Mechanical and automatic spraying device

An automatic spraying and mechanical technology, applied in spraying devices, spray booths, etc., can solve the problems of not being able to change the position, inconvenient to use, etc., and achieve the effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solutions of the present invention easier to understand and grasp.

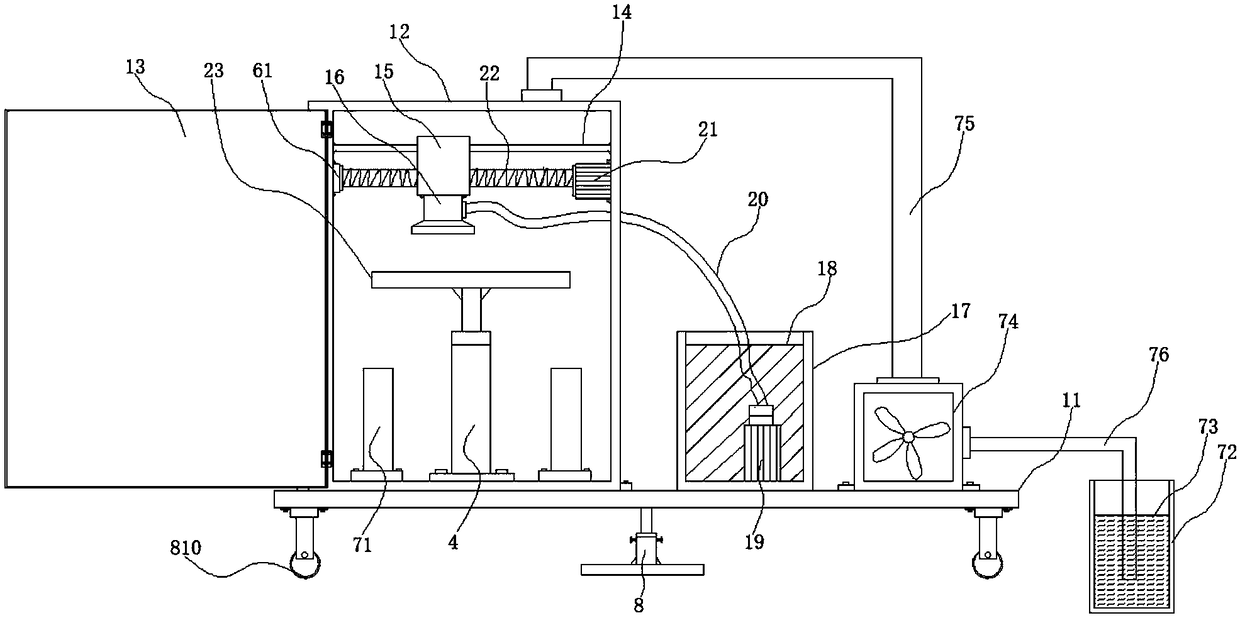

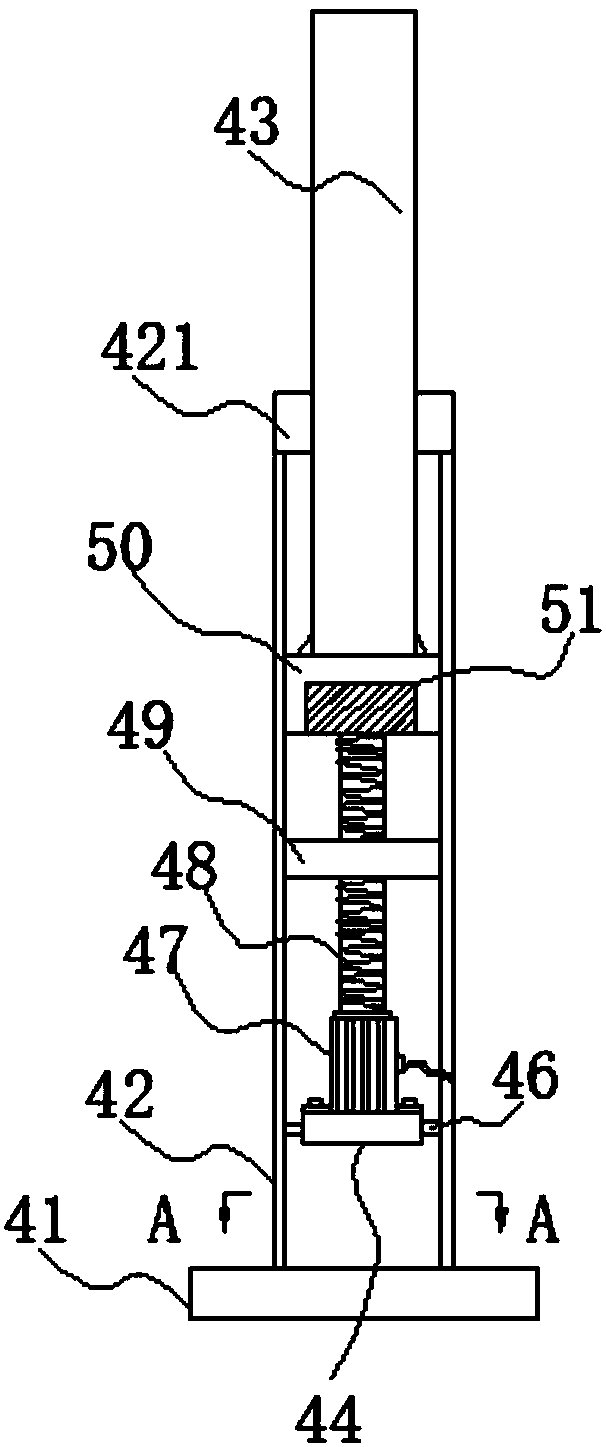

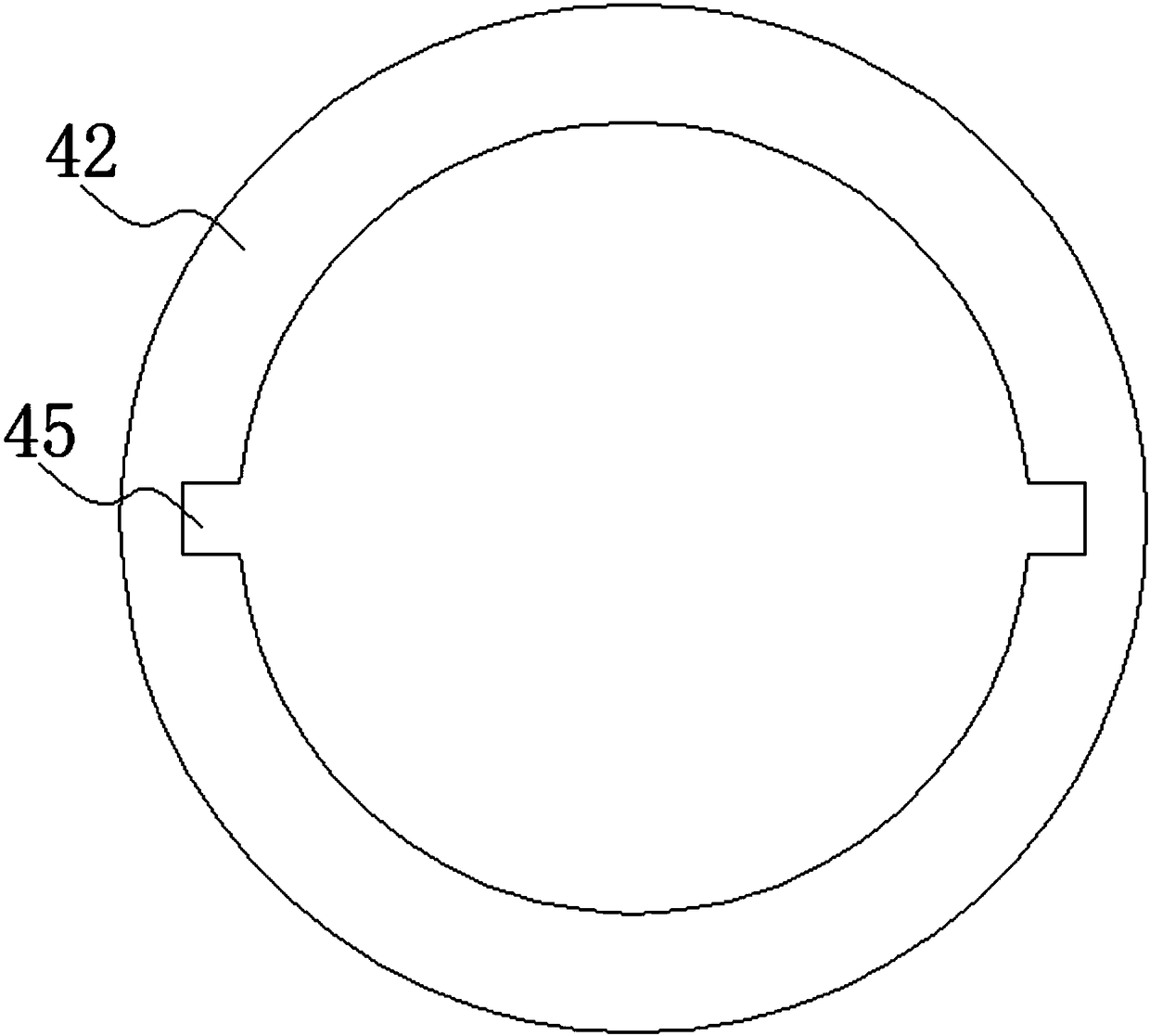

[0020] Such as figure 1 , 2 , shown in 3 and 4, a kind of mechanical automatic spraying device comprises base plate 11, is fixed on base plate 11 top by screws and the front is the spraying box 12 of opening, and the front outer wall of spraying box 12 is connected with door body 13 by hinge.

[0021] The inner wall of the spraying box 12 is welded with a horizontal bar 14, a sliding seat 15 is provided on the horizontal bar 14, the bottom of the sliding seat 15 is installed with a spray head 16 by screws, and a receiving groove 17 is placed at the bottom of the base plate 11. The receiving groove 17 The inside is filled with paint 18 , and a booster pump 19 is placed at the bottom of the holding tank 17 , and the outlet of the booster ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com