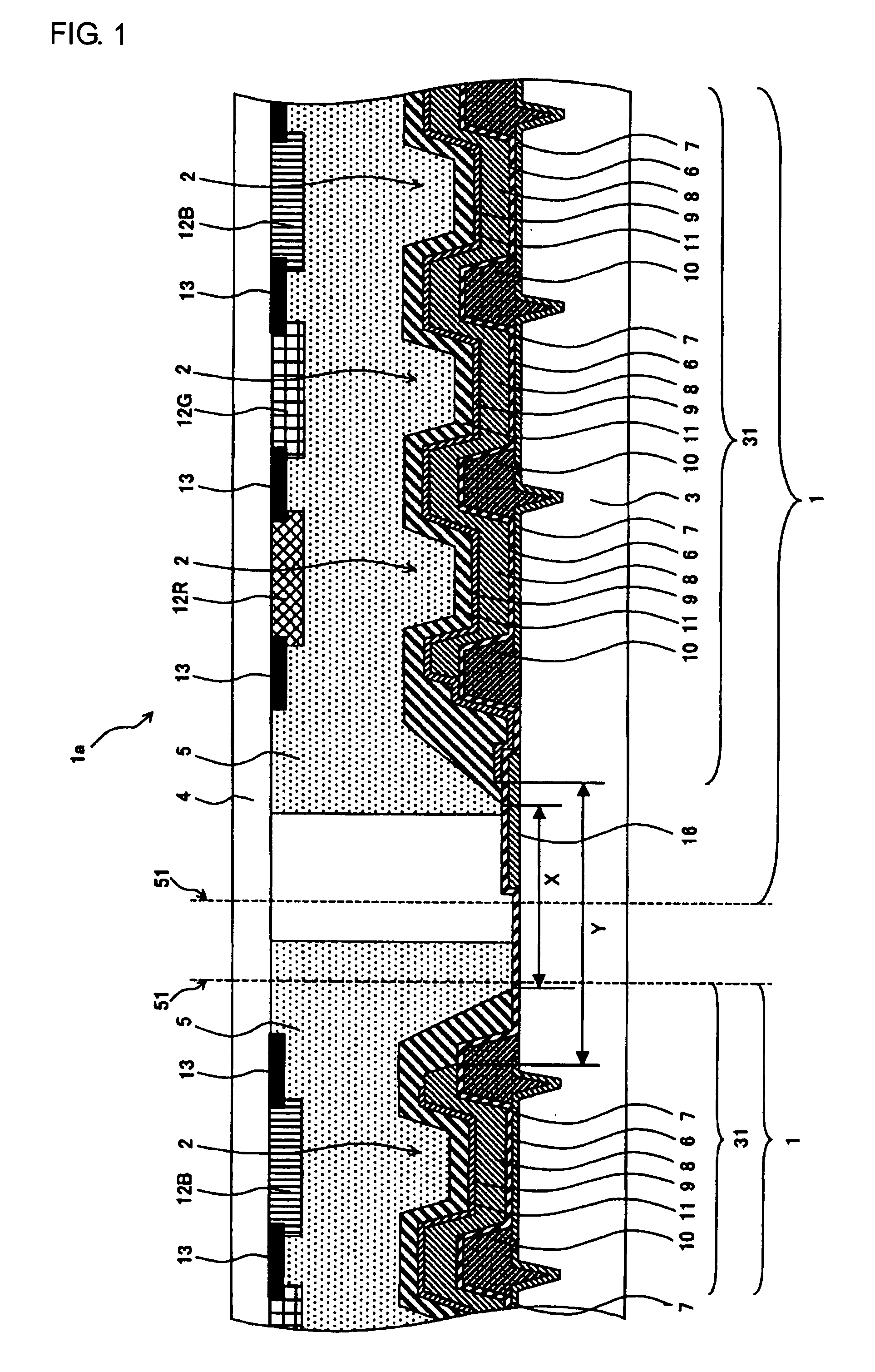

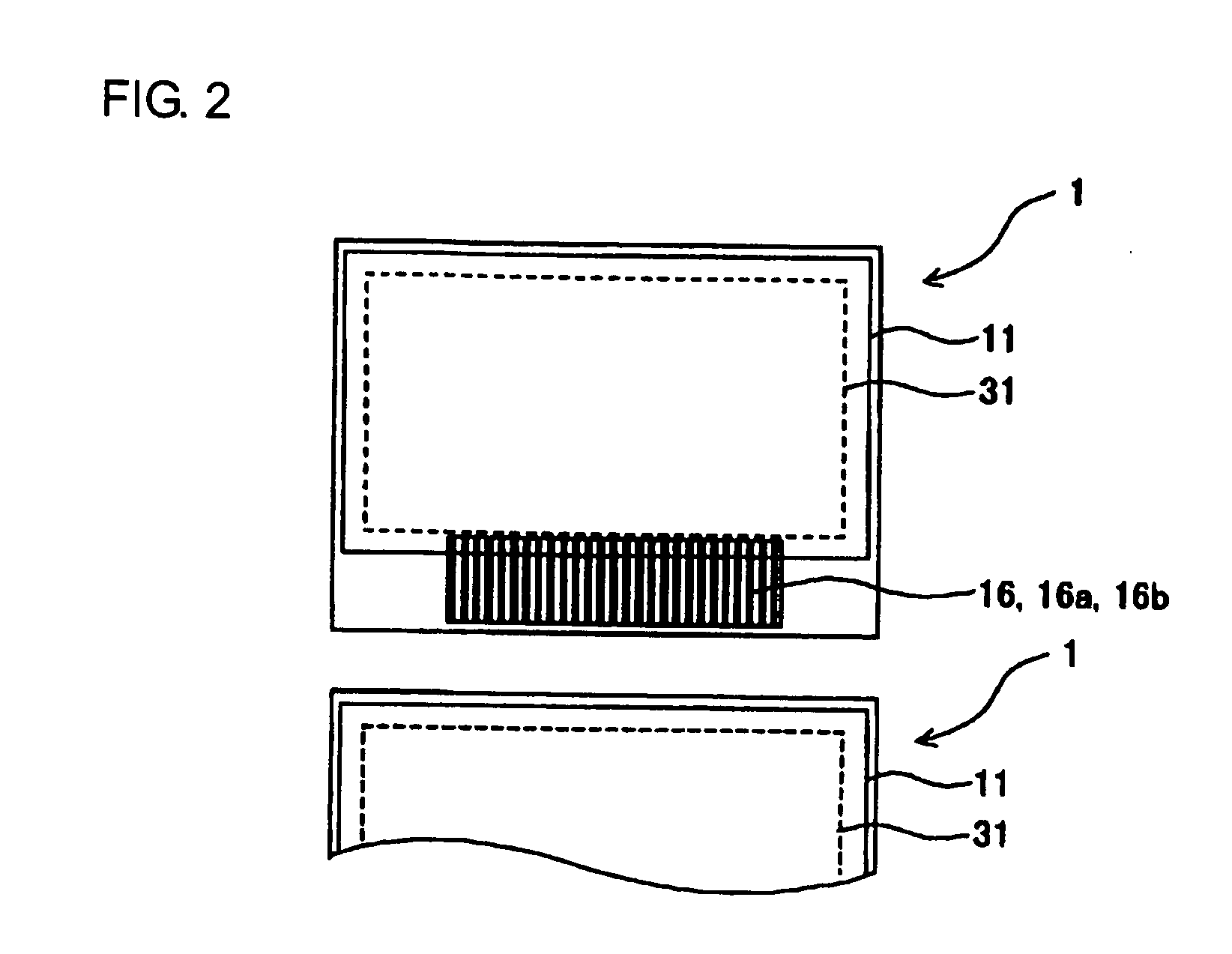

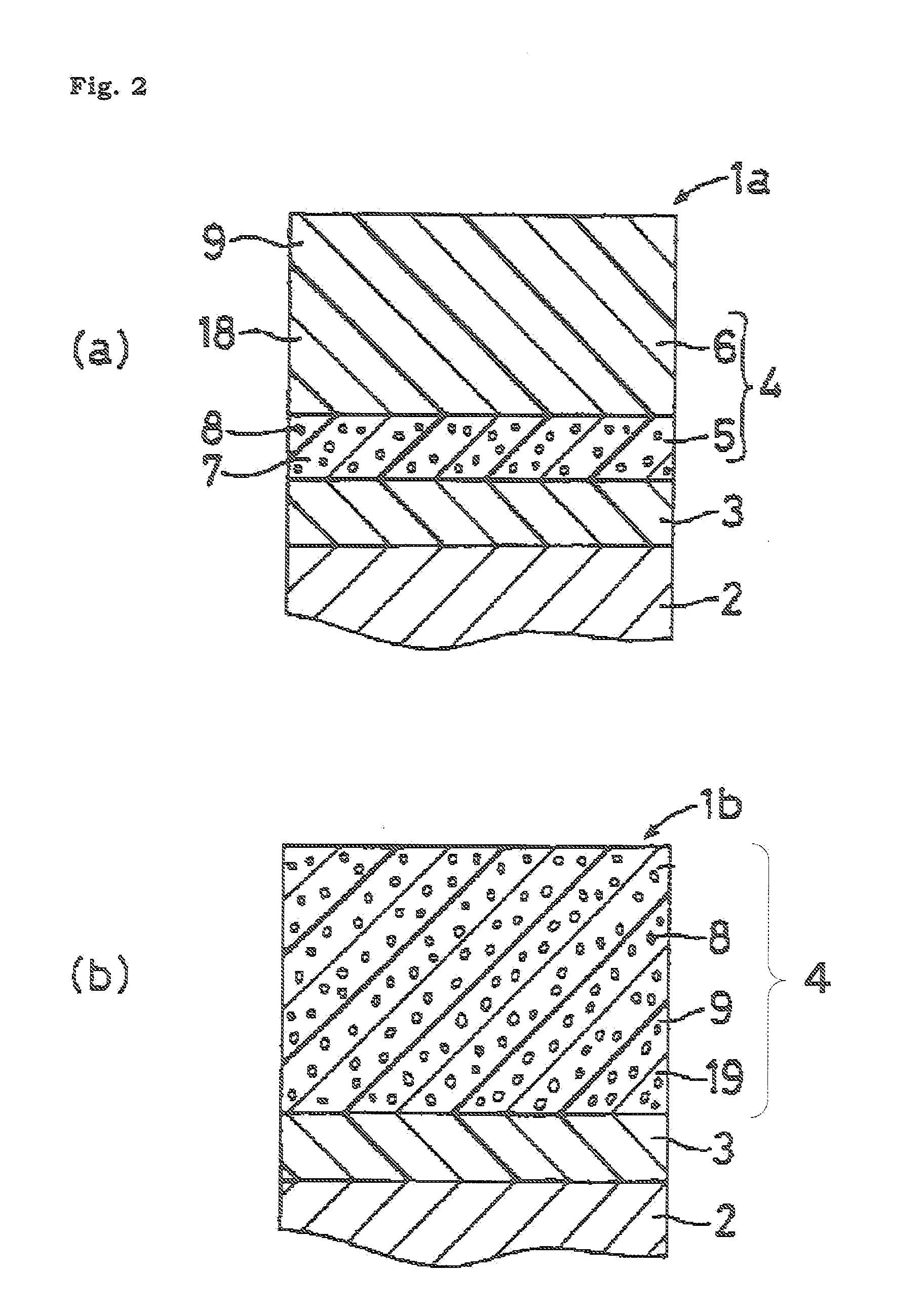

Process of producing light emitting panel, process of producing display panel and display panel

ActiveUS20060220550A1Reduce in quantityAvoid stickingDischarge tube luminescnet screensLamp detailsAdhesiveDisplay device

The invention relates to a process of producing a display panel, the process comprising a step of providing plural display regions on the principal plane of a support substrate, a step of applying an adhesive to the principal plane of the support substrate so as to cover the display region, to form a seal layer and laminating a seal plate through the seal layer to form a laminate and a step of dividing the laminate at the positions between the display adjacent to each other to produce plural light emitting panels each having the display region, the process further comprising a step of forming an adhesion preventive layer that inhibits adhesion to the adhesive on the principal plane of the support substrate between the display regions adjacent to each other prior to the application of the adhesive.

Owner:SANYO ELECTRIC CO LTD

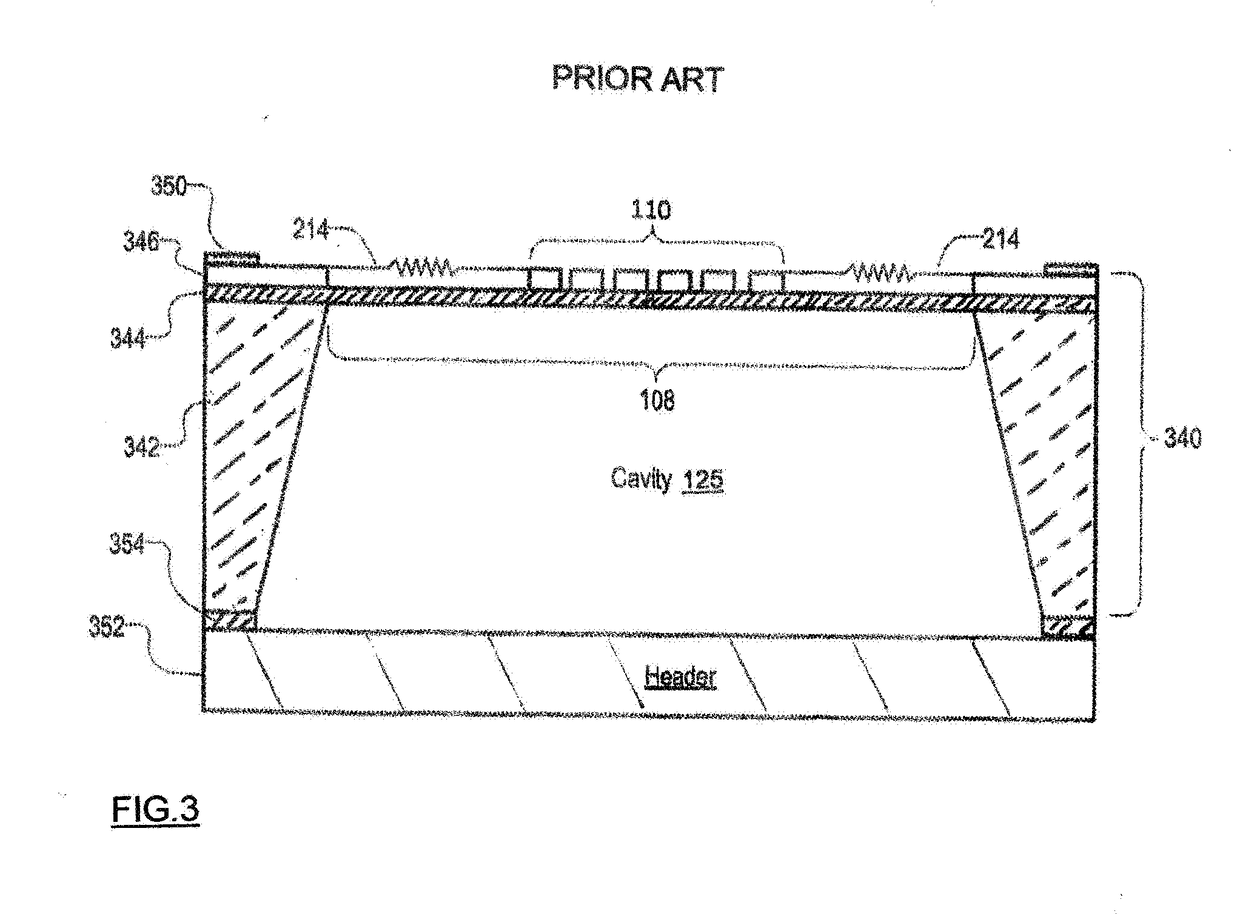

Semiconductor device embedded with pressure sensor and manufacturing method thereof

ActiveUS20070262401A1High precision measurementReduced footprintFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsDevice materialSilicon oxide

The method for promoting the size reduction, the performance improvement and the reliability improvement of a semiconductor device embedded with pressure sensor is provided. In a semiconductor device embedded with pressure sensor, a part of an uppermost wiring is used as a lower electrode of a pressure detecting unit. A part of a silicon oxide film formed on the lower electrode is a cavity. On a tungsten silicide film formed on the silicon oxide film, a silicon nitride film is formed. The silicon nitride film has a function to fill a hole or holes and suppress immersion of moisture from outside to the semiconductor device embedded with pressure sensor. A laminated film of the silicon nitride film and the tungsten silicide film forms a diaphragm of the pressure sensor.

Owner:HITACHI LTD

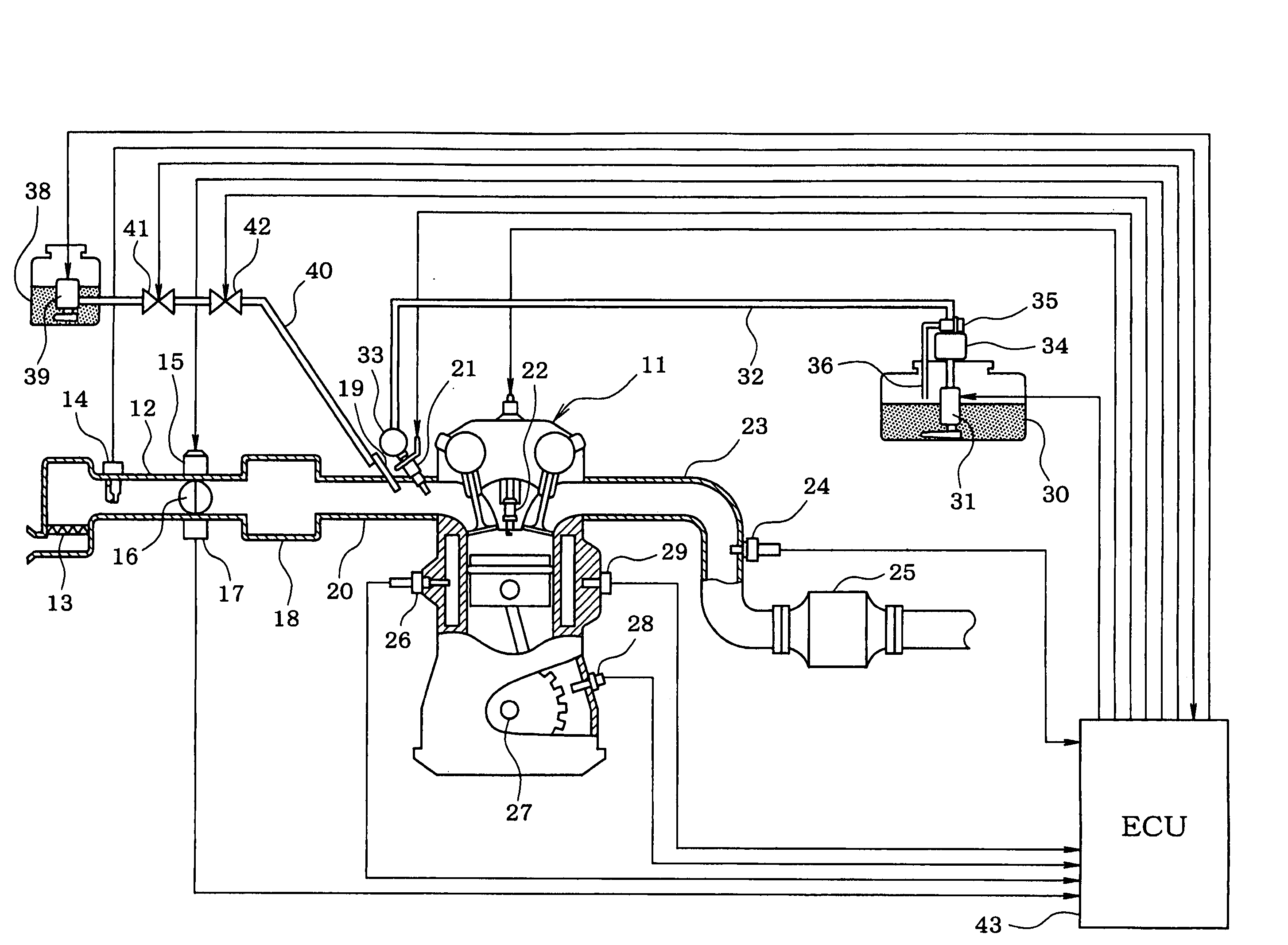

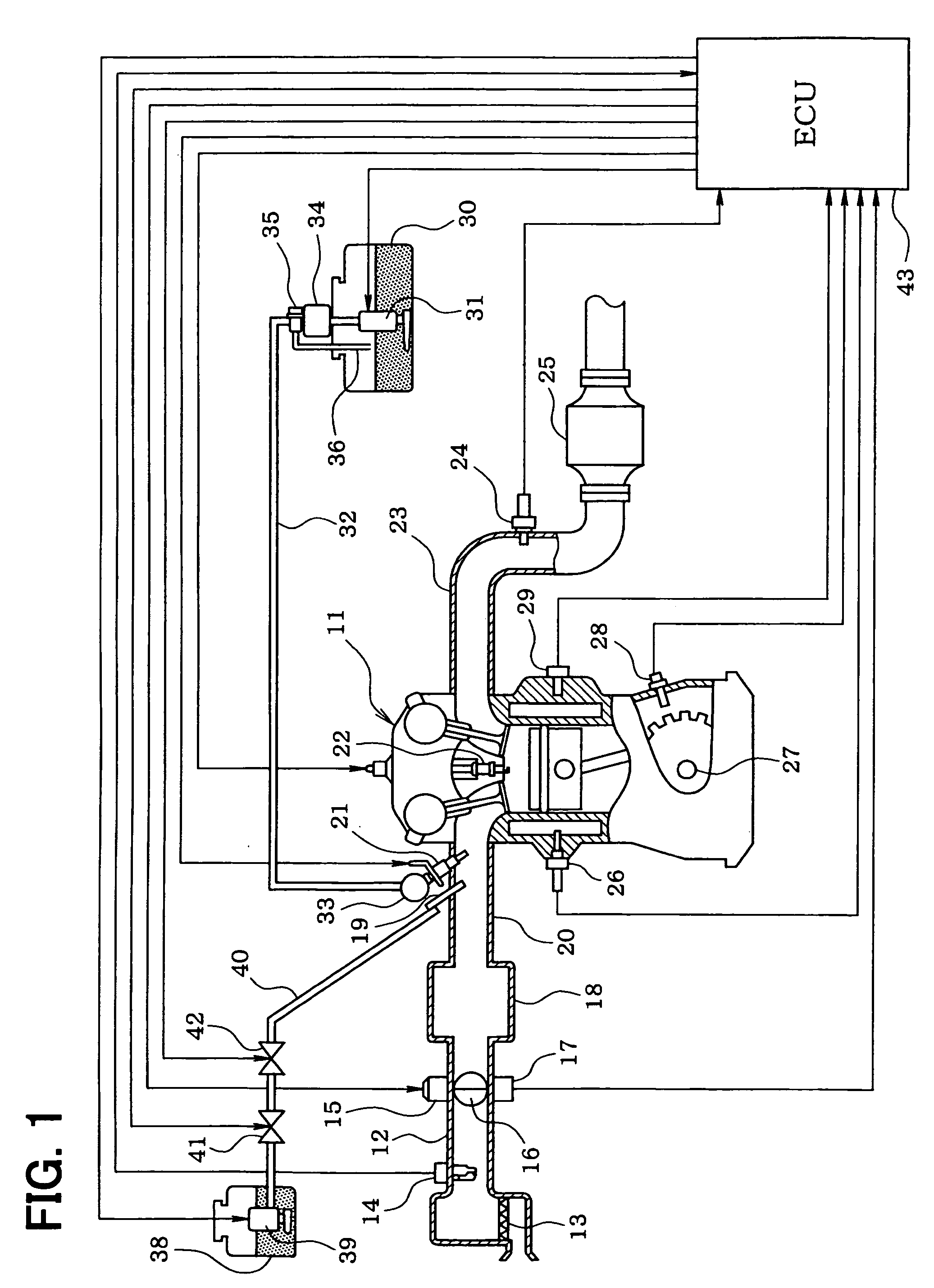

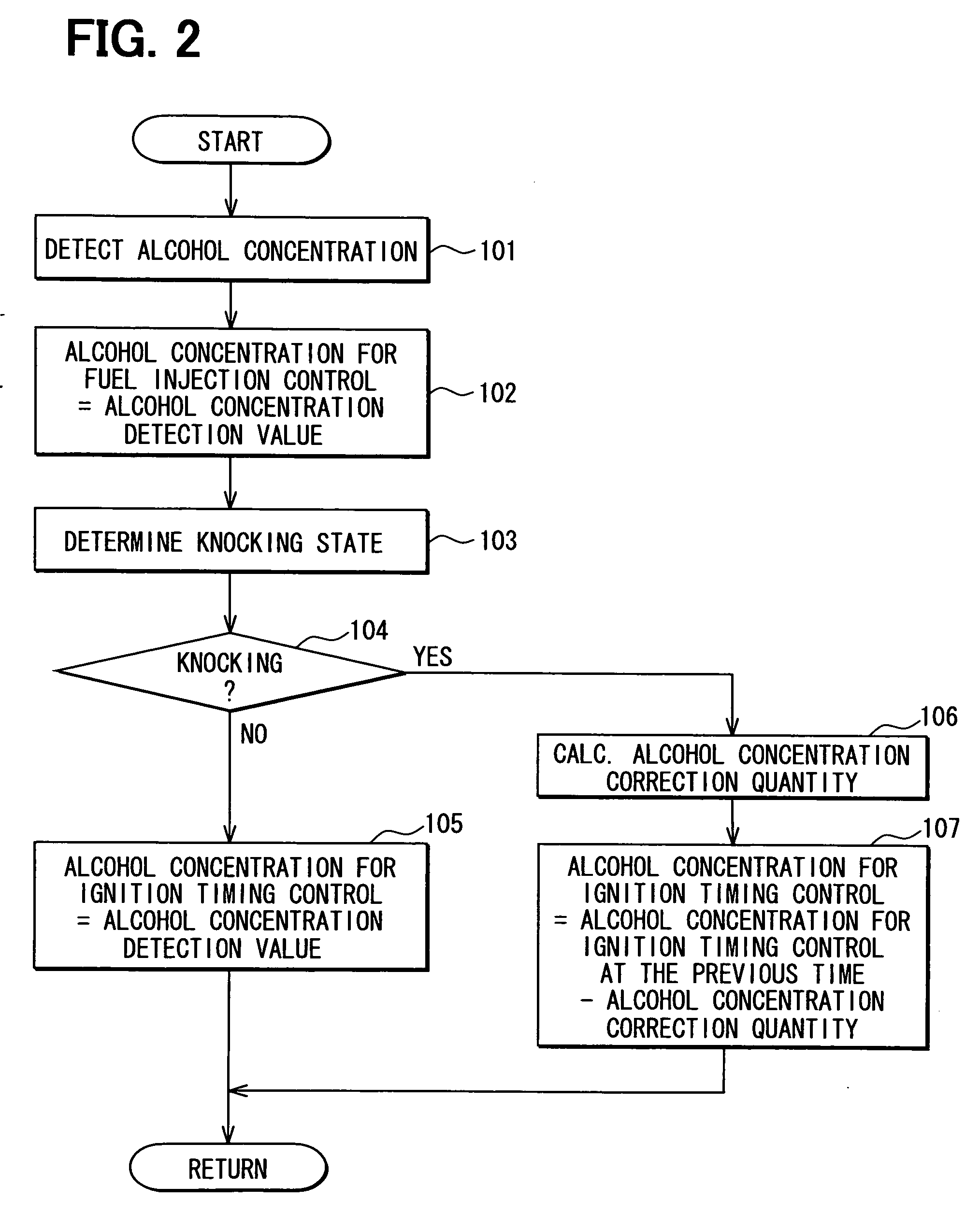

Controller for internal combustion engine

InactiveUS20080312810A1Avoid it happening againAvoid quantityAnalogue computers for vehiclesElectrical controlAlcoholEngineering

The alcohol concentration detection value estimated or detected by the alcohol concentration sensor is corrected in accordance with intensity, frequency and the like of knocking to set the alcohol concentration detection value after the correction as the alcohol concentration for ignition timing control. Thereby, occurrence of the knocking can be prevented by changing ignition timing in accordance with the knocking state. In regard to the fuel injection control, the alcohol concentration detection value before the correction is used as the alcohol concentration for fuel injection control as it is without using the alcohol concentration detection value corrected in accordance with the knocking state. This prevents a fluctuation of the fuel injection quantity due to correcting the alcohol concentration detection value in accordance with the knocking state, leading to prevention of a torque fluctuation or combustion deterioration.

Owner:DENSO CORP

Semiconductor device embedded with pressure sensor and manufacturing method thereof

ActiveUS20060070449A1High precision measurementReduced footprintFluid pressure measurement by electric/magnetic elementsSolid-state devicesDevice materialSilicon oxide

The method for promoting the size reduction, the performance improvement and the reliability improvement of a semiconductor device embedded with pressure sensor is provided. In a semiconductor device embedded with pressure sensor, a part of an uppermost wiring is used as a lower electrode of a pressure detecting unit. A part of a silicon oxide film formed on the lower electrode is a cavity. On a tungsten silicide film formed on the silicon oxide film, a silicon nitride film is formed. The silicon nitride film has a function to fill a hole or holes and suppress immersion of moisture from outside to the semiconductor device embedded with pressure sensor. A laminated film of the silicon nitride film and the tungsten silicide film forms a diaphragm of the pressure sensor.

Owner:HITACHI LTD

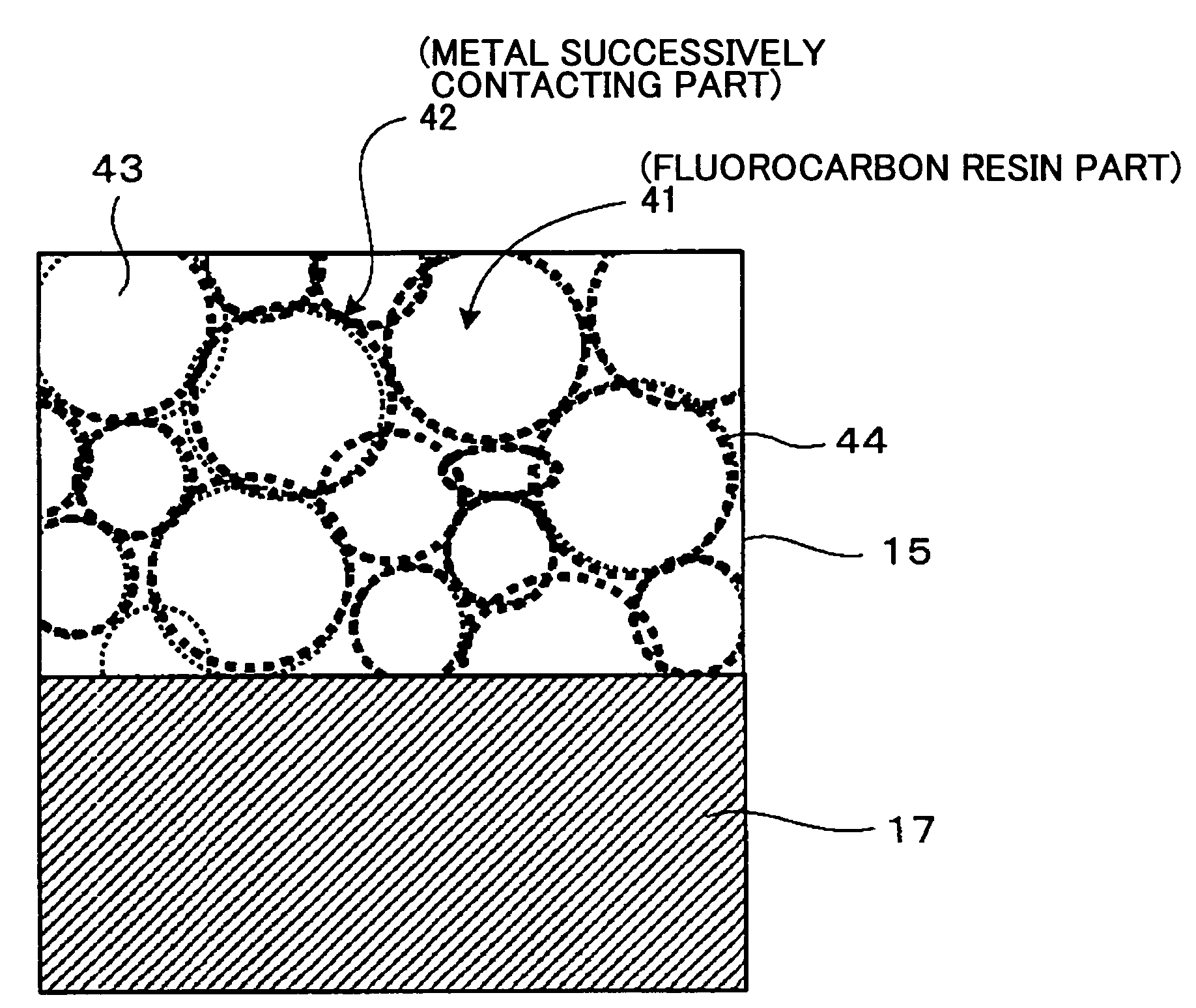

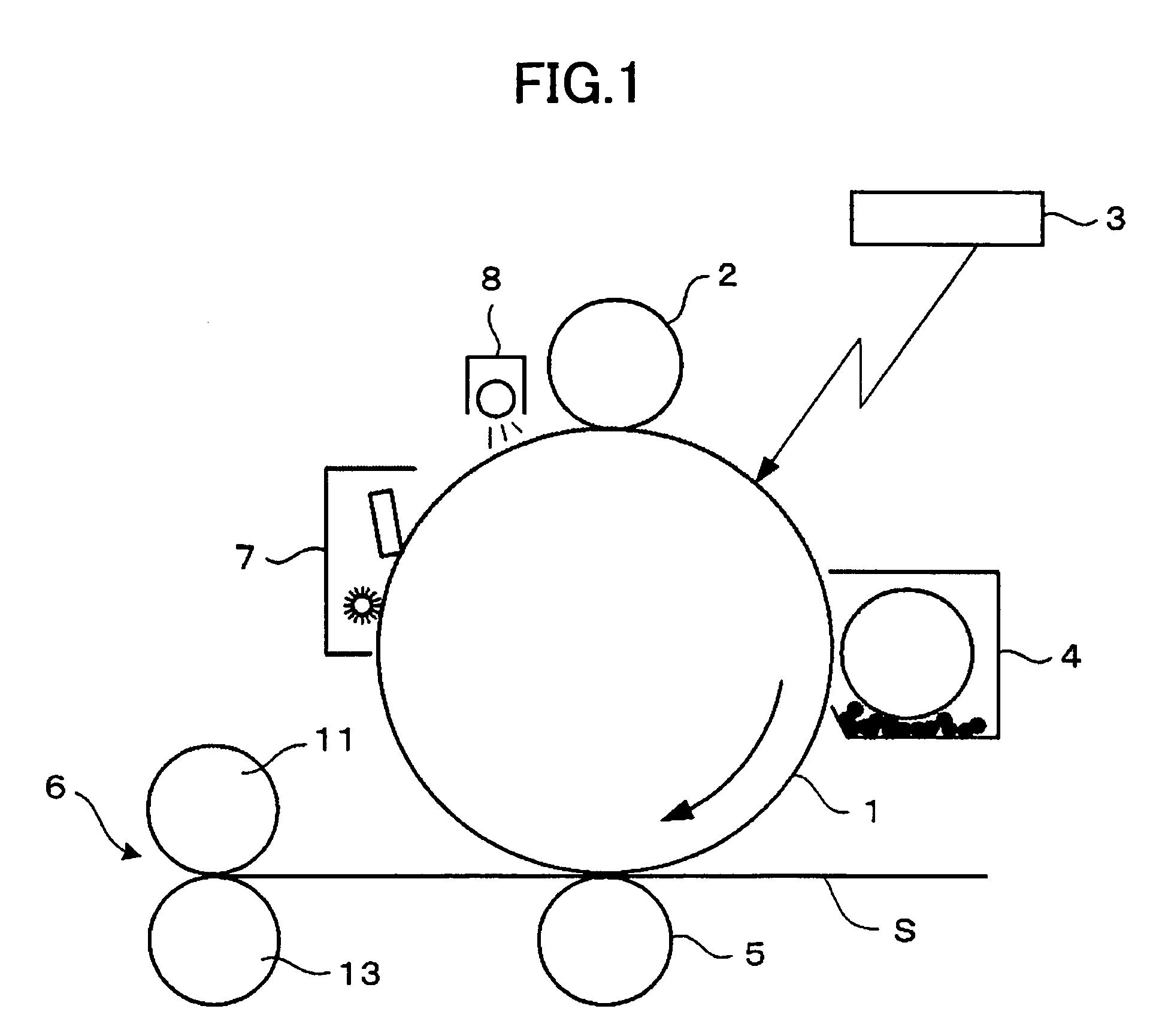

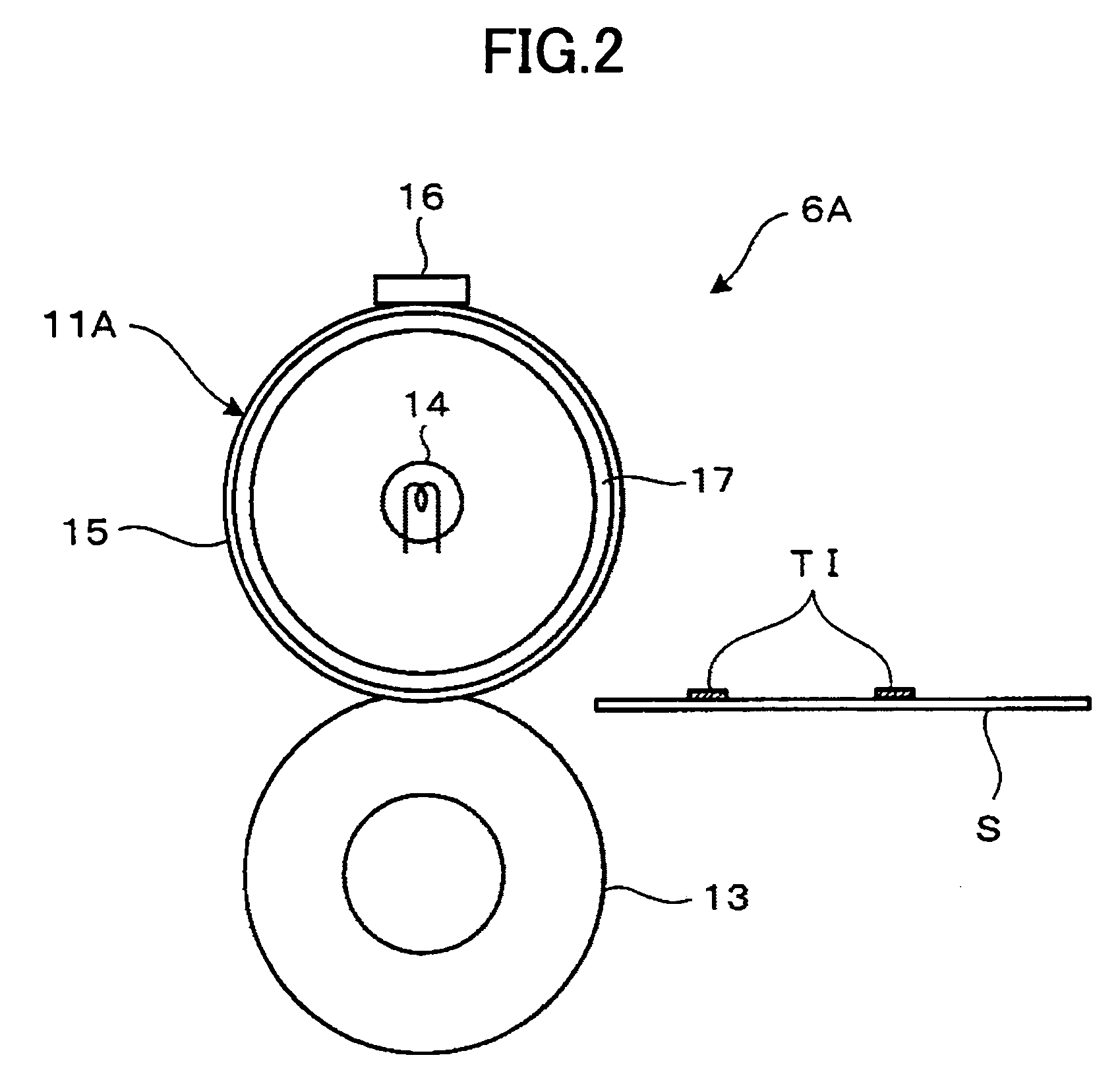

Heating member, heating member surface layer producing method, fixing member, heating device, fixing method, fixing device and image forming apparatus

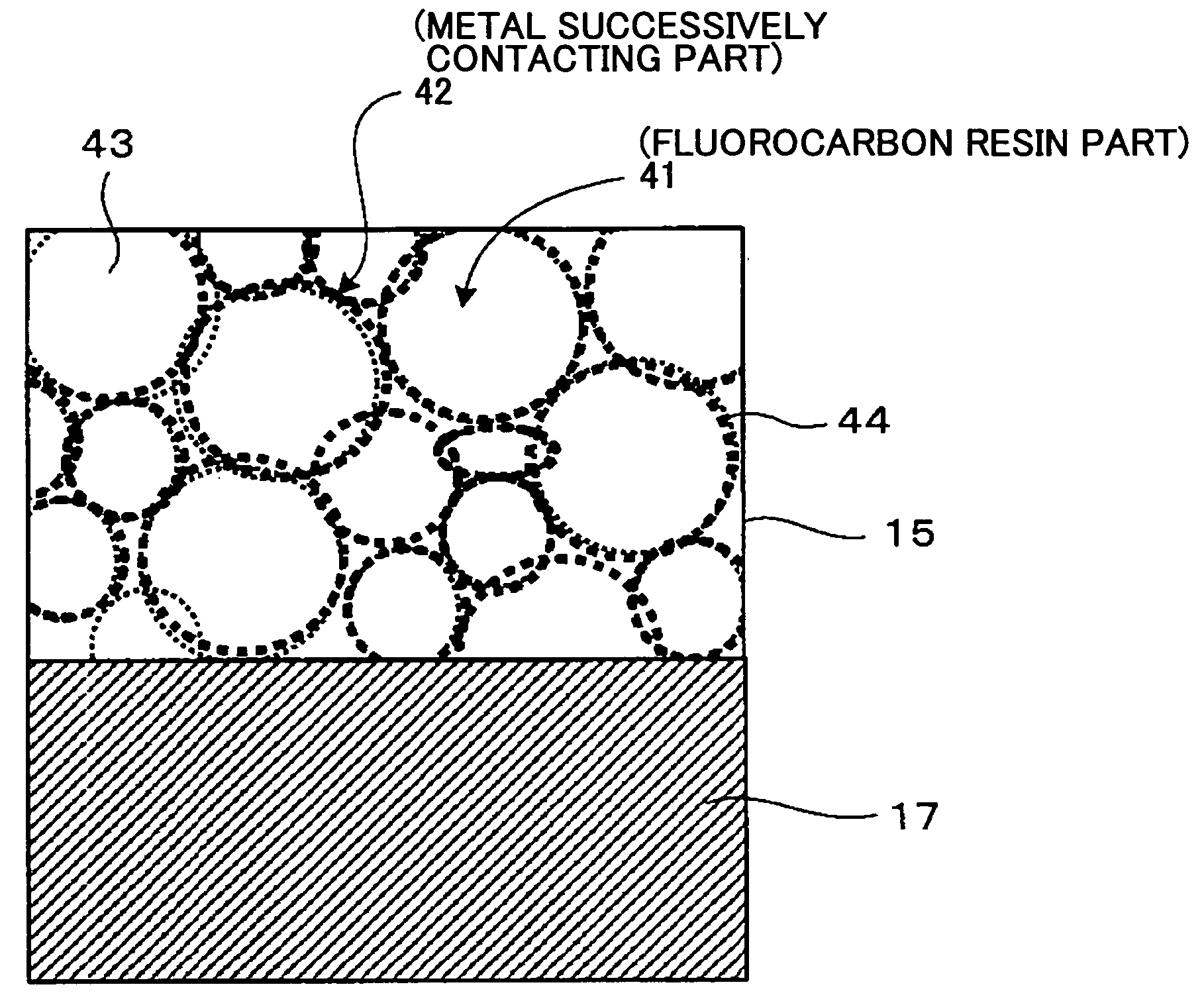

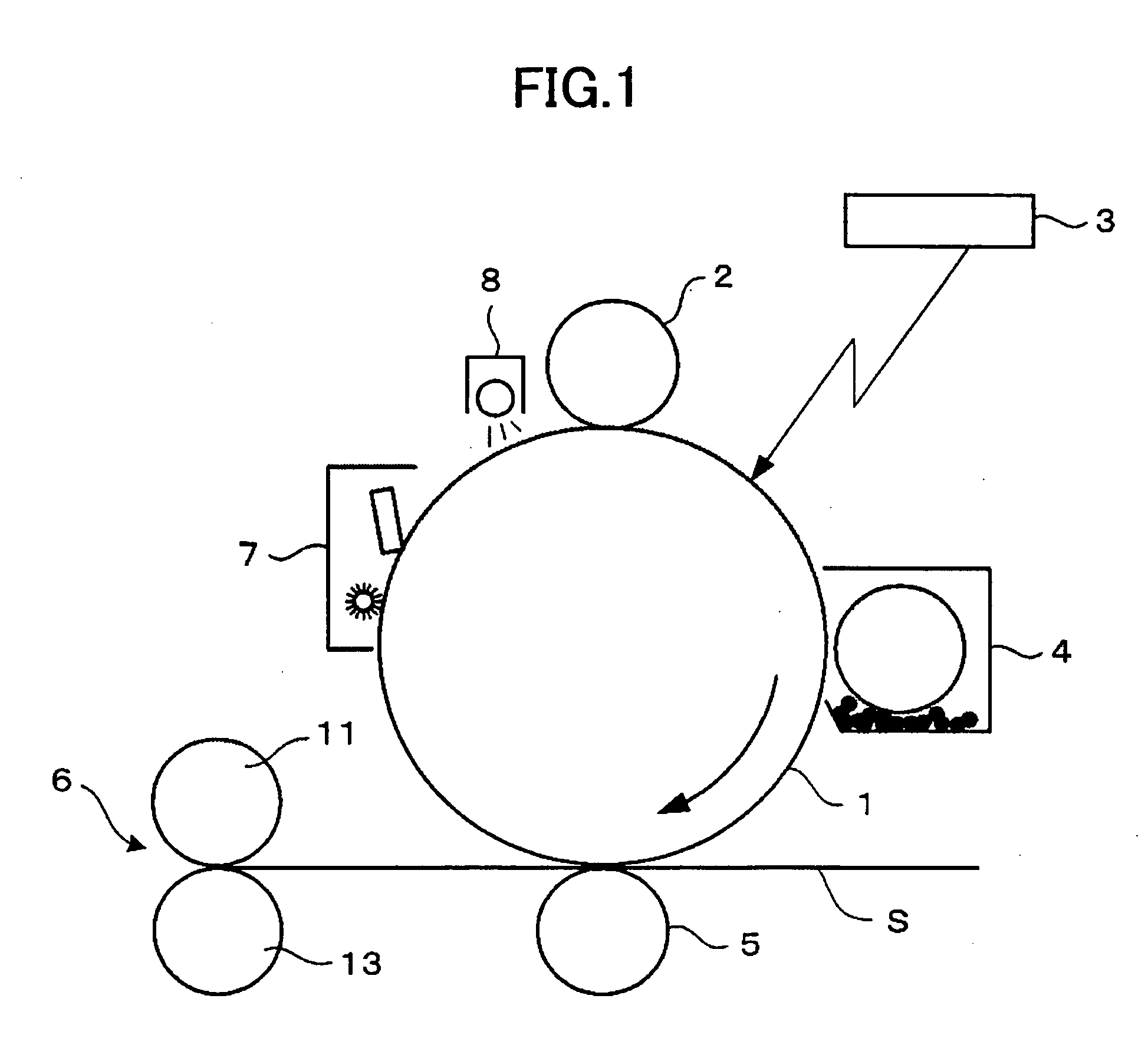

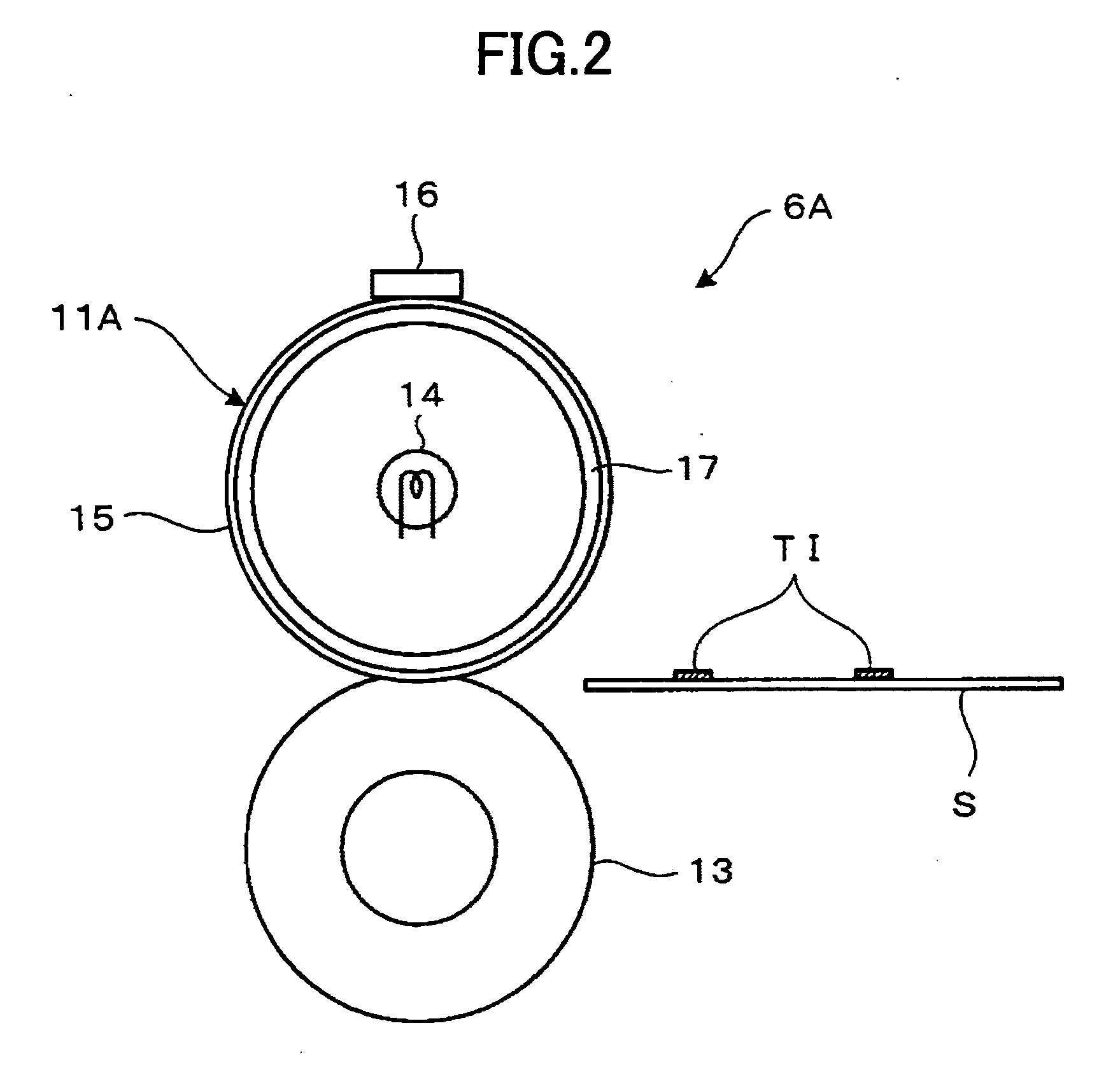

InactiveUS20060014021A1Reduce material usageImprove heating efficiencySynthetic resin layered productsOhmic-resistance heatingSurface layerFluorocarbon

The present invention is characterized in that, for the purpose of achieving a heating member (fixing member) in which thermal conductivity or electrical conductivity is given to a resin surface layer without loss of releasability, and heating efficiently is improved, the heating member contacting a to-be-heated member and heating the same has a surface layer 15 in which, in a resin material 43 having releasability, a material (for example, metal) 44 having either one or both thermal conductivity and electrical conductivity is mixed, and the material contact successively. Specifically, the heating member (fixing member) according to the present invention has the surface layer 15 in which the metal 44 is mixed into the fluorocarbon resin 43, and the metal 44 forms metal successively contacting part 42 in which the metal 44 successively contacts in such a manner as to surround the fluorocarbon resin part 41. Thereby, it is possible to improve thermal conductivity or electrical conductivity while maintaining releasability.

Owner:RICOH KK

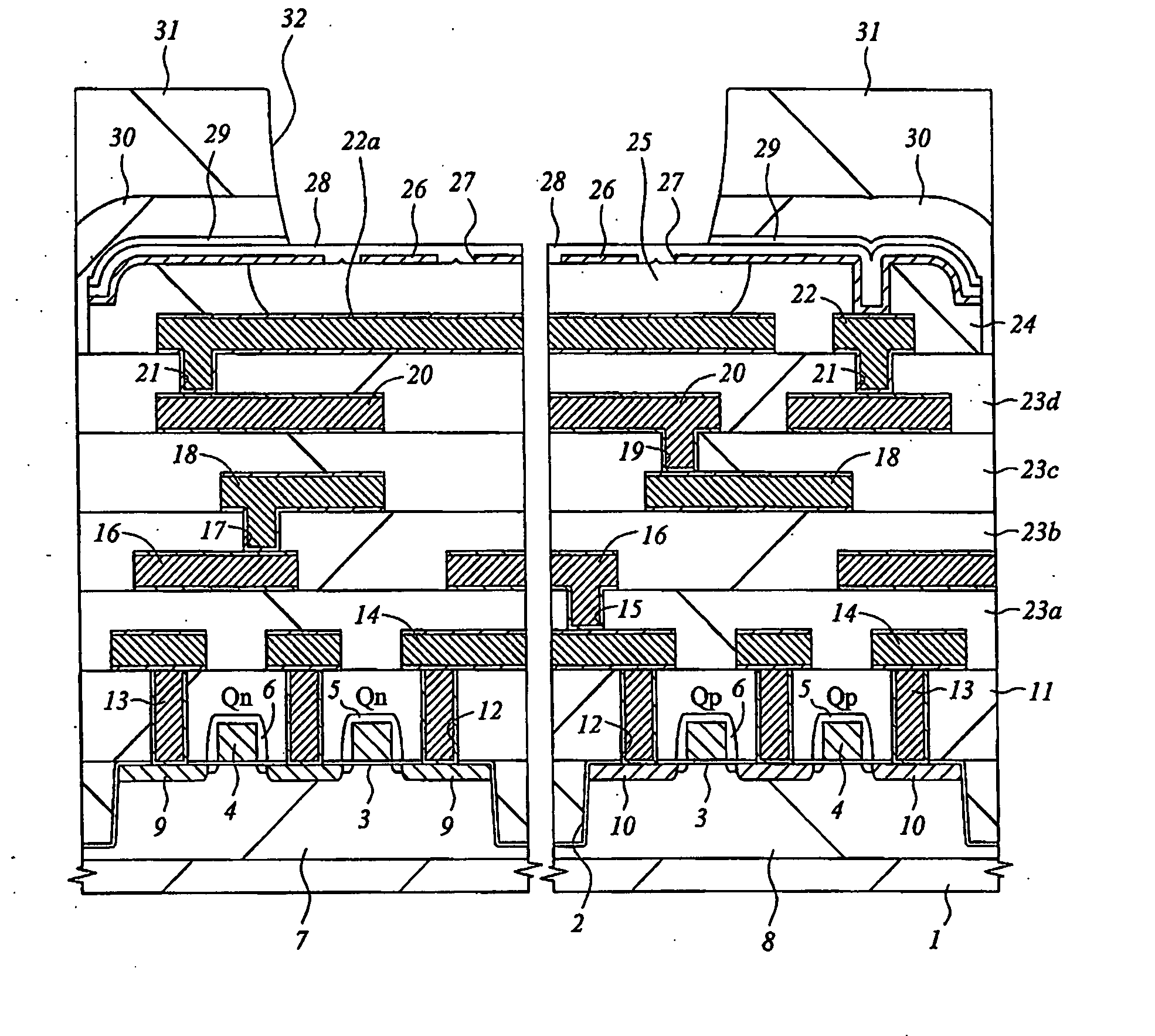

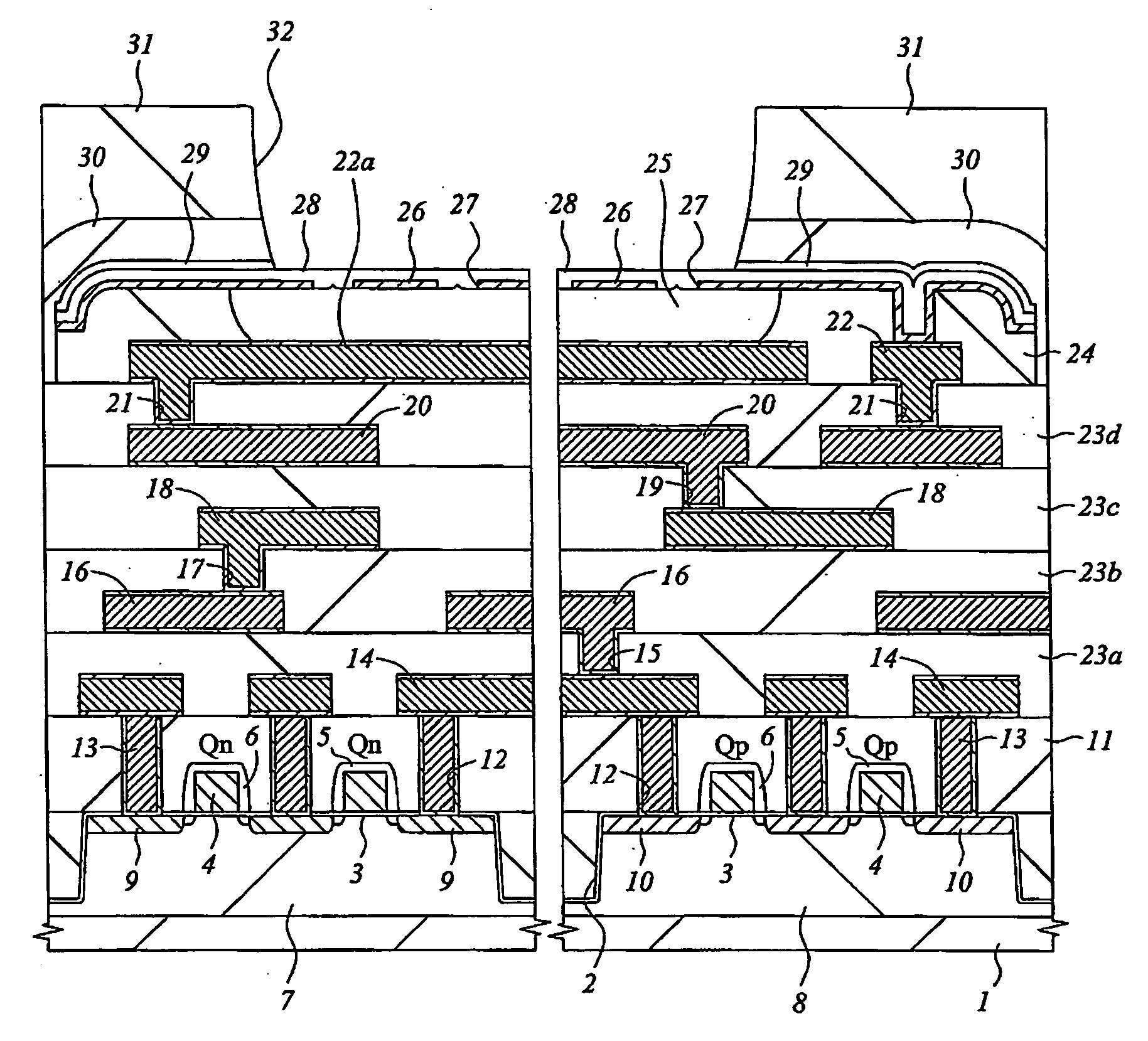

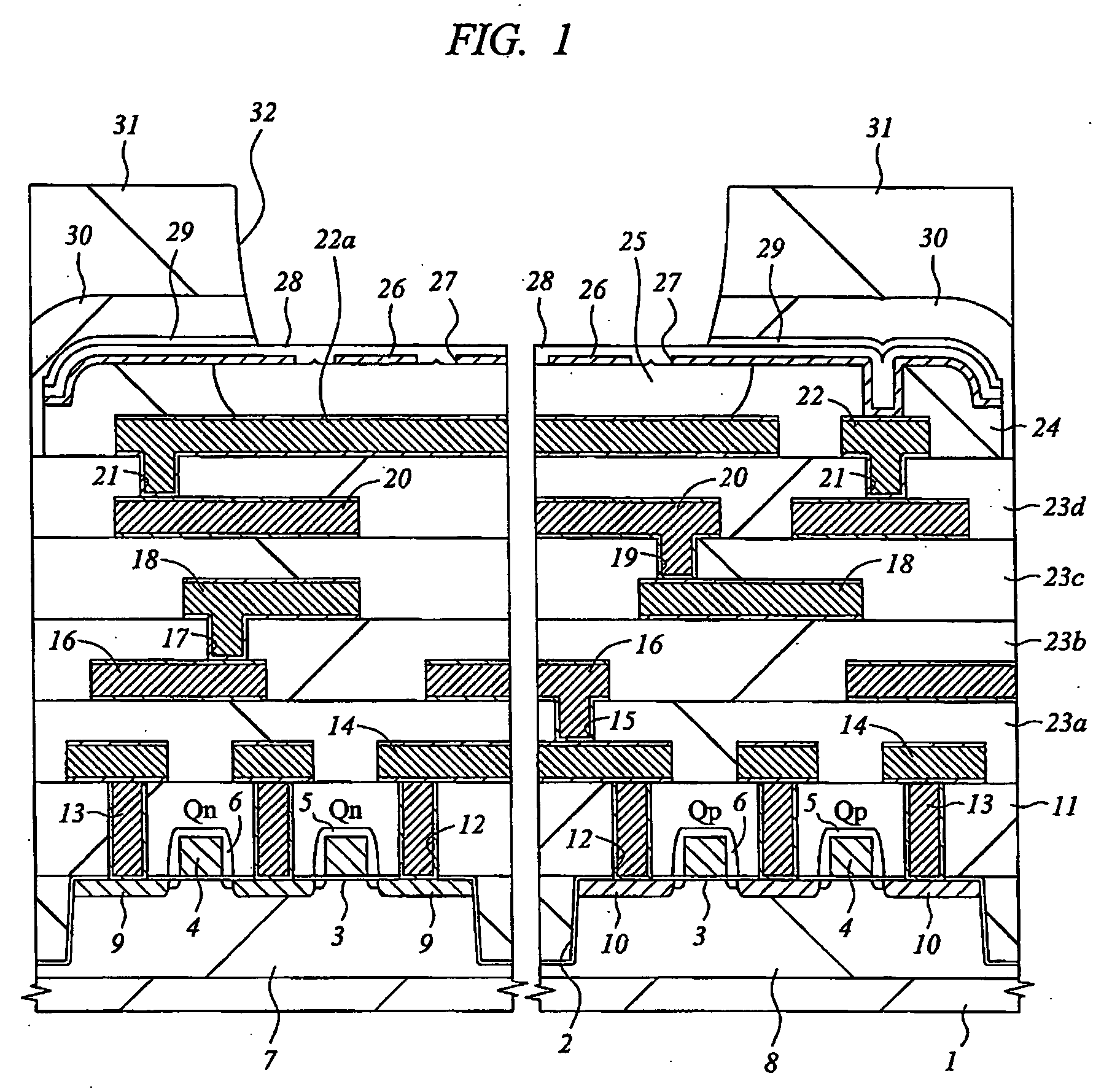

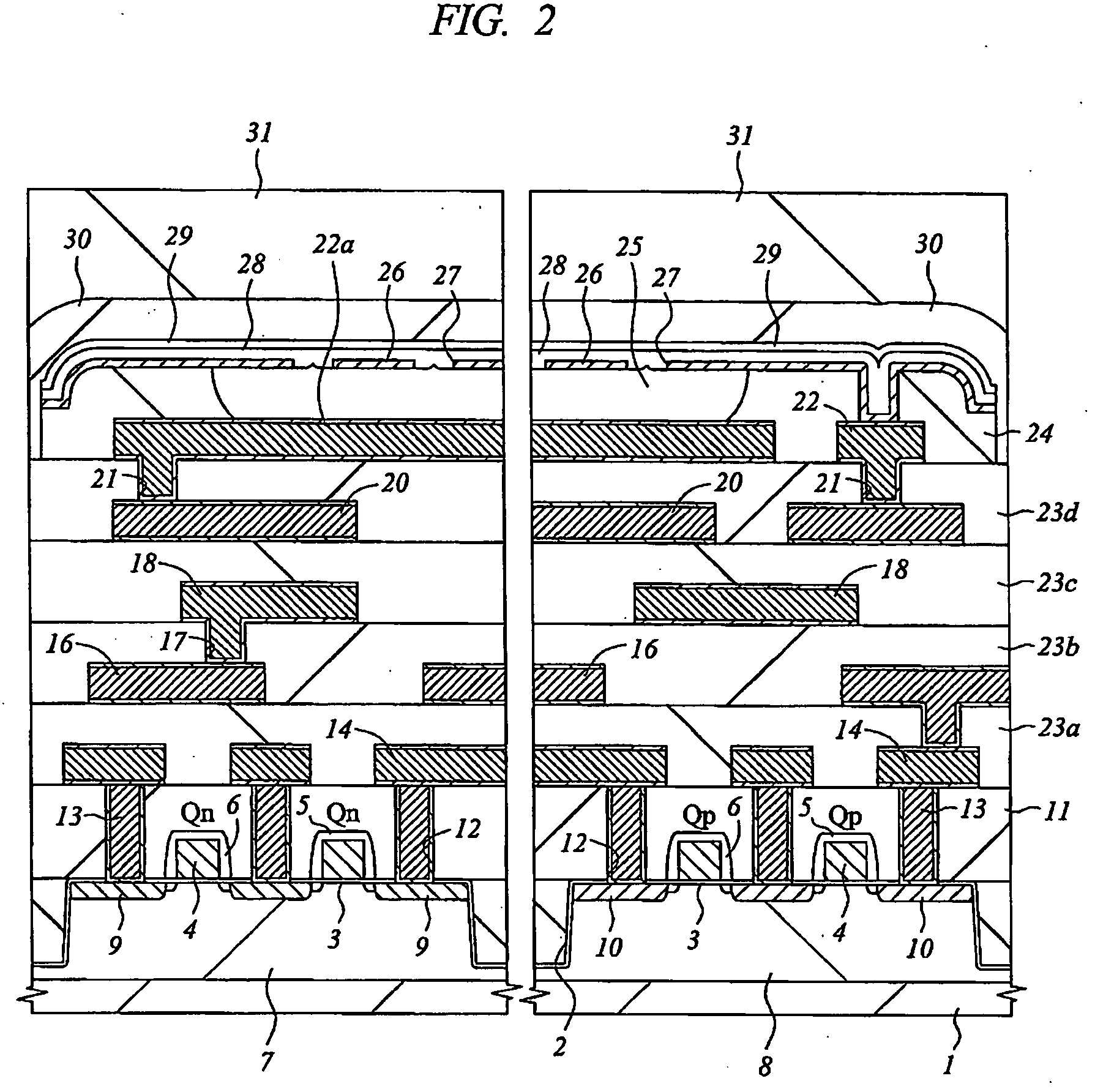

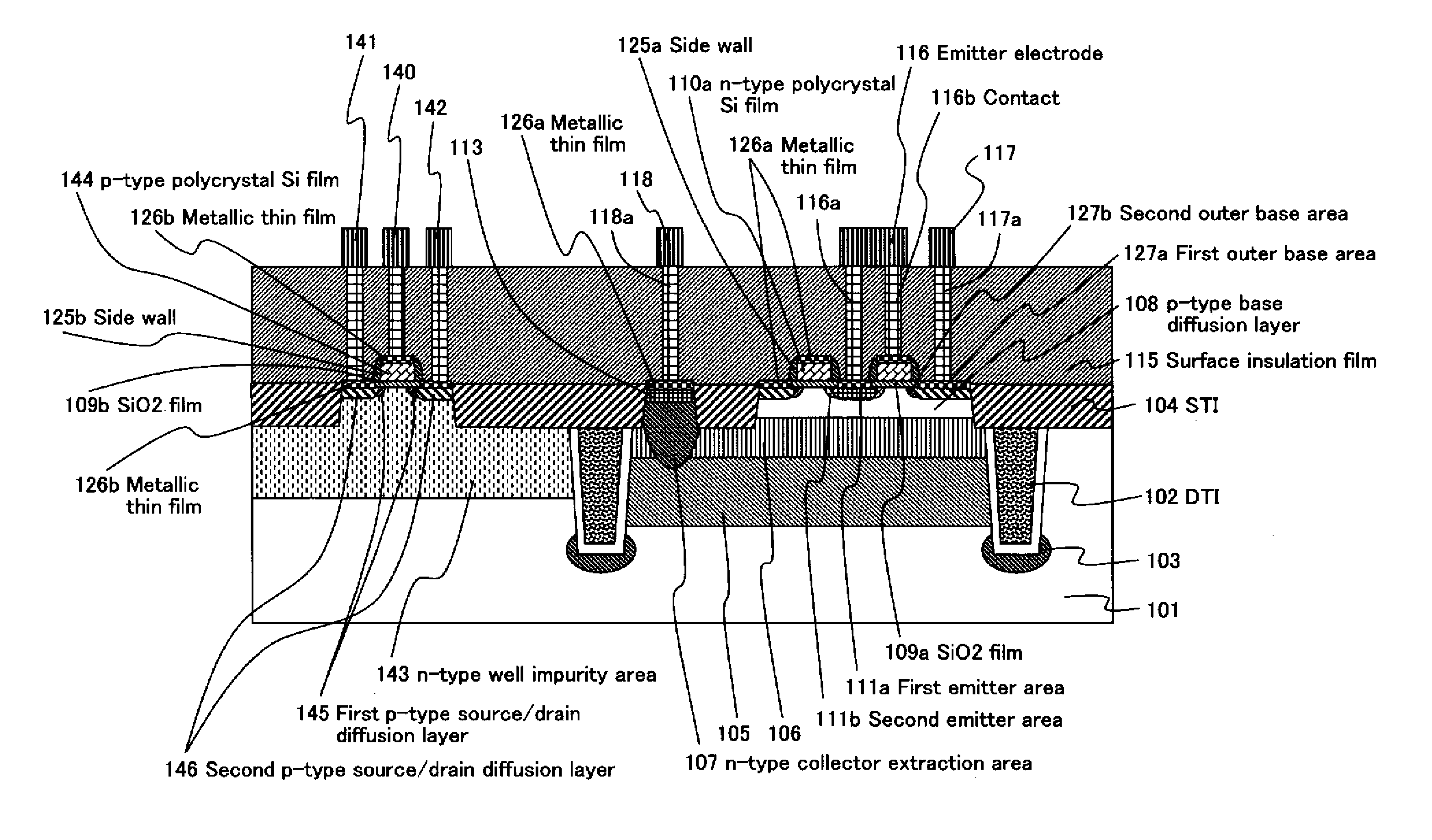

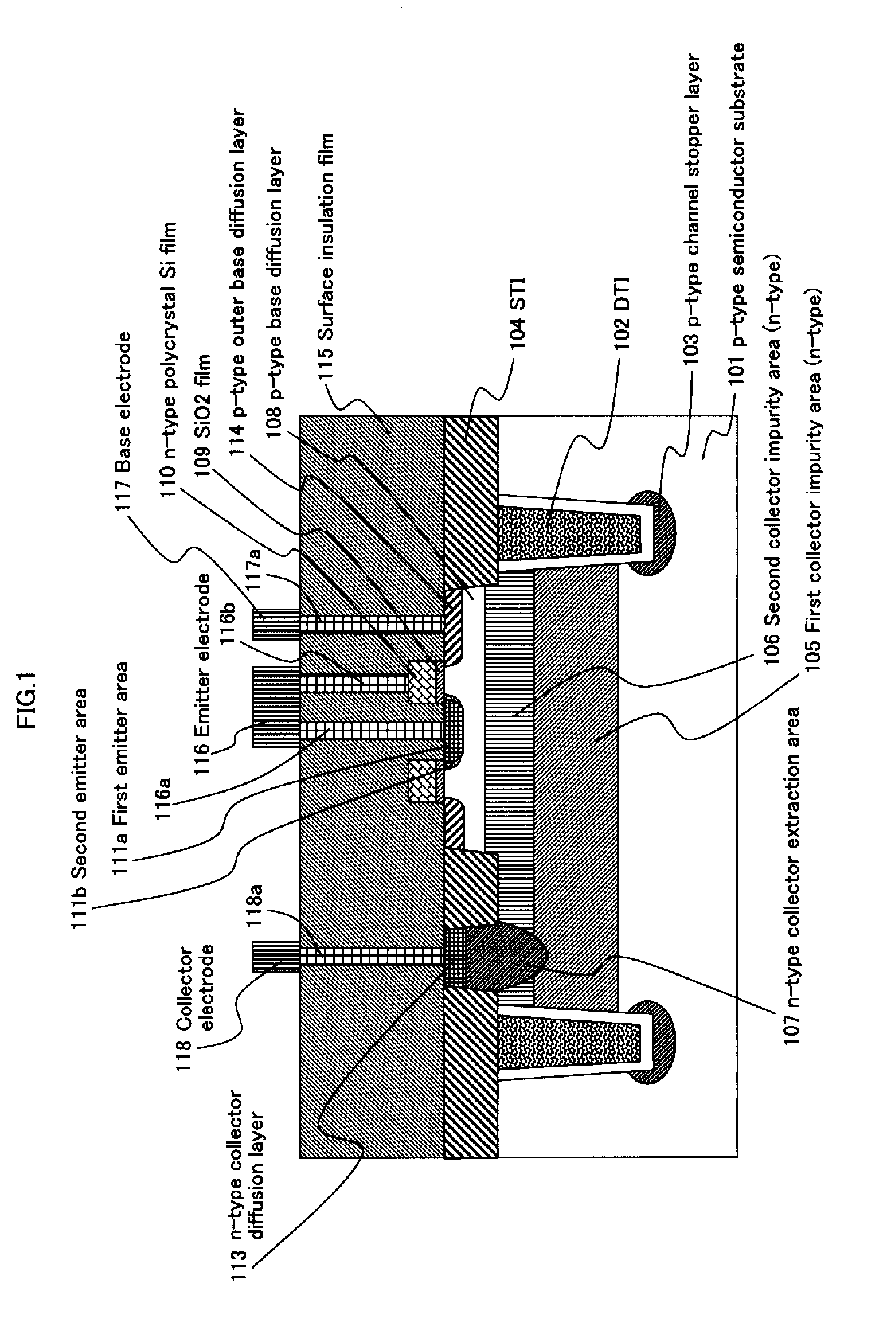

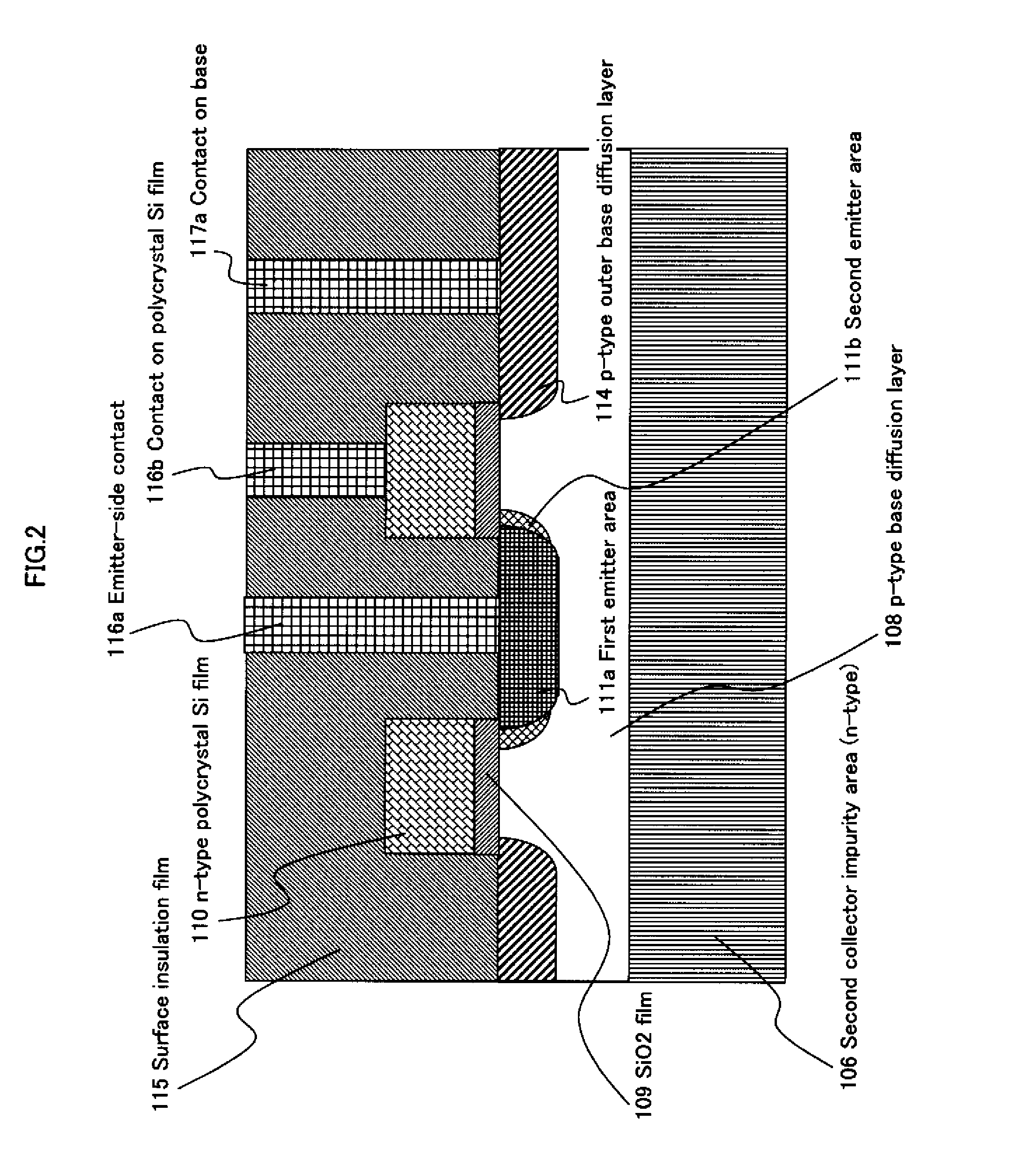

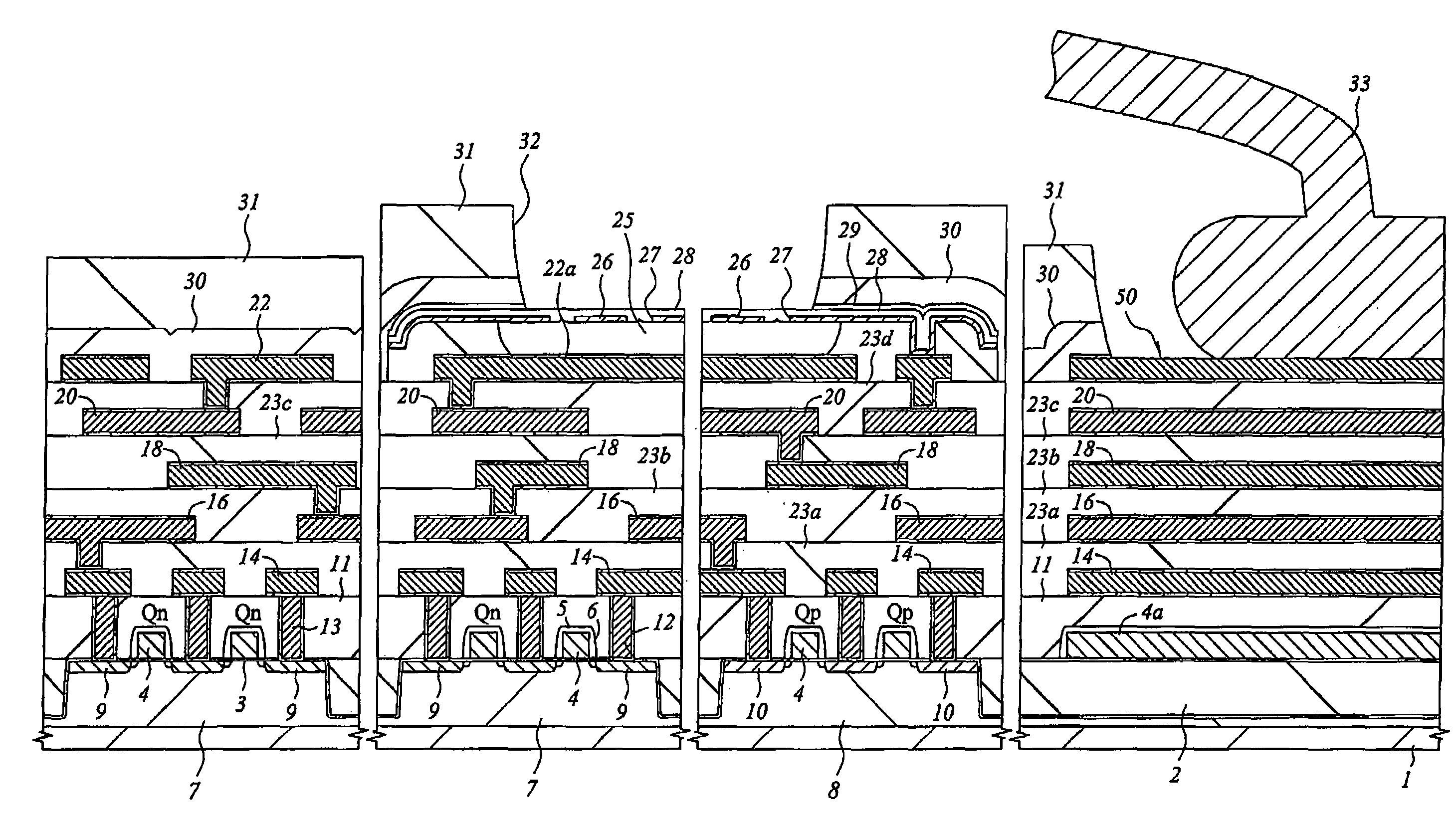

Semiconductor apparatus and manufacturing method thereof

InactiveUS20110127615A1Reduce leakage currentReduce electric field strengthTransistorSolid-state devicesElectrical field strengthImpurity ions

A high-performance semiconductor apparatus which can be easily introduced into the MOS process, reduces the leakage current (electric field strength) between the emitter and the base, and is insusceptible to noise or surge voltage, and a manufacturing method of the semiconductor apparatus. The emitter 111 is formed by performing the ion implantation twice by using the conductive film (109) as a mask. The second emitter area (111b) is formed by ion implantation of a low impurity density impurity ion, and the first emitter area (111a) is formed by ion implantation of a high impurity density impurity ion. As a result, the low impurity density second emitter area is formed in the circumference of the emitter 111, which lowers the electric field strength, and reduces the leakage current. Also the conductive film is connected with the emitter electrode (116), which makes the apparatus insusceptible to noise.

Owner:PANASONIC CORP

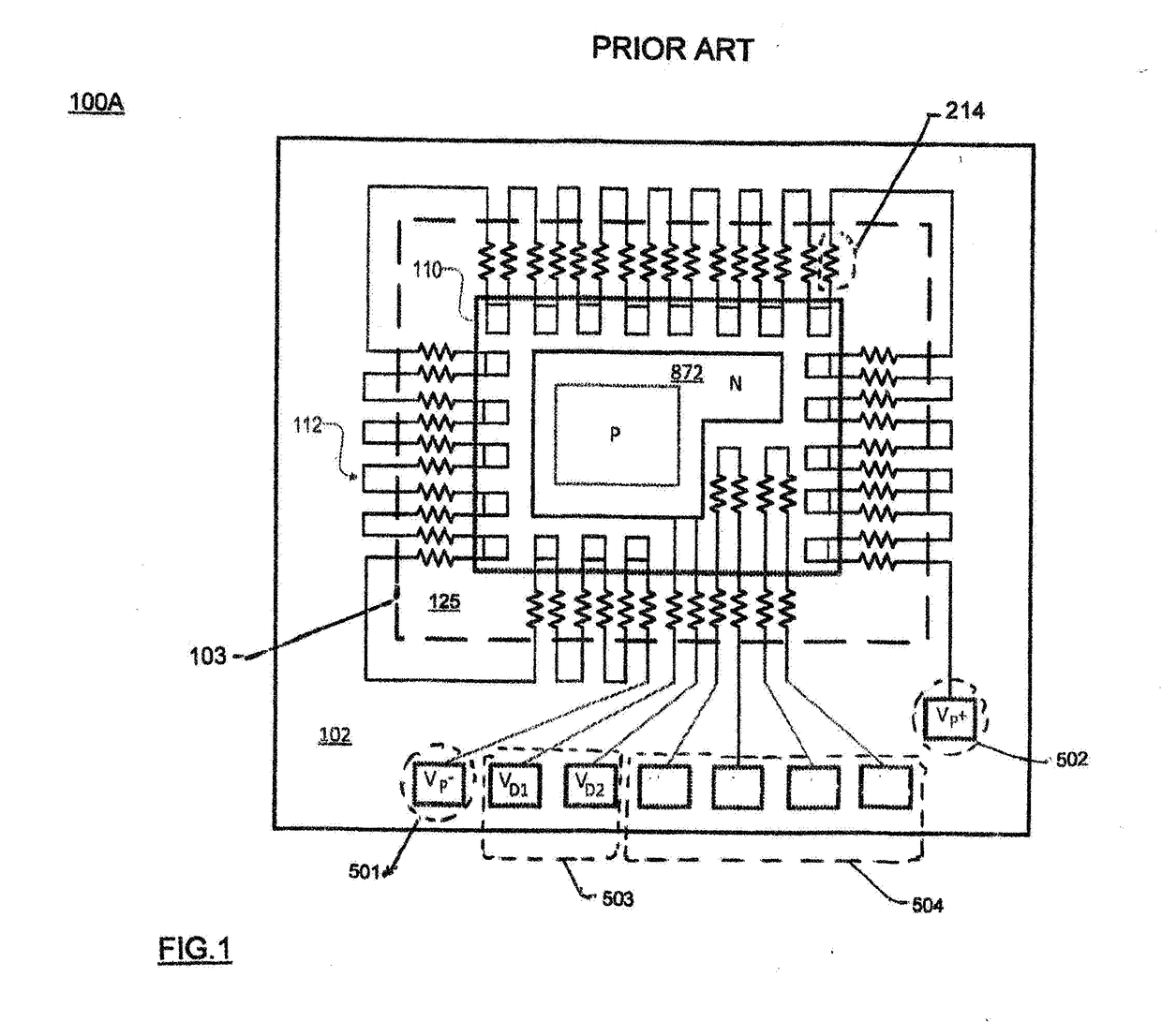

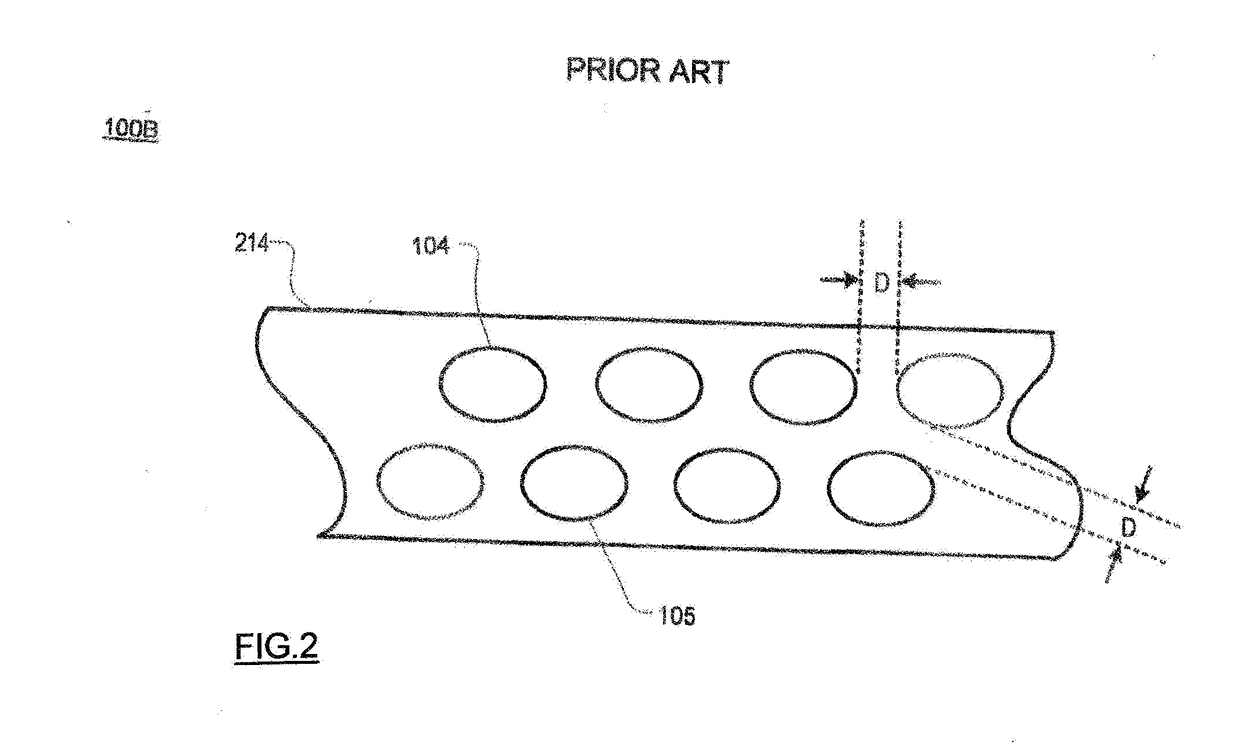

Metamaterial Thermal Pixel for Limited Bandwidth Electromagnetic Sourcing and Detection

InactiveUS20180374981A1Reduce mean free pathLower limitThermoelectric device with peltier/seeback effectSolid-state devicesNanowireMillimeter

A metamaterial pixel providing an electromagnetic emitter and / or en electromagnetic detector operating within a limited bandwidth. The metamaterial pixel is comprised of plasmonic elements arranged within a periodic photonic crystal array providing an electromagnetic emitter and / or an electromagnetic detector adapted in embodiments for operation at selected bandwidths within the wavelength range of visible out to a millimeter. Performance of the pixel in applications is enhanced with nanowires structured to enhance phononic scattering providing a reduction in thermal conductivity. In embodiments multiple pixels are adapted to provide a spectrometer for analyzing thermal radiation or electromagnetic reflection from a remote media. In other embodiments emitter and detector pixels are adapted to provide an absorptive spectrophotometer. In other embodiments one or more of metamaterial pixels are adapted as the transmitter and / or receiver within a communication system. In a preferred embodiment the pixel is fabricated using a silicon SOI starting wafer.

Owner:CARR WILLIAM N

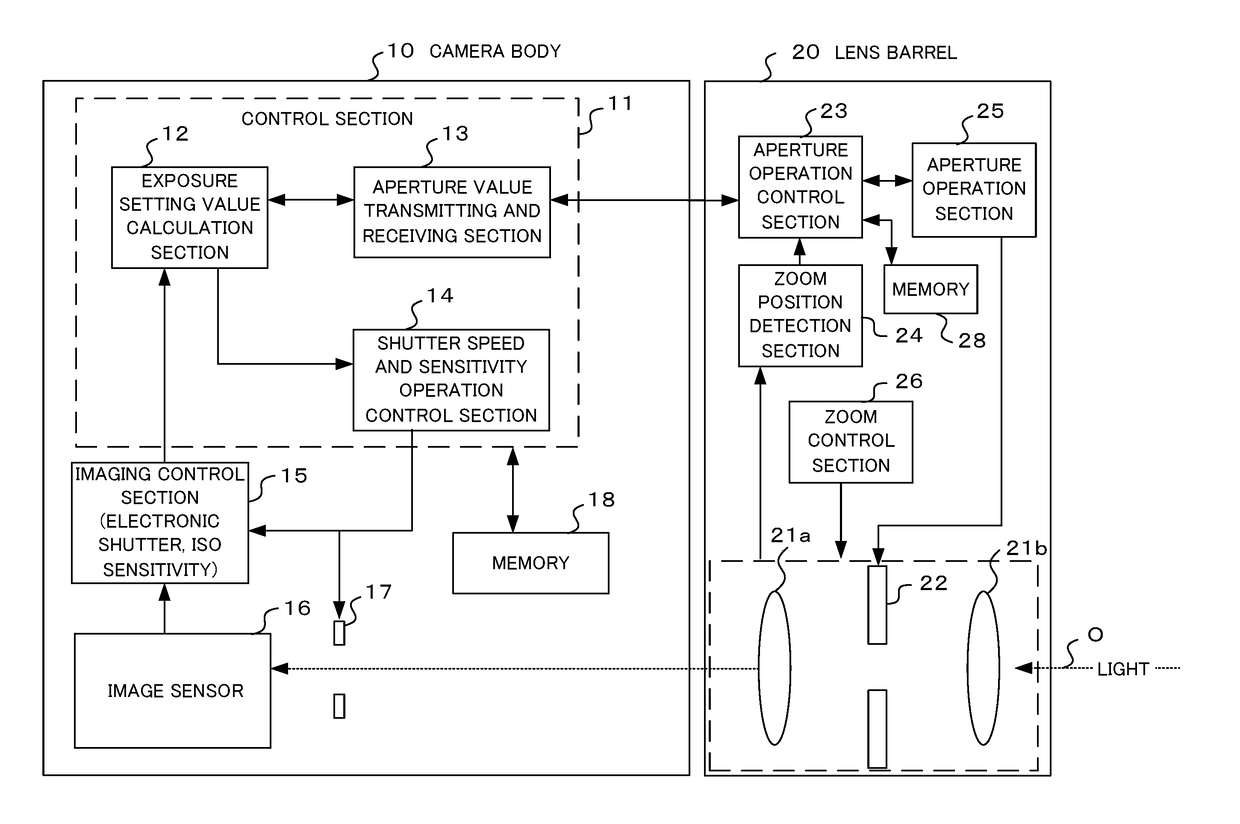

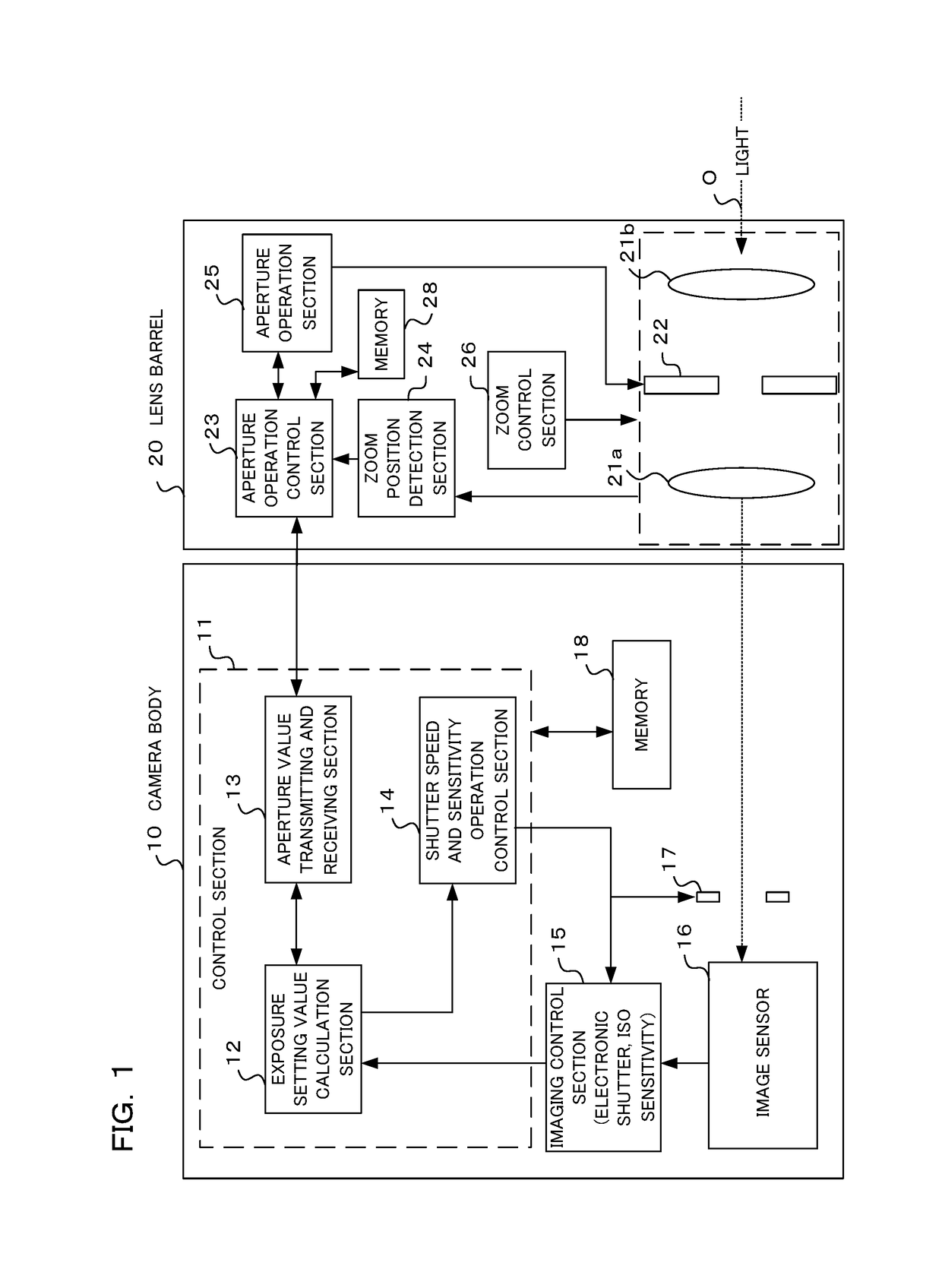

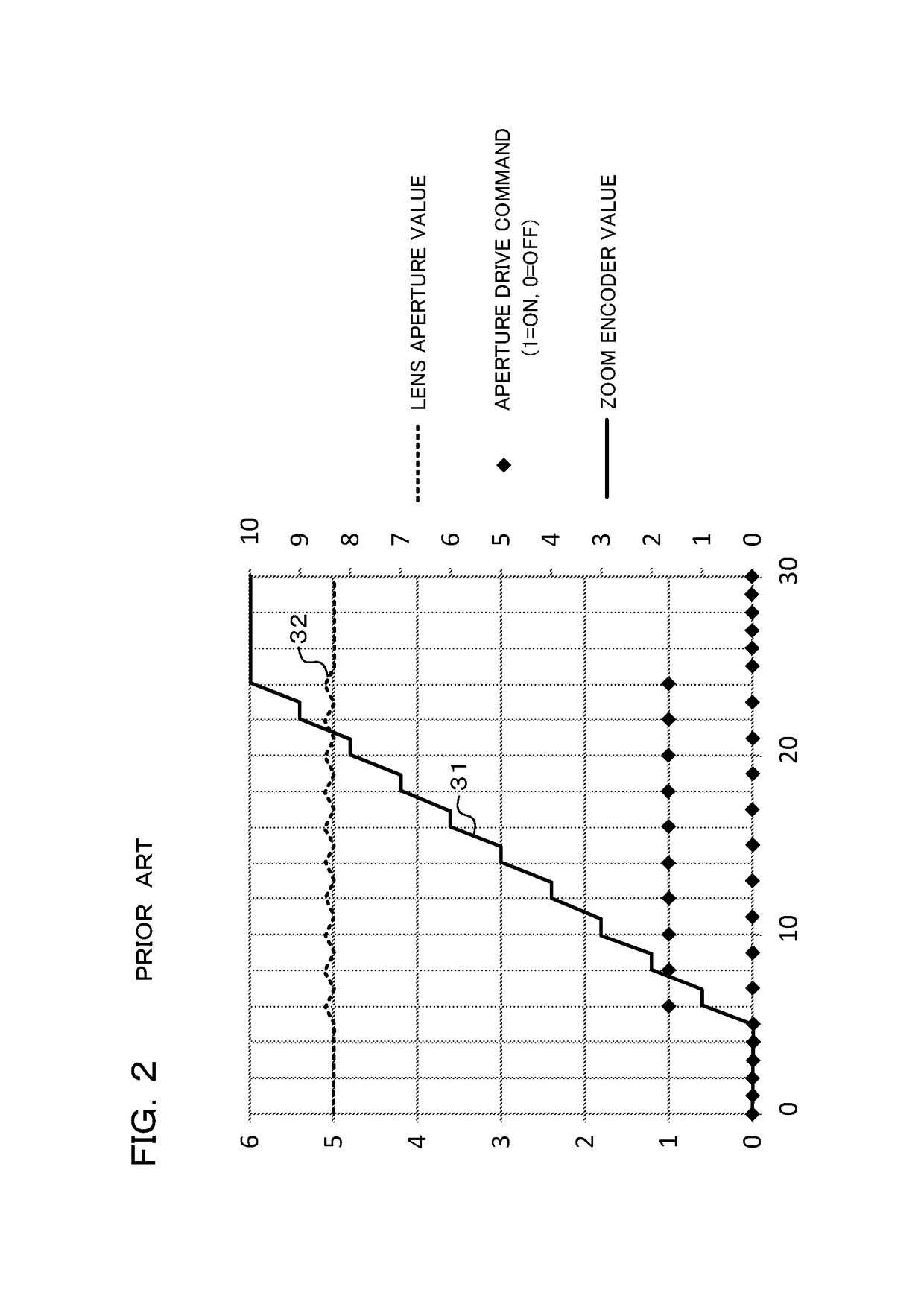

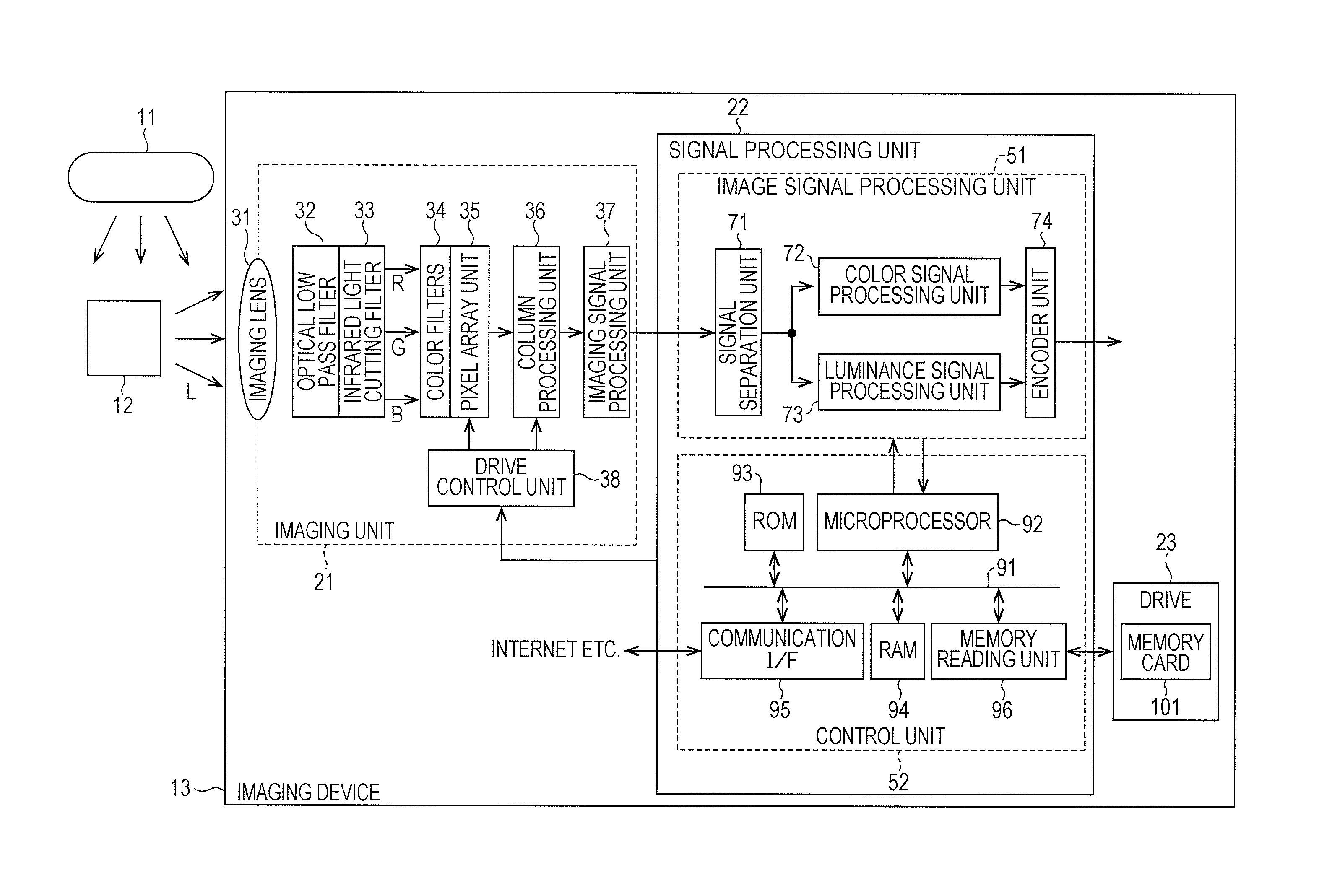

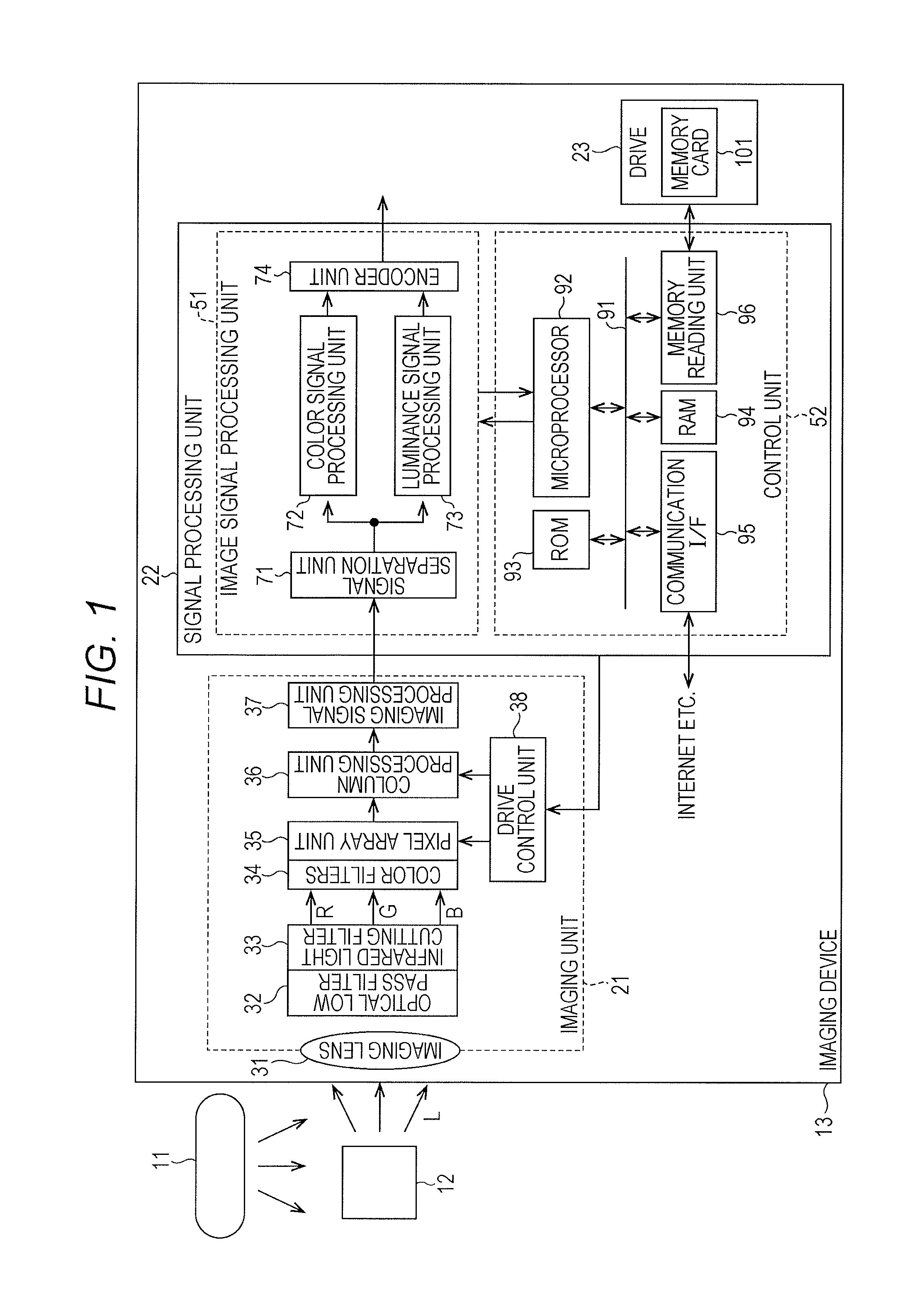

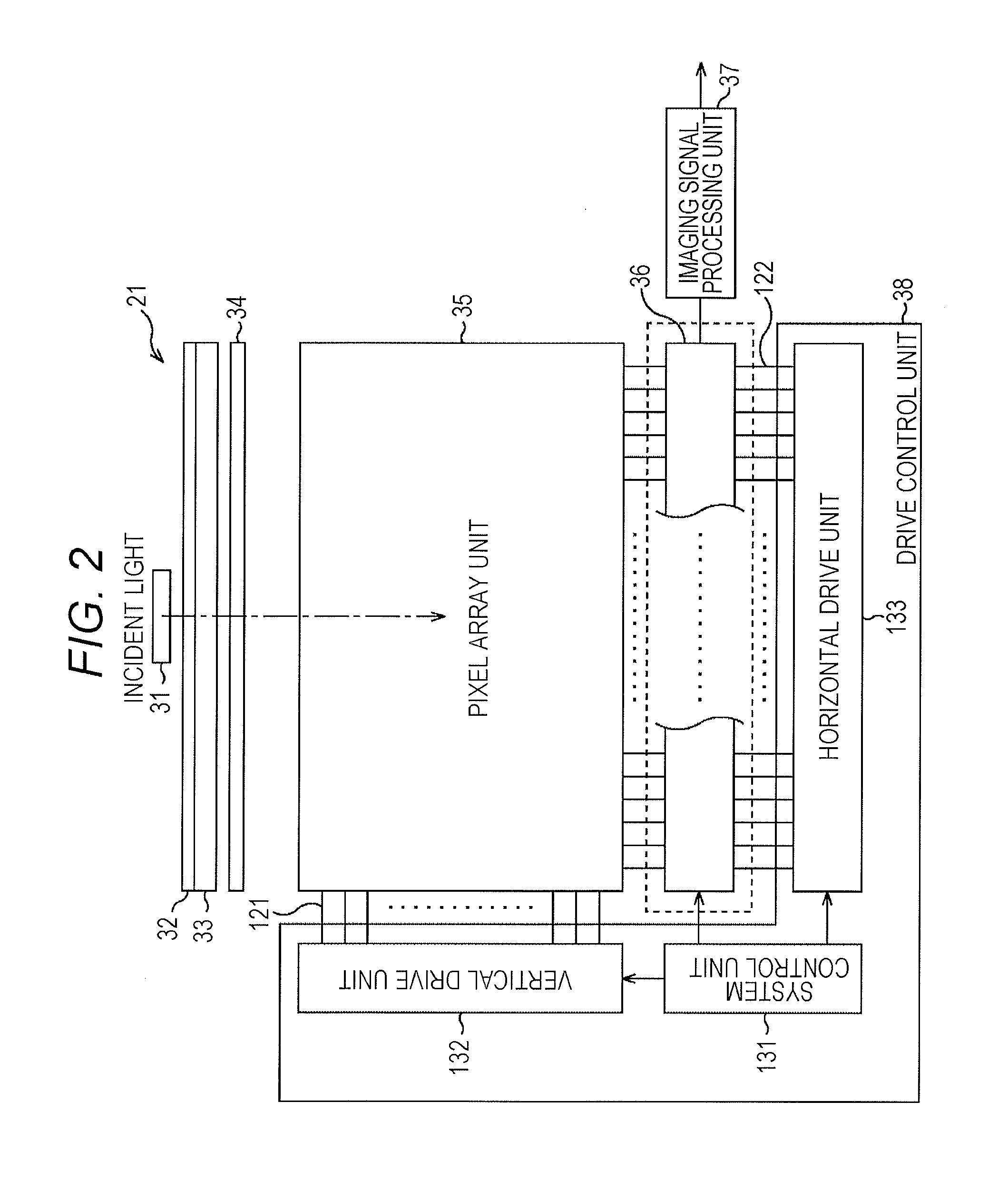

Imaging apparatus and imaging method

ActiveUS9712758B2Lower limitTelevision system detailsColor television detailsCamera lensControl signal

An imaging apparatus, comprising a lens unit having a photographing optical system, and a body having an image sensor for generating a pixel signal by imaging subject light that has passed through the photographing optical system, comprising an exposure control section for adjusting exposure amount for image data based on a pixel signal generated by the image sensor, by transmitting an aperture control signal to the aperture control section and changing opening of the aperture, and a determination section for determining whether or not the aperture control section is able to control opening of the aperture based on information from the lens unit, wherein the exposure control section does not transmit aperture control signals to the aperture control section when it is determined by the determination section that the aperture control section is able to control opening of the aperture.

Owner:OM DIGITAL SOLUTIONS CORP

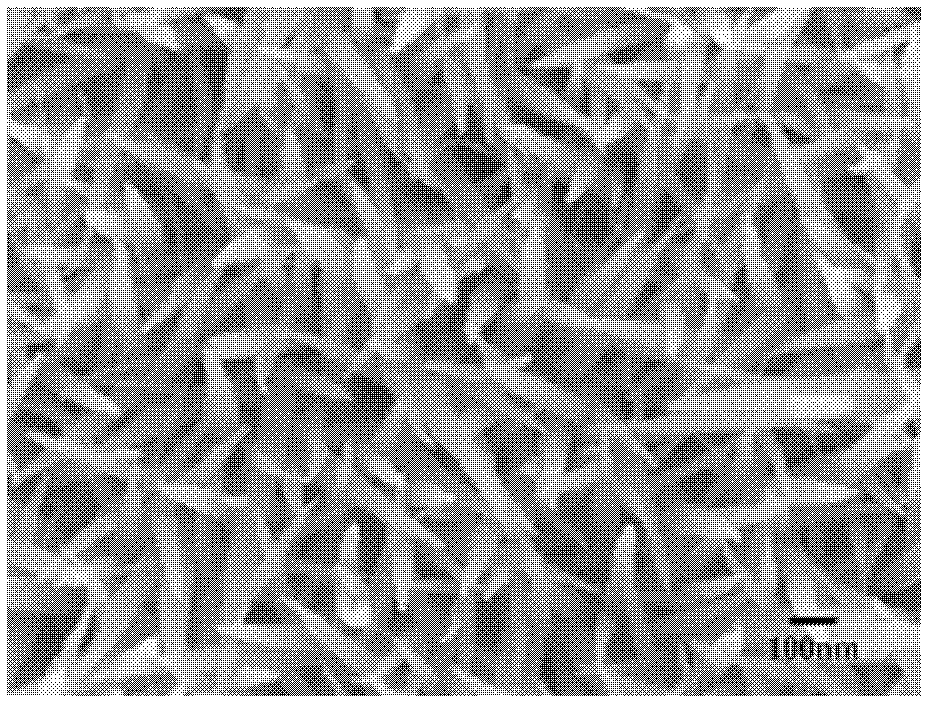

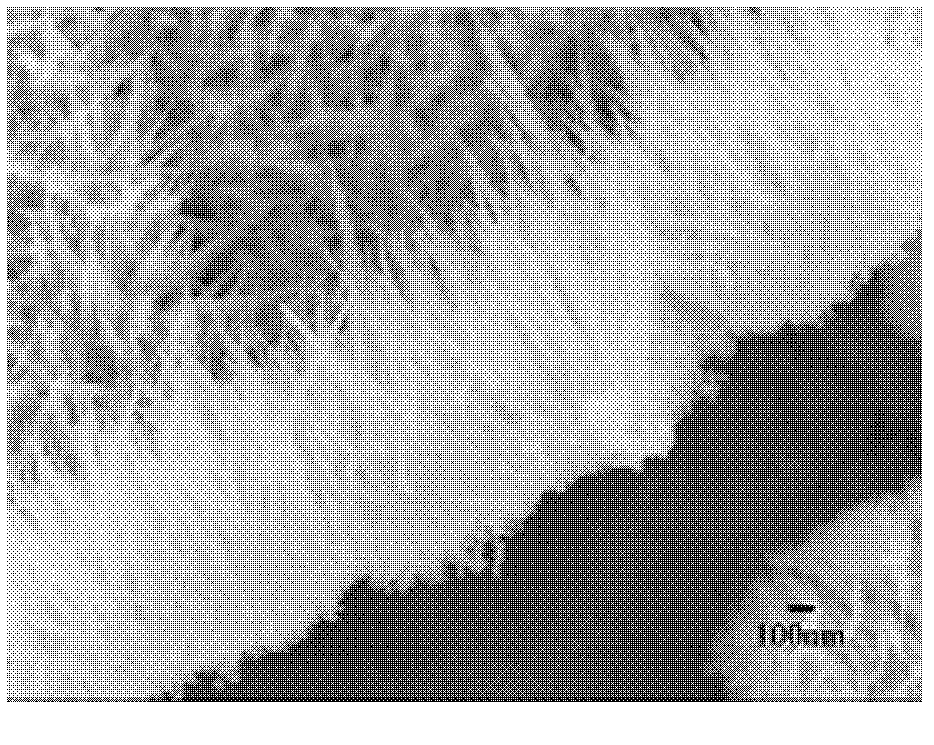

Porous nickel-copper oxide nanowire array enzyme-free glucose sensor electrode on titanium substrate

InactiveCN102507692AImprove workabilityGuaranteed stabilityMaterial analysis by electric/magnetic meansGlucose sensorsTitanium metal

The invention relates to a porous nickel-copper oxide nanowire array enzyme-free glucose sensor electrode on a titanium substrate. The electrode is of a porous nanowire array structure formed by alternately assembling nickel-copper oxide nanoparticles on the titanium substrate, wherein single nanowire has the top-end diameter of 20+ / -1 nm and the length of 2+ / -0.2 mu m; the nanowires are vertically, uniformly and compactly distributed on the surface of titanium metal so as to form an array; the single nanowire is formed by alternately assembling copper oxide and nickel oxide nanoparticles with particle size of 5+ / -0.2 nm; and nanopores with size of 5+ / -0.2 nm are uniformly distributed in the nanowires. The preparation method comprises the steps of: placing a clean titanium metal sheet in an aqueous solution of copper chloride dihydrate, nickel chloride hexahydrate and urea, sealing and heating in an autoclave with polytetrafluoroethylene inner lining to 120 DEG C and maintaining for 24 hours; naturally cooling, and taking out the titanium metal sheet to obtain a precursor (Ni,Cu)2(OH)2CO3 nanowire array film of an electrode sample; and respectively annealing the precursor sample in air at 350 DEG C and 500 DEG C to obtain the sensor electrode. The obtained electrode can be applied to biological, medical, electronic instruments and other products.

Owner:HUAZHONG NORMAL UNIV

Heating member for an image forming apparatus, having improved releasibility and conductivity

InactiveUS7558520B2Reduce material usageImprove heating efficiencySynthetic resin layered productsOhmic-resistance heatingSurface layerMetallurgy

The present invention is characterized in that, for the purpose of achieving a heating member (fixing member) in which thermal conductivity or electrical conductivity is given to a resin surface layer without loss of releasability, and heating efficiently is improved, the heating member contacting a to-be-heated member and heating the same has a surface layer 15 in which, in a resin material 43 having releasability, a material (for example, metal) 44 having either one or both thermal conductivity and electrical conductivity is mixed, and the material contact successively. Specifically, the heating member (fixing member) according to the present invention has the surface layer 15 in which the metal 44 is mixed into the fluorocarbon resin 43, and the metal 44 forms metal successively contacting part 42 in which the metal 44 successively contacts in such a manner as to surround the fluorocarbon resin part 41. Thereby, it is possible to improve thermal conductivity or electrical conductivity while maintaining releasability.

Owner:RICOH KK

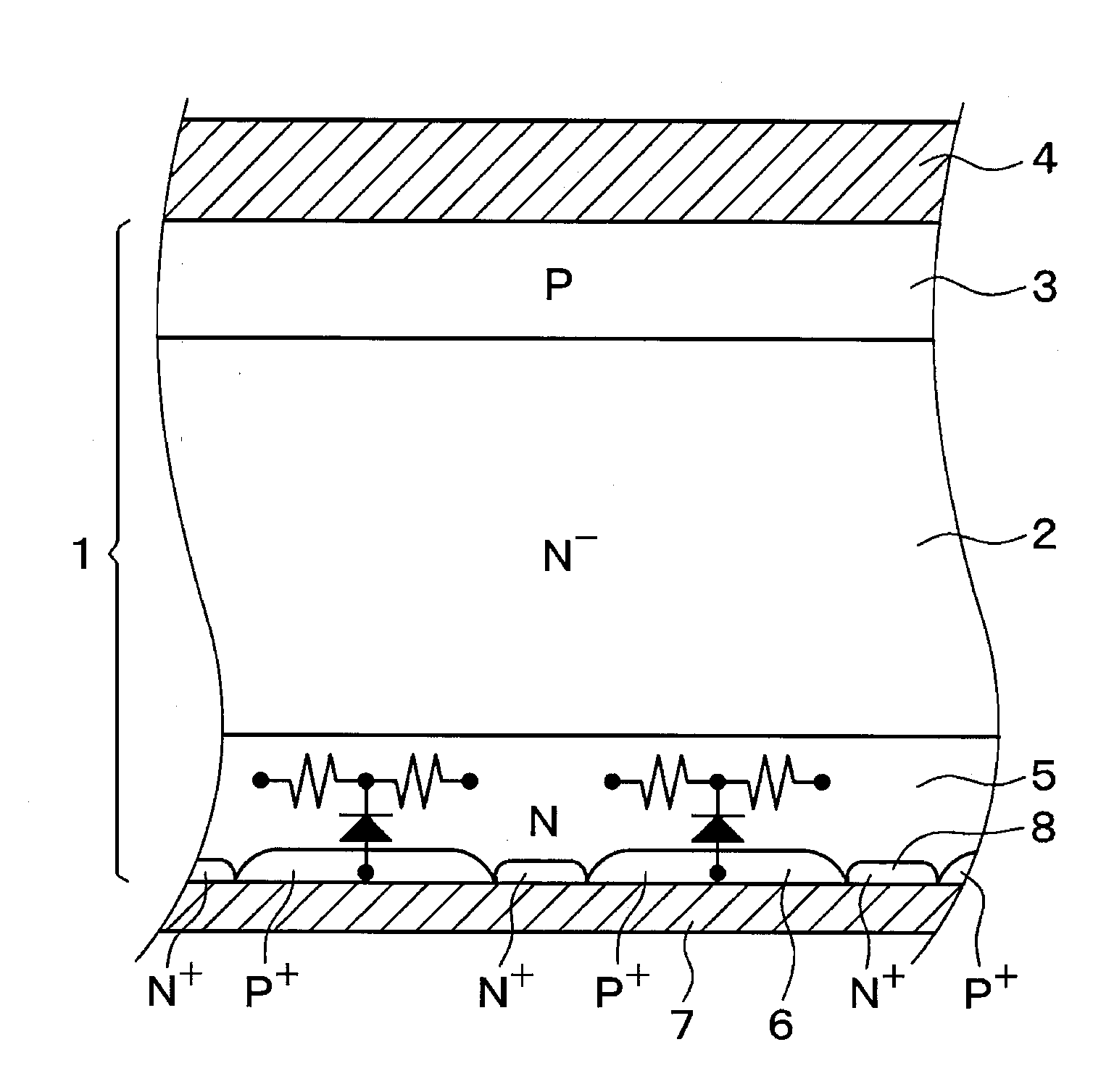

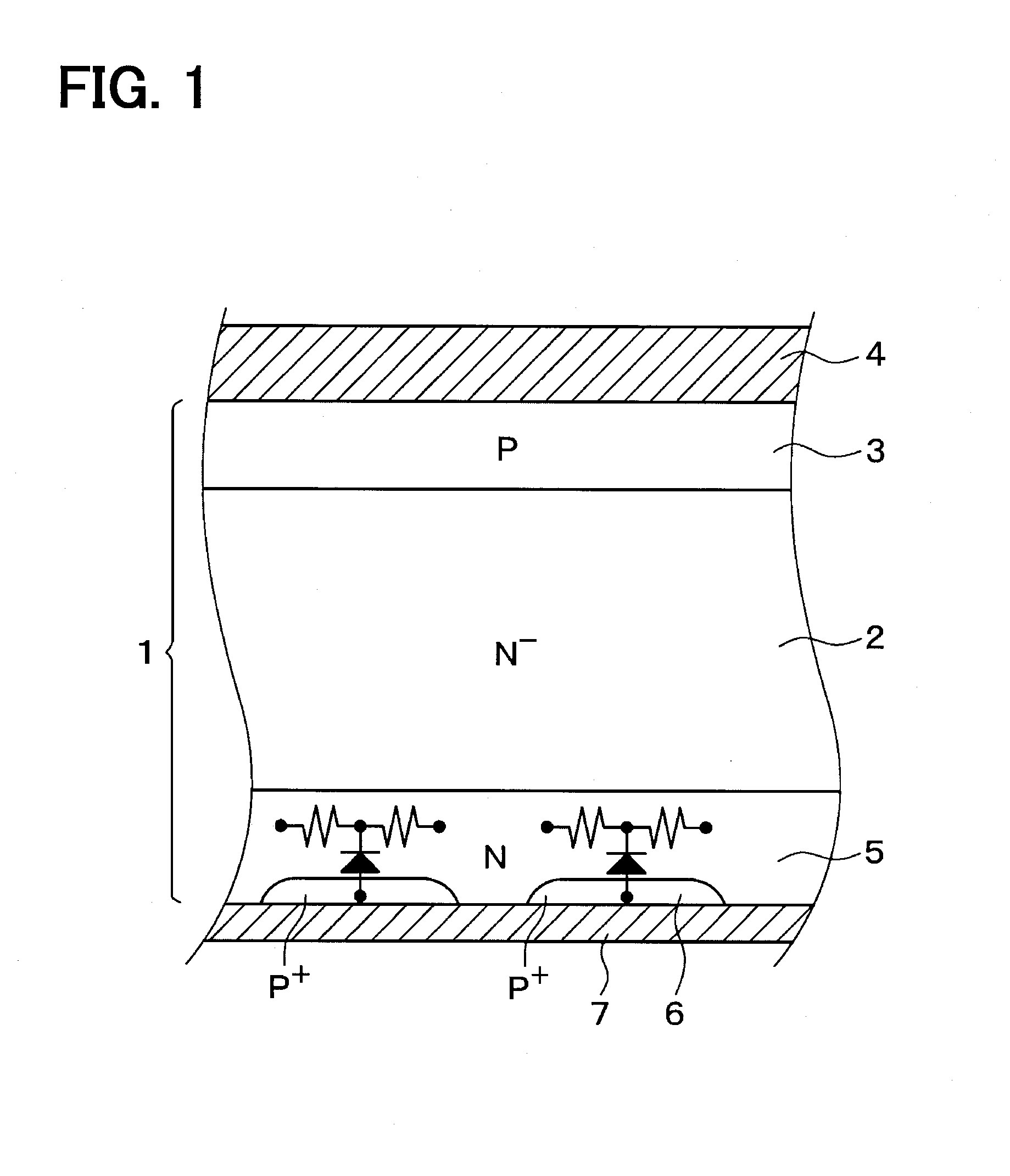

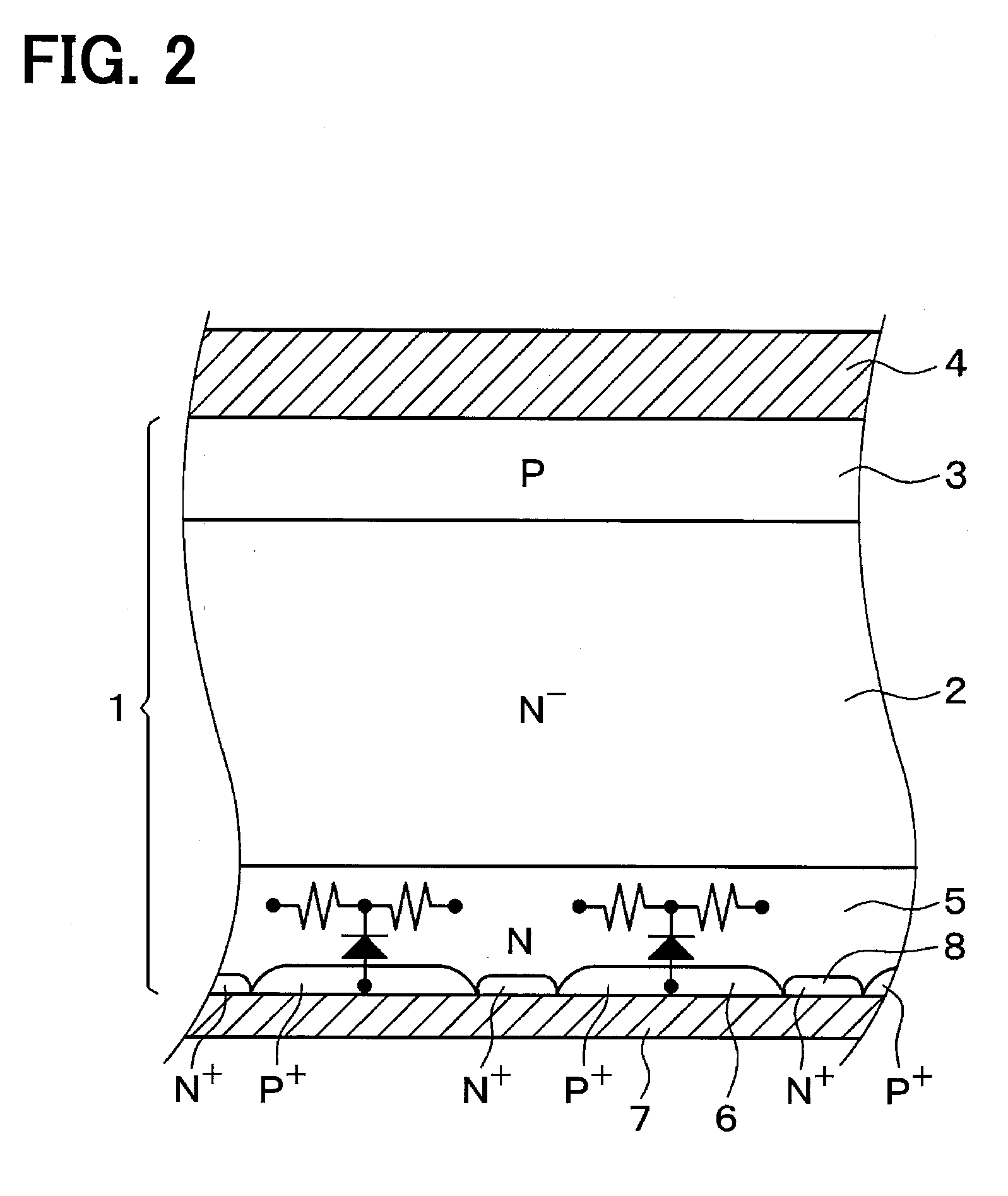

Semiconductor device

InactiveUS20150061090A1Facilitate conductionRecovery is limitedSemiconductor devicesPower semiconductor deviceHole injection layer

A semiconductor device includes: a drift layer having a first conductive type; a first semiconductor layer having a second conductive type and arranged in a surface portion of the drift layer; a second semiconductor layer having the first conductive type, arranged at a position of the drift layer spaced apart from the first semiconductor layer, and having a carrier density larger than the drift layer; a hole injection layer having the second conductive type and arranged selectively in the second semiconductor layer; a first electrode electrically connecting to the first semiconductor layer; a second electrode electrically connecting to the second semiconductor layer and the hole injection layer. The second semiconductor layer has a carrier density smaller than a spatial charge density.

Owner:DENSO CORP

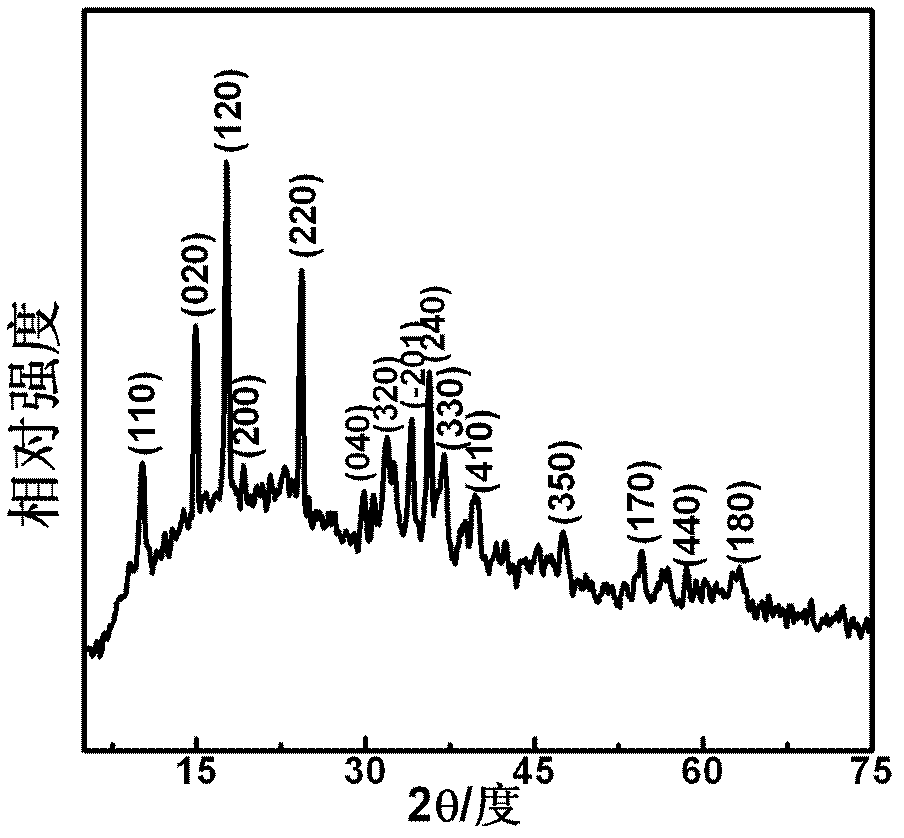

Electrophotographic photoconductor and image forming apparatus including the same, and coating solution for undercoat layer formation in electrophotographic photoconductor

ActiveUS20120051786A1Inhibit the generation of defectsPrevent image defectsElectrographic process apparatusPolyamide coatingsElectrical conductorOptoelectronics

An electrophotographic photoconductor comprising a conductive support, an undercoat layer and a photosensitive layer, the undercoat layer and the photosensitive layer being formed on the conductive support in sequence, wherein the undercoat layer contains a binder resin, titanium oxide particles surface-treated with at least anhydrous silicon dioxide and titanium oxide particles surface-treated with at least hydrous silicon dioxide.

Owner:SHARP KK

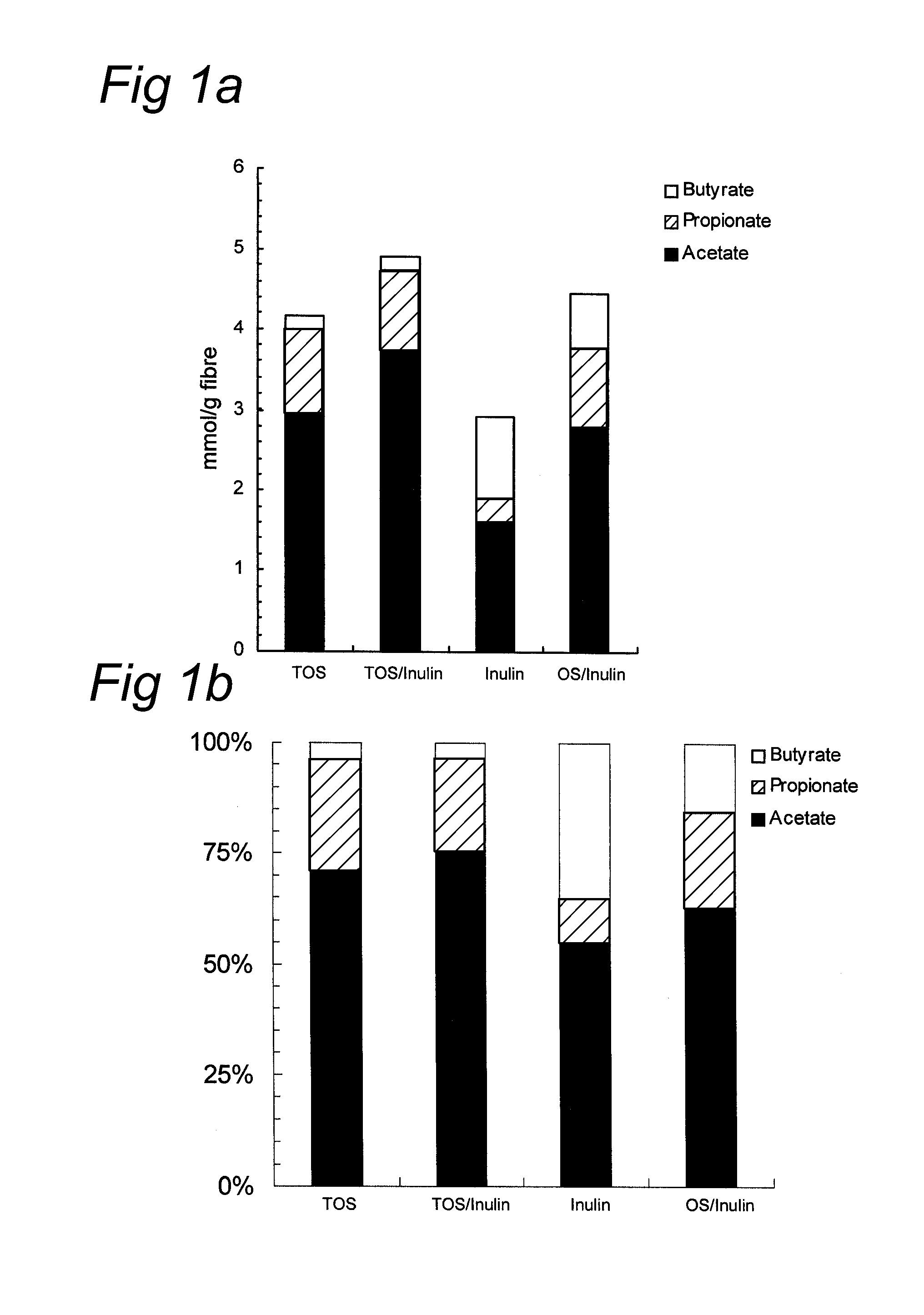

Composition comprising bifidobacterium infantis and fructo- and galacto-oligosaccharides for the prevention of intestinal discomfort in infants

InactiveUS20100322904A1Lower Level RequirementsReduce the populationBiocideBacteria material medical ingredientsGalactooligosaccharideFructooligosaccharide

Compositions comprising bifidobacteria and galactooligosaccharides and fructooligosaccharides are provided that support the introduction of solid weaning foods in the diet of infants that receive infant milk formula or breast milk.

Owner:NUTRICIA

Semiconductor device embedded with pressure sensor and manufacturing method thereof

ActiveUS7270012B2High precision measurementReduced footprintFluid pressure measurement by electric/magnetic elementsSolid-state devicesSilicon oxideMoisture

The method for promoting the size reduction, the performance improvement and the reliability improvement of a semiconductor device embedded with pressure sensor is provided. In a semiconductor device embedded with pressure sensor, a part of an uppermost wiring is used as a lower electrode of a pressure detecting unit. A part of a silicon oxide film formed on the lower electrode is a cavity. On a tungsten silicide film formed on the silicon oxide film, a silicon nitride film is formed. The silicon nitride film has a function to fill a hole or holes and suppress immersion of moisture from outside to the semiconductor device embedded with pressure sensor. A laminated film of the silicon nitride film and the tungsten silicide film forms a diaphragm of the pressure sensor.

Owner:HITACHI LTD

Imaging device, imaging method, electronic device, and program

ActiveUS20150138407A1Lower limitDecrease can be minimizedTelevision system detailsTelevision system scanning detailsCheckerboard patternSignal processing

The present technique relates to an imaging device and an imaging method, an electronic device, and a program, which are configured to improve an SN ratio by combining addition reading and thin-out reading by signal processing similar to signal processing using thin-out reading.First, as illustrated in the left side of the drawing, G pixel and B pixel, which are sub-colors, of the top row of regions Z1, Z2 are subjected to thin-out reading. Next, for W pixels of the main color arranged in a checkerboard pattern in the regions Z1, Z2, two pixels tied by a straight line in the drawing are subjected to addition reading at the same tone timing. For W pixels of the main color arranged in a checkerboard pattern in regions Z3, Z4, two pixels tied by a straight line in the drawing are also subjected to addition reading at the same tone timing. R and G pixels, which are sub-colors, of the lower stage of the regions Z3, Z4 are read.According to a relative relation between the main color and the sub-colors of the regions Z1 to Z4 as illustrated in the center of the drawing, Bayer arrangement is obtained as illustrated in the right side of the drawing. The present technique can be applied to an imaging device.

Owner:SONY CORP

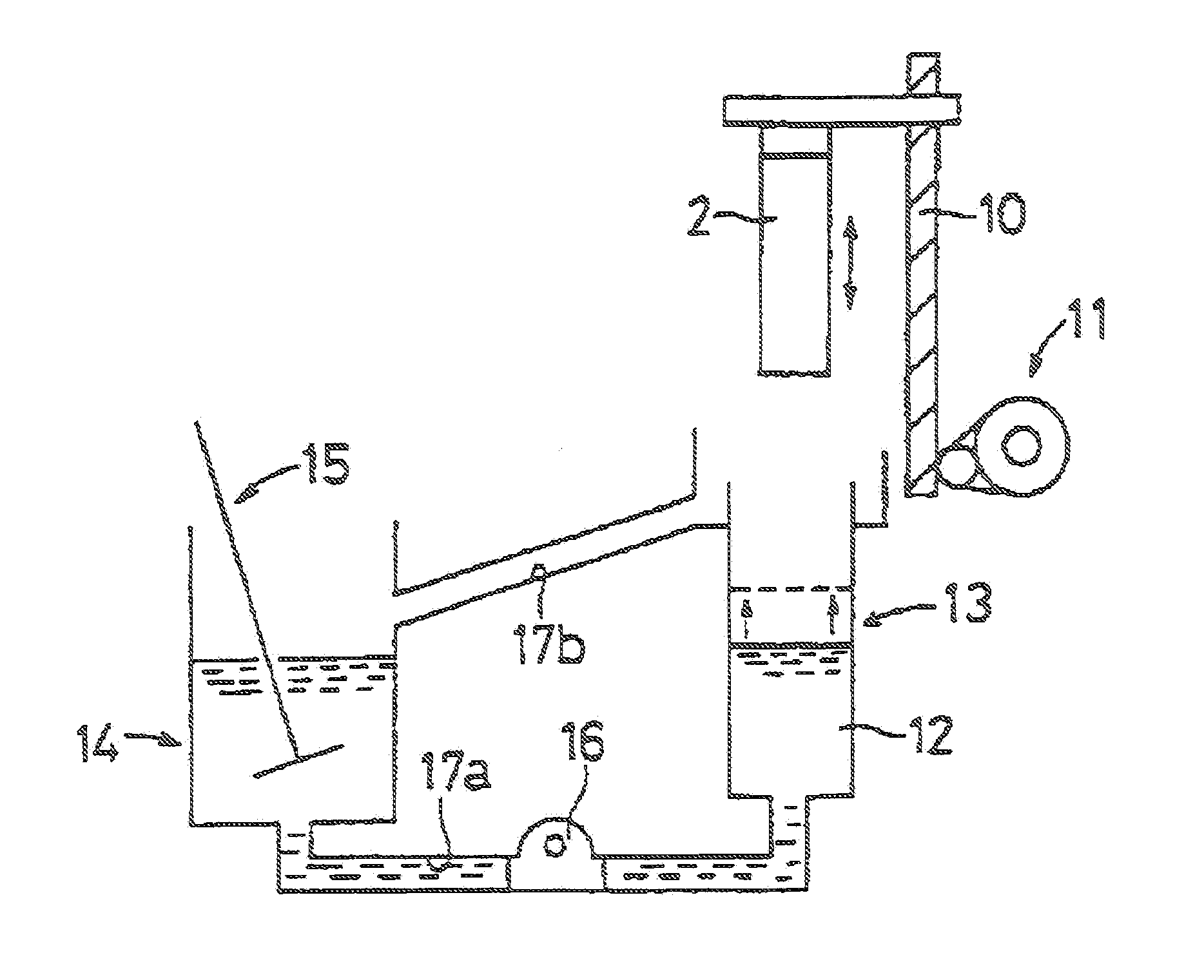

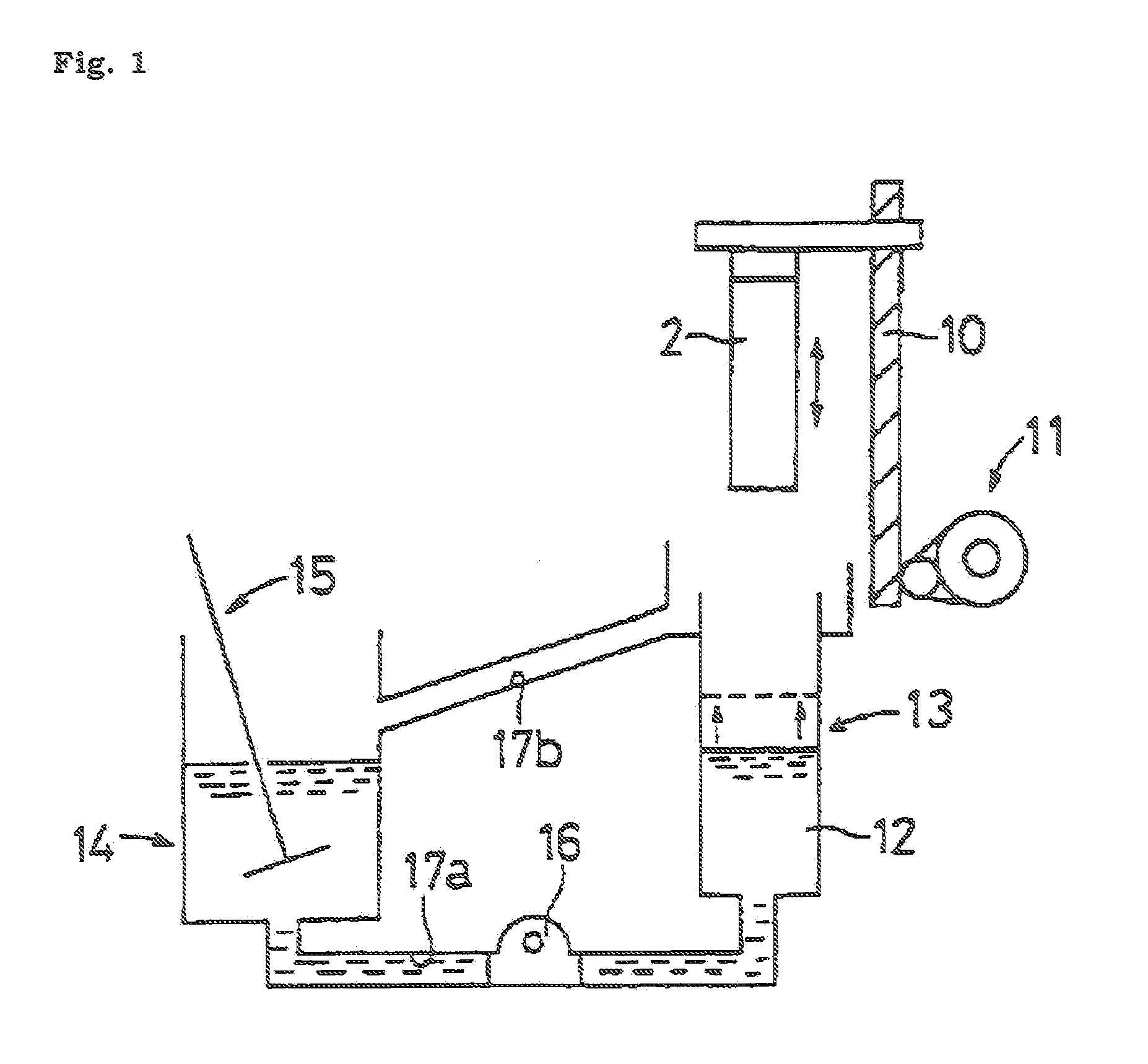

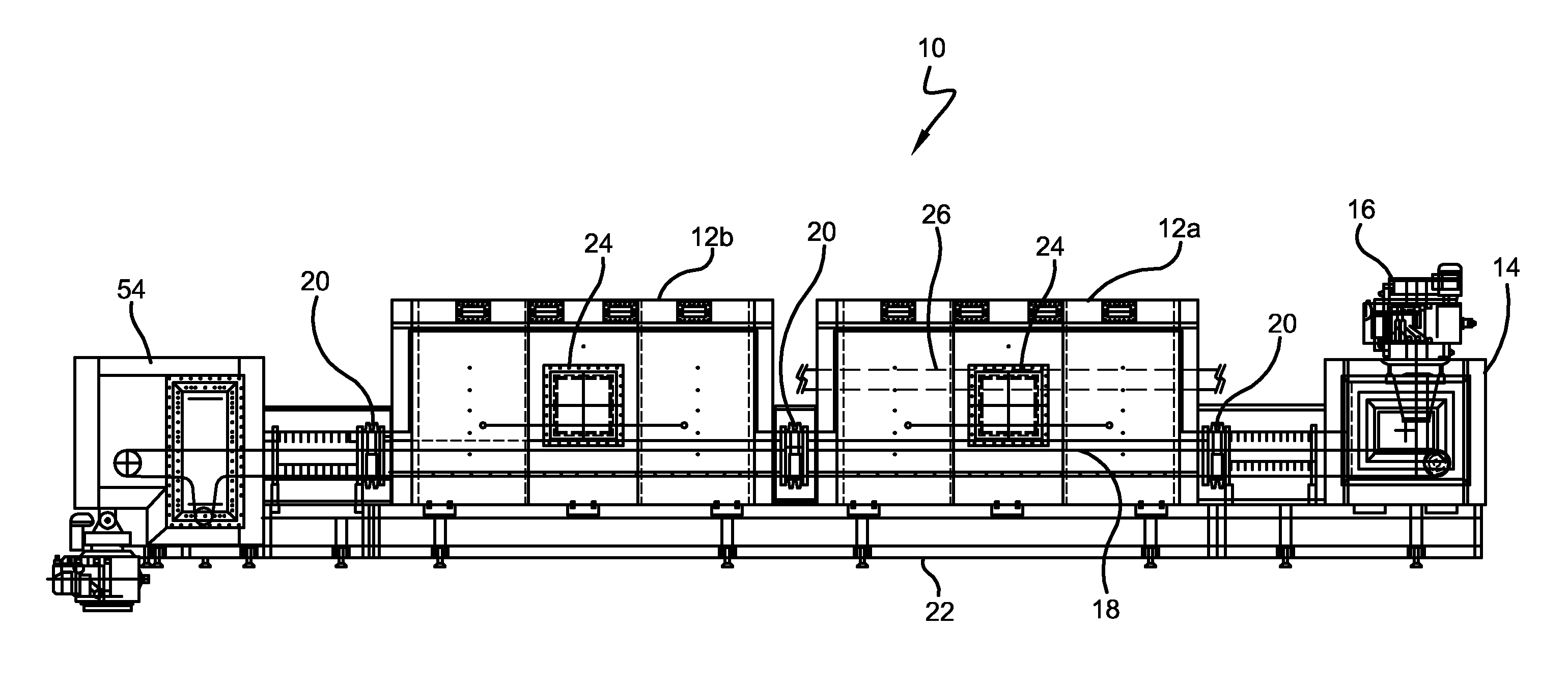

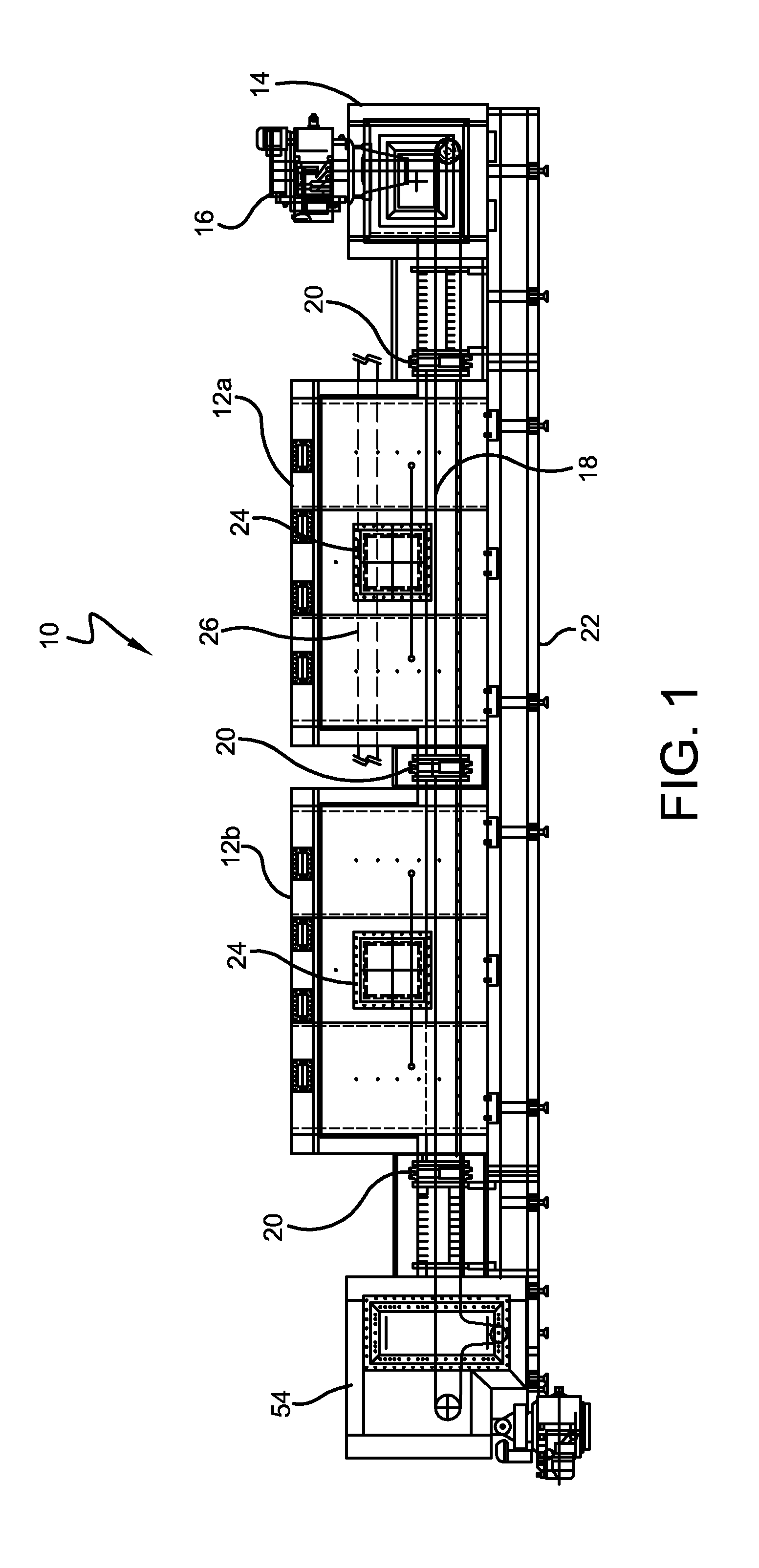

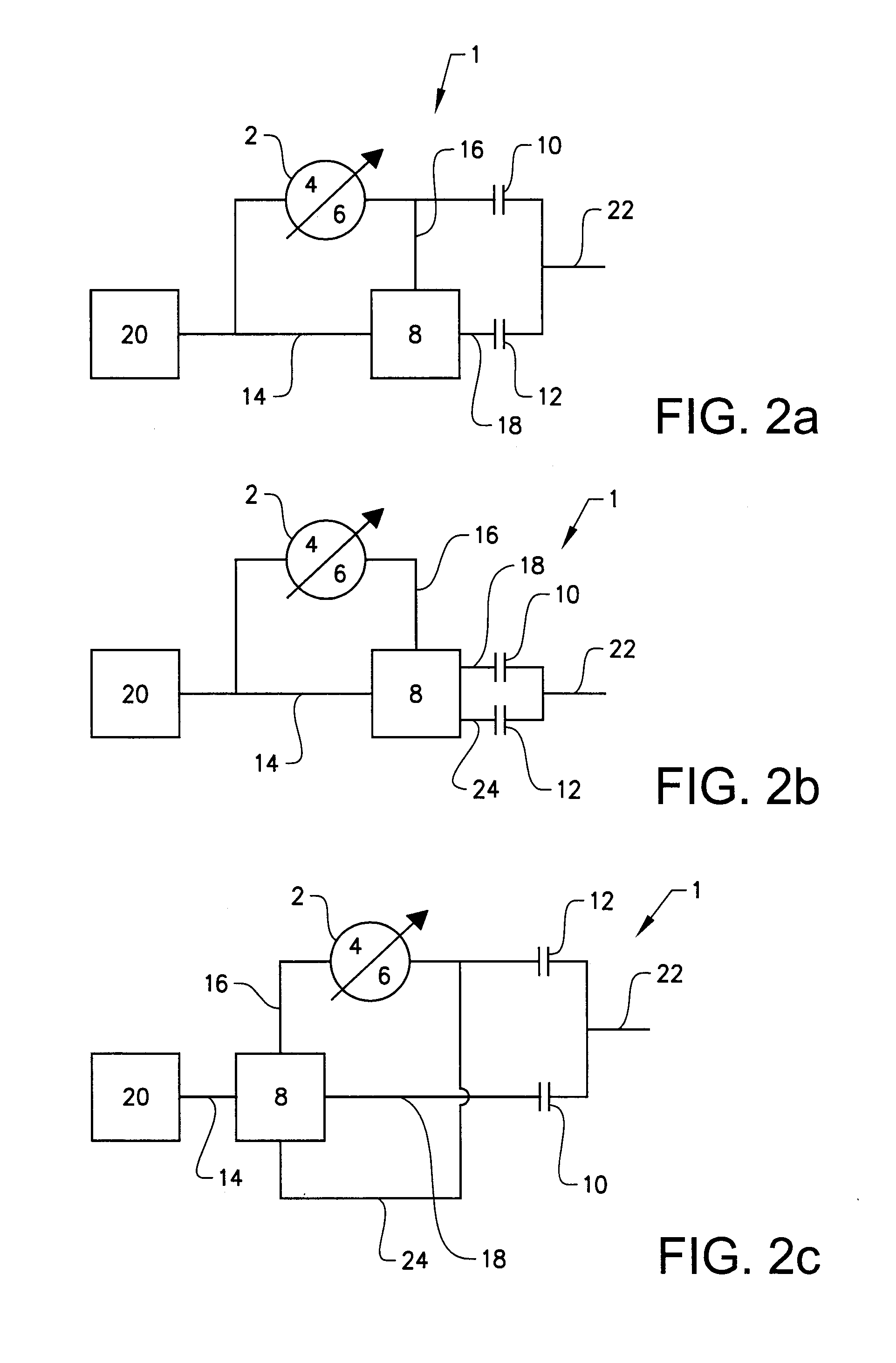

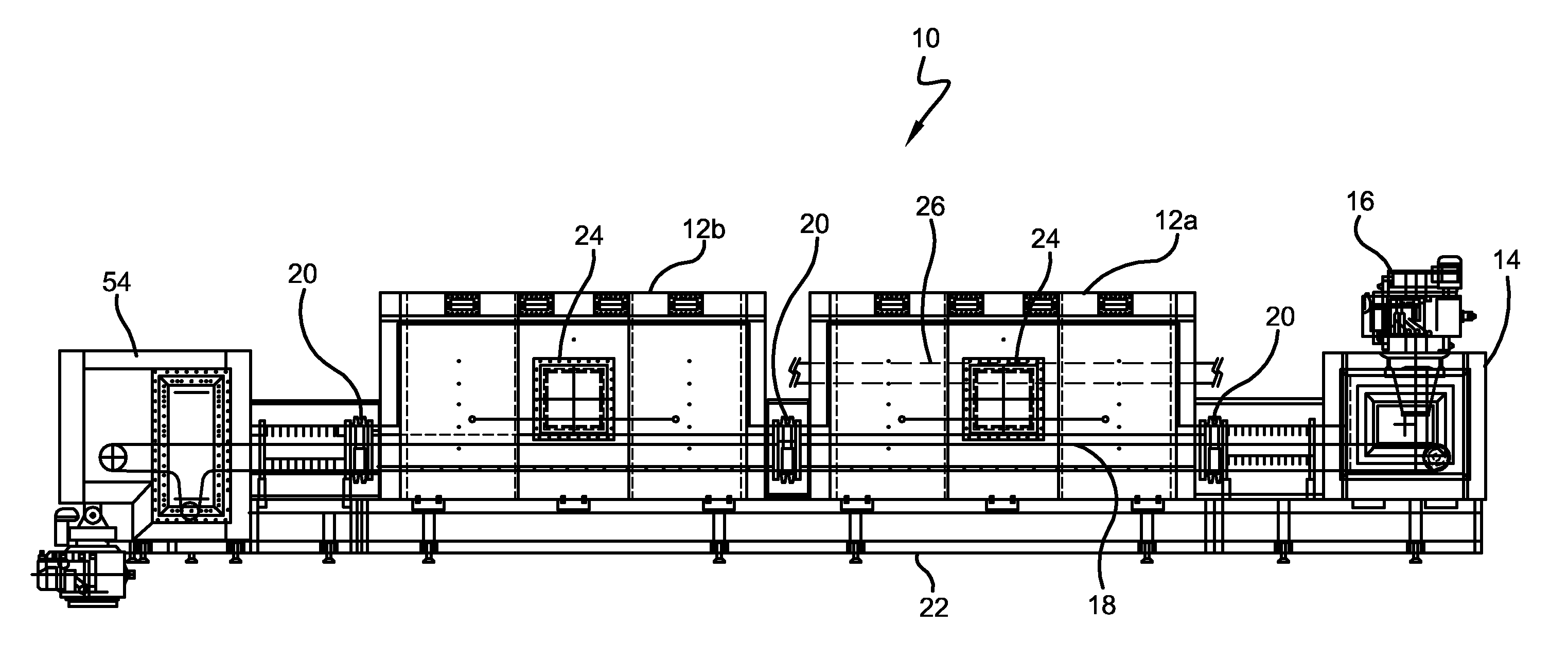

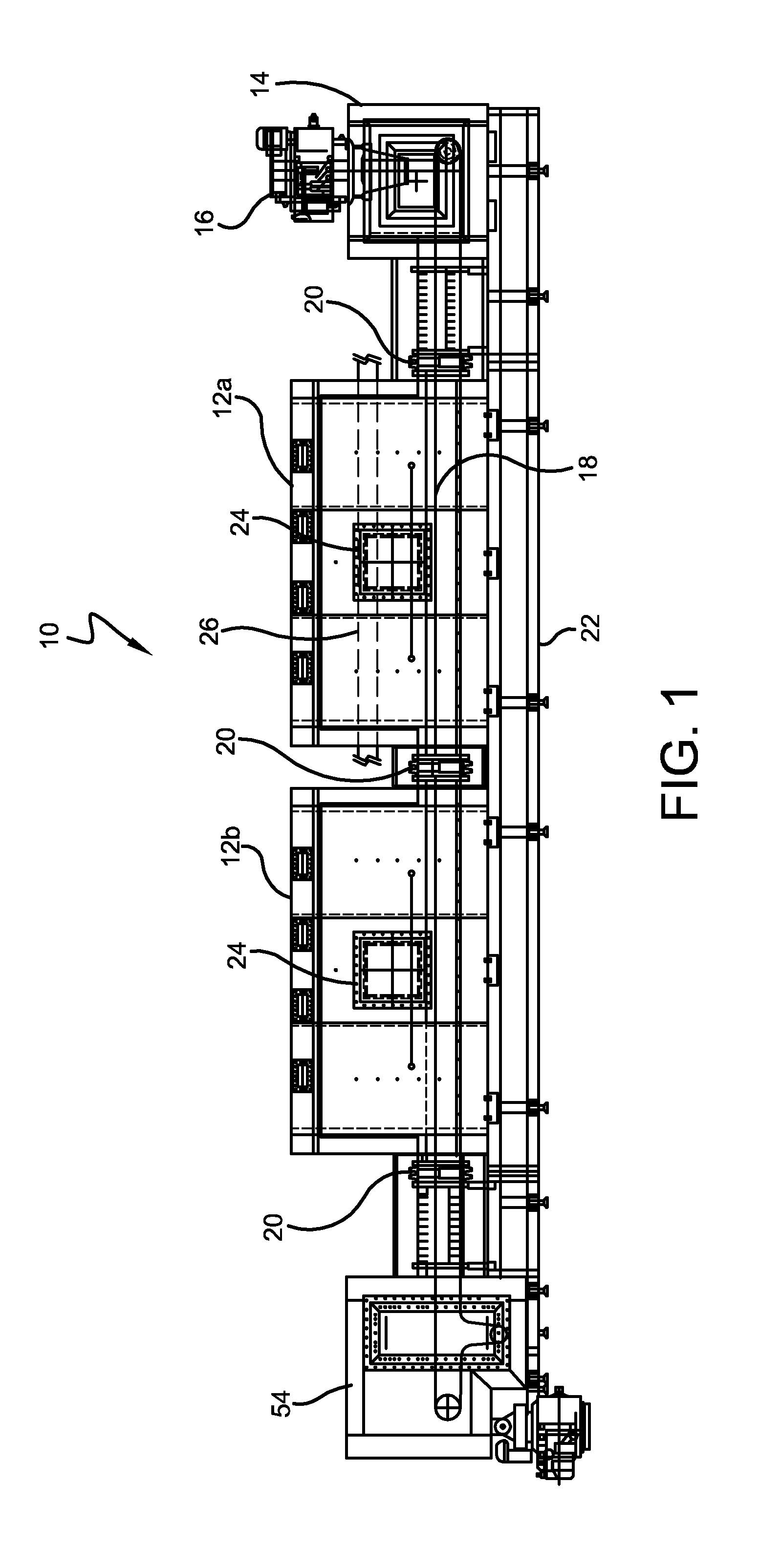

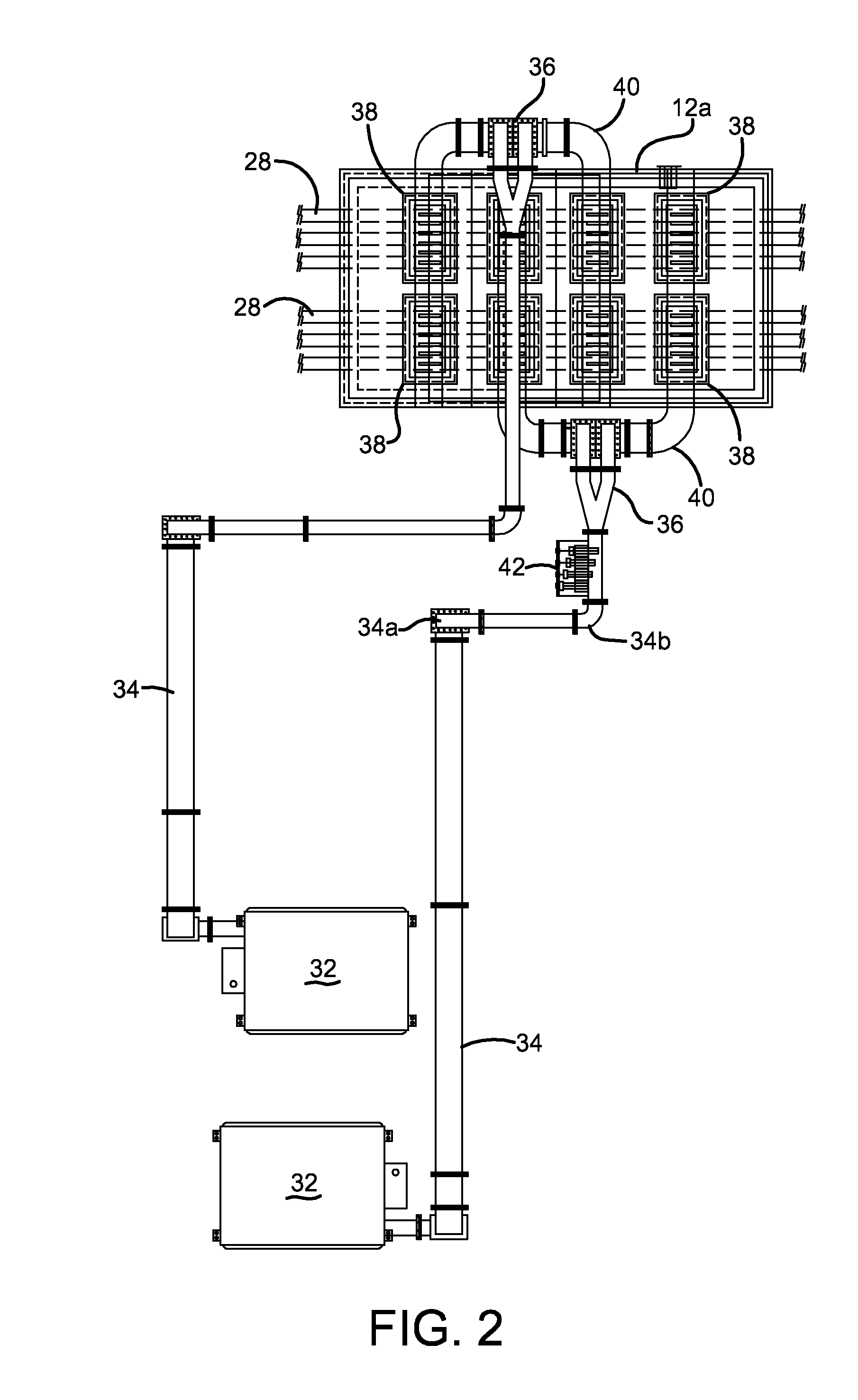

Method and apparatus for dual applicator microwave design

ActiveUS20120125920A1Improve efficiencyIncrease costThermal non-catalytic crackingInduction heatingSyngasMicrowave

The invention described herein pertains generally to a more efficient and cost-effective method and apparatus for: (1) coupling of microwave energy from a microwave generator or plurality of microwave generators into an integral set of applicators; (2) extraction and separation of organic compounds from a mixture of organic and inorganic compounds; and (3) recovery and conversion of the organic compounds to gaseous and liquid fuels. The apparatus described in this invention result in improved microwave absorption within the mixture flowing through the applicators by increasing residence time within the applicators, resulting in a higher temperature within the material. The higher temperature lowers the viscosity of the solution, but also provides a limited reduction of the combination of complex chain and aromatic organic compounds to allow recovery of syngas and fuel oil.

Owner:NOVAK JUDITH

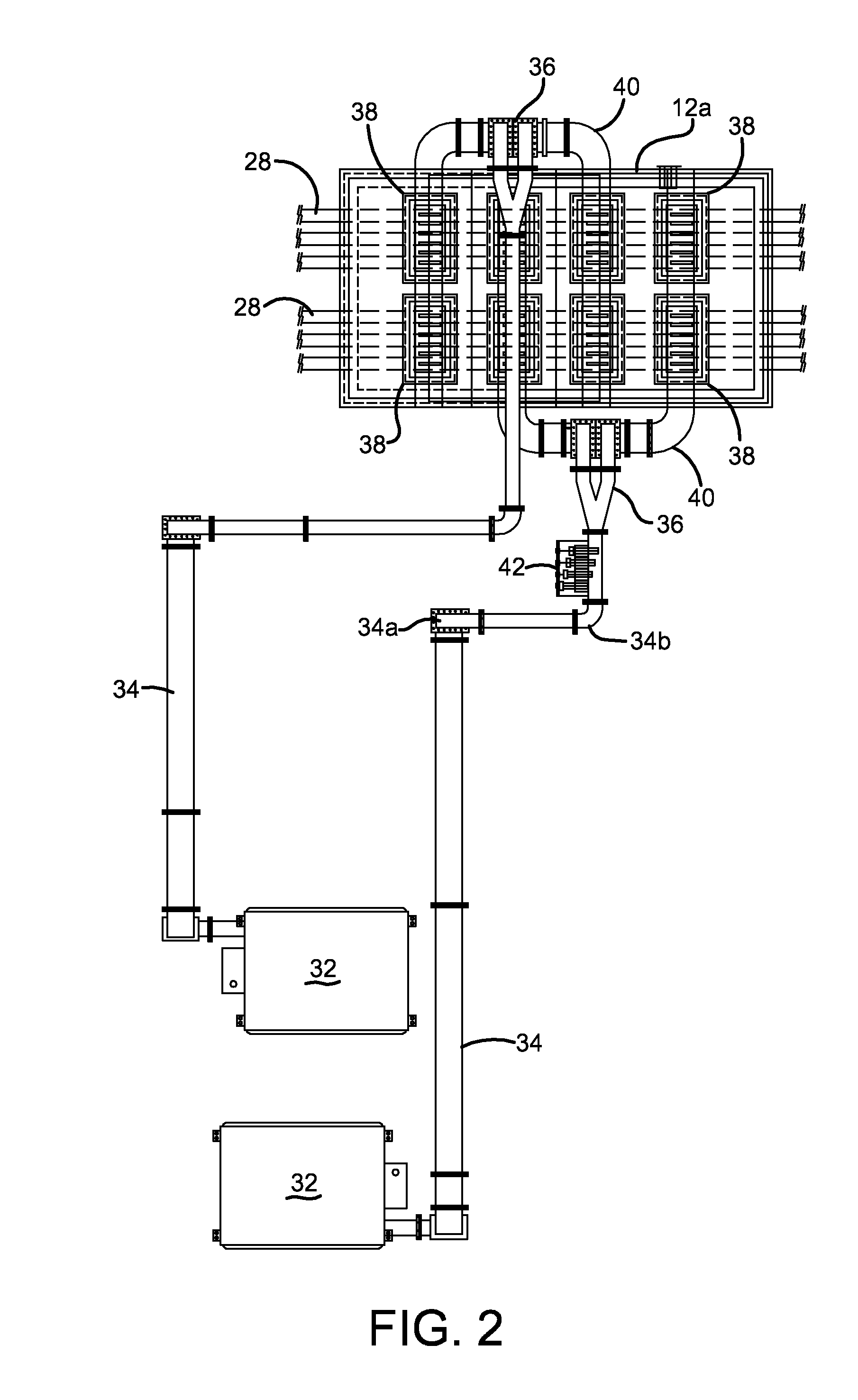

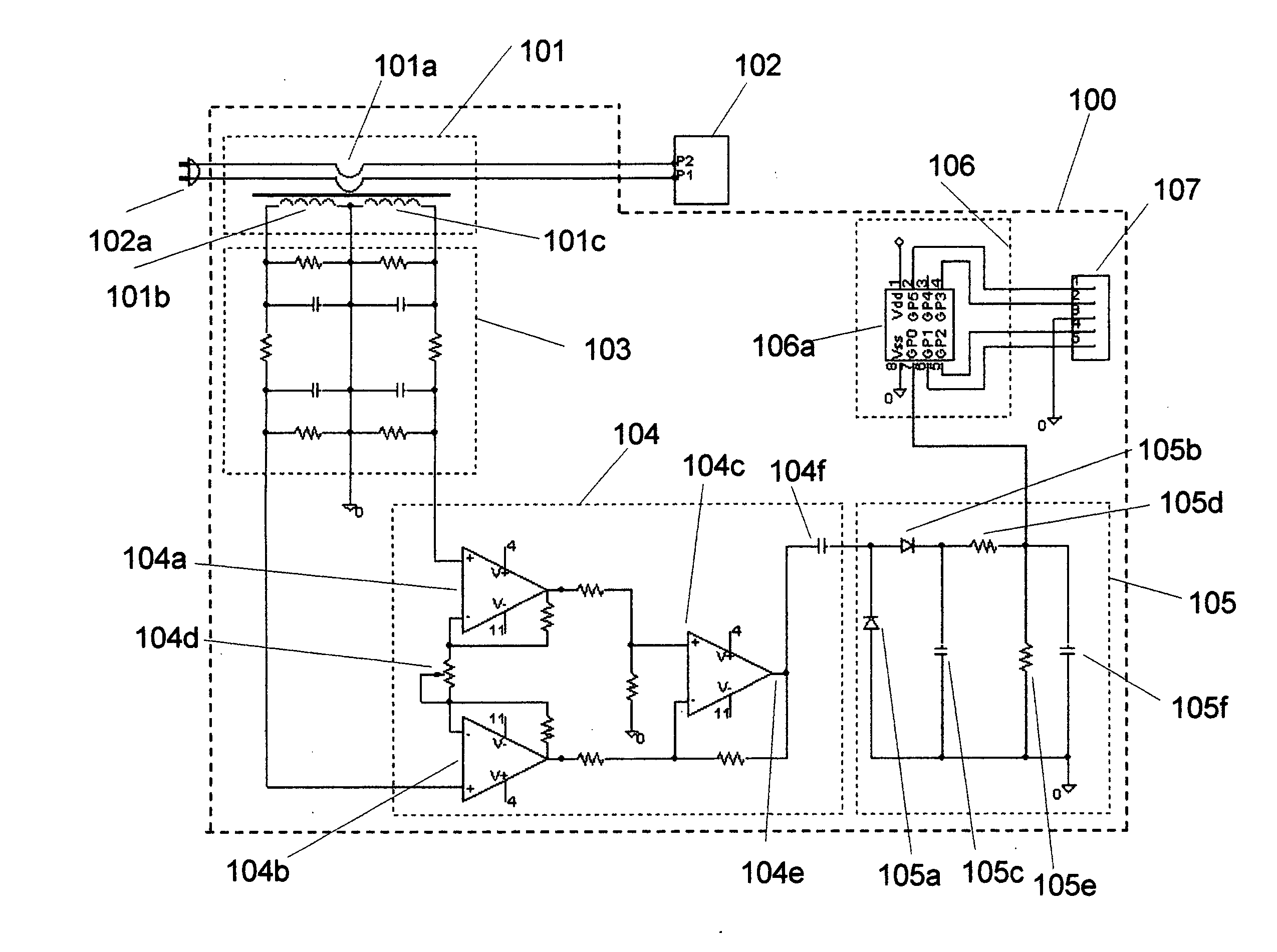

Electronic judging apparatus for working state of the equipment

InactiveUS20070108988A1Low costReduce noiseNoise figure or signal-to-noise ratio measurementElectronic circuit testingDigital signal processingCommunications system

The invention provides the electronic judging apparatus to detect the working state of the other electric equipment without modifying it inside. The common mode noise around the electric power supplying wires of the other equipment is measured by using the special magnetic core detector attached around the power supplying wire, and the common mode noise is compared with the one measured on the non-working time after amplifying and digital signal treatment of the detected signal. As the modification of the equipment is not required, the monitoring of the working state can be available for various equipments easily and also available from a remote place by transmitting the digital treated signal on the internet communication system.

Owner:KONNO AKIRA

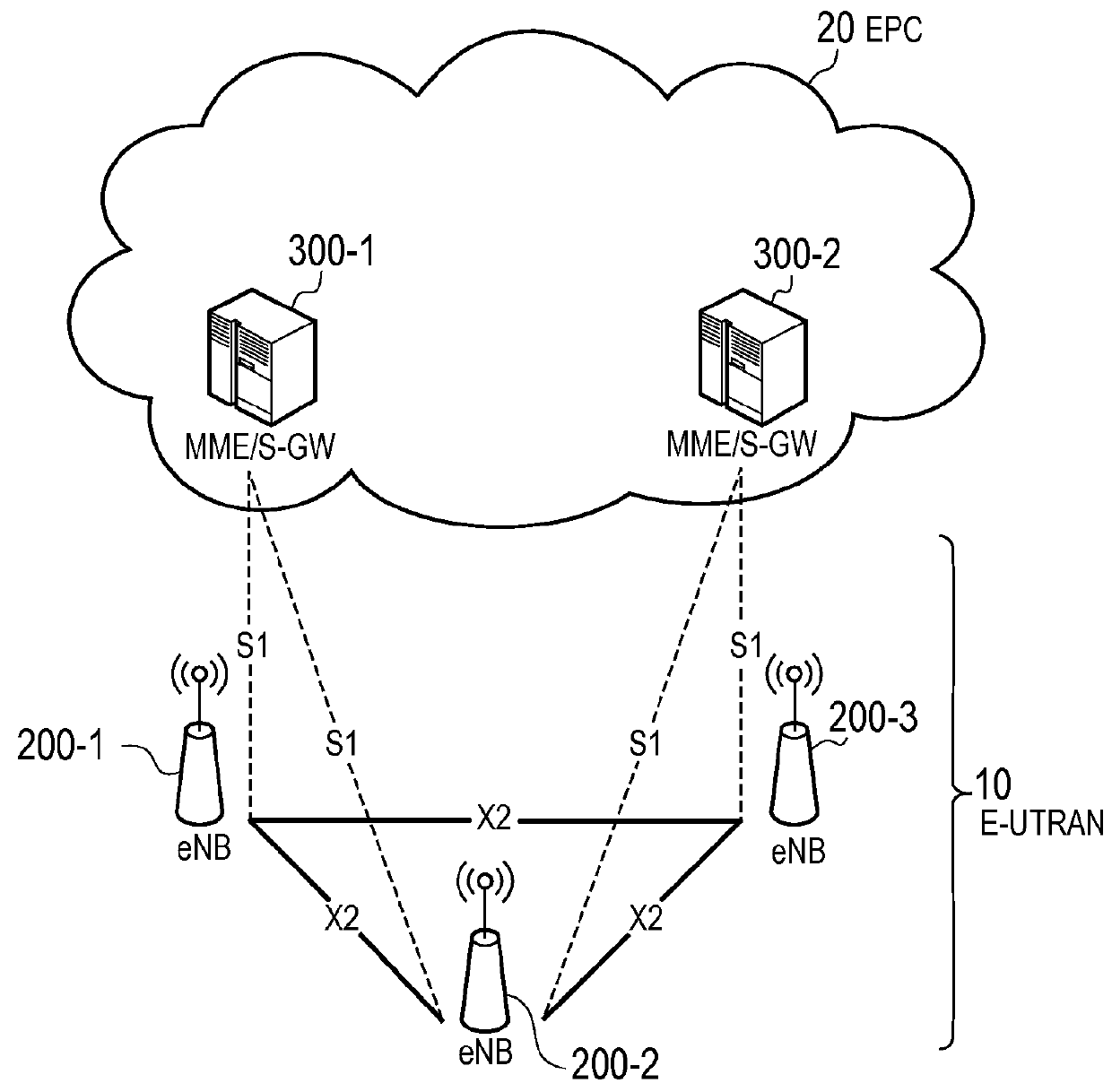

Base station

InactiveUS20160057689A1Save energyLower quality of servicePower managementWireless commuication servicesHandoverBase station

A base station according to an embodiment is a base station for performing communication with a user terminal in a self-cell. The base station comprises: a controller configured to control handover of the user terminal to a neighboring base station before setting a power saving communication mode for performing communication with the user terminal while reducing consumed power in the base station.

Owner:KYOCERA CORP

Integrated thermal sensor comprising a photonic crystal waveguide

ActiveUS20200018714A1Reduce mean free pathLower limitSpectrometer detectorsMaterial thermal conductivityToxic gasPhotonic crystal

An integrated thermal sensor comprising photonic crystal elements that enable photonic elements for photonic sourcing, spectral switching and filtering, sensing of an exposed analyte and detection. In embodiments, applications are disclosed wherein these photonic elements provide a spectrophotometer, a photonic channel switch and a standalone sensor for toxic gases and vapors. An application coupled with a mobile phone is disclosed.

Owner:CARR WILLIAM N

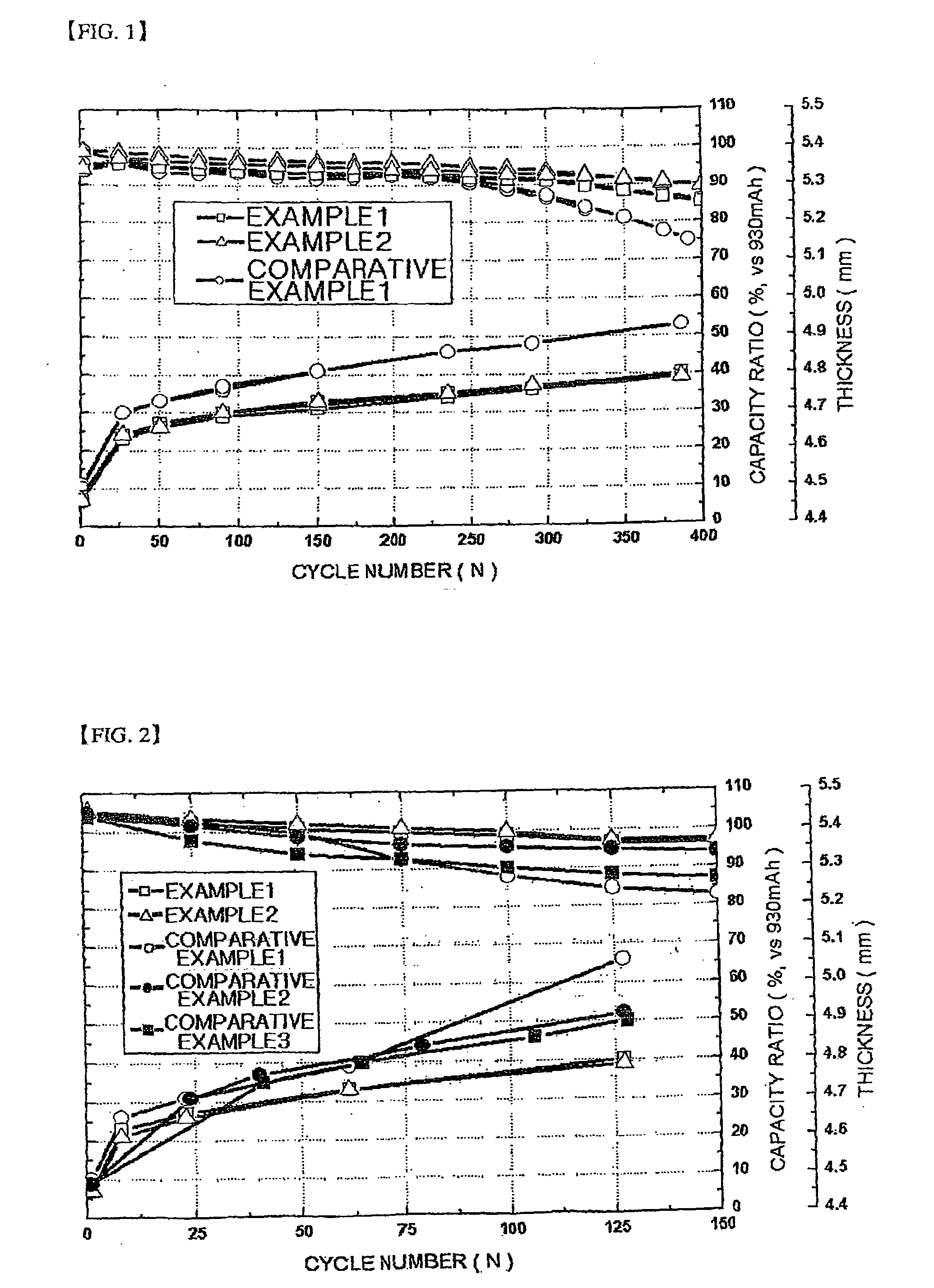

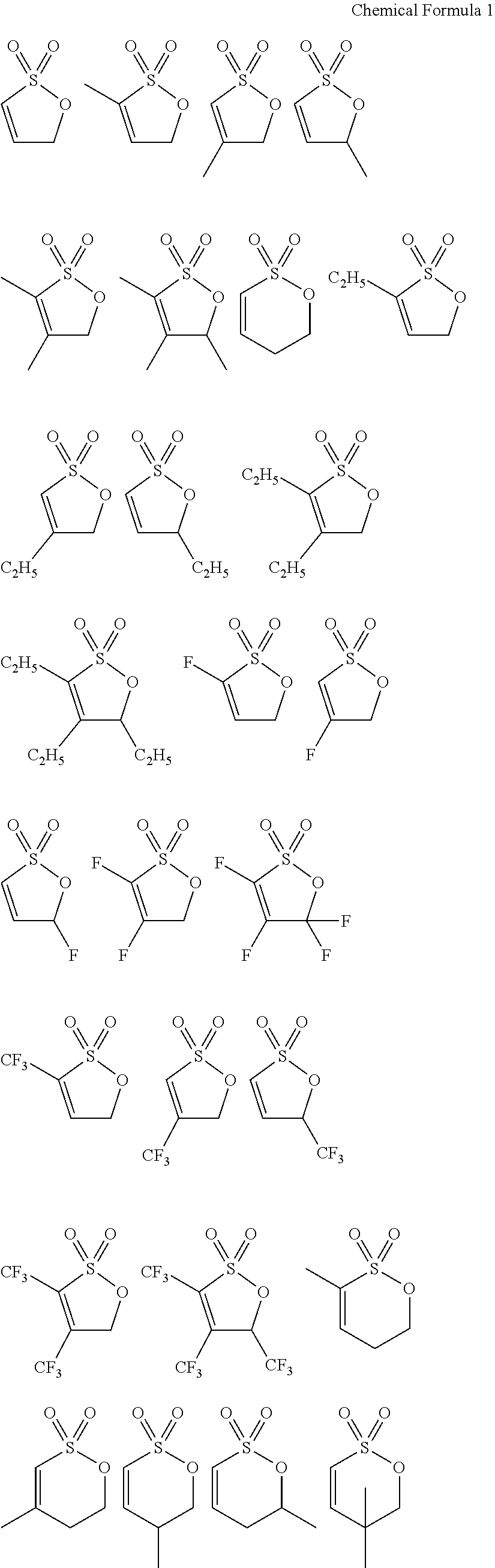

Non-aqueous electrolyte solution for lithium secondary battery and lithium secondary battery having the same

ActiveUS20110111306A1Extend battery lifeInhibit side effectsAlkaline accumulatorsCell electrodesElectrolytic agentPhysical chemistry

A non-aqueous electrolyte solution for a lithium secondary battery includes a lithium salt and an organic solvent. Based on 100 parts by weight of the non-aqueous electrolyte solution, the non-aqueous electrolyte solution includes 1 to 5 parts by weight of sultone-based compound having a carbon-carbon unsaturated bond in a cyclic structure; 1 to 5 parts by weight of cyclic carbonate compound with a vinyl group; 5 to 10 parts by weight of cyclic carbonate compound that is substituted with halogen; and 1 to 5 parts by weight of dinitrile-based compound. This non-aqueous electrolyte solution improves stability of a SEI film formed on a surface of an anode of a lithium secondary battery and thus improves normal temperature cycle performance and high temperature cycle performance.

Owner:LG ENERGY SOLUTION LTD

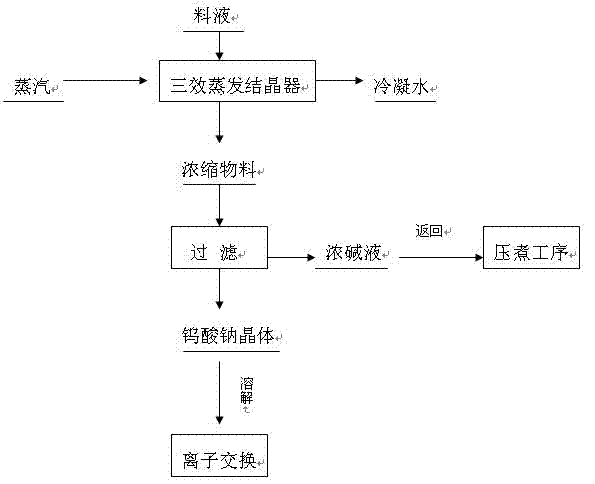

Method of recycling residual alkali from sodium tungstate solution in tungsten smelting

InactiveCN102963911AIncrease alkali concentrationImprove energy efficiencyChemical industryAlkali metal oxides/hydroxidesEvaporationMixed materials

The invention discloses a method of recycling residual alkali from sodium tungstate solution in tungsten smelting, which comprises the steps of: performing liquid-solid separation on mixed material solution discharged from a pressure cooking kettle through a press filter, pumping the filtrate into a three-effect evaporation crystallizer through a pump, firstly preheating the filtrate in a first preheating pipe, then conveying the filtrate into a first-effect evaporation crystallizer, using the secondary vapor generated by first-effect evaporation concentration as a heat source of second-effect evaporation concentration, and conveying sodium tungstate crystals separated out from a second-effect evaporation crystallizer into a plate-and-frame filter press to perform solid-liquid separation; conveying the concentrated solution into a third-effect concentrator, and performing solid-liquid separation on the sodium tungstate crystals separated out from a crystallization kettle of the third-effect evaporation crystallizer; performing solid-liquid separation on the crystals separated out by the second-effect evaporation crystallizer and the third-effect evaporation crystallizer in the plate-and-frame filter press; and conveying the filtrate into a storage tank to return to the pressure cooking procedure to prepare alkali, and discharging the filter residues in a dissolving tank. The method disclosed by the invention is mature in technique and equipment, high in automation degree, high in utilization rate of effective resources, good in energy-saving effect and high in recycled economic benefit, and the method is an important comprehensive recycling component in tungsten smelting.

Owner:ZHONGXIANG TUNGSTEN IND

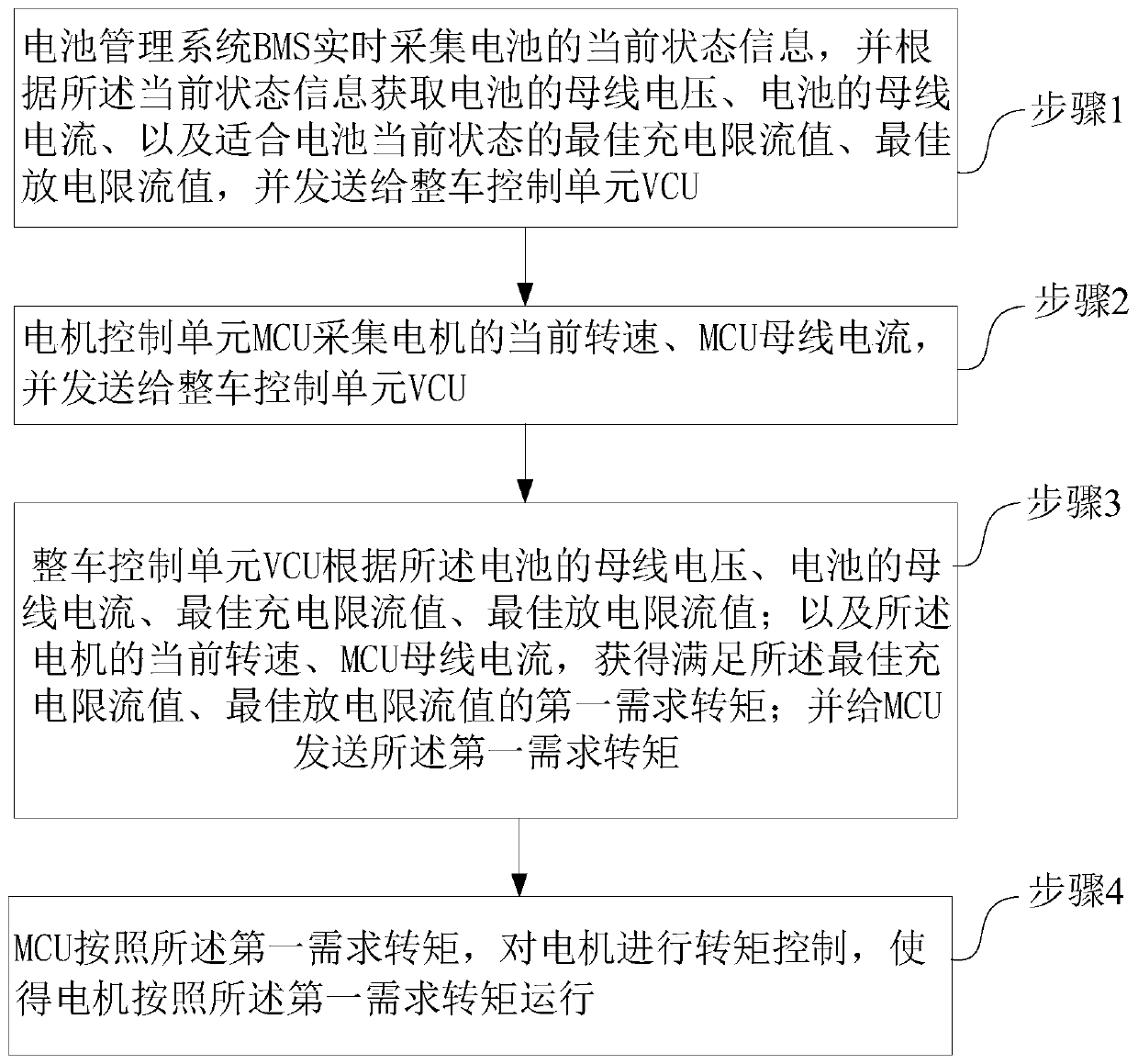

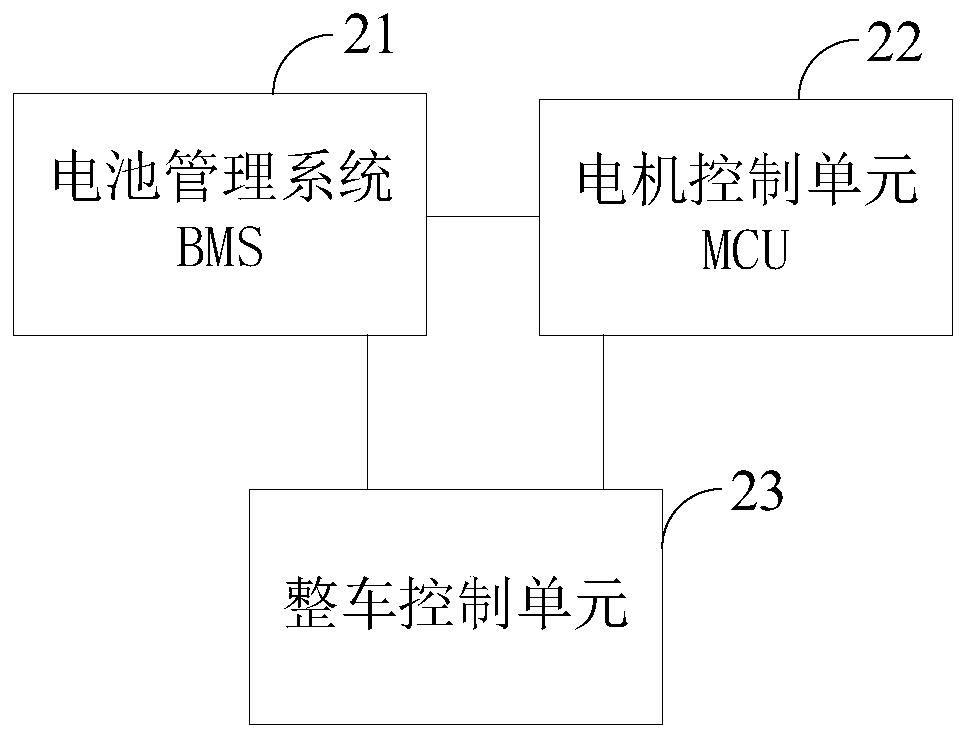

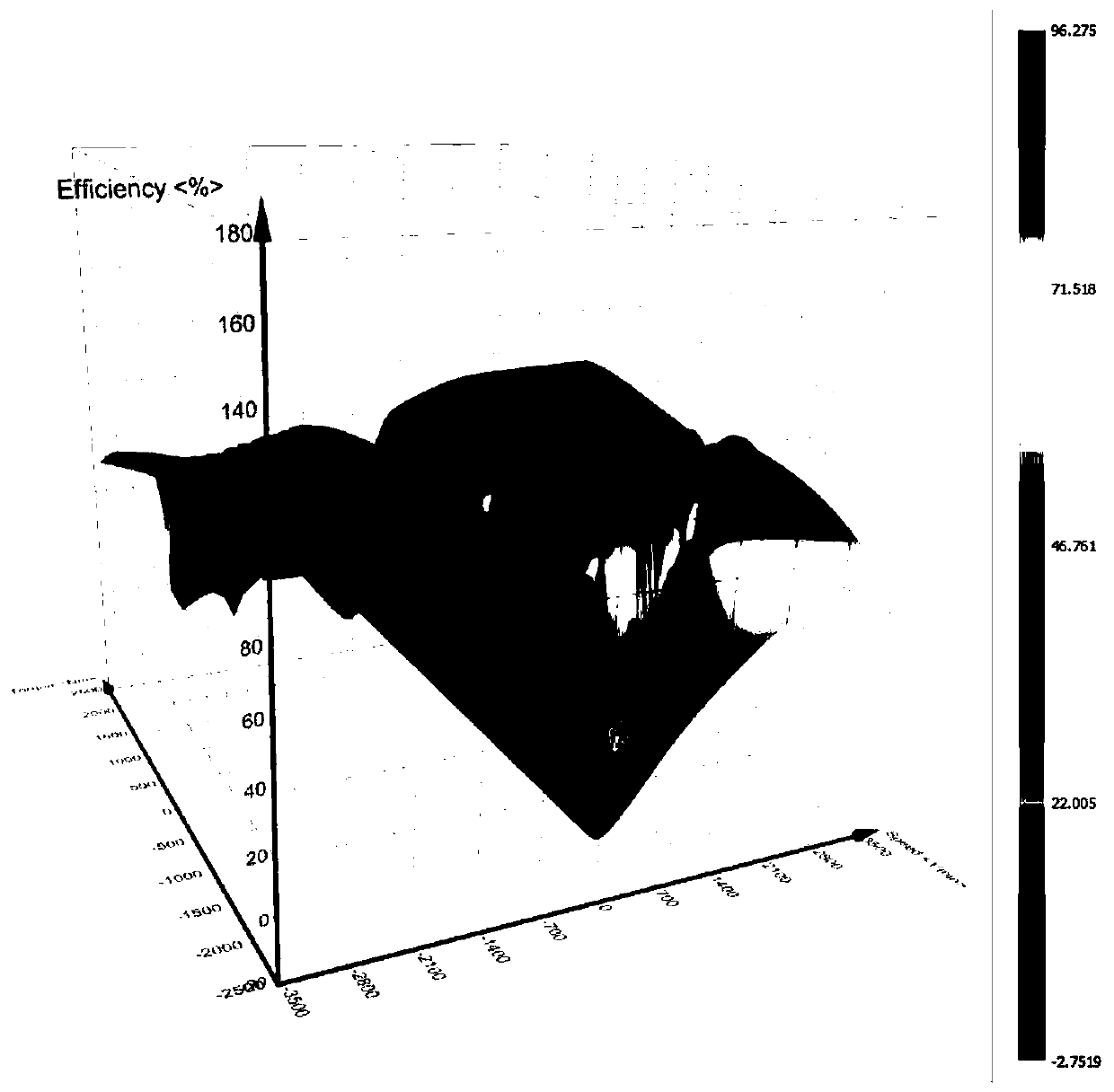

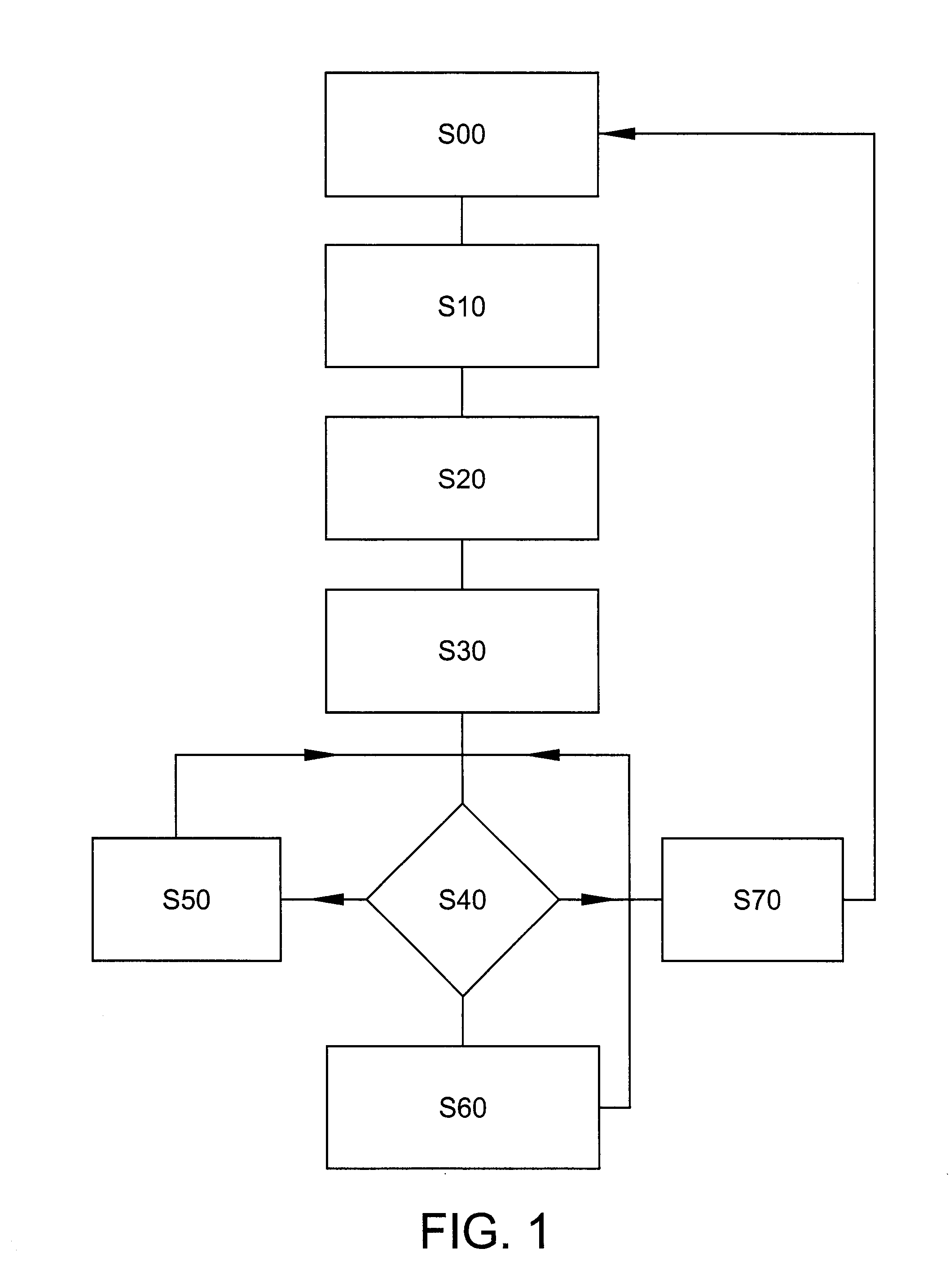

Electric car battery current limiting protection method and system

ActiveCN110281811ADynamic current limiting protectionReduce charge and discharge currentSpeed controllerVehicular energy storageCurrent limitingCharge current

The embodiment of the invention discloses an electric car battery current limiting protection method and system. The method comprises the steps that a battery management system collects current status information of a battery in real time, acquires the busbar voltage of the battery and the busbar current of the battery according to the current status information and the optimal charging current limiting value and the optimal discharging current limiting value suitable for the current status of the battery and transmits the busbar voltage of the battery and the busbar current of the battery, the optimal charging current limiting value and the optimal discharging current limiting value to a finished car control unit; a motor control unit collects the current rotational speed and the current busbar current of a motor and transmits the current rotational speed and the current busbar current of the motor to the finished car control unit; the finished car control unit acquires a first required torque satisfying the optimal charging current limiting value and the optimal discharging current limiting value according to the busbar voltage and the busbar current of the battery, the optimal charging current limiting value, the optimal discharging current limiting value and the current rotational speed and the current busbar current of the motor and transmits the first required torque to an MCU; and the torque of the motor is controlled according to the first required torque and is made to operate according to the first required torque.

Owner:SHANDONG YIXING ELECTRIC AUTO CO LTD

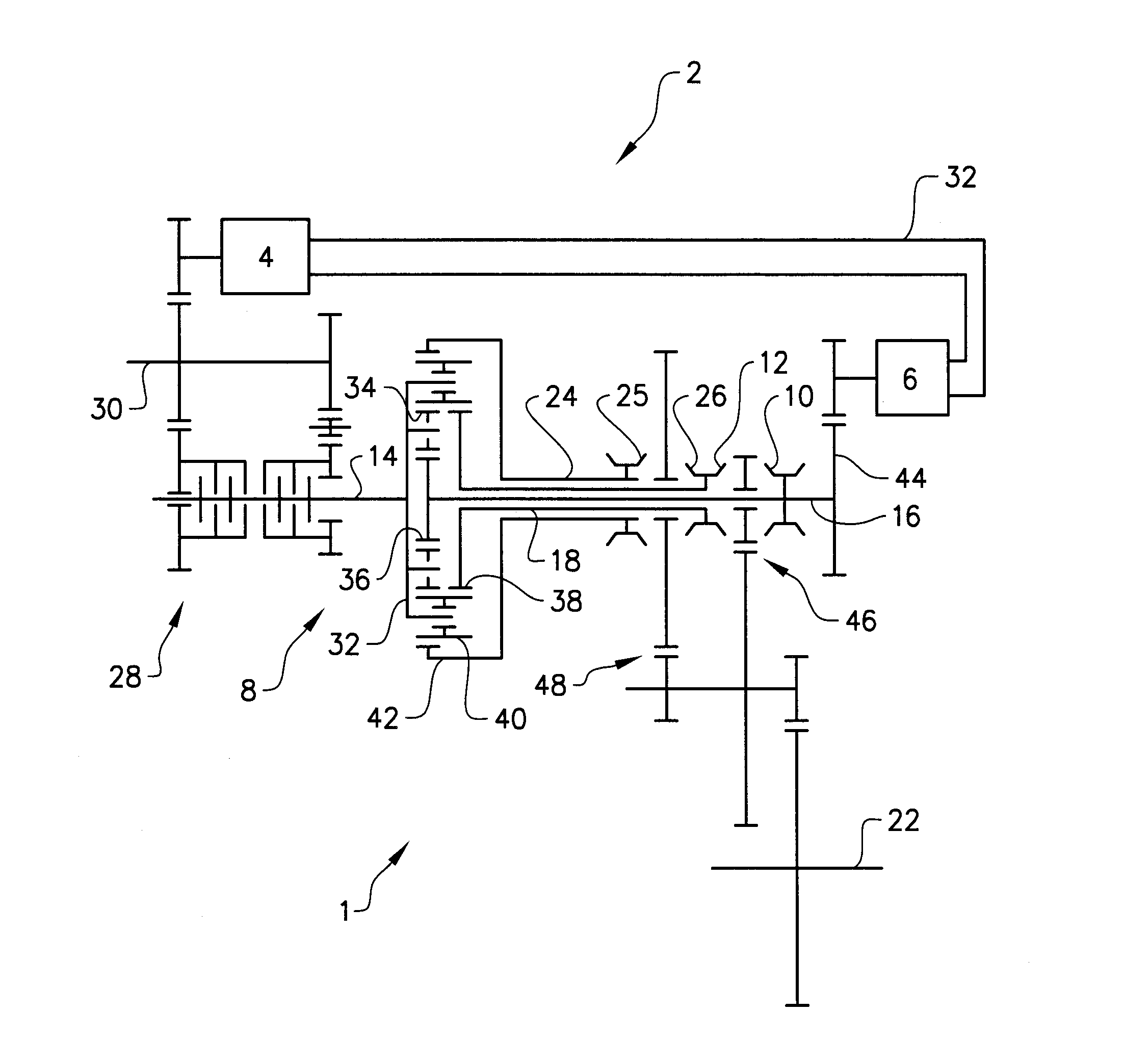

Method for controlling a power split continuously variable transmission and a power split continuously variable transmission

InactiveUS20150018153A1Improve power efficiencyReduce displacementGearing controlTransmission elementsPower splitGear wheel

A power split continuously variable transmission is provided including a variator unit having a first and a second variable displacement hydrostatic machine and a planetary gear unit. The power split continuously variable transmission is arranged to be controlled to perform a simultaneous reduction of displacements of the first and second variable displacement hydrostatic machines during at least a part of a lock up state of the power split continuously variable transmission. A method of operating such a transmission is also provided.

Owner:VOLVO CONSTR EQUIP

Method and apparatus for constructing MAP IE using reduced CID in broadband OFDMA systems

ActiveUS8018969B2Reduce overheadReduce system overheadWith electric batteriesTime-division multiplexBroadbandSubcarrier

A method for transmitting burst allocation information by a base station in a broadband wireless communication system in which a transmitted frame includes symbols, and orthogonal subcarriers in a frequency axis constitute each of the symbols based on a predetermined time unit. The method includes the steps of generating a reduced connection identifier (CID) by reducing a basic CID of a mobile terminal connected to the base station when the basic CID exists within a preset range, and inserting an MAP, which includes an enabled field representing the reduced CID and one of use and non-use of the reduced CID, into the frame, and transmitting the frame to the mobile terminal.

Owner:SAMSUNG ELECTRONICS CO LTD

Current sensor

ActiveUS20140333293A1Reduce measurementReduce detectionTransformersCurrent measurements onlyElectrical conductorPower flow

A current sensor includes: a magneto electric conversion element; and a magnetic field concentrating core applying a magnetic field caused by a measurement object current to the magneto electric conversion element. A planar shape of the magnetic field concentrating core perpendicular to a current flowing direction is a ring shape with a gap. The magneto electric conversion element is arranged in the gap. A part of a conductor for flowing the current is surrounded by the magnetic field concentrating core. The magnetic field concentrating core includes two first magnetic members and at least one second magnetic member, which are stacked alternately in the current flowing direction. Parts of the two first magnetic members adjacent to each other via the one second magnetic member are opposed to each other through a clearance or an insulator.

Owner:DENSO CORP +1

Method and apparatus for dual applicator microwave design

ActiveUS8586898B2Improve microwave absorption performanceExtended stayThermal non-catalytic crackingInduction heatingSyngasMicrowave

The invention described herein pertains generally to a more efficient and cost-effective method and apparatus for: (1) coupling of microwave energy from a microwave generator or plurality of microwave generators into an integral set of applicators; (2) extraction and separation of organic compounds from a mixture of organic and inorganic compounds; and (3) recovery and conversion of the organic compounds to gaseous and liquid fuels. The apparatus described in this invention result in improved microwave absorption within the mixture flowing through the applicators by increasing residence time within the applicators, resulting in a higher temperature within the material. The higher temperature lowers the viscosity of the solution, but also provides a limited reduction of the combination of complex chain and aromatic organic compounds to allow recovery of syngas and fuel oil.

Owner:NOVAK JUDITH

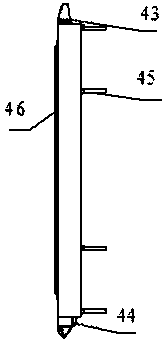

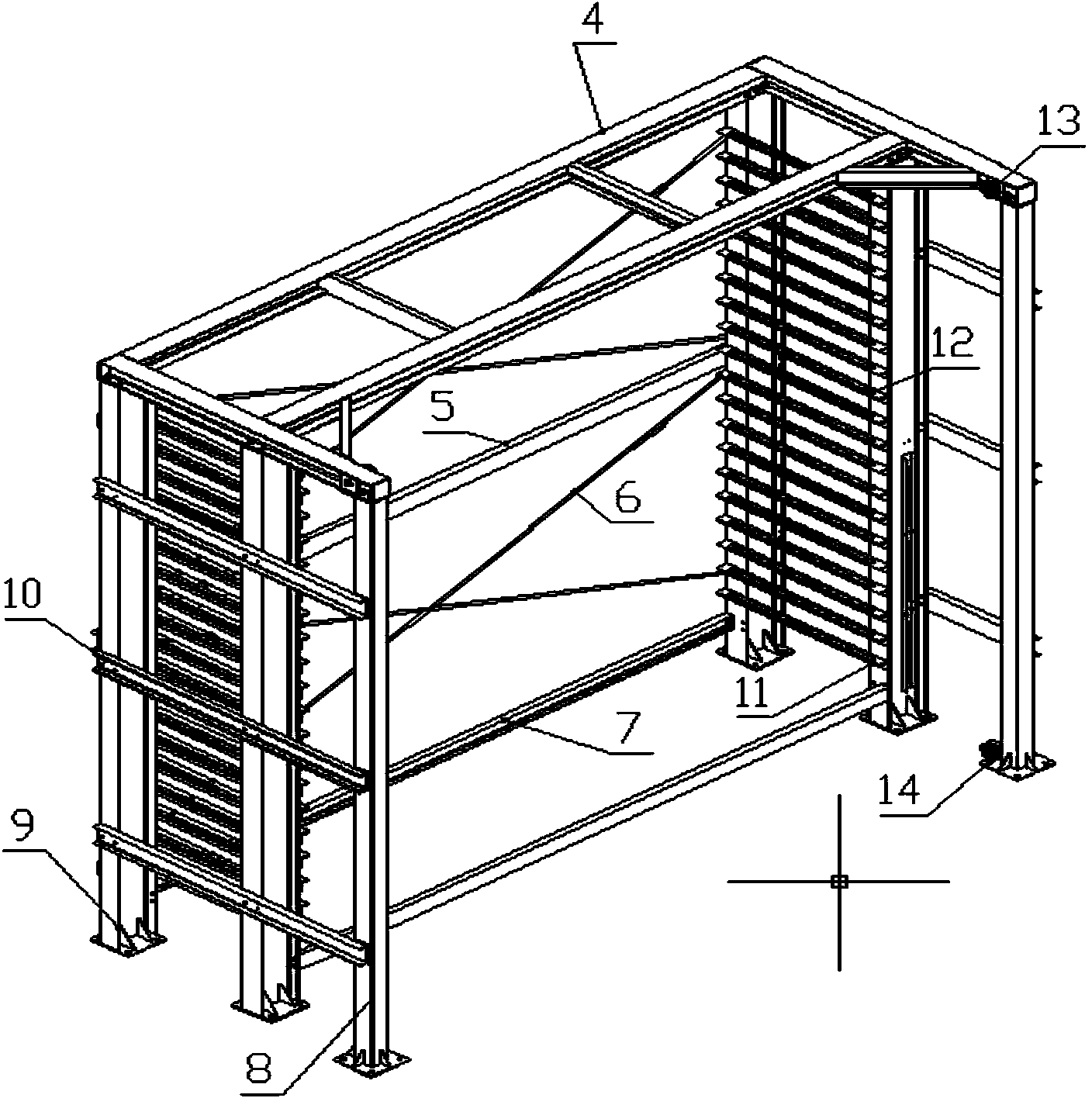

Special-specification vertical goods storing warehouse

ActiveCN104355027AImprove efficiencyCompact structureBuilding constructionsStorage devicesEngineeringUltimate tensile strength

Owner:SHANGDONG TONGLIDA INTELLIGENT MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com