High-precision front axle concentricity testing equipment

A detection equipment and a technology for front wheel axles, which are applied in the field of high-precision front wheel axle concentricity detection equipment, can solve the problems of difficulty in determining the reference axis and low detection accuracy of the front wheel axle, and improve market competitiveness, accuracy, and alignment. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

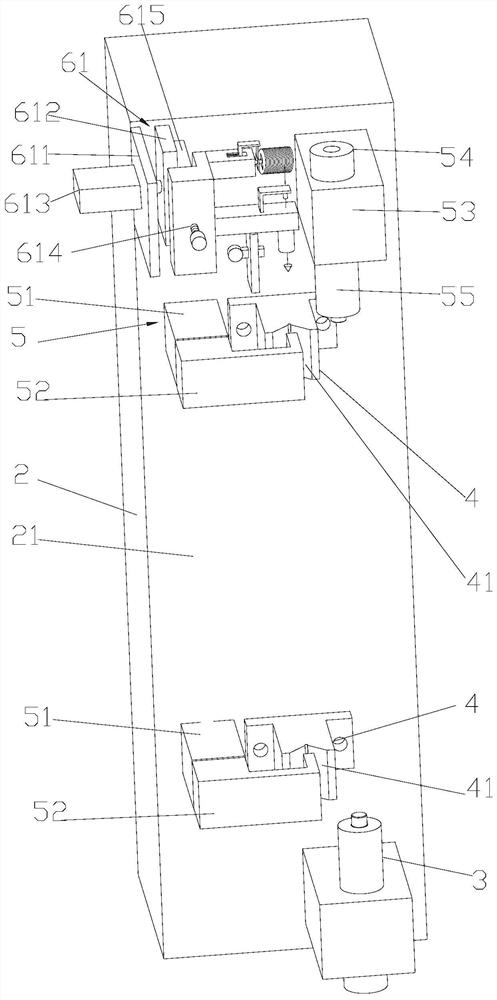

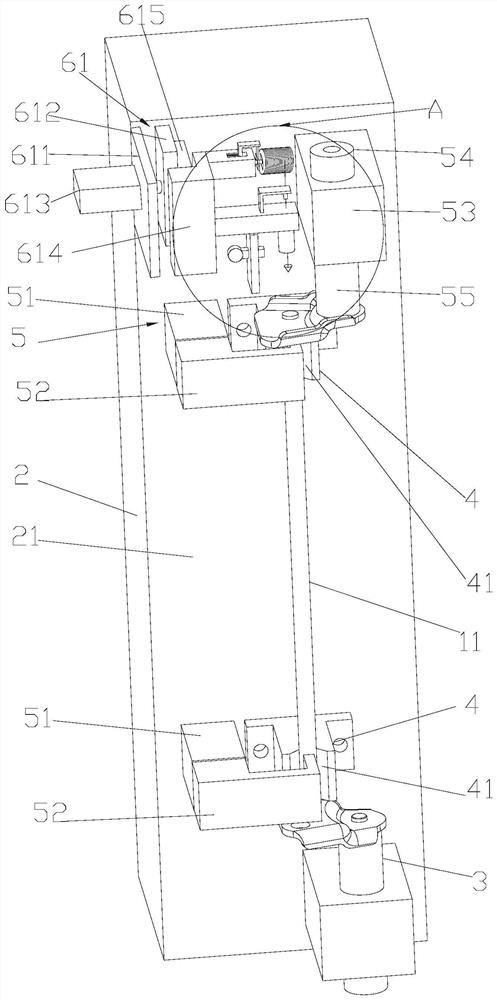

[0053] like figure 2 , image 3 as well as Figure 4 As shown, this embodiment proposes a high-precision front wheel axle concentricity detection device, including:

[0054] Detection platform 2, the height of the detection platform 2 is greater than the height of the front wheel axle, and a plane of the detection platform 2 that is parallel to both the vertical direction and the horizontal direction is the detection plane 21;

[0055] The vertical support seat 3 is arranged on the detection plane 21 and is disposed close to the bottom edge of the detection plane 21, and the vertical support seat 3 is used to support the first mounting plate or the second mounting plate of the rear wheel axle;

[0056] The horizontal support base 4 is arranged on the detection plane 21 and is located between the vertical support base 3 and the vertical pressing arm, and its surface is concave to form a V-shaped groove 41, and the V-shaped groove 41 is used to place the shaft body of the rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com