Zipper feeding device of flat machine

A technology of zipper device and flat car, which is applied in the direction of textiles and papermaking, cloth feeding mechanism, sewing equipment, etc. It can solve the problems of poor sewing straight line accuracy, defective products, and easy deviation, so as to achieve high straight line accuracy and avoid defective products. the effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

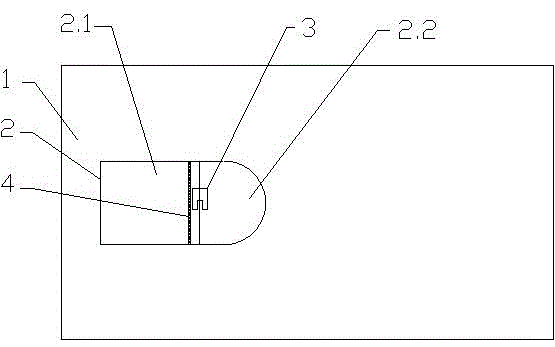

[0014] see figure 1 , a zipper device on a flat car that the present invention relates to, which includes a machine plate 1 of a flat car, on which a needle plate 2 is embedded, and the needle plate 2 includes a fixed needle plate 2.1 arranged left and right and a driving needle plate 2.2. A presser foot 3 is arranged above the needle plate 2, and the needle plate 2 on the left side of the center line of the presser foot 3 is provided with a longitudinally arranged material guide groove 4, and the material guide groove 4 is arranged on the needle plate 2 for a long length. The depth of the material guide groove 4 is 3~4mm, and the position of the material guide groove 4 can be on the fixed needle plate 2.1 or on the driving needle plate 2.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com