Permanent-magnet type eddy current tuned mass damper

A technology for tuning mass damping and eddy currents, applied to bridge parts, building components, bridges, etc., can solve problems such as difficult adjustment of damping, and achieve the effect of large damping ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

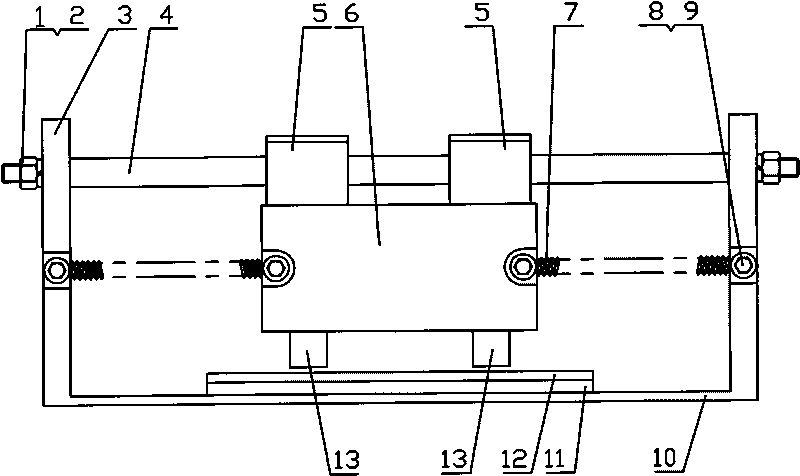

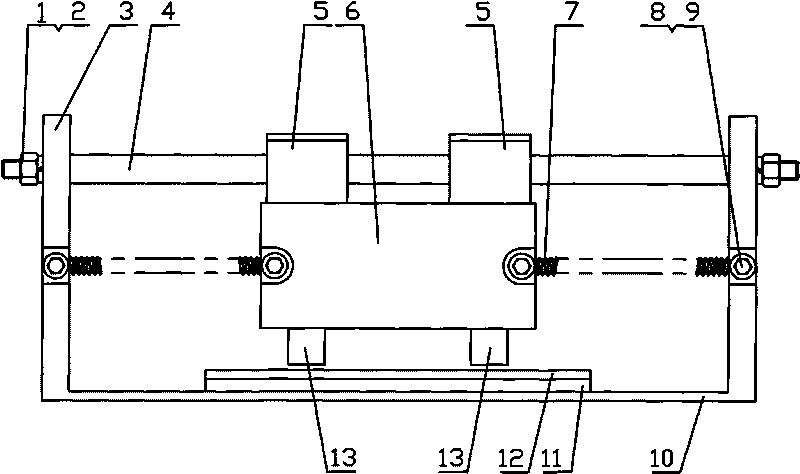

[0026] A permanent magnet eddy current tuned mass damper, such as figure 1 As shown, it includes a magnetically permeable bottom plate 10, and the two ends of the magnetically permeable bottom plate 10 have end plates 3; A linear bearing seat 5 that can slide on the round shaft 4, the lower part of the bearing seat 5 is connected with a mass block 6, and the two sides of the mass block 6 are respectively connected to the corresponding end plate 3 through a coil spring 7; the mass block 6. The lower part is connected with a permanent magnet 13, and a copper plate 12 is arranged under the permanent magnet 13, and the copper plate 12 is connected with the magnetically permeable bottom plate 10 through a spacer 11.

[0027] Described bearing seat (5) is 2-4 (referring to figure 1 ), there are at least two permanent magnets 13.

[0028] The linear bearing seat 5 is a linear ball bearing, and the spring 7 is a helical tension spring.

[0029] When the main structure connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com