Industrial welding robot

A welding robot and industrial technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of extensive trial use, many welding parts, and high welding freedom.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions, and beneficial effects of the present invention clearer, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of the skilled person.

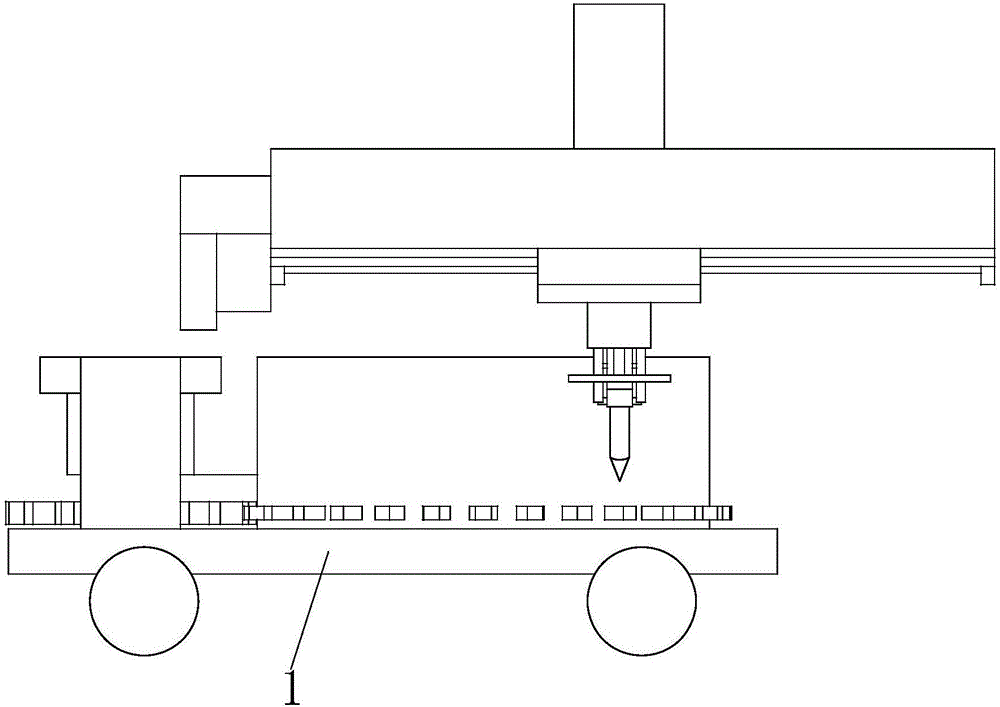

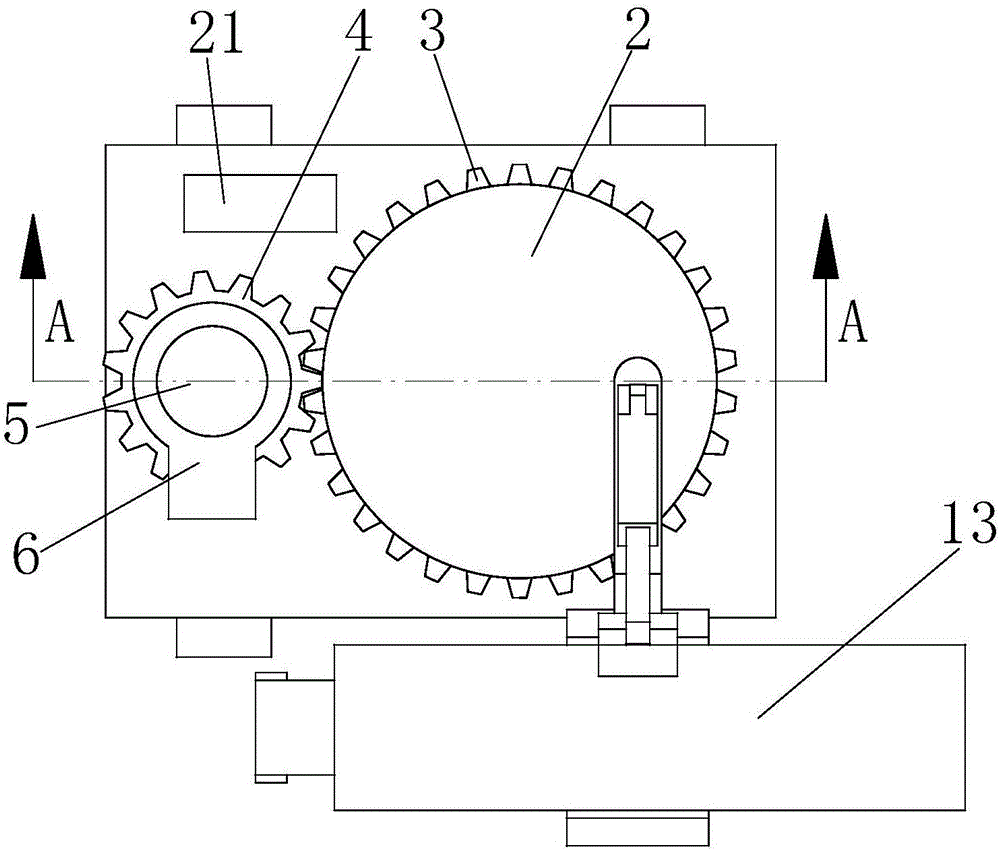

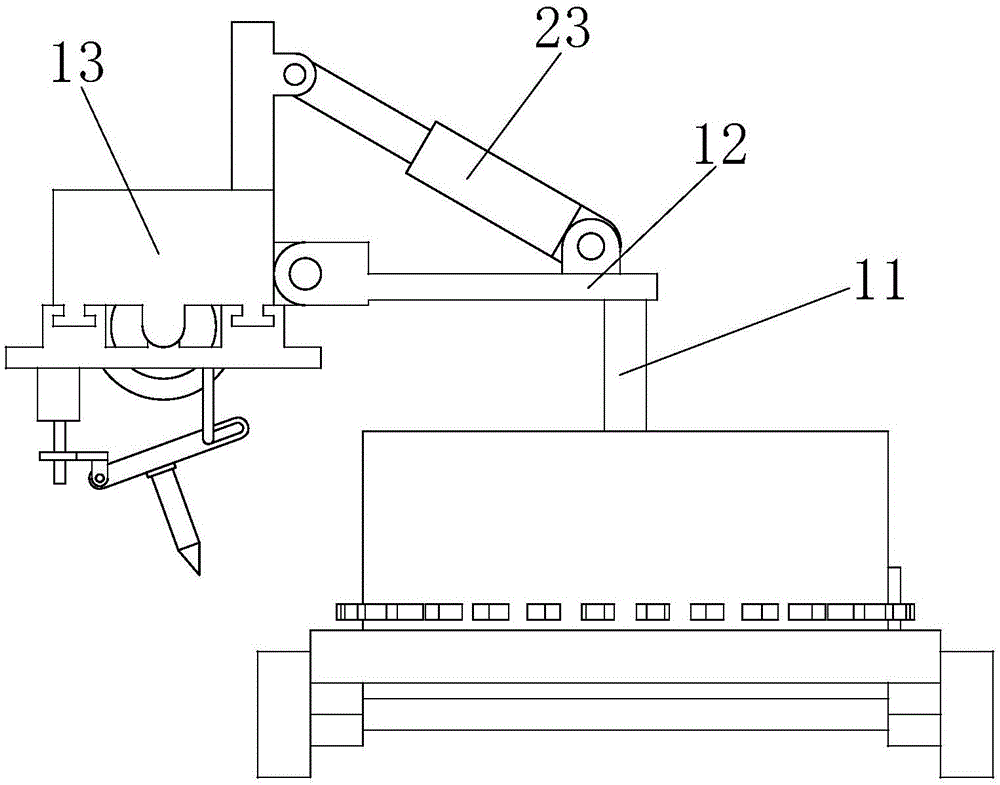

[0025] Such as Figure 1 to Figure 6 As shown, an industrial welding robot includes a vehicle model base 1 on which a main disc 2 is mounted through bearings, and straight teeth 3 are uniformly distributed on the arc surface of the main disc 2 A gear 4 is meshed, and the gear 4 is connected to a motor 5.

[0026] A second motor 7 is installed inside the main disk 2, and the second motor 7 is connected to a first bevel gear 8, the first bevel gear 8 vertically meshes with a second bevel gear 9, and the second bevel gear 9 A round roller 10 is coaxially connected, and the arc surface of the round roller 10 is evenly distributed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com