Patents

Literature

93results about How to "Accurate movement distance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

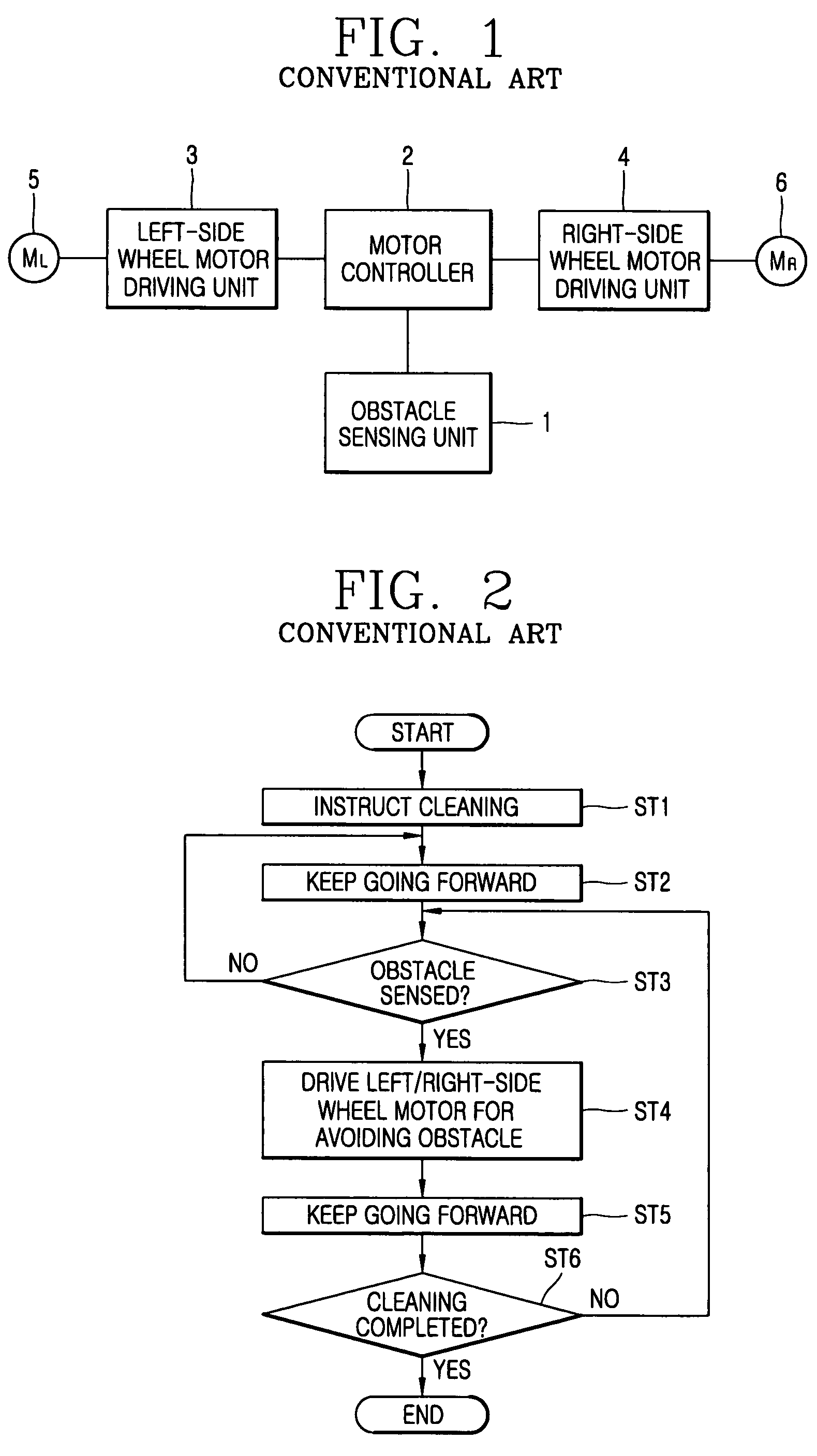

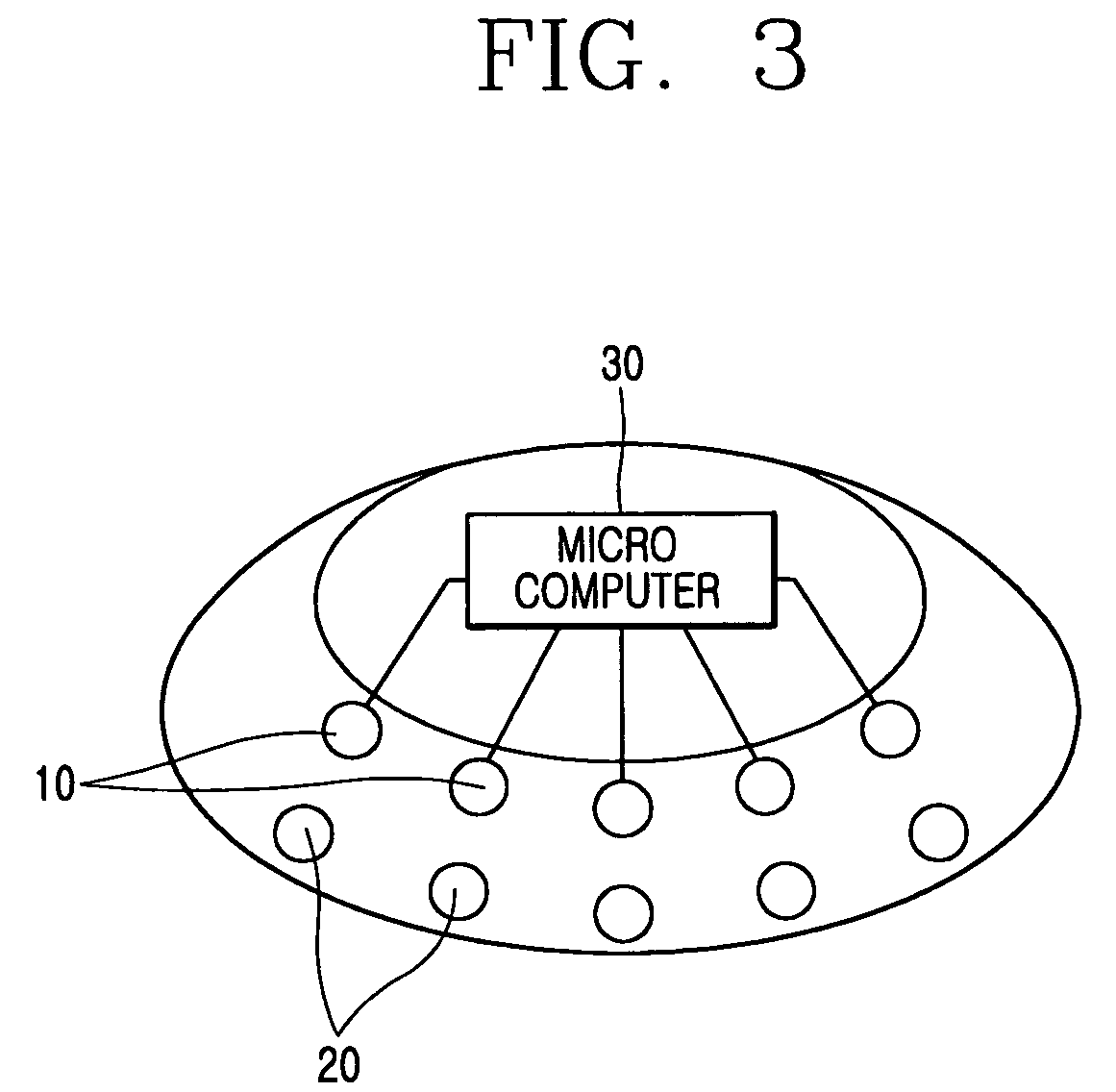

Mobile robot using image sensor and method for measuring moving distance thereof

ActiveUS7171285B2Accurate movement distanceAccurate calculationVehicle testingAutomatic obstacle detectionMicrocomputerComputer science

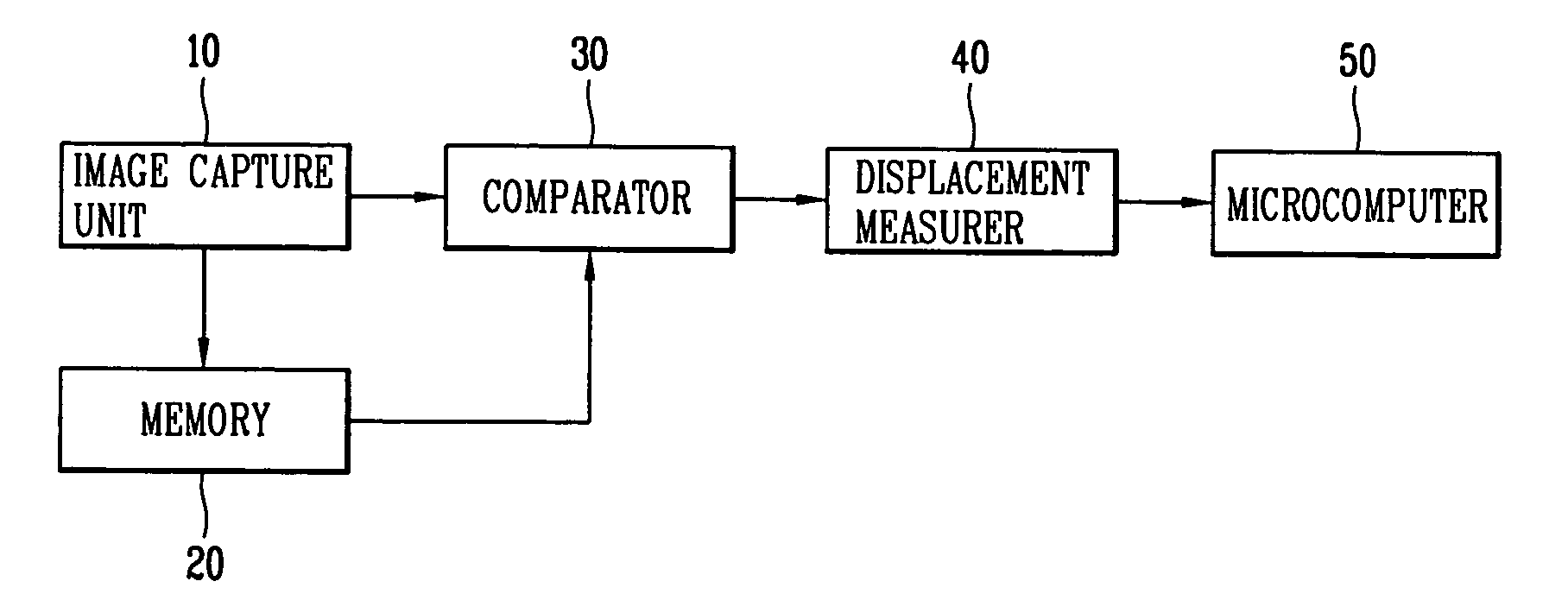

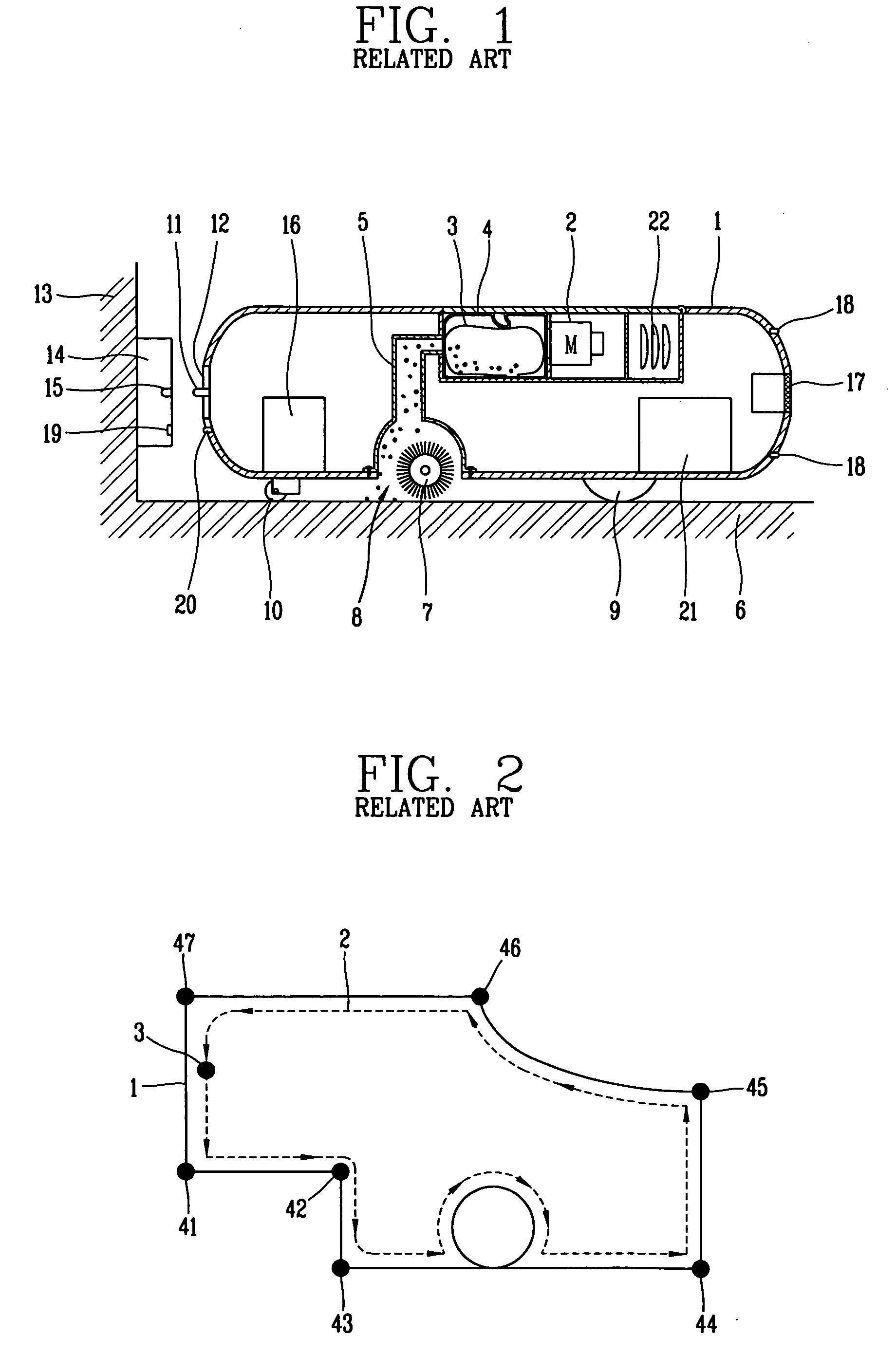

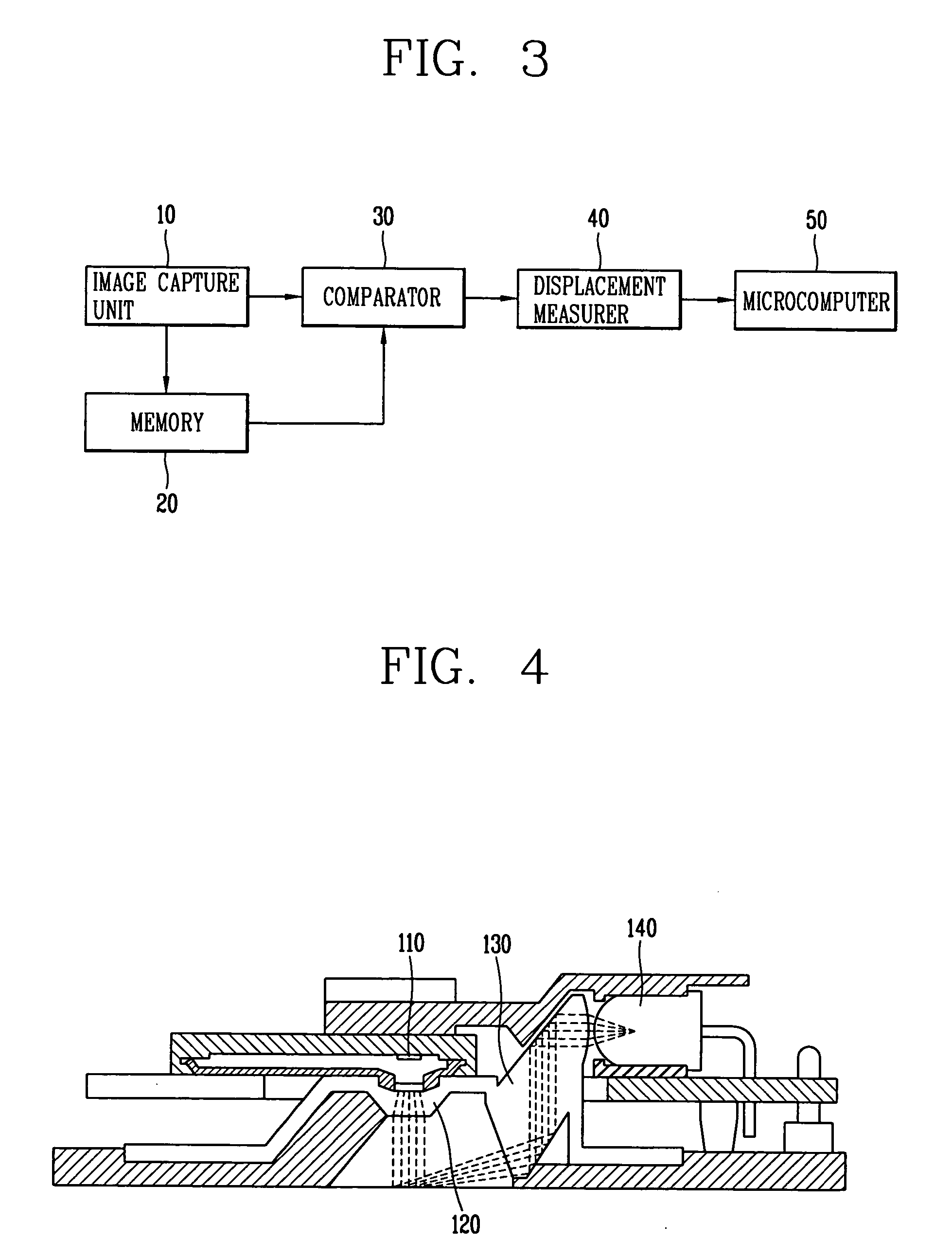

In a mobile robot and a method for measuring a moving distance thereof, by including an image capture unit for photographing the bottom surface according to motion of a mobile robot at a certain intervals and capturing images; a displacement measurer for measuring displacement about the captured image; and a microcomputer for outputting an actual moving distance by direction and motion of the mobile robot on the basis of the measured displacement value, it is possible to measure an accurate moving distance of the mobile robot with only one image sensor installed at the center of a body of the mobile robot, and accordingly it is possible to simplify a mechanical structure and facilitate maintenance and repairing.

Owner:LG ELECTRONICS INC

Moving distance sensing apparatus for robot cleaner and method therefor

InactiveUS7706921B2Accurate movement distanceProgramme controlMeasurement devicesShortest distanceEngineering

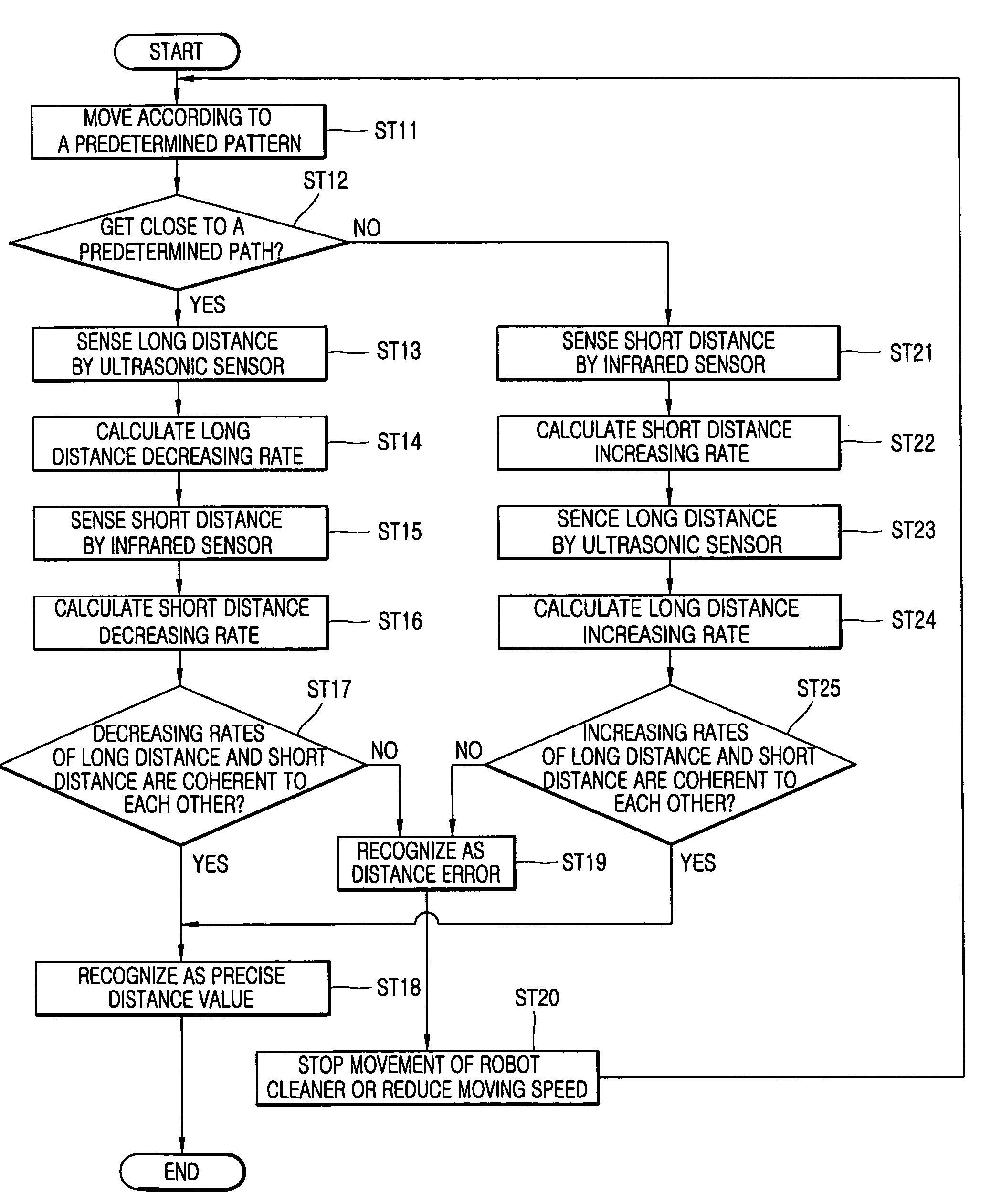

Disclosed are a moving distance sensing apparatus for a robot cleaner and a method therefor capable of determining a precise moving distance with respect to the robot cleaner by setting a long distance sensor and a short distance sensor having respectively different sensing method from each other on the same sensing line in the robot cleaner to sense the long distance and the short distance for the same direction, and then by determining coherency to each moving distance on the basis of information provided by the two different sensors, the moving distance sensing apparatus comprising: a long distance sensor for sensing a moving distance with respect to a long distance; a short distance sensor mounted on the same sensing line in one-to-one correspondence with the long distance sensor, for sensing a moving distance with respect to a short distance; and a micro computer for determining a moving distance error on the basis of moving distance information with respect to the same direction provided by the long distance sensor and the short distance sensor.

Owner:LG ELECTRONICS INC

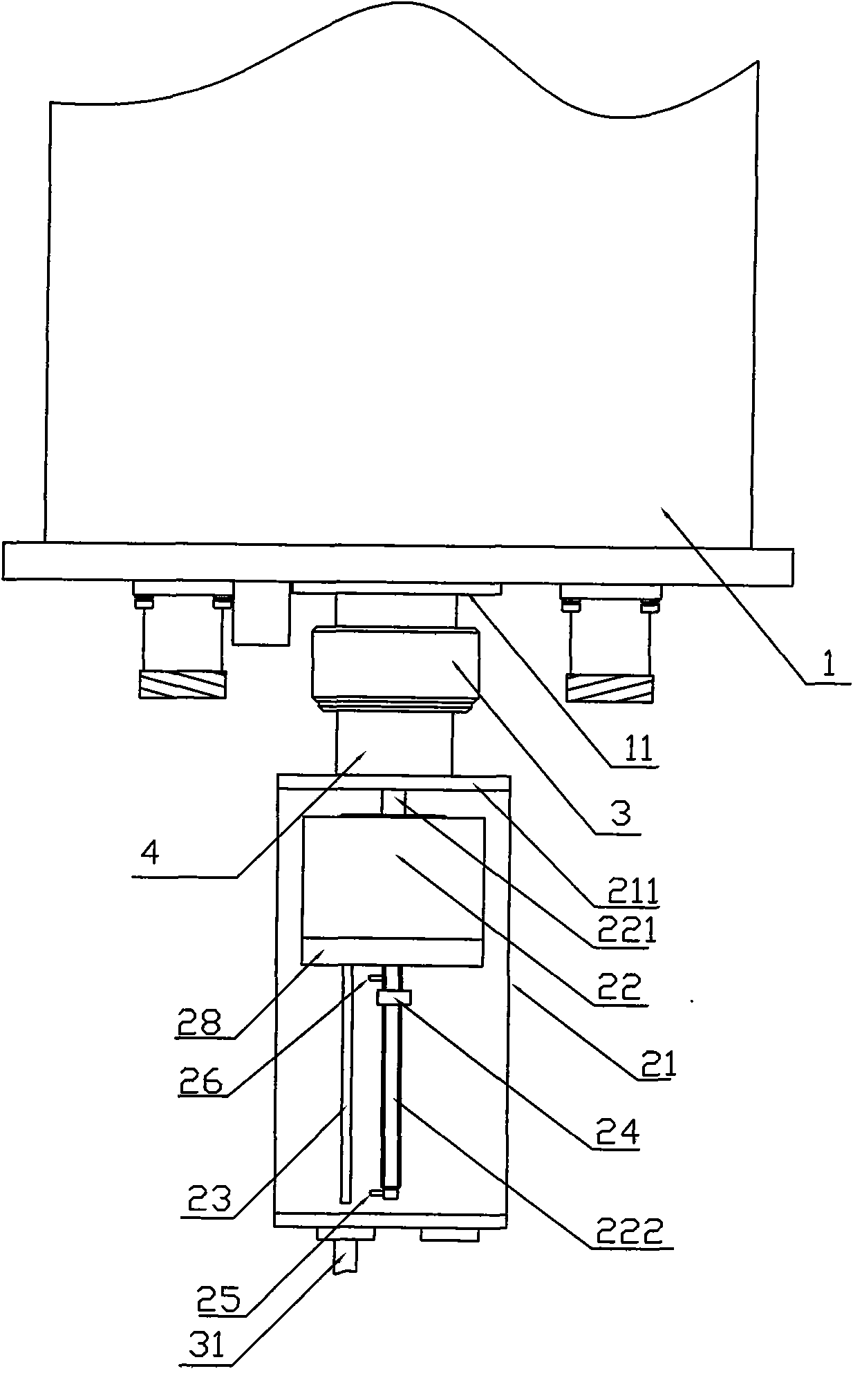

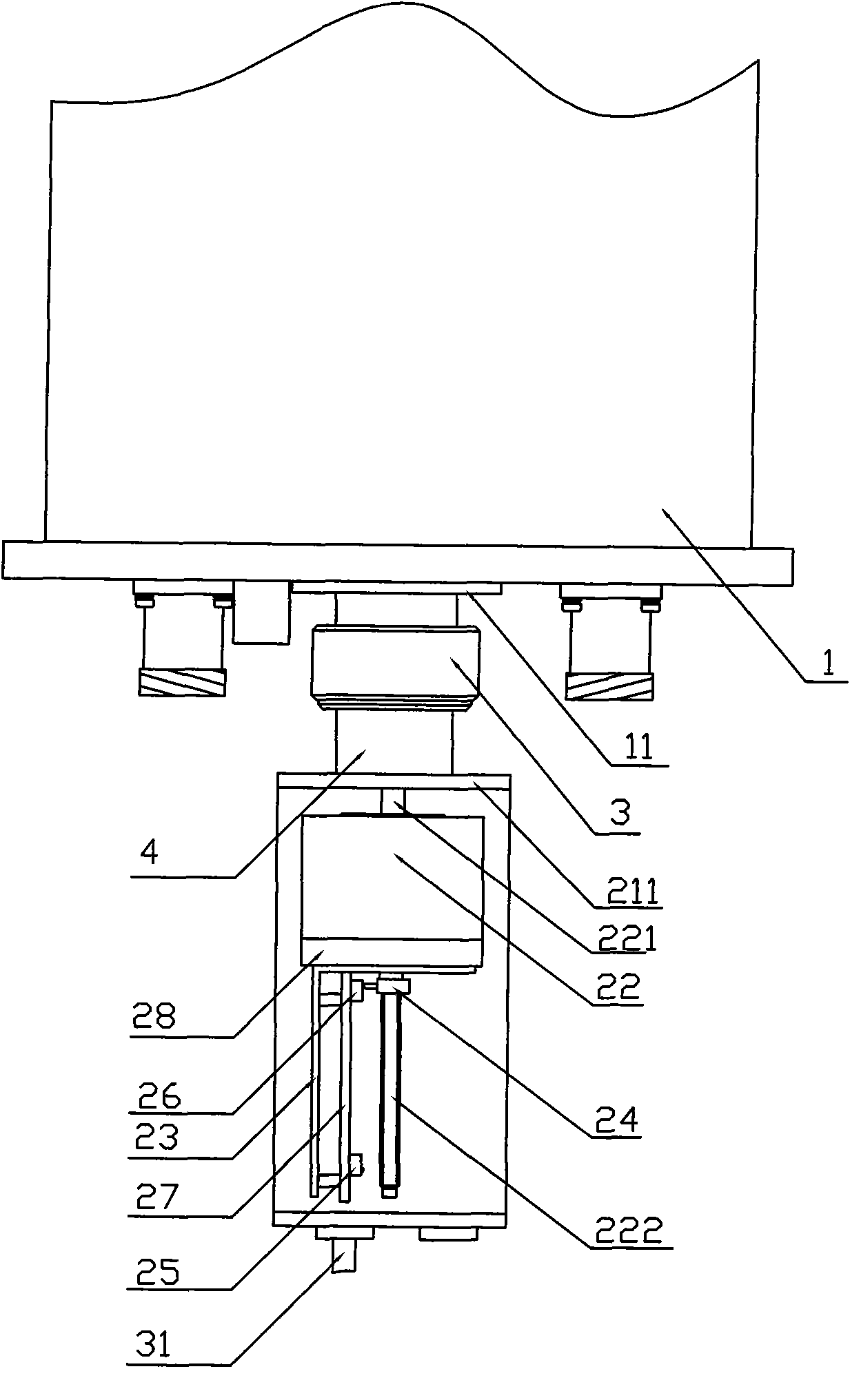

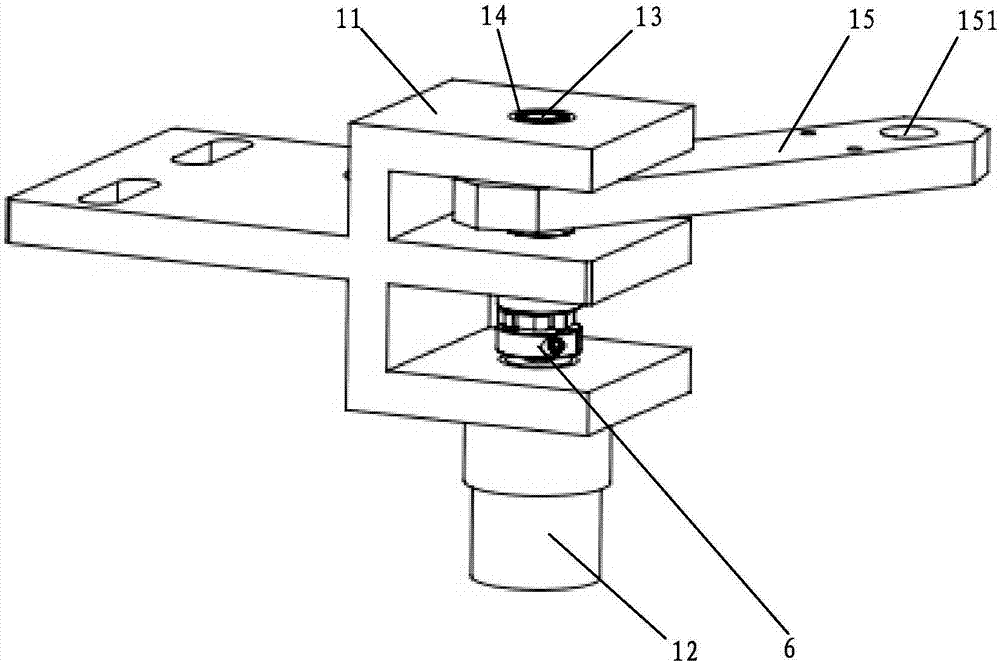

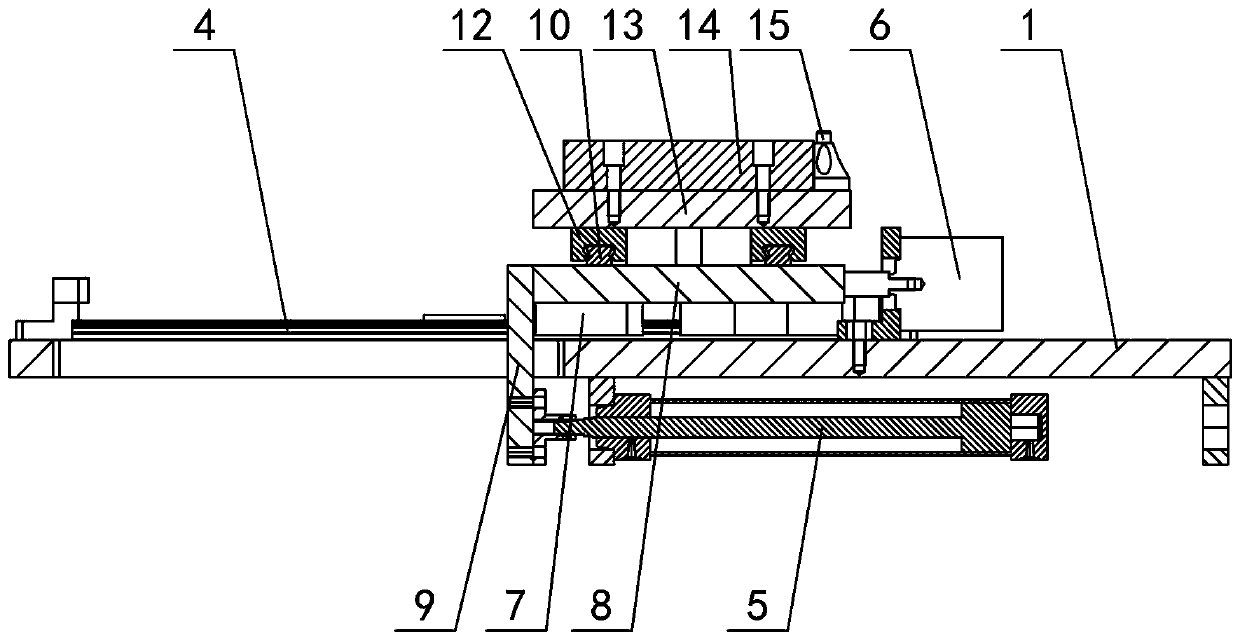

Control device of electrically adjusted antenna

The invention relates to a control device of an electrically adjusted antenna, comprising a motor and a declinational angle control module of the electrically adjusted antenna, wherein the motor is provided with a rotating shaft; the front end of the rotating shaft of the motor is connected with a phaser rotating shaft of the electrically adjusted antenna; and the declinational angle control module of the electrically adjusted antenna is connected with the motor. The control device of the electrically adjusted antenna is characterized in that the rear end of the rotating shaft of the motor is provided with an extending section extending outwards and provided with a screw thread thereon, and a slide block is sleeved on the extending section at the rear end of the rotating shaft of the motor in a sliding way; the control device of the electrically adjusted antenna also comprises two limit switches which can be triggered by the slide block, the distance between the two limit switches is consistent with the mechanical adjustment range of the electrically adjusted antenna, and the output ends of the two limit switches are connected with the declinational angle control module of the electrically adjusted antenna. Compared with the prior art, the invention has the advantages of accurately obtaining the moving distance of a phaser and having simple structure and convenient use.

Owner:NINGBO TIANYUN ANTENNA TECHNOLOGICAL

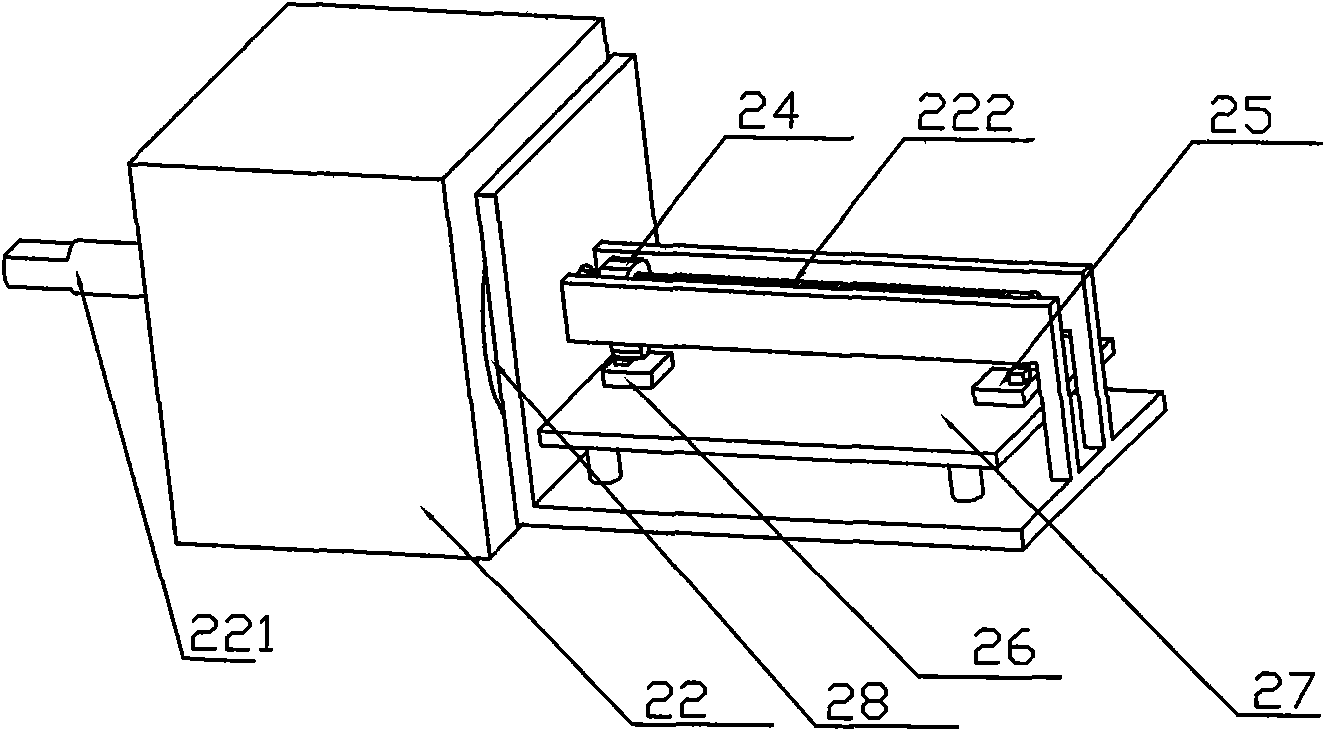

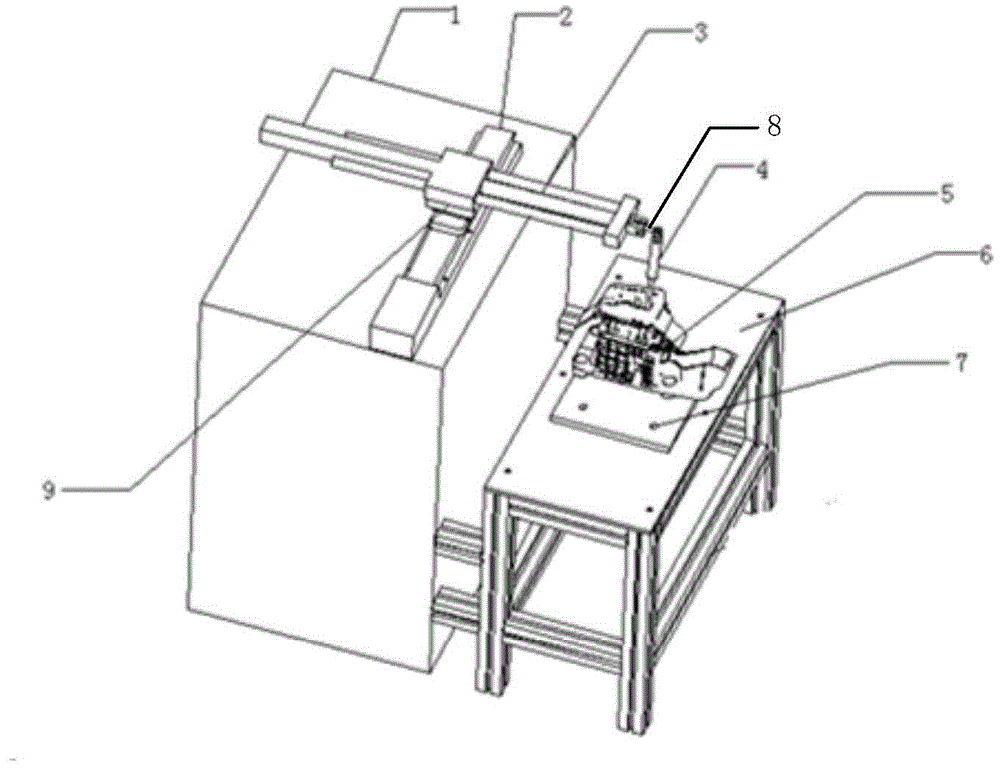

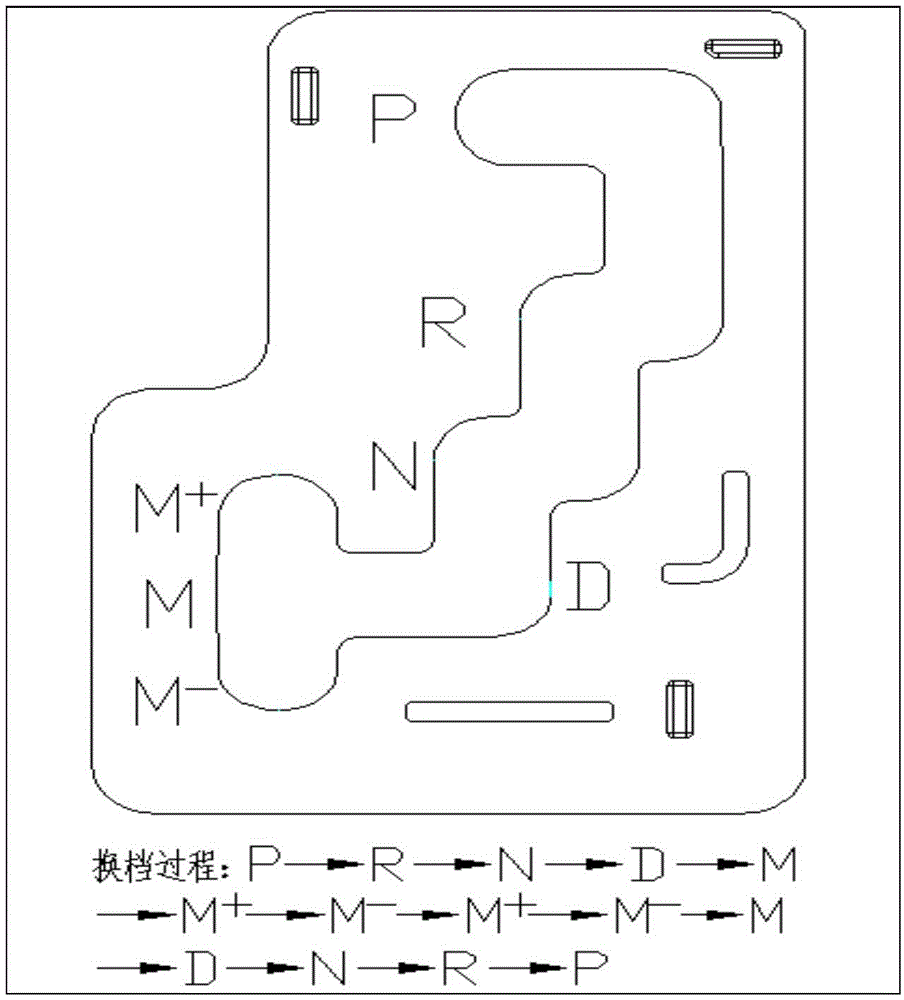

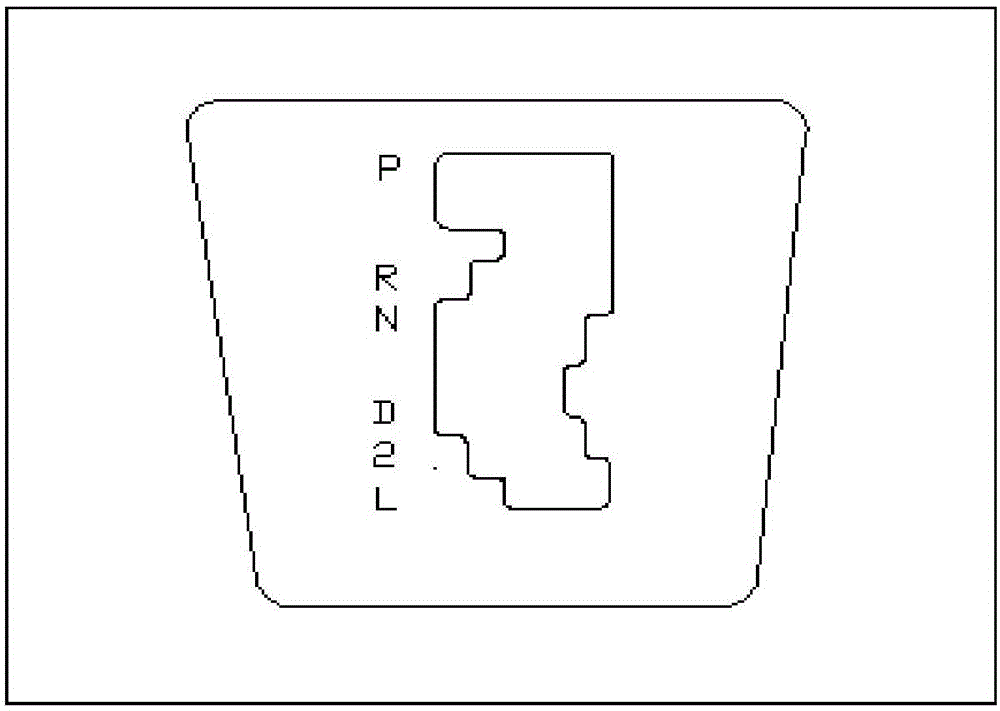

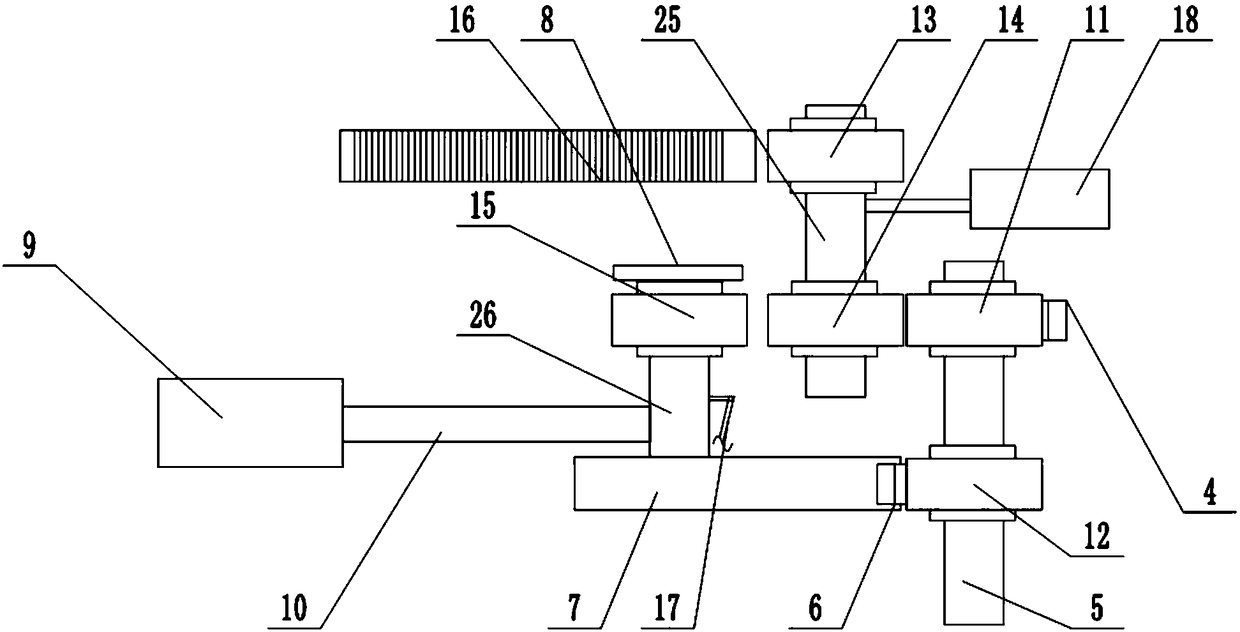

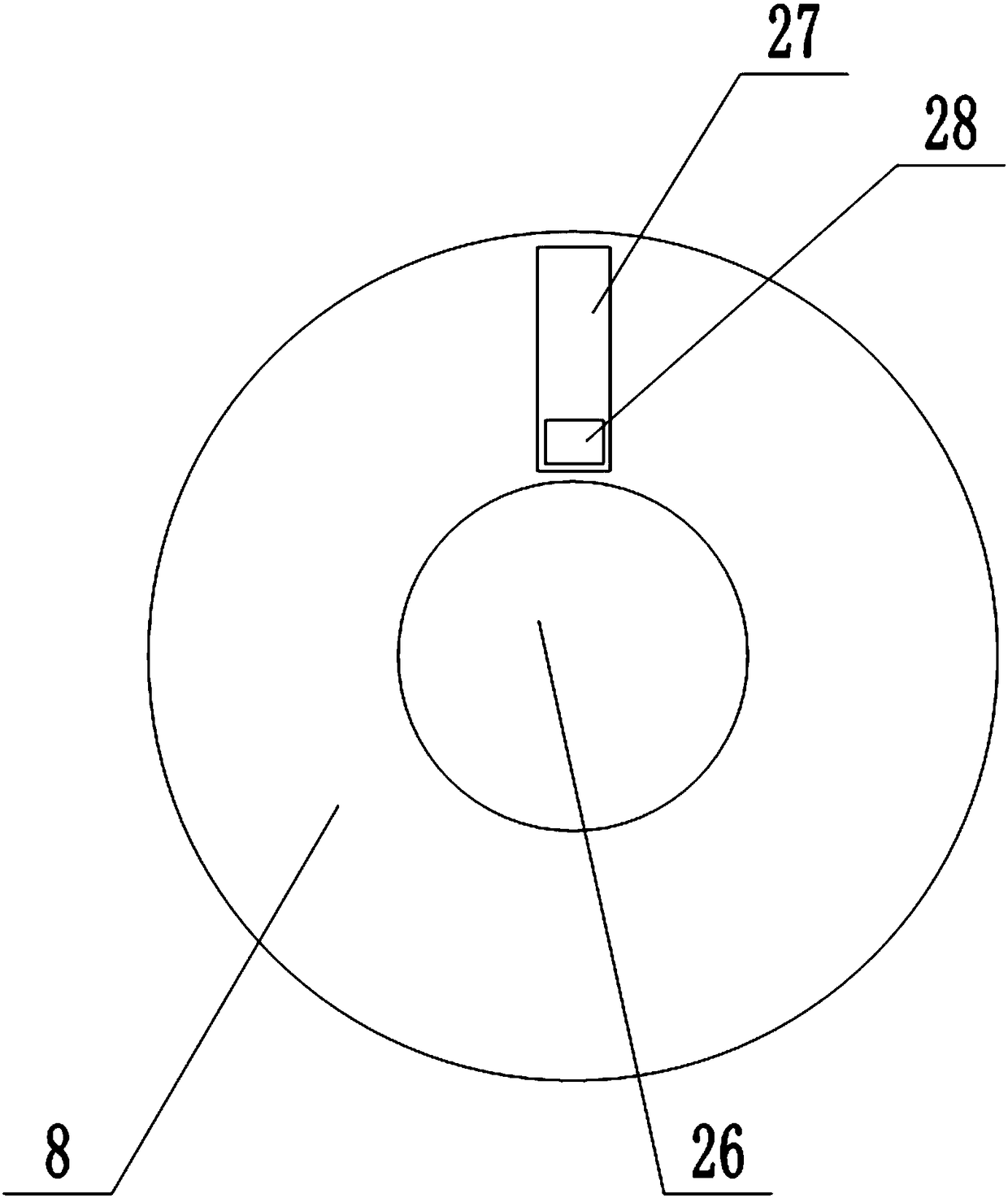

Durability test device and system for gear shift mechanism

InactiveCN104596762AReduce movement distanceAccurate movement distanceMachine gearing/transmission testingTelescopic cylinderProgrammable logic controller

The invention discloses a durability test device and a durability test system for a gear shift mechanism, and belongs to the technical field of gear shifting. The durability test device includes a first electric cylinder, a second electric cylinder, a PLC (programmable logic controller) and a first support, wherein a controller of the first electric cylinder is electrically connected with the PLC, and a controller of the second electric cylinder is electrically connected with the PLC; the fixed end of the first electric cylinder is fixed on the first support, and the movable end of the first electric cylinder is connected with the fixed end of the second electric cylinder, for controlling the second electric cylinder to move in the extending direction of the first electric cylinder; the movable end of the second electric cylinder is used for being connected with the control lever of the gear shift mechanism; the first electric cylinder is mutually perpendicular to the extending direction of the second electric cylinder. By using the durability test device and system, the gear shift mechanism with the complex gear shifting track can be tested.

Owner:CHERY AUTOMOBILE CO LTD

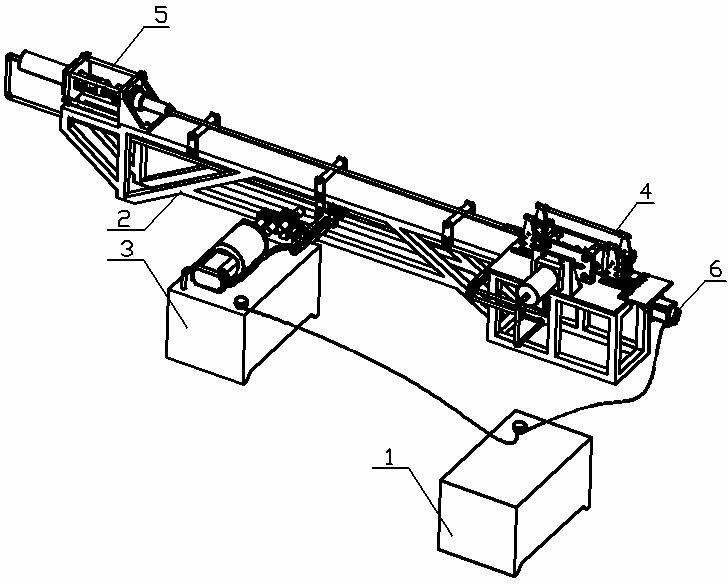

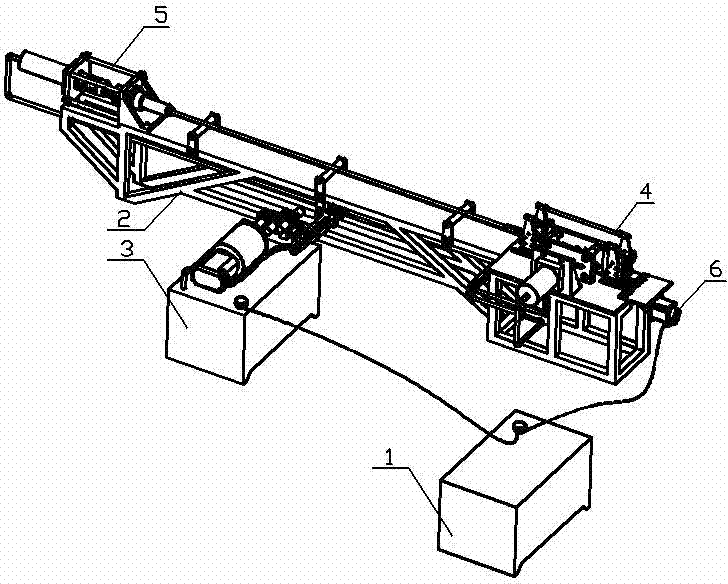

Full-automatic punching flanging device

The utility model provides a full-automatic punching flanging device, relating to a compound device which carries out punching and flanging on a workpiece. The full-automatic punching flanging device is composed of a control console, a frame body, an oil tank, a front cylinder assembly, a rear cylinder assembly and a motor. The full-automatic punching flanging device is characterized in that the front cylinder assembly and the rear cylinder assembly are respectively arranged at the two ends of the frame body, the oil tank is arranged outside the frame body and respectively provides power for the front cylinder assembly and the rear cylinder assembly, the motor is arranged outside the frame body of the front cylinder assembly, and the control console is respectively connected with the oil tank and the motor. The utility model has the beneficial effects that: a flanging punch is designed into the mode that the cross section is in a stepped appearance or trapezoid shape, punching and flanging can be completed in one step, displacement is accurate, pitch accuracy is high, punching and flanging can be continuously carried out on a pipe, the operation is simple, the working efficiency is high, and the production cost is low.

Owner:JIANGXI AVONFLOW HVAC TECH CO LTD

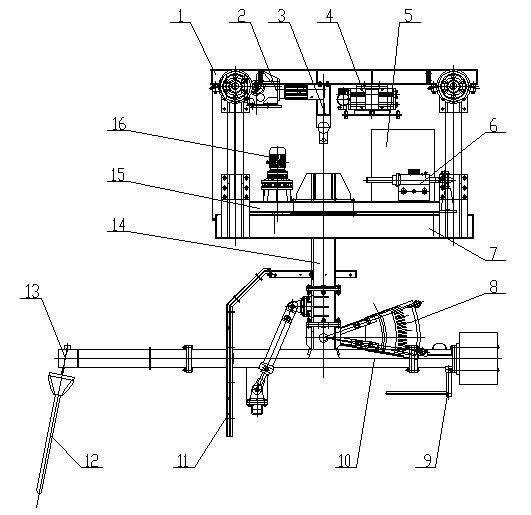

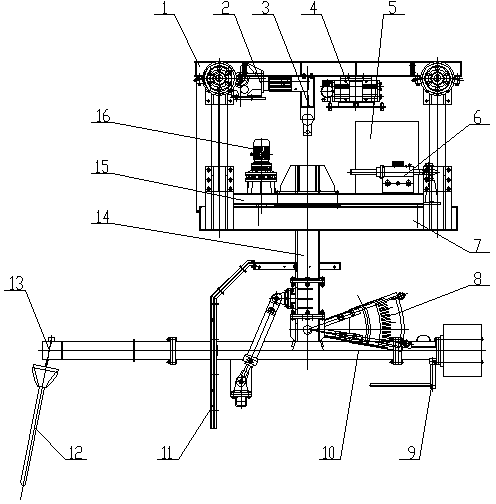

Suspension type skimbar putting device

The invention relates to a suspension type skimbar putting device, which comprises a cantilever pole tilting device (10), a skimbar clamping device (13) and an energy medium system (3), wherein the energy medium system (3) is used for cooling the cantilever pole tilting device (10); the energy medium system (3) and a vehicle-mounted hydraulic station (5) are arranged on a rotating platform (15); the rotating platform (15) is arranged on a suspension platform (7) and is rotated relatively to the suspension platform (7); the suspension platform (7) is arranged on a walking platform (1); a walking driving device (2) is arranged on the walking platform (1); the suspension platform (7) is driven by the walking driving device (2) to move; and the vehicle-mounted hydraulic station (5) is used for driving the cantilever pole tilting device (10) and the skimbar clamping device (13) to operate. The suspension type skimbar putting device has a compact structure, is reliable to operate, and has high putting accuracy, and convenience in maintaining, overhauling and replacing easily damaged parts.

Owner:HUATIAN ENG & TECH CORP MCC

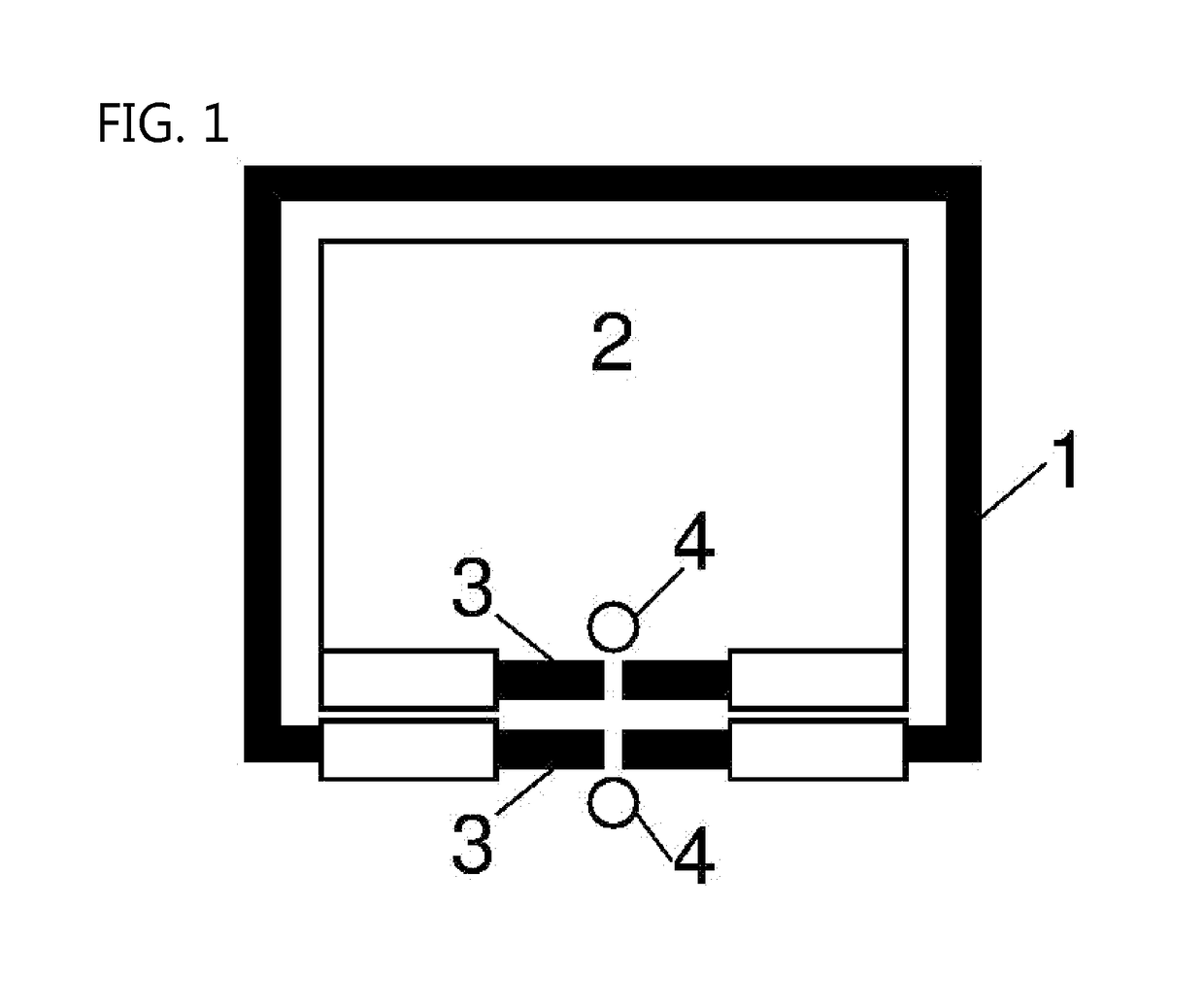

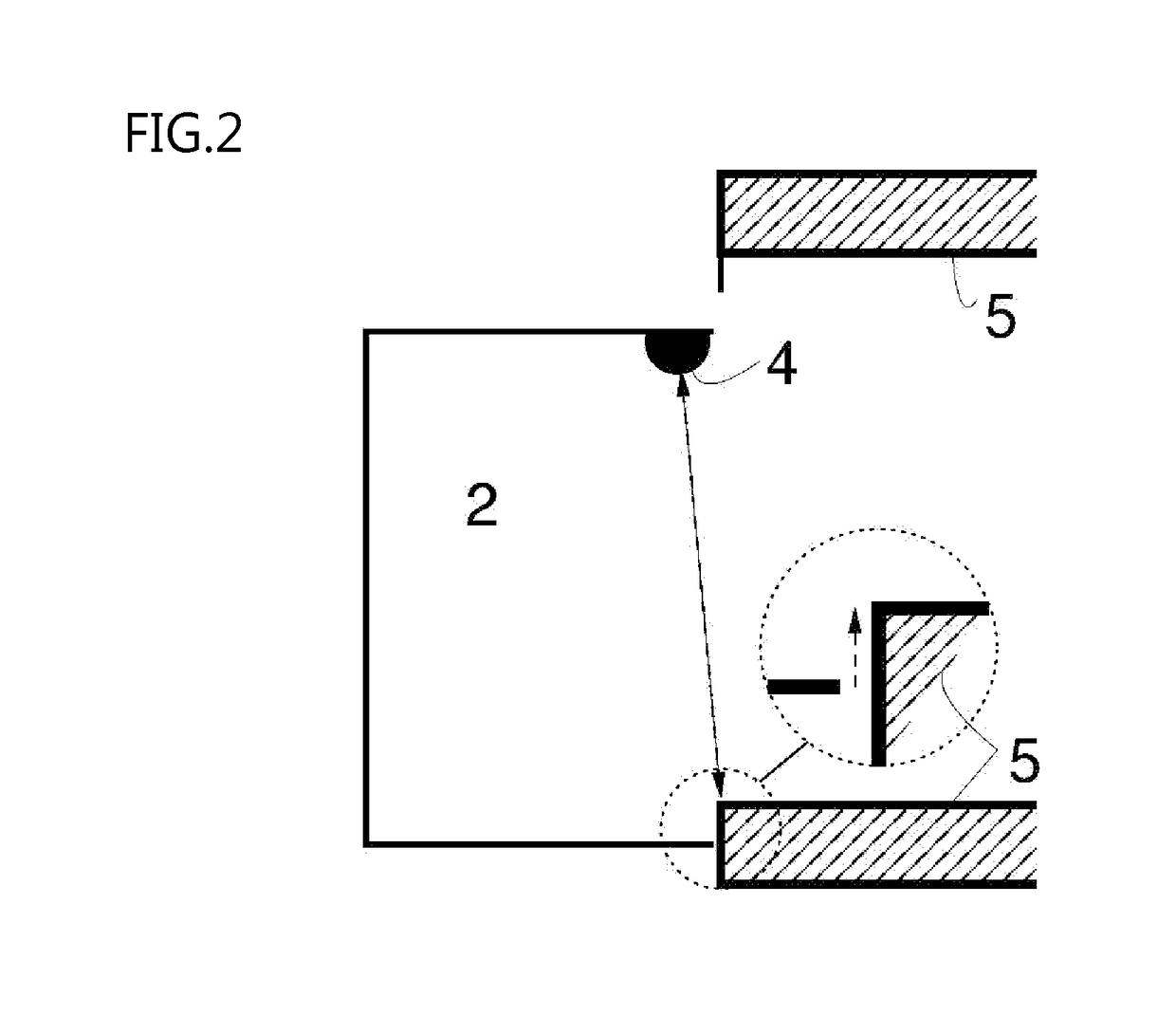

System and method for enhancing elevator positioning

PendingUS20190062105A1Enhancing elevator positioningPrecise positioningImage enhancementImage analysisComputer system designSystems design

A method and a system for enhancing elevator positioning includes a camera system designed to record pictures and a computer system designed to determine an absolute distance or a distance between two elements of the recorded pictures. The device is designed to determine the relative distance between the floor of an elevator car and the floor of a landing.

Owner:KONE CORP

Valve throttling engine speed reducer

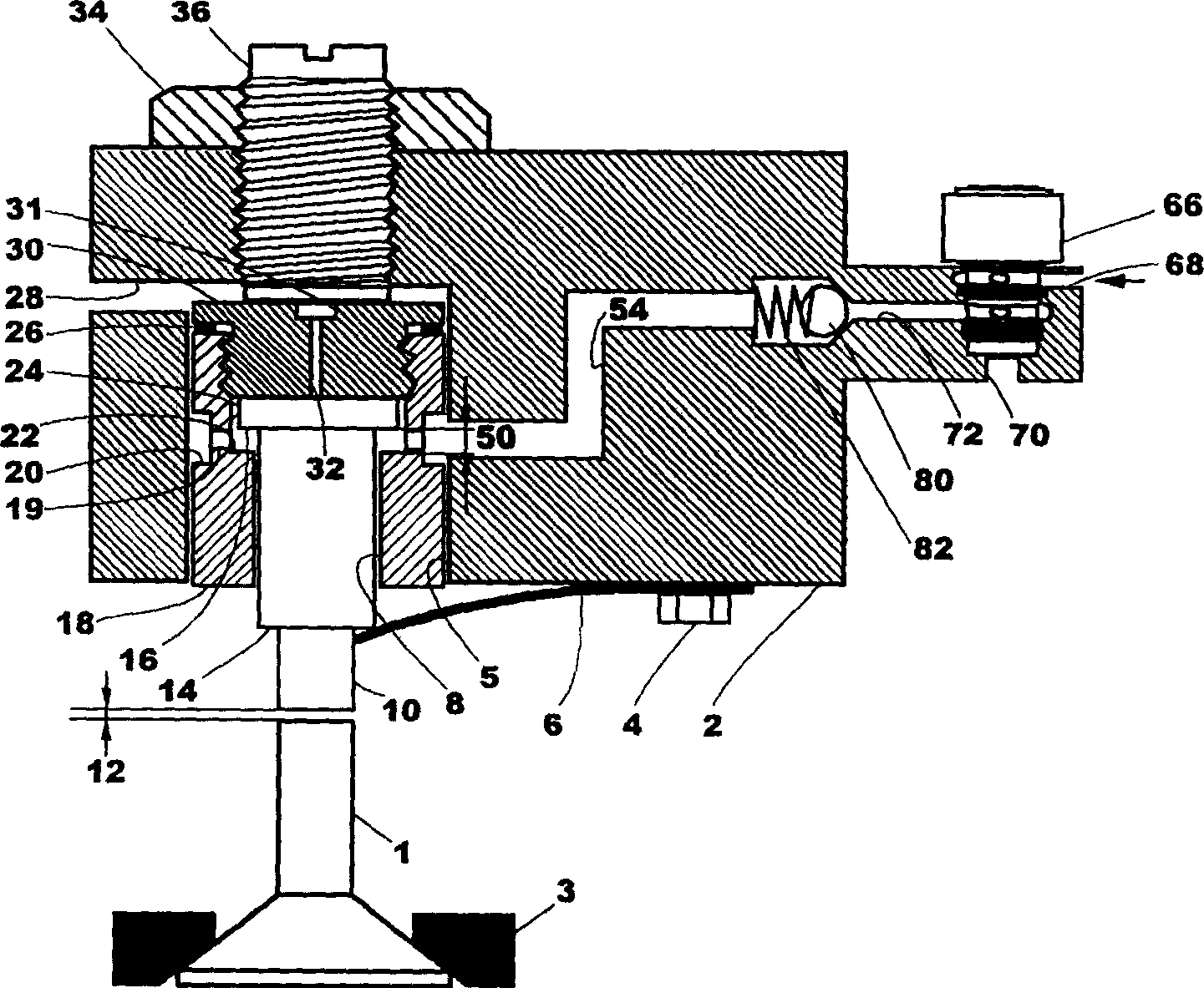

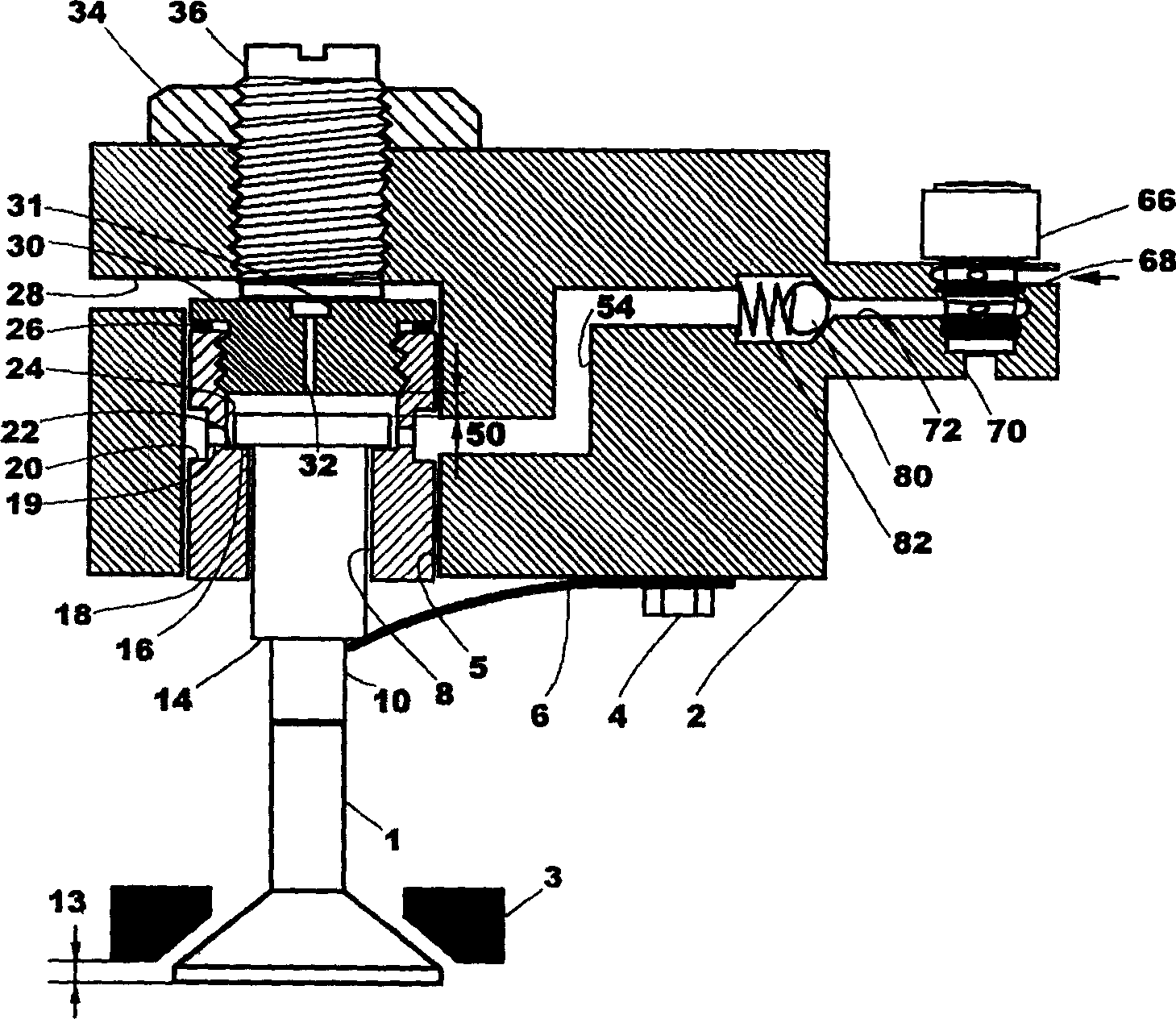

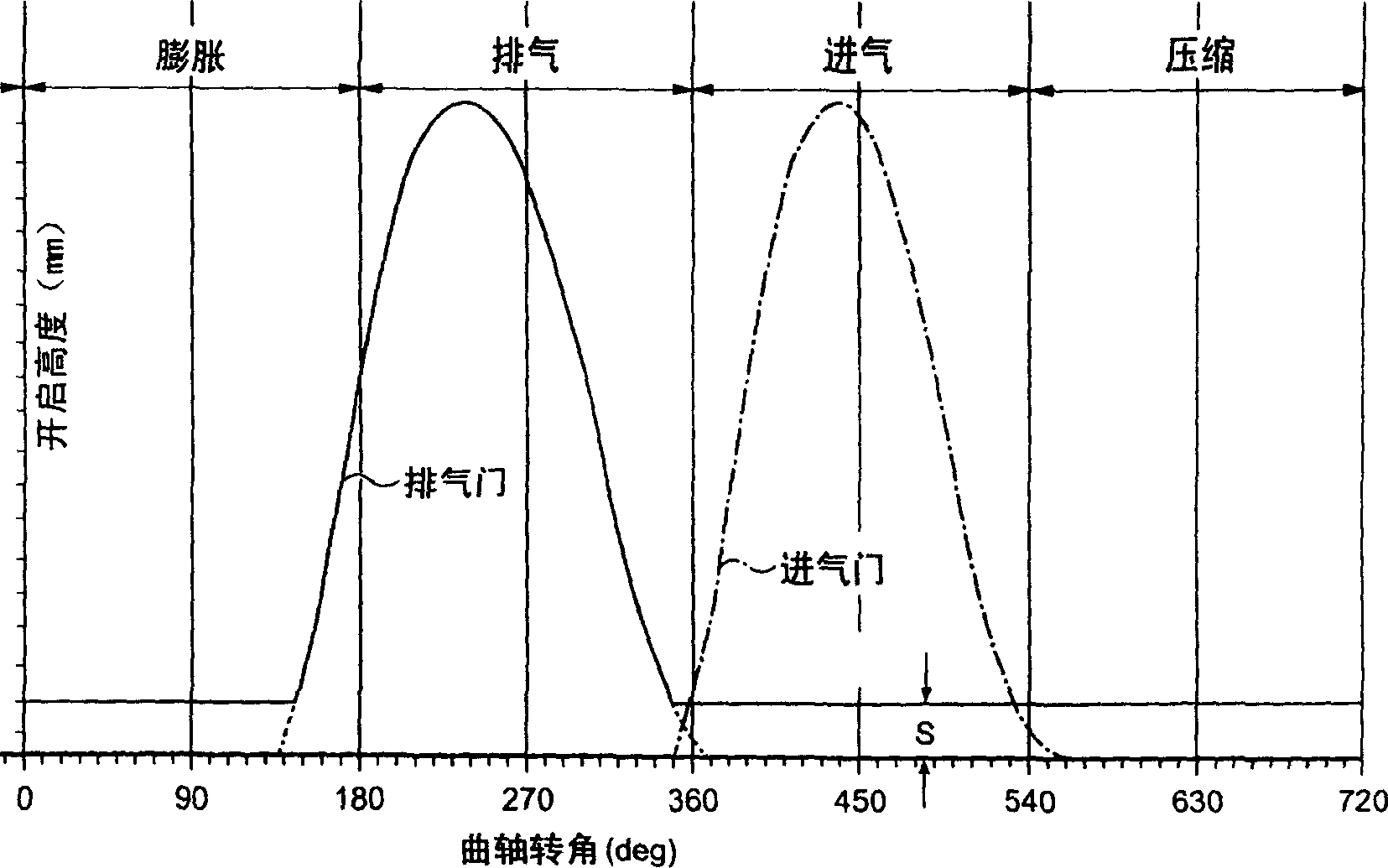

InactiveCN1673504AReasonable designAccurate movement distanceEngine controllersMachines/enginesInlet channelSolenoid valve

The novel engine retarder includes oil inlet channel, solenoid valve, oil outlet channel, non-return valve, work oil channel, driving piston, spring sheet, etc. It has two regulating structures, the first regulating structure has one regulating washer to regulate the interval between the screw plug and the limiting step on the regulating piston to ensure the precise moving distance of the driving piston, and the second regulating structure has regulating screw to regulate the assembly of screw plug and the regulating piston in proper position inside the piston cavity to ensure the precise gap between the driving piston and regulating piston and the precise initial opening height of the exhaust door. The present invention has also oil discharging channel to regulate the throttle opening and ideal braking force under different rotation speed.

Owner:马银良

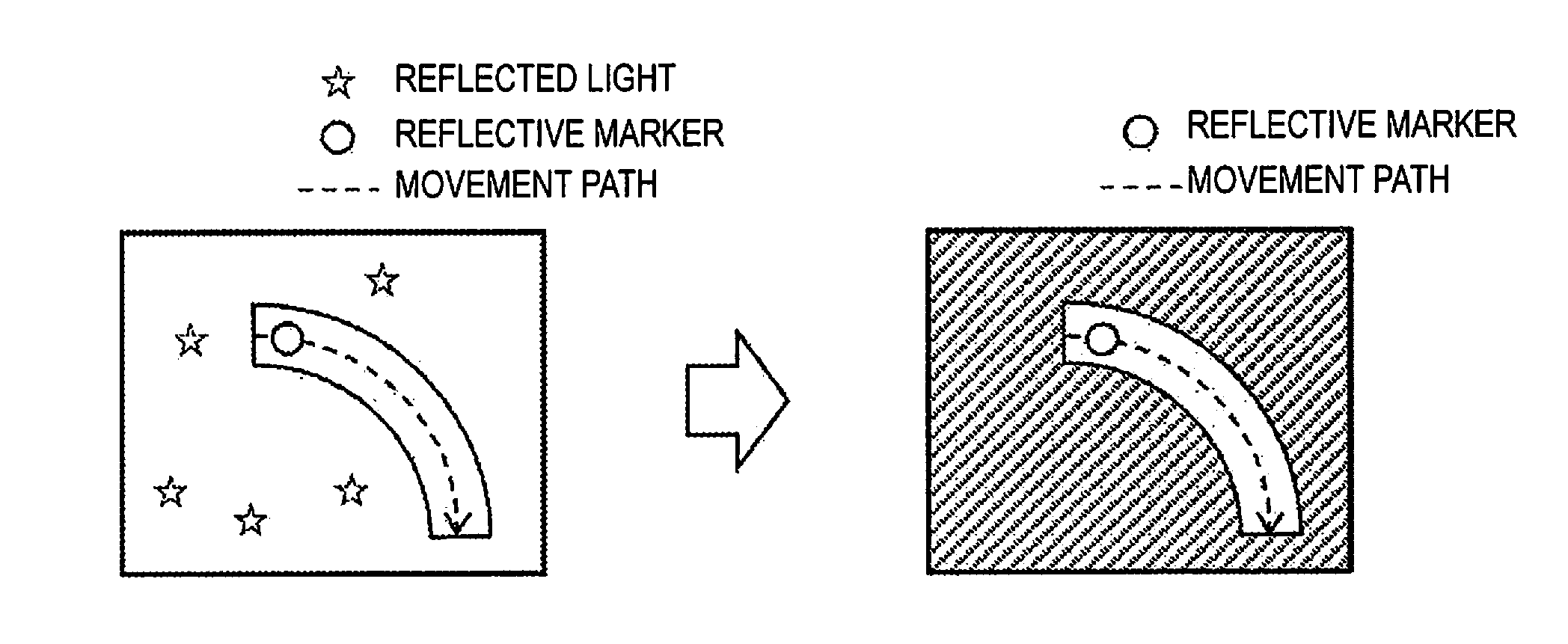

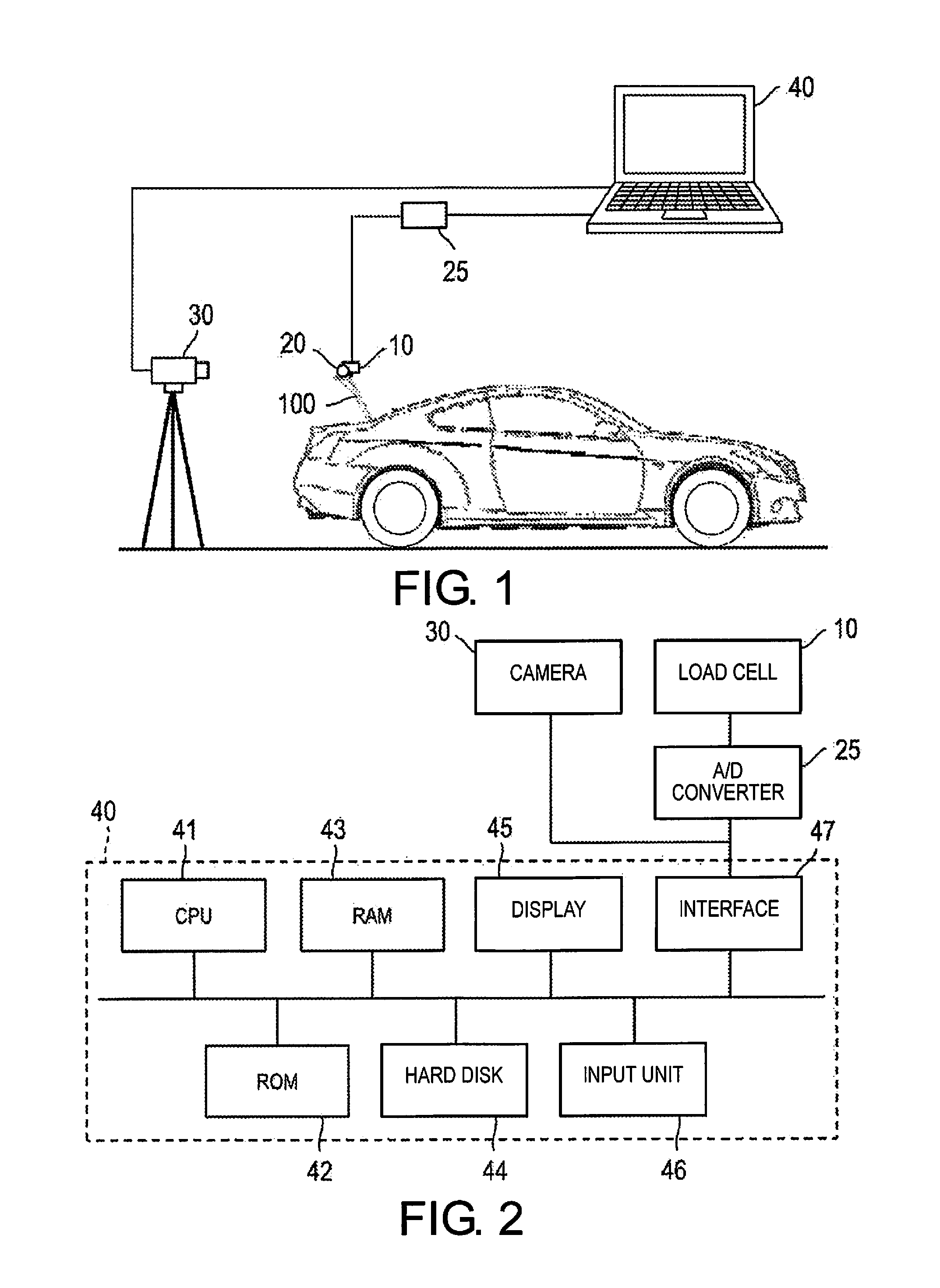

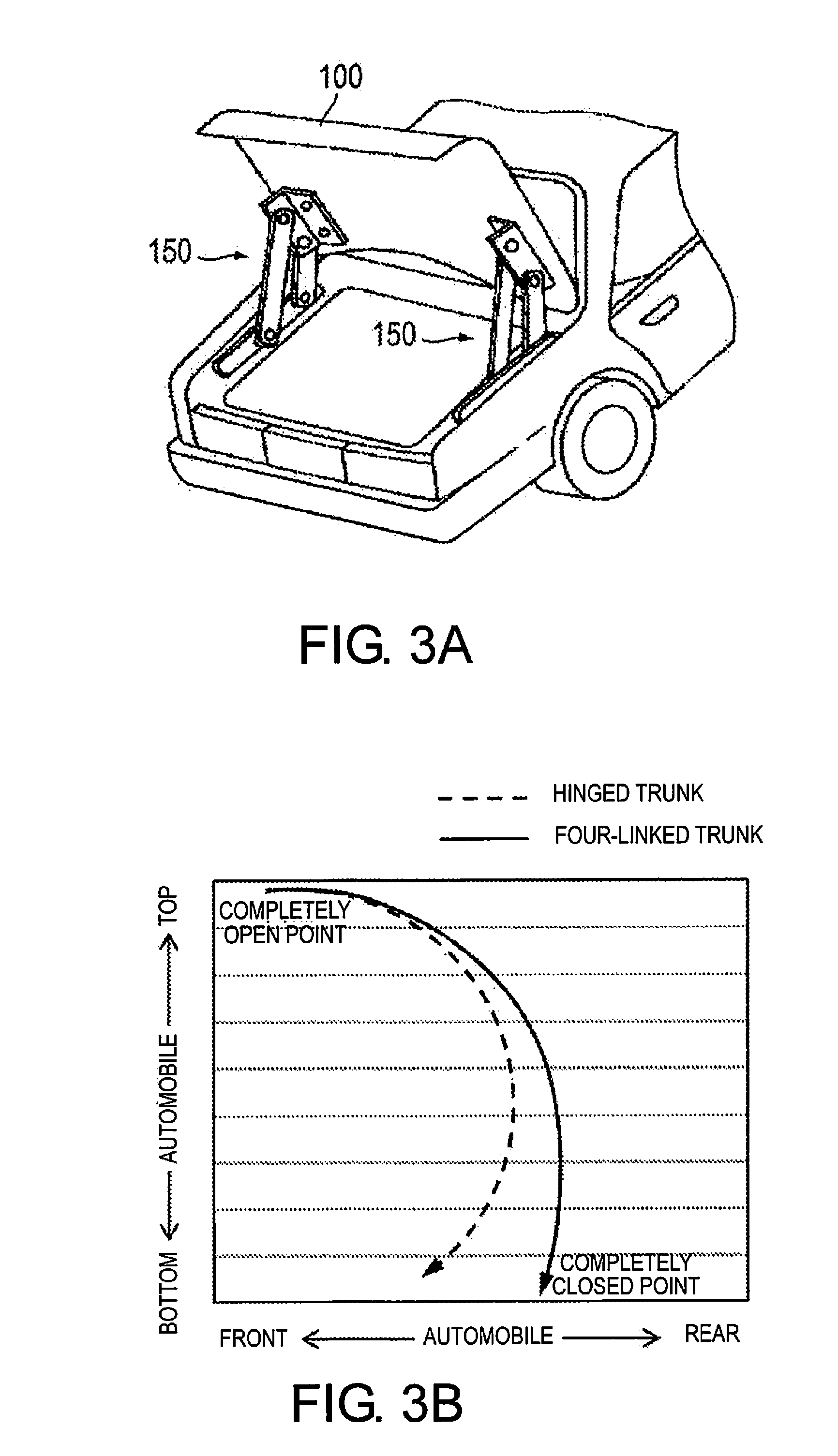

Opening/closing body inspection apparatus and opening/closing body inspection method

ActiveUS20150043781A1Accurate movement distanceAccurate calculationVehicle testingImage enhancementImaging processingEngineering

An opening / closing body inspection apparatus evaluates the closing performance of an opening / closing body open-and-closably attached to an opening / closing body support member. The apparatus includes a marker configured to be attached to the opening / closing body, a load-detecting device for detecting a load upon the opening / closing body attached to the marker, an image-capturing device for capturing an image of the movement path of the marker as the marker moves in tandem with the motion of the opening / closing body being closed by the load, an image-processing device for analyzing image data obtained by the image-capturing device, and a performance-assessing device for assessing the closing performance of the opening / closing body on the basis of the movement distance calculated by the image-processing device and the load detected by the load-detecting device.

Owner:NISSAN MOTOR CO LTD

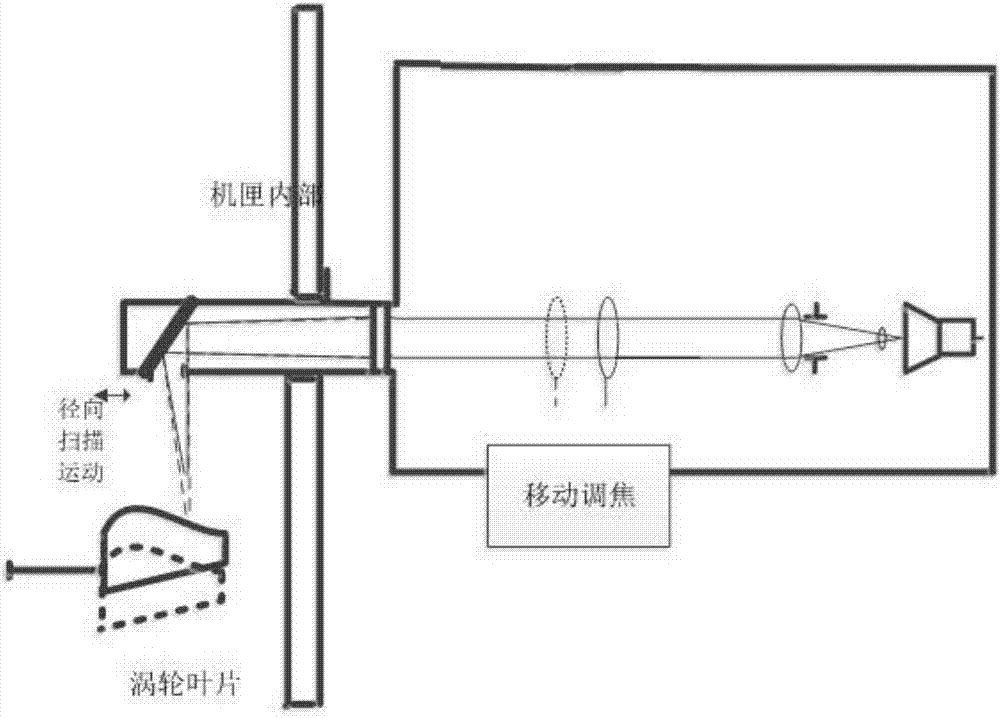

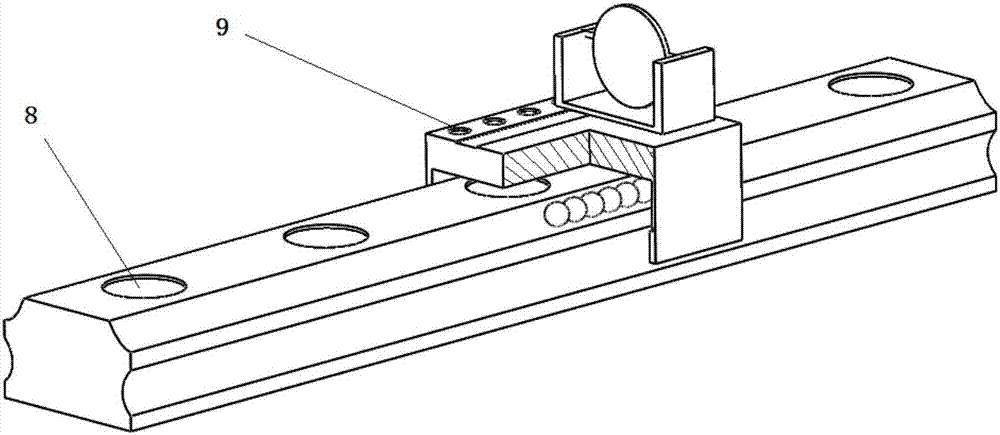

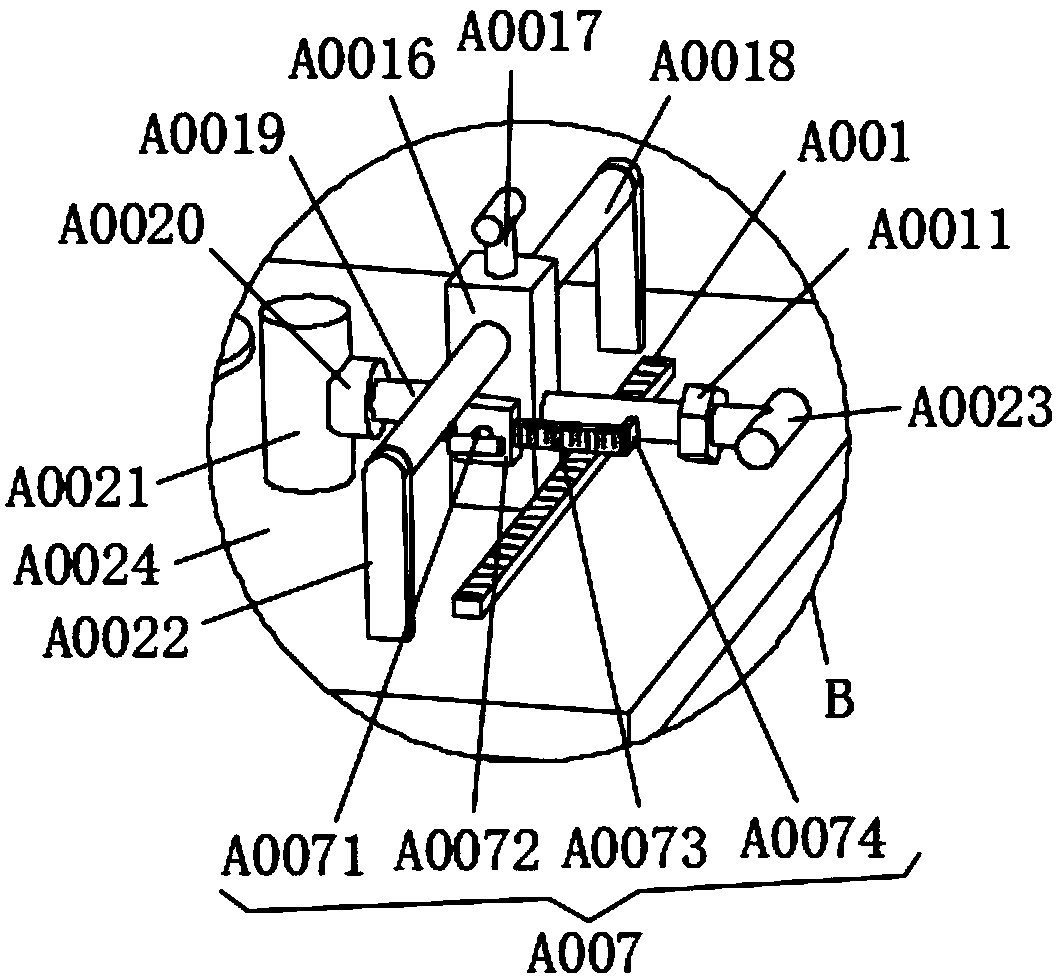

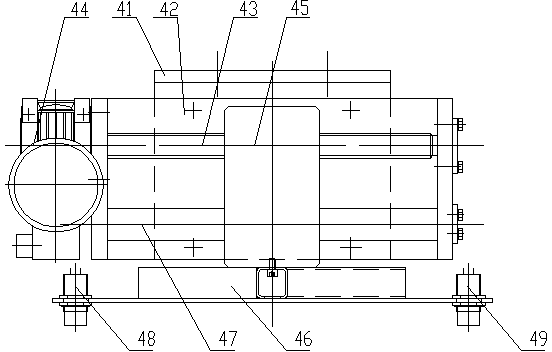

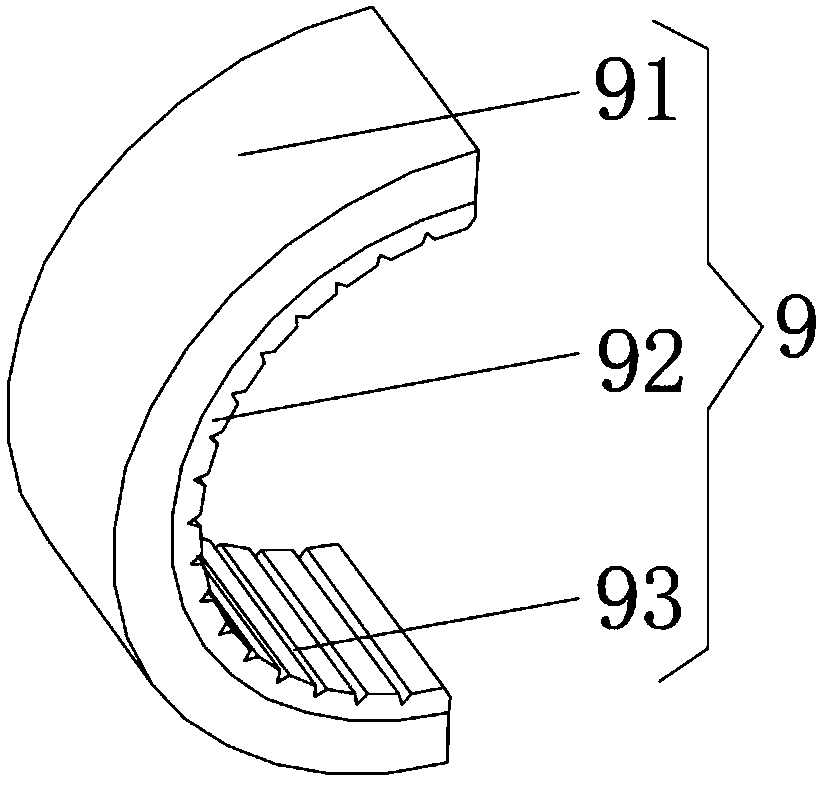

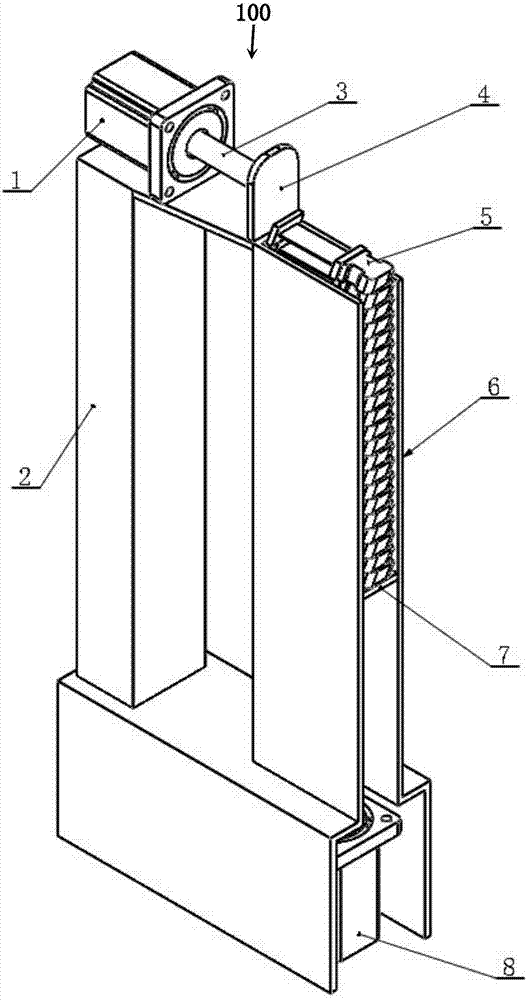

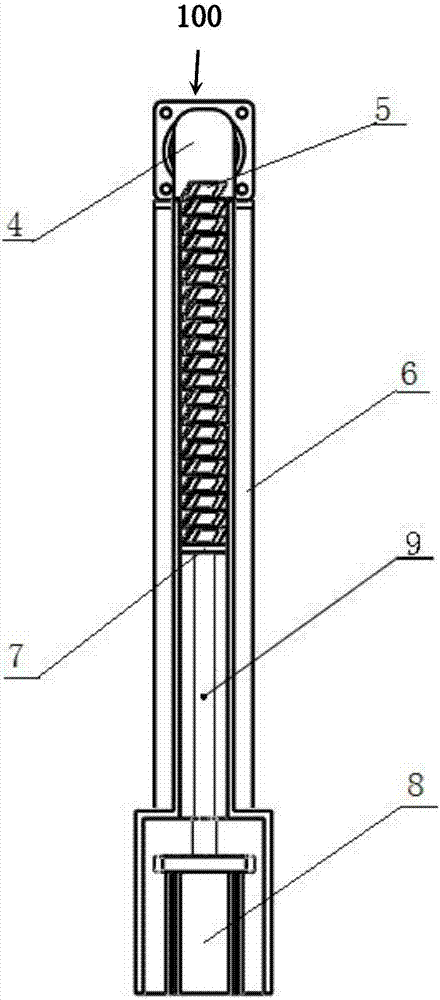

Turbine blade infrared radiation light collection device

InactiveCN107314818AMove preciselyAccurate movement distancePyrometry using electric radation detectorsLocation detectionGear wheel

The invention discloses a turbine blade infrared radiation light collection device, which belongs to the field of mechanical structures. A light focusing method is particularly designed. Infrared radiation light on the surface of the turbine blade is collected through a reflector, the light is collimated by a collimating mirror, the light is finally collected by a received through a focusing mirror, the collimating mirror is arranged on a collimating sliding block, the collimating sliding block is arranged on a collimating guide rail, a small rigid ball is adopted between the collimating sliding block and the collimating guide rail for realizing sliding connection, accurate movement of the collimating sliding block is realized through engagement between a gear and a rack, and in order to enable the movement distance of the collimating sliding block to be more accurate, a position detection point is arranged on the collimating guide rail for position detection and correction on the collimating sliding block. Thus, the device has the advantage that the turbine blade infrared radiation light collection can be realized, and the focusing precision is high.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

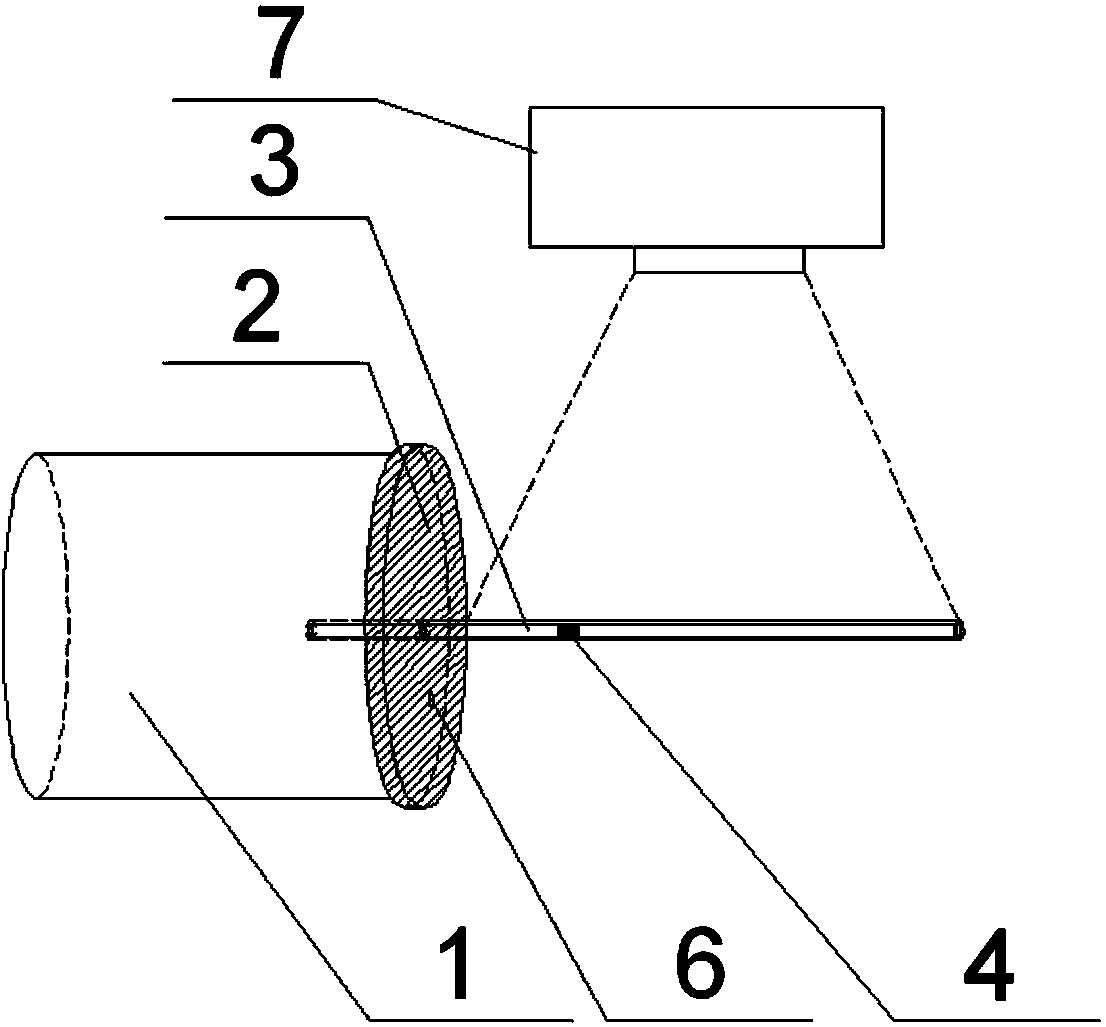

Blood-culture carbon dioxide trace-gas detection system and detection method thereof

InactiveCN103808628AEasy to observe and measureIncrease automation and precisionMaterial analysisObservations and MeasurementsTrace gas

The invention relates to a blood-culture carbon dioxide trace-gas detection system and a detection method thereof. The blood-culture carbon dioxide trace-gas detection system is characterized by comprising a detection device and an image collection device, wherein the detection device comprises a reaction bottle, the opening of the reaction bottle is provided with a seal cover, the seal cover is provided with a capillary glass tube insertion hole, one end of a capillary glass tube is inserted into the reaction bottle through the capillary glass tube insertion hole, and color liquid is contained in the capillary glass tube and forms a liquid column in the capillary glass tube; the image collection device aims at photographing the color liquid in the capillary glass tube, and a picture taken by the image collection device is transmitted to a computer to be processed. The blood-culture carbon dioxide trace-gas detection system has the beneficial effects that the micro increment of gas is changed to the obvious displacement of liquid, so that observation and measurement are easy; the stationary image collection device is used for taking picture, and after the picture is subjected to computer image processing, the distance is measured, so that the movement distance of the liquid column before and after the reaction can be measured; moreover, the blood-culture carbon dioxide trace-gas detection system is simple in structure, convenient to operate, low in cost, high in precision and wide in application range.

Owner:CHONGQING MEDICAL UNIVERSITY

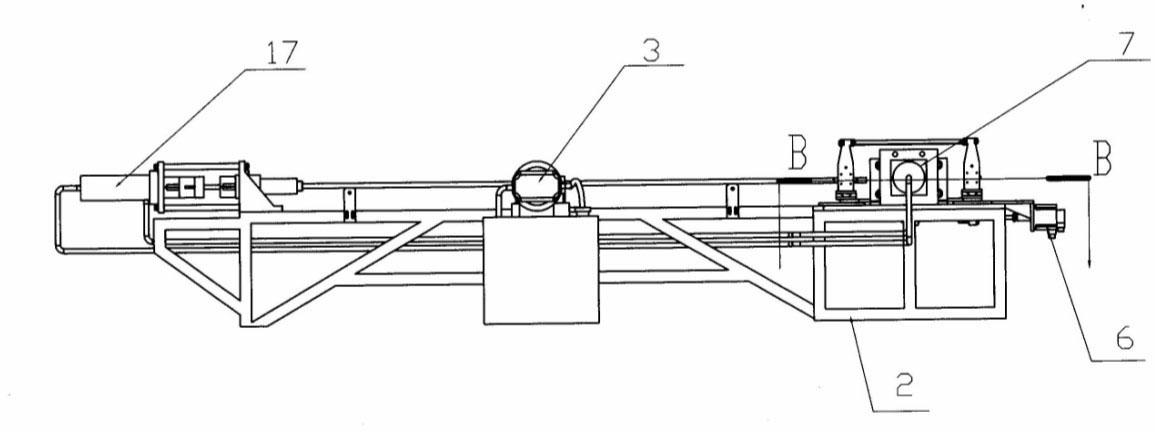

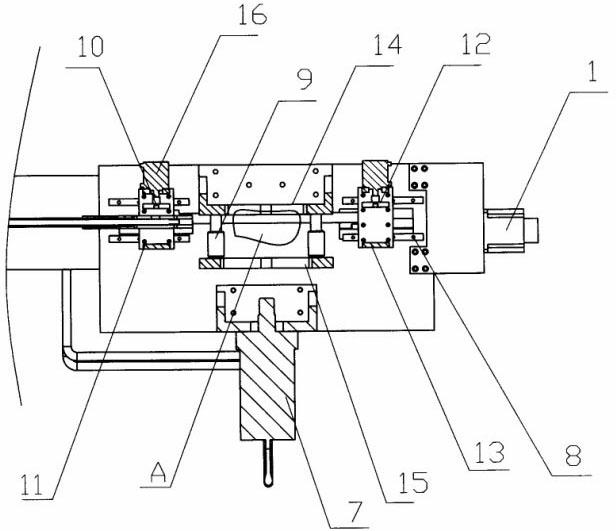

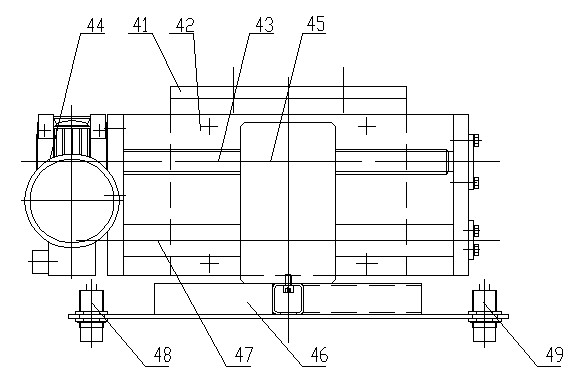

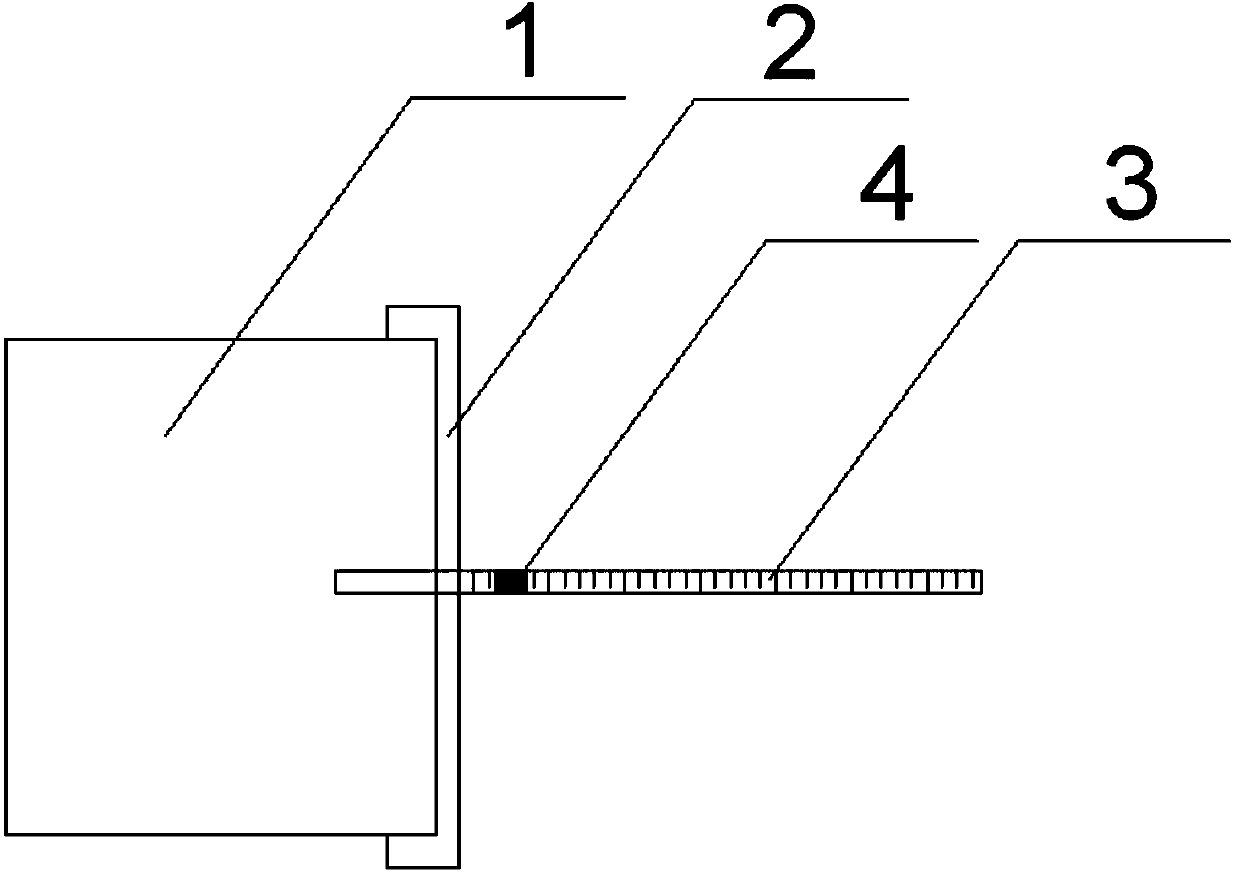

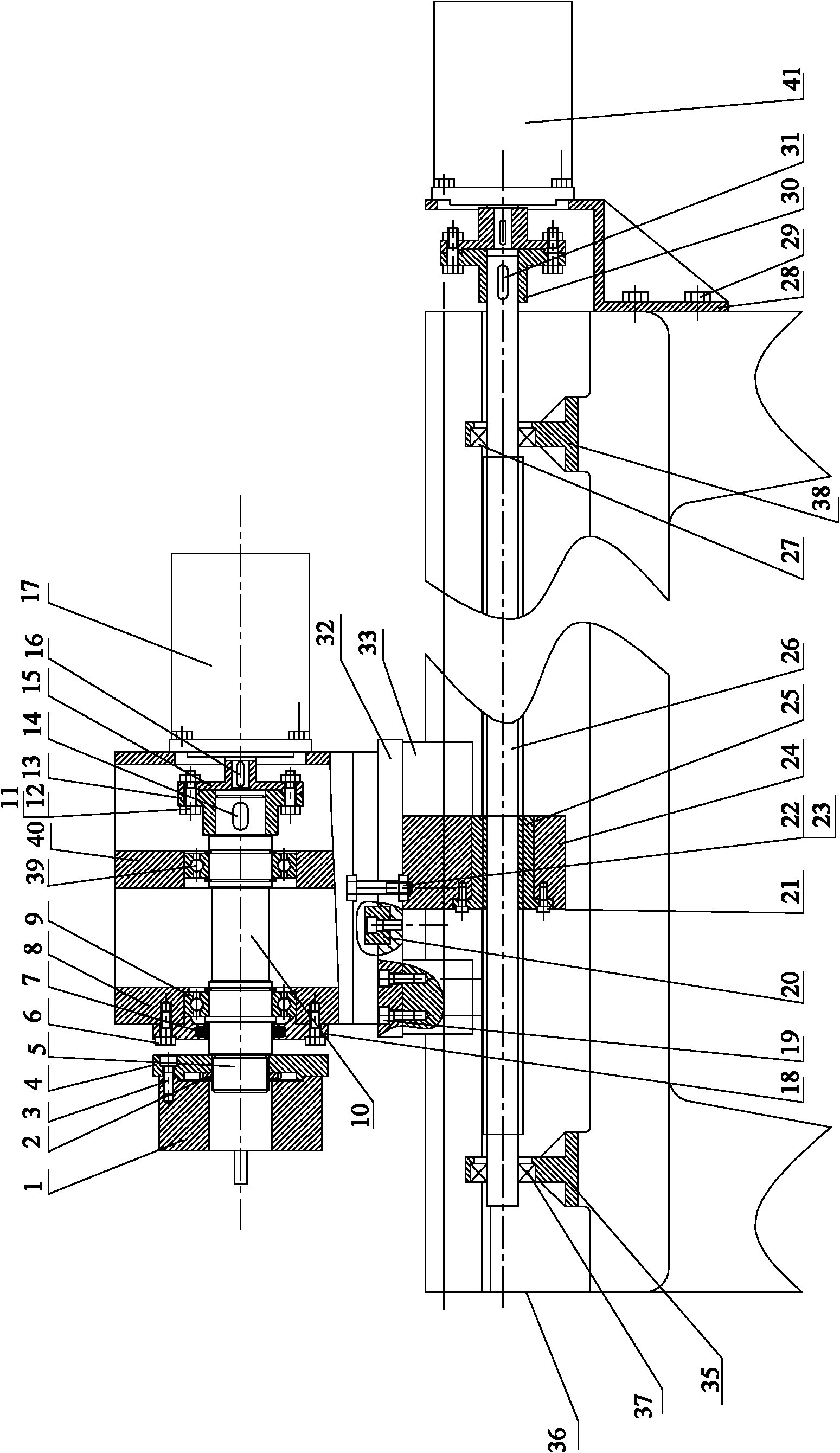

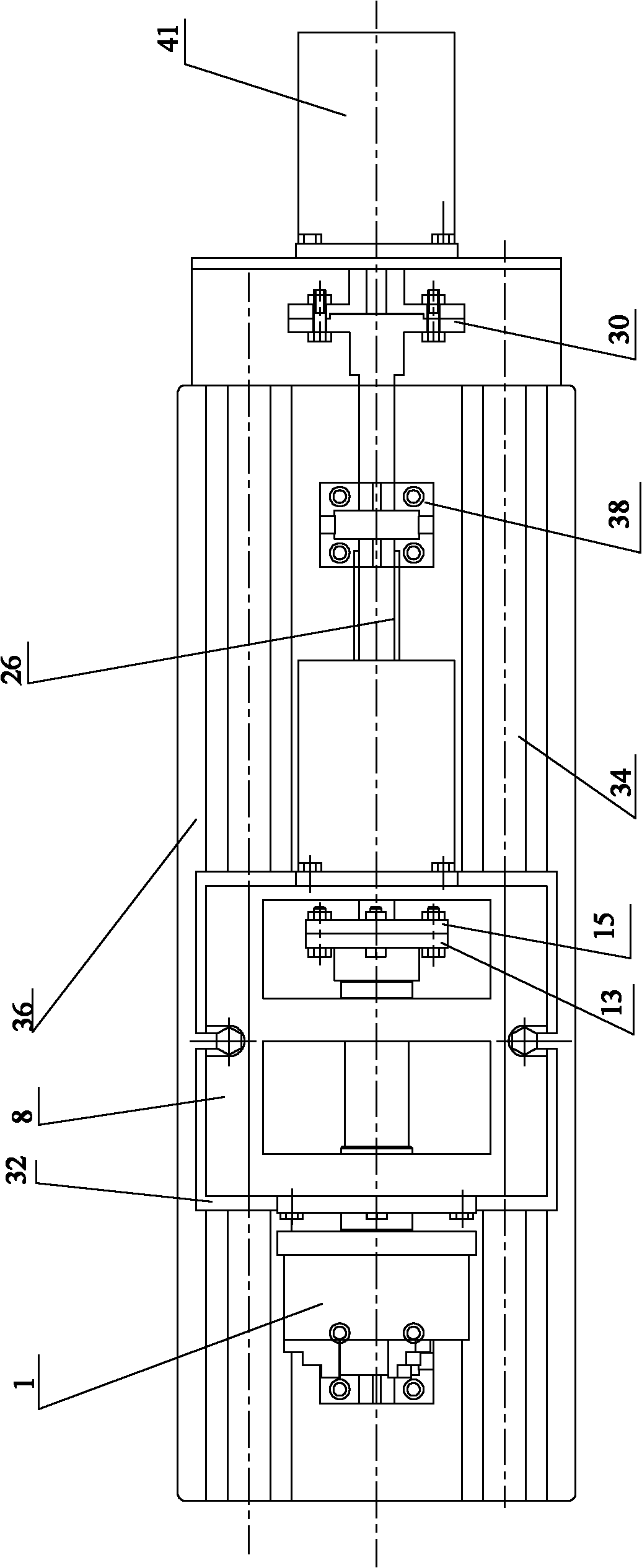

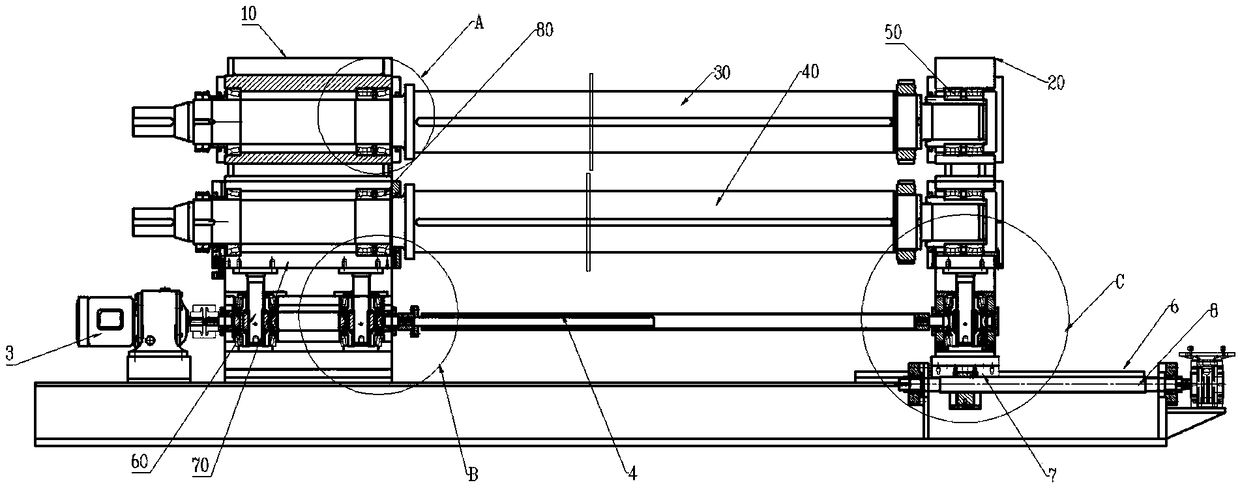

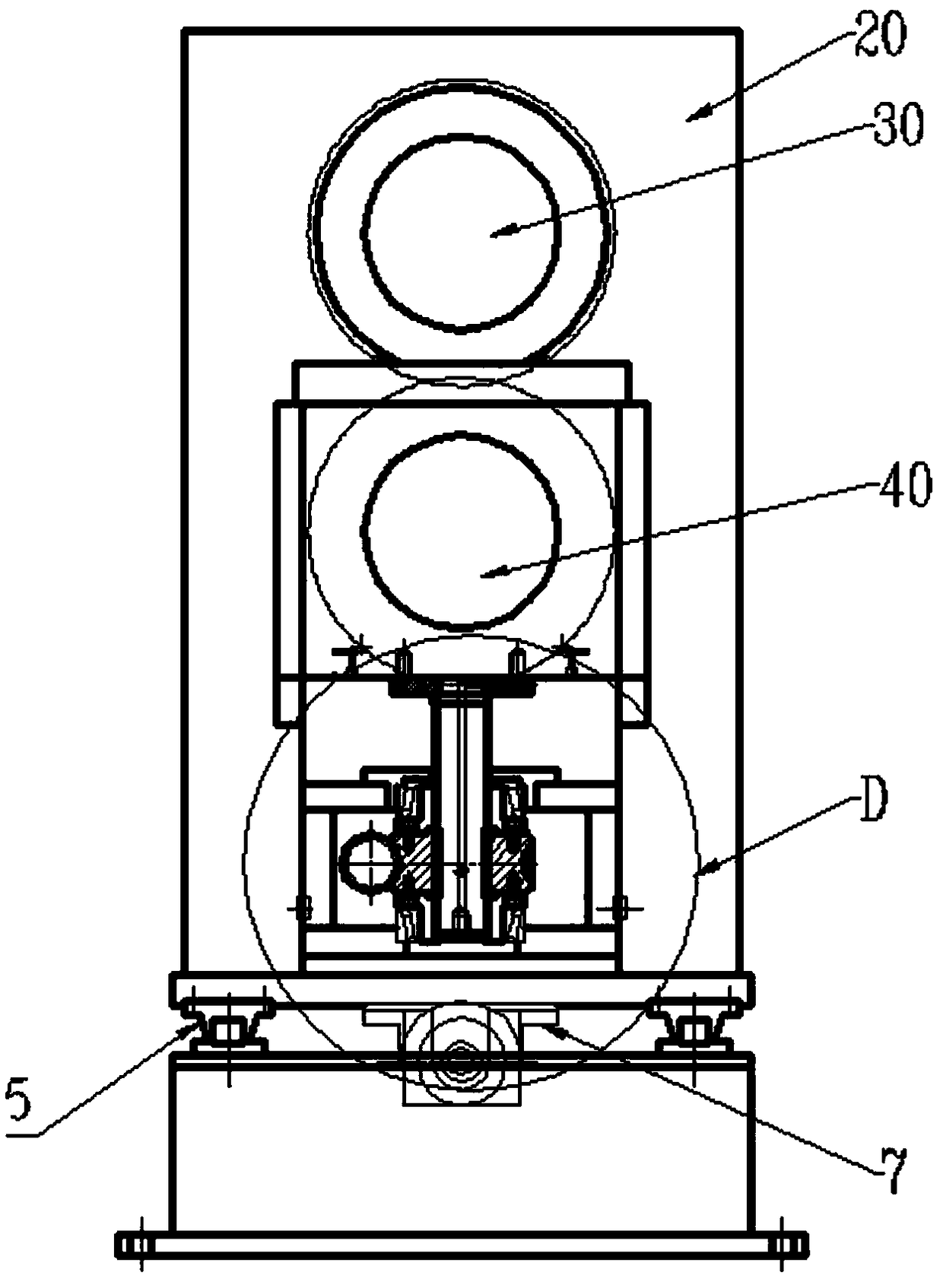

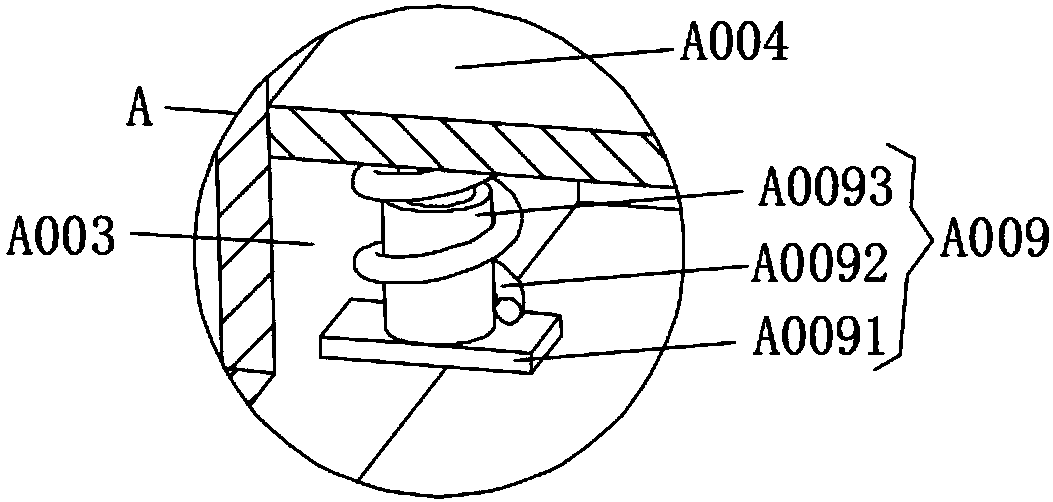

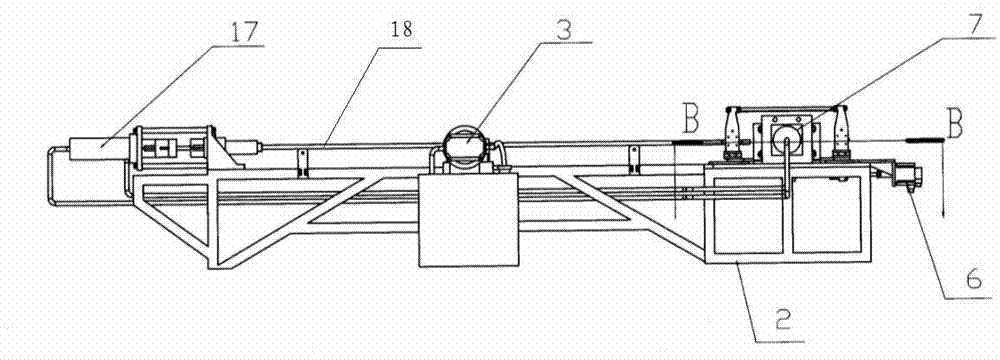

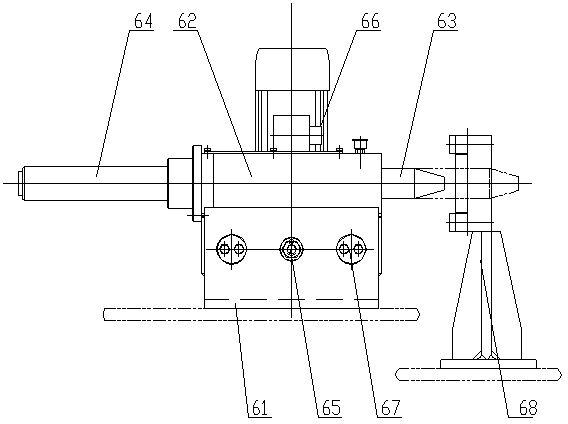

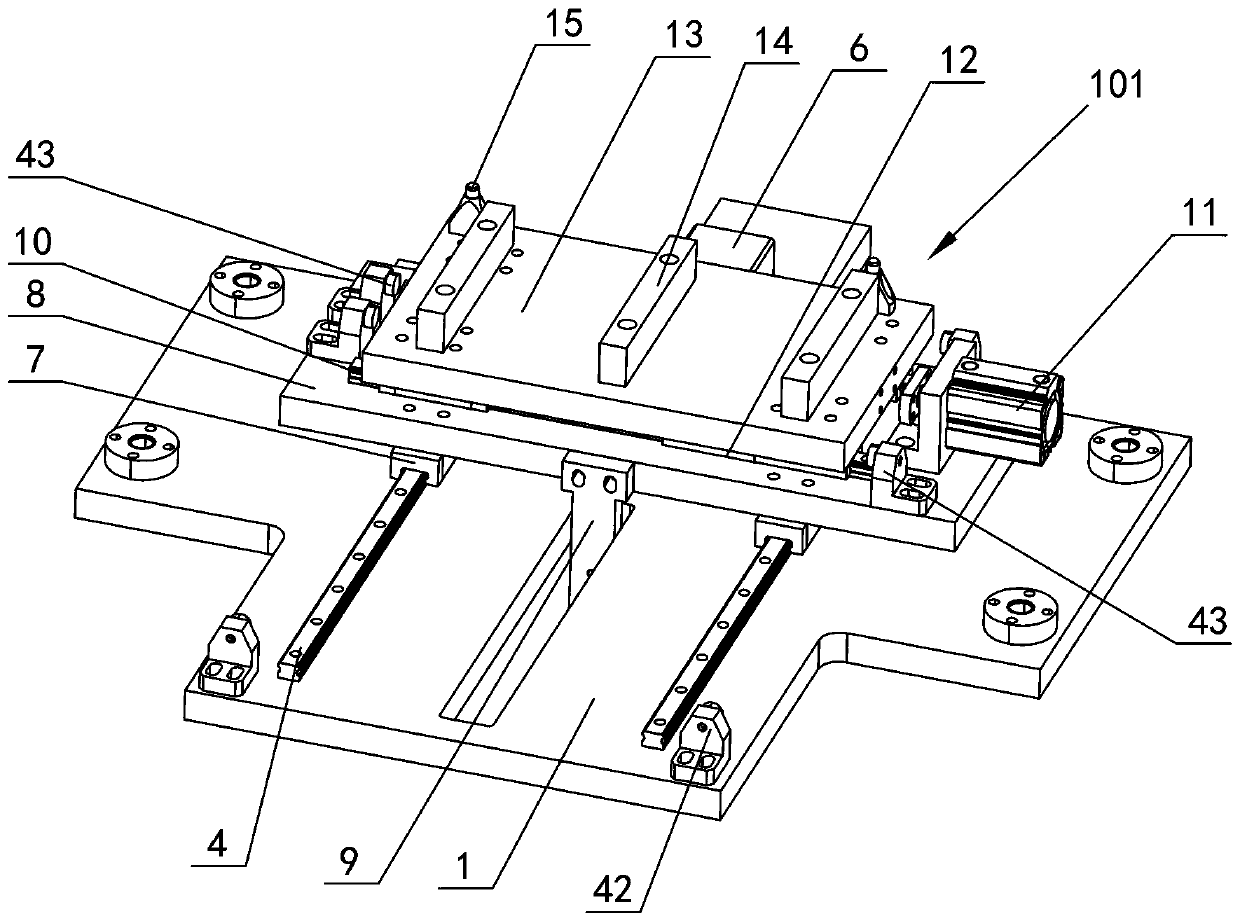

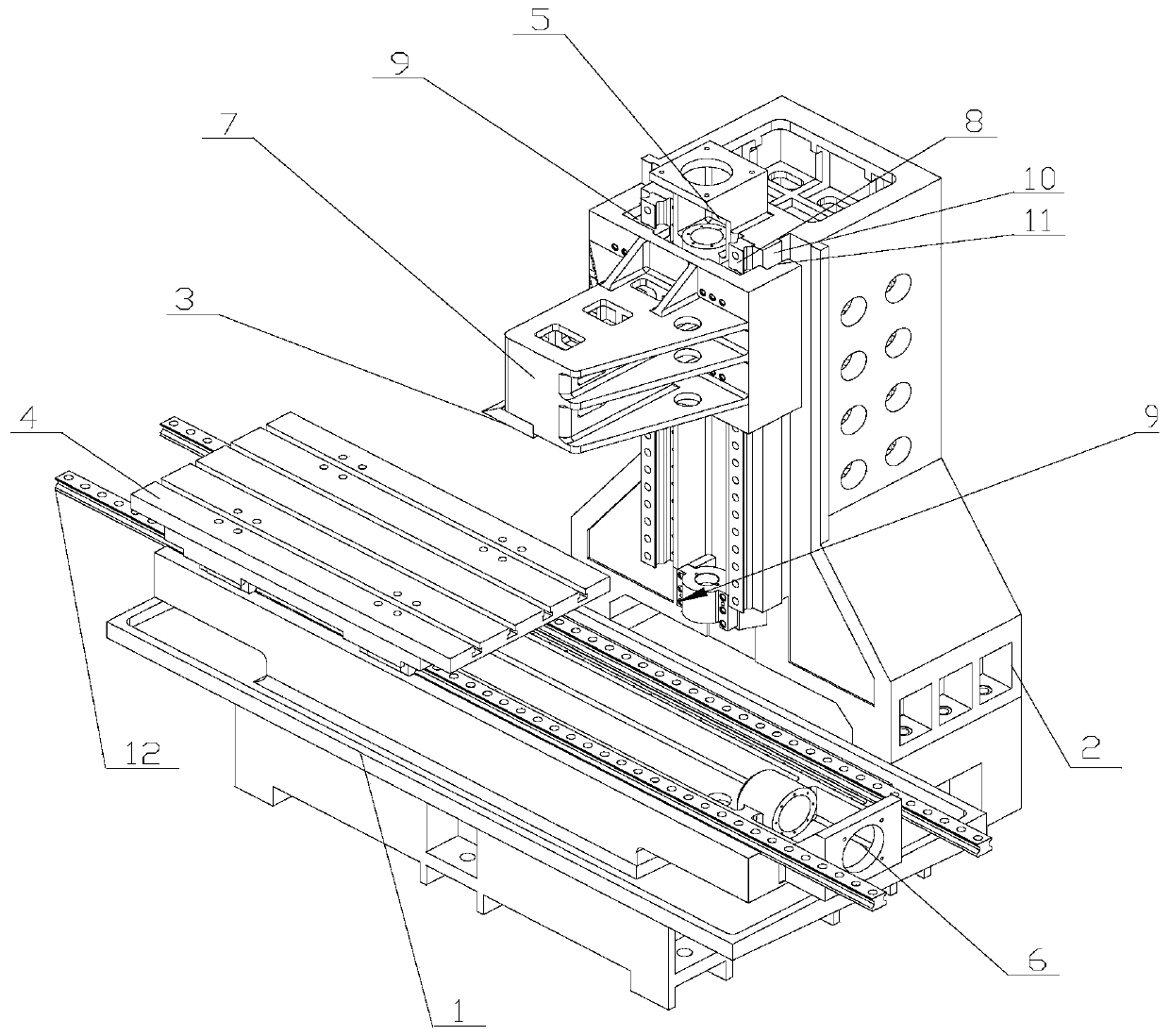

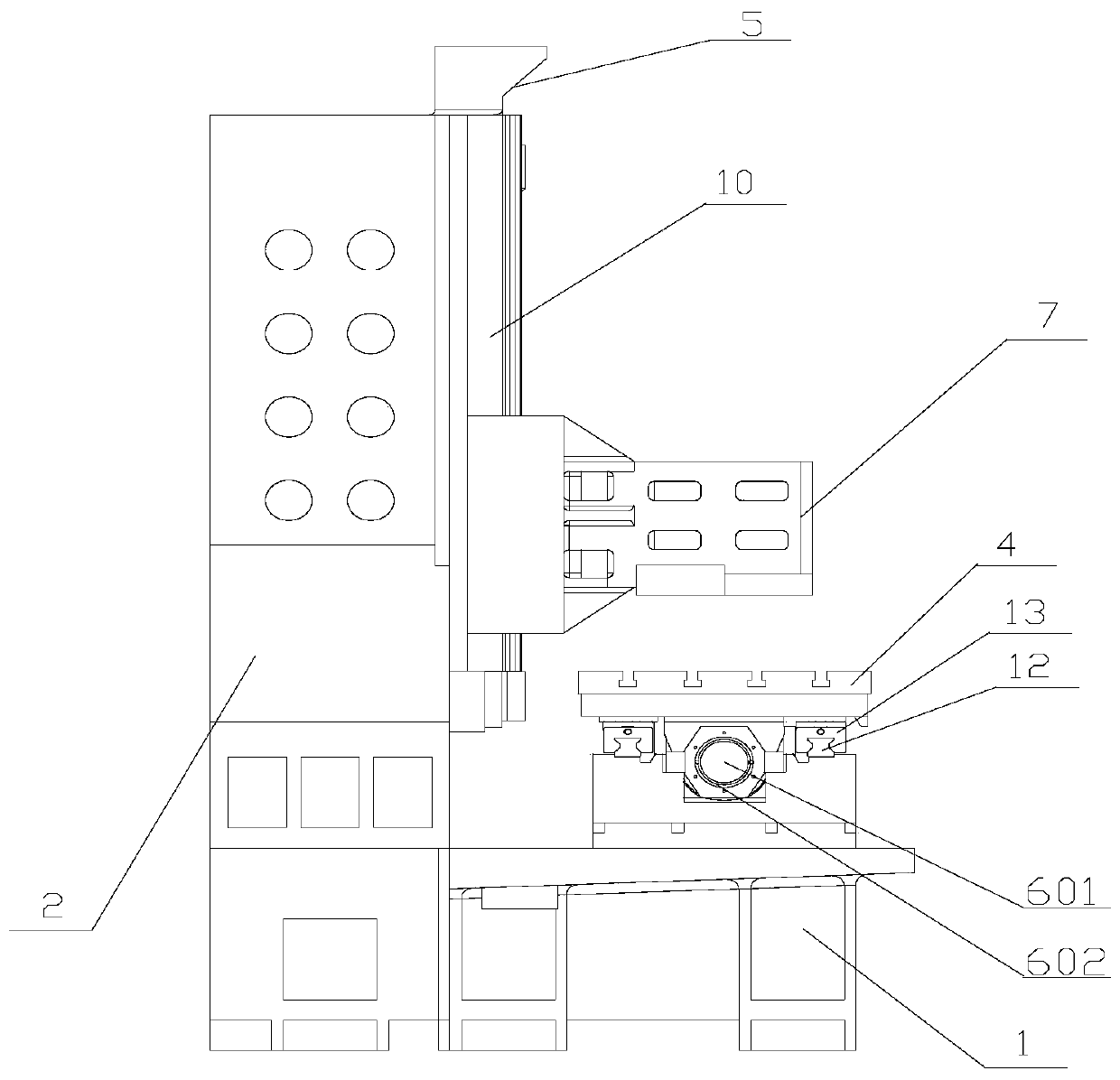

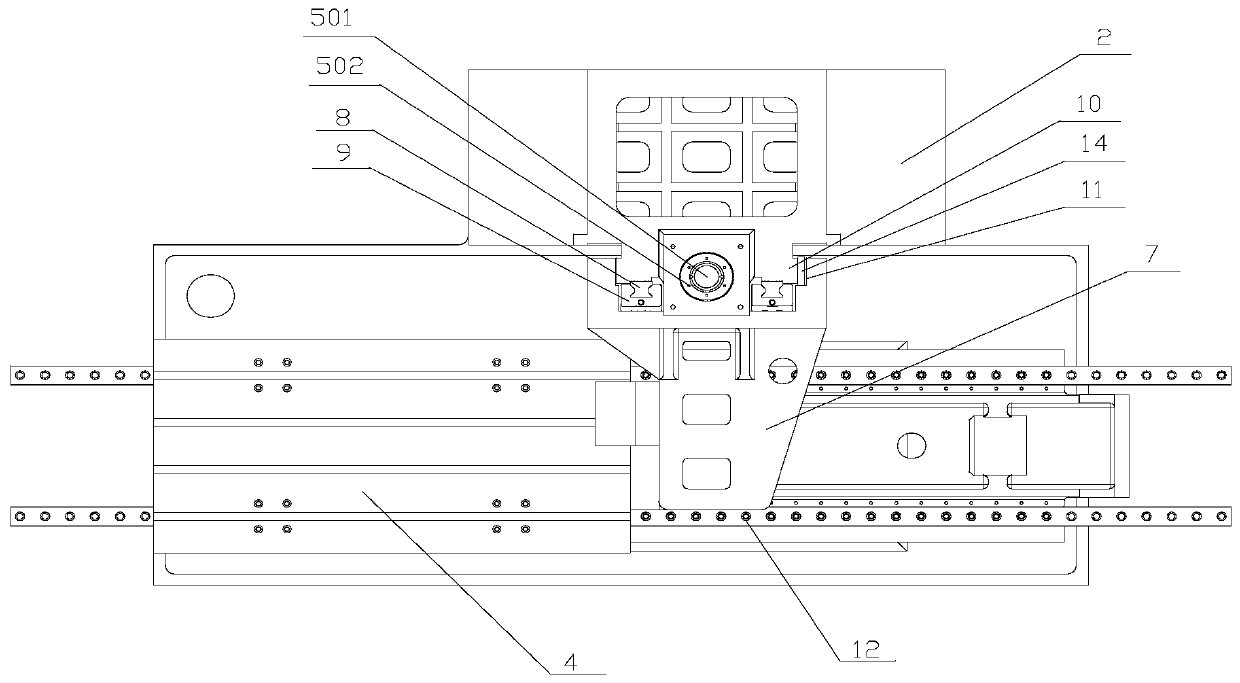

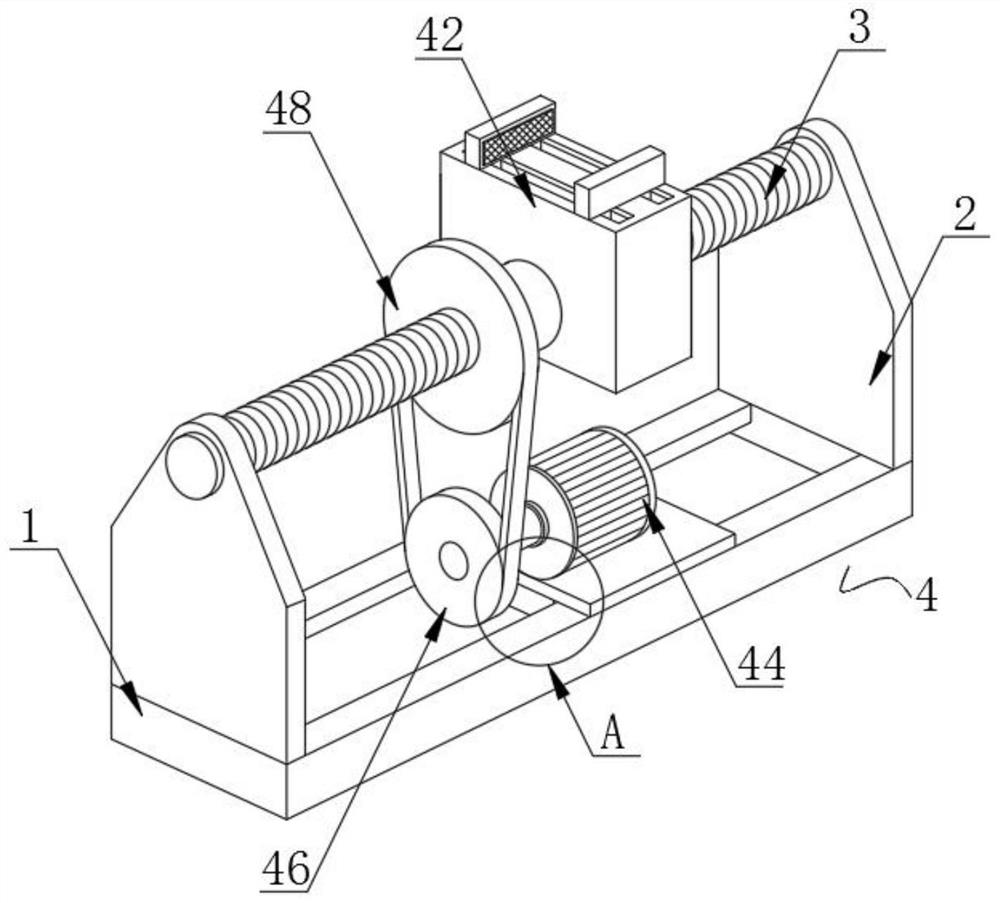

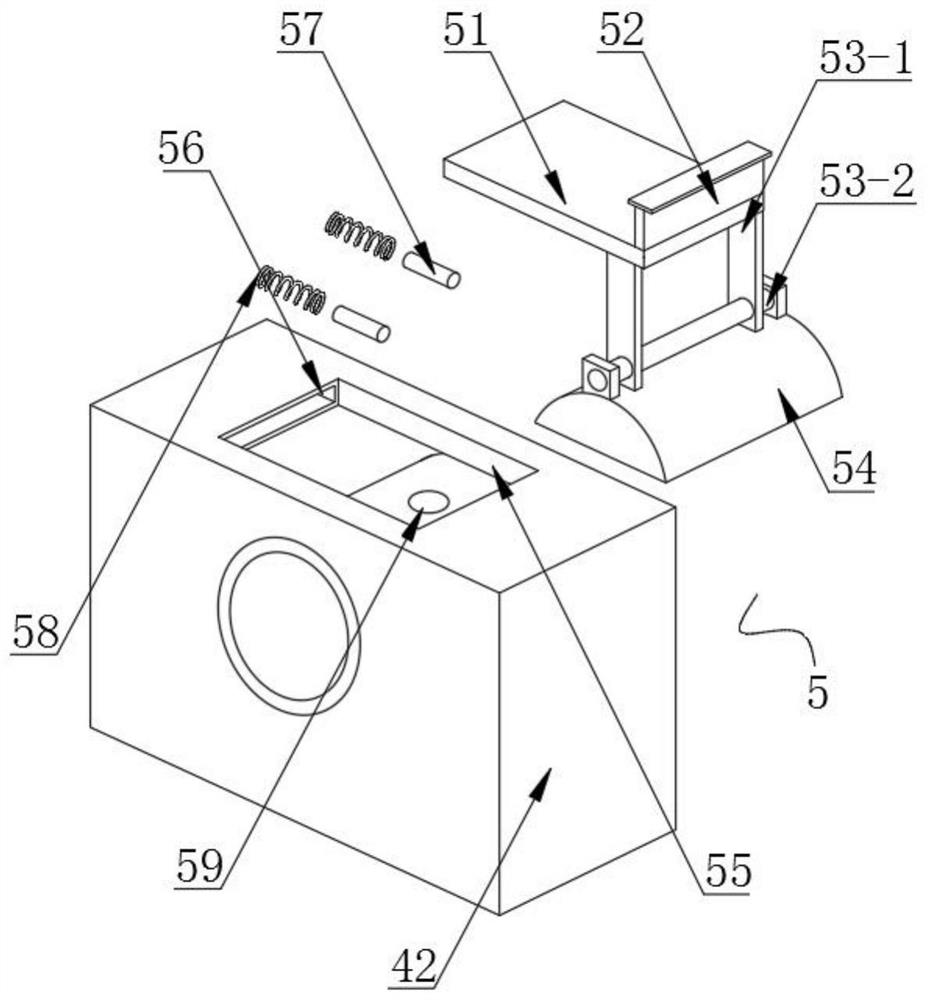

Machining and positioning device for fin-reinforced heat exchange tube and machining and positioning method therefor

InactiveCN102139384AImprove machining accuracyQuick responsePrecision positioning equipmentChucksEngineeringLinear displacement

The invention provides a machining and positioning device for a fin-reinforced heat exchange tube. The machining and positioning device comprises a box body, a rotating mechanism, a clamping mechanism, a distance determining mechanism, a base plate and a lathe bed, wherein the lower part of the box body is fixed on the base plate; the clamping mechanism is arranged at the front end of the box body; the rotating mechanism is arranged in the box body, extends out of the box body and is connected with the clamping mechanism; both the distance determining mechanism and the lathe bed are arranged below the base plate; and the distance determining mechanism is connected with the distance determining mechanism and the lathe bed respectively. The invention also provides a machining and positioning method for the device. In the invention, a machined workpiece is positioned and clamped through a three-jaw chuck; as the front position and the rear position of the three-jaw chuck can be adjustable, the machining and positioning device has the advantage of being suitable for machining fin-reinforced heat exchange tubes of different tube diameters; moreover, the machining and positioning devicehas the advantages of adopting the rotating mechanism and the distance determining mechanism to control the rotation angle and the linear displacement distance of the workpiece, having high machiningaccuracy and the like.

Owner:GUANGDONG IND TECHN COLLEGE

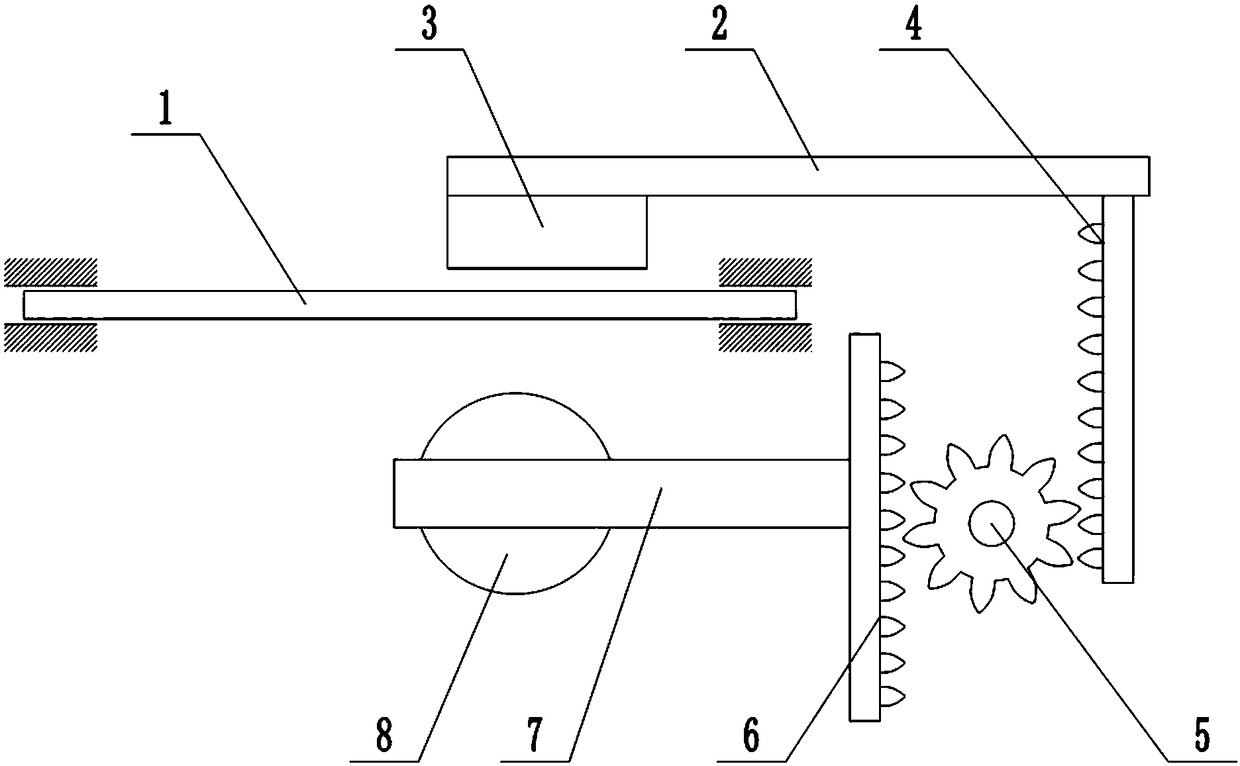

Panel grooving device

The invention belongs to the panel grooving device, and in particular relates to a panel grooving device. The panel grooving device comprises a rack, wherein a worktable is arranged on the rack; a cutting slit is formed in the worktable; a cutting shaft, a first rotary shaft and a second rotary shaft are successively arranged from left to right below the worktable; a first gear and a driving gearare arranged on the first rotary shaft; a first rack parallel to the direction of the cutting slit and engaged to the first gear is fixedly connected to the rack; an air cylinder is also arranged on the right side of the first rotary shaft on the rack; and a push rod of the air cylinder leans against the first rotary shaft; a disc saw web is arranged right below the cutting slit on the cutting shaft; and a second gear engaged to the second rack is arranged on the second rotary shaft. By adopting the scheme, the demand of compressing the panel is met during grooving, and the grooving precisionis ensured.

Owner:重庆鸥能建筑劳务有限公司

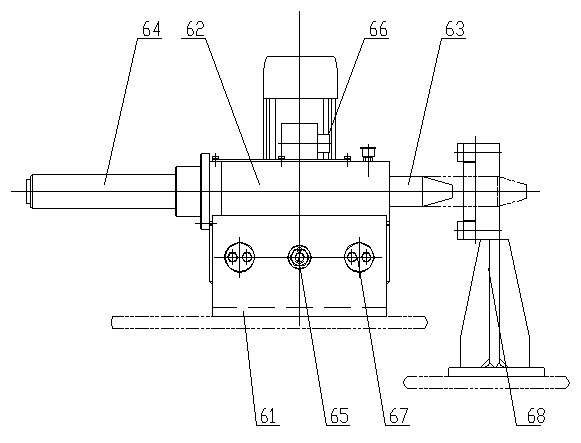

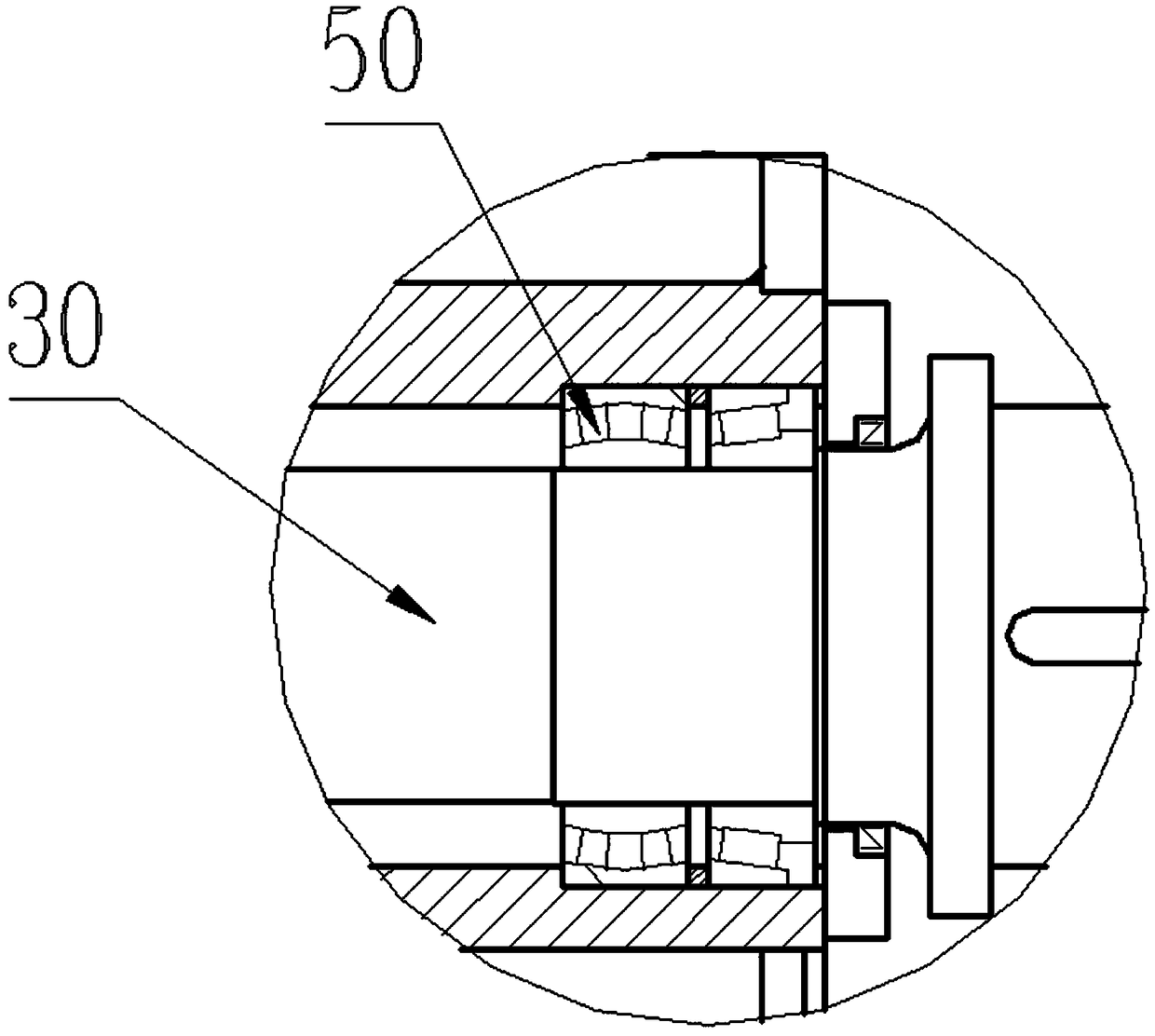

Down-adjustment type high-speed thin sheet longitudinal shearing machine

PendingCN108971612AAccurate movement distanceSmooth motionShearing machinesShearing machine accessoriesThin slabEngineering

The invention provides a down-adjustment type high-speed thin sheet longitudinal shearing machine, belongs to the technical field of longitudinal shearing machines. The down-adjustment type high-speedthin sheet longitudinal shearing machine comprises a left side machine frame, a right side machine frame, an upper cutter shaft and a lower cutter shaft, wherein the upper cutter shaft and the lowercutter shaft are arranged between the left side machine frame and the right side machine frame, upper side bearings are fixedly arranged in the left side machine frame and the right side machine framecorrespondingly, the upper side bearings are arranged at the two ends of the upper cutter shaft in a sleeving mode, the upper cutter shaft is fixed between the left side machine frame and the right side machine frame through the upper side bearings, lead screws which are arranged straightly are movably supported in the left side machine frame and the right side machine frame, lead screw nuts areconnected with lead screws in a sleeving mode, a lower cutter holder is fixed on the lead screw nuts, a lower side bearing is arranged in the lower cutter holder, the lower cutter shaft is arranged between the left side machine frame and the right side machine frame through the lower side bearing, the lower cutter holder is driven by the lead screw nuts to slide on the left side machine frame or the right side machine frame, a worm and gear mechanism is further arranged on the left side machine frame and the right side machine frame, and the lead screws can move under the linkage action of theworm and gear mechanism. The down-adjustment type high-speed thin sheet longitudinal shearing machine has the advantages that precision of the longitudinal shearing machines can be improved, and convenience is brought to a user to use.

Owner:江苏新益机械有限公司

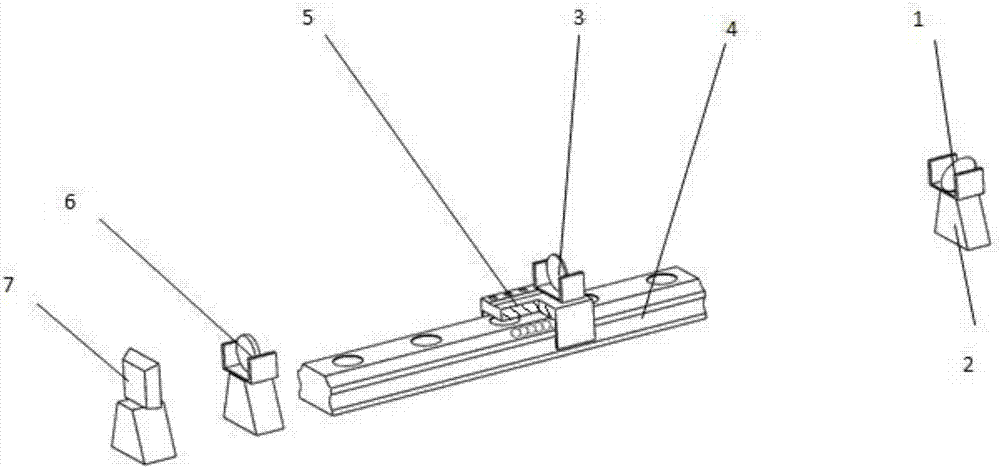

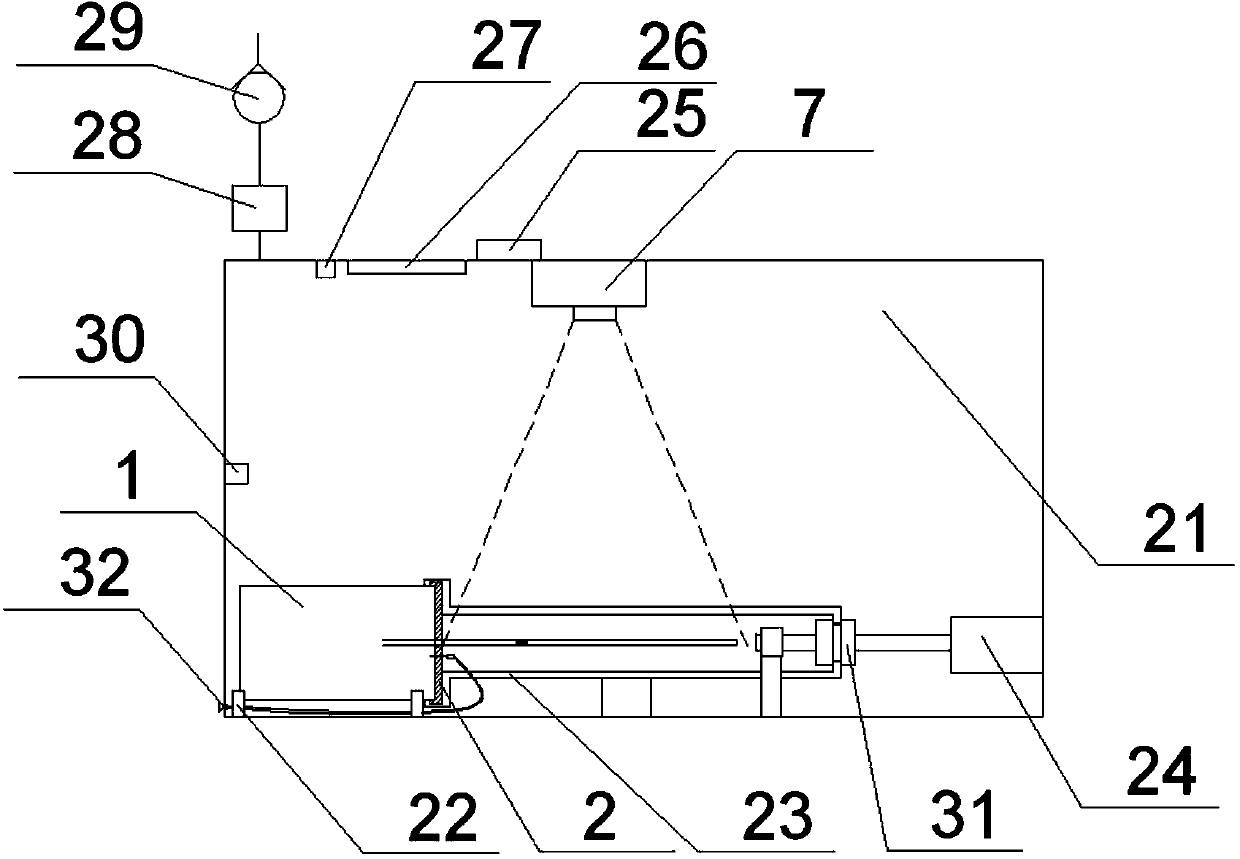

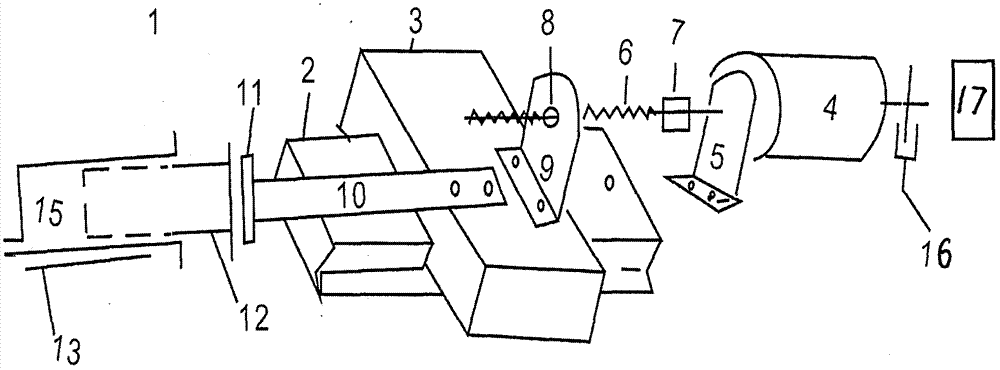

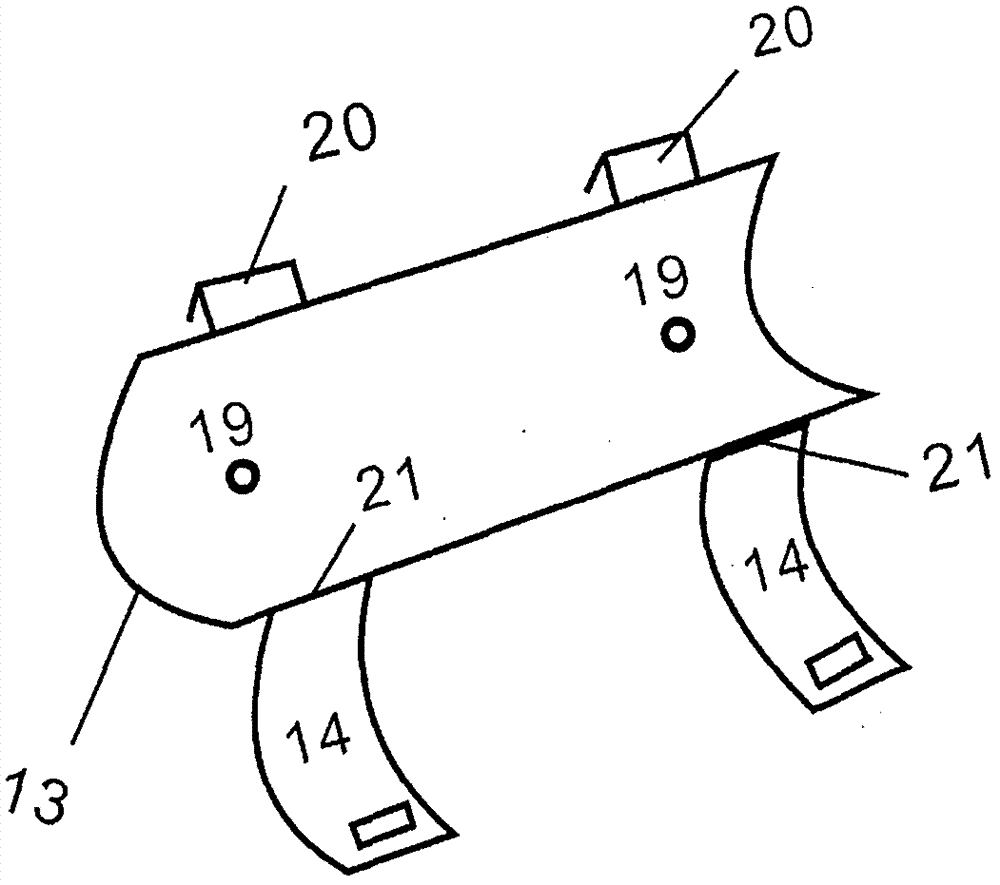

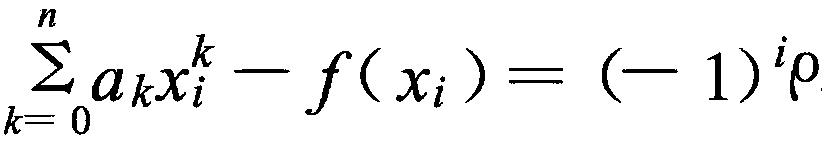

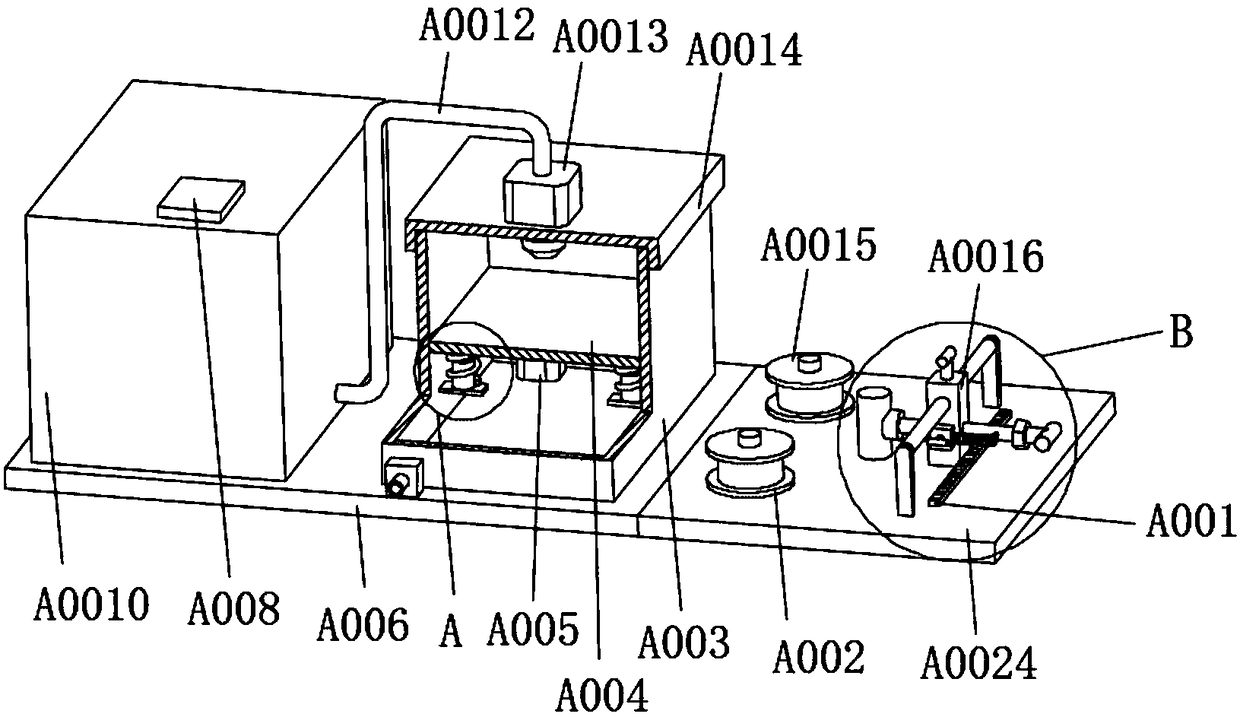

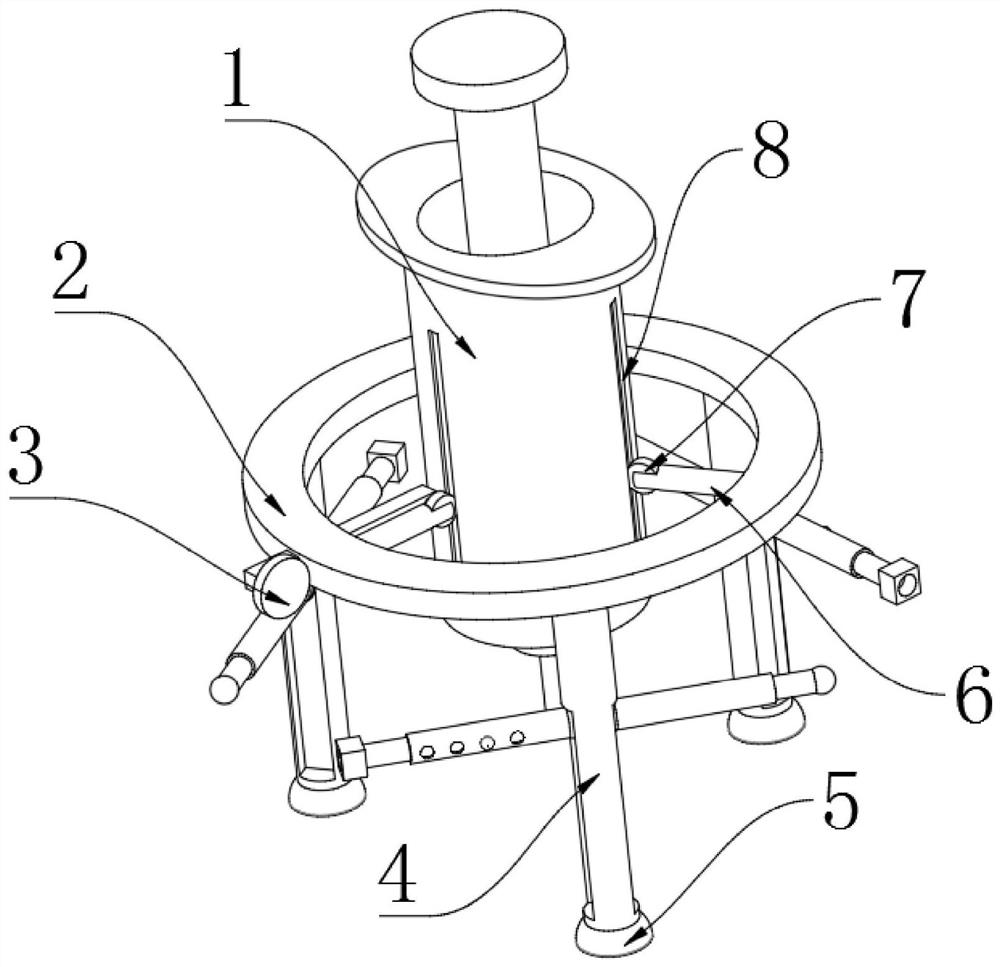

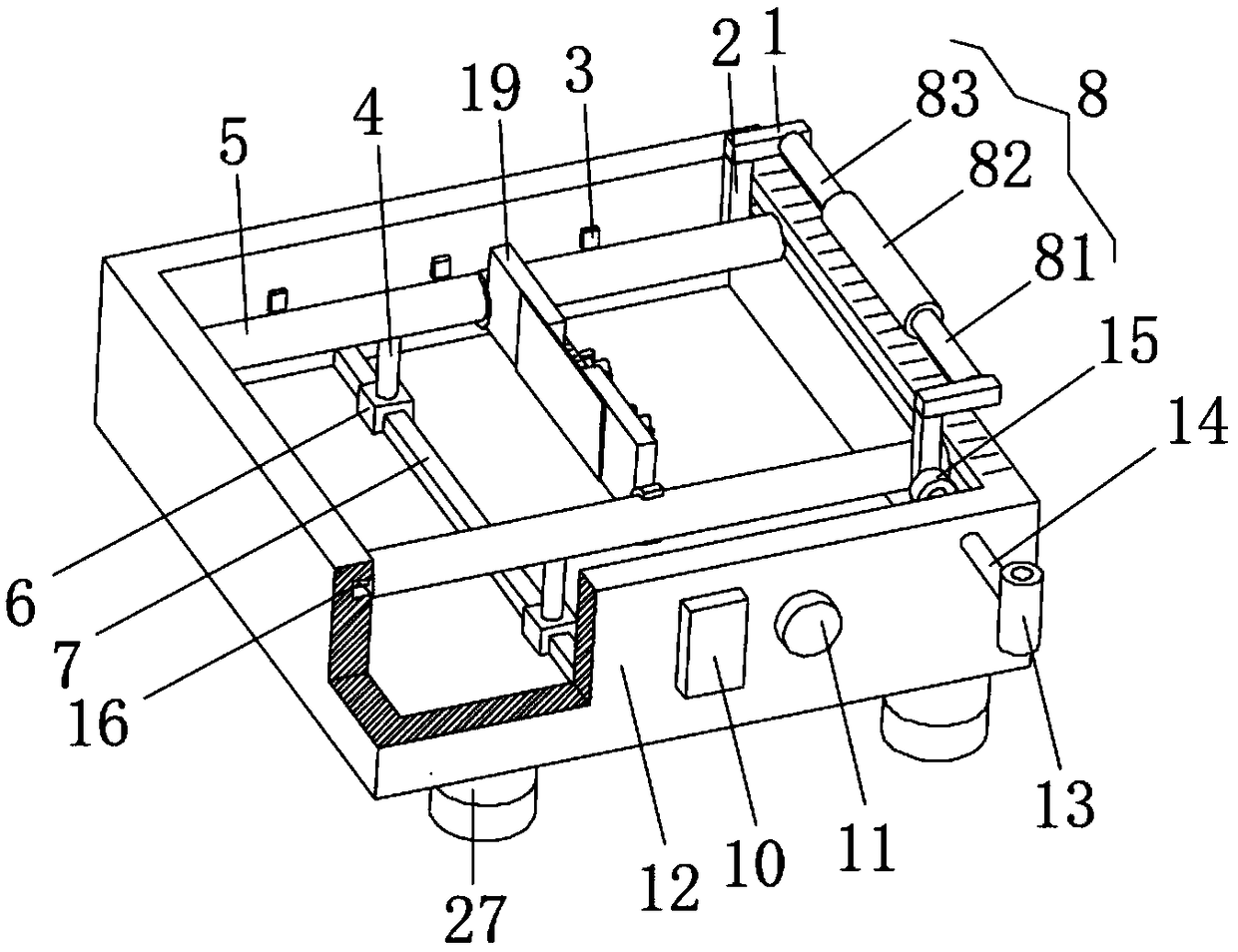

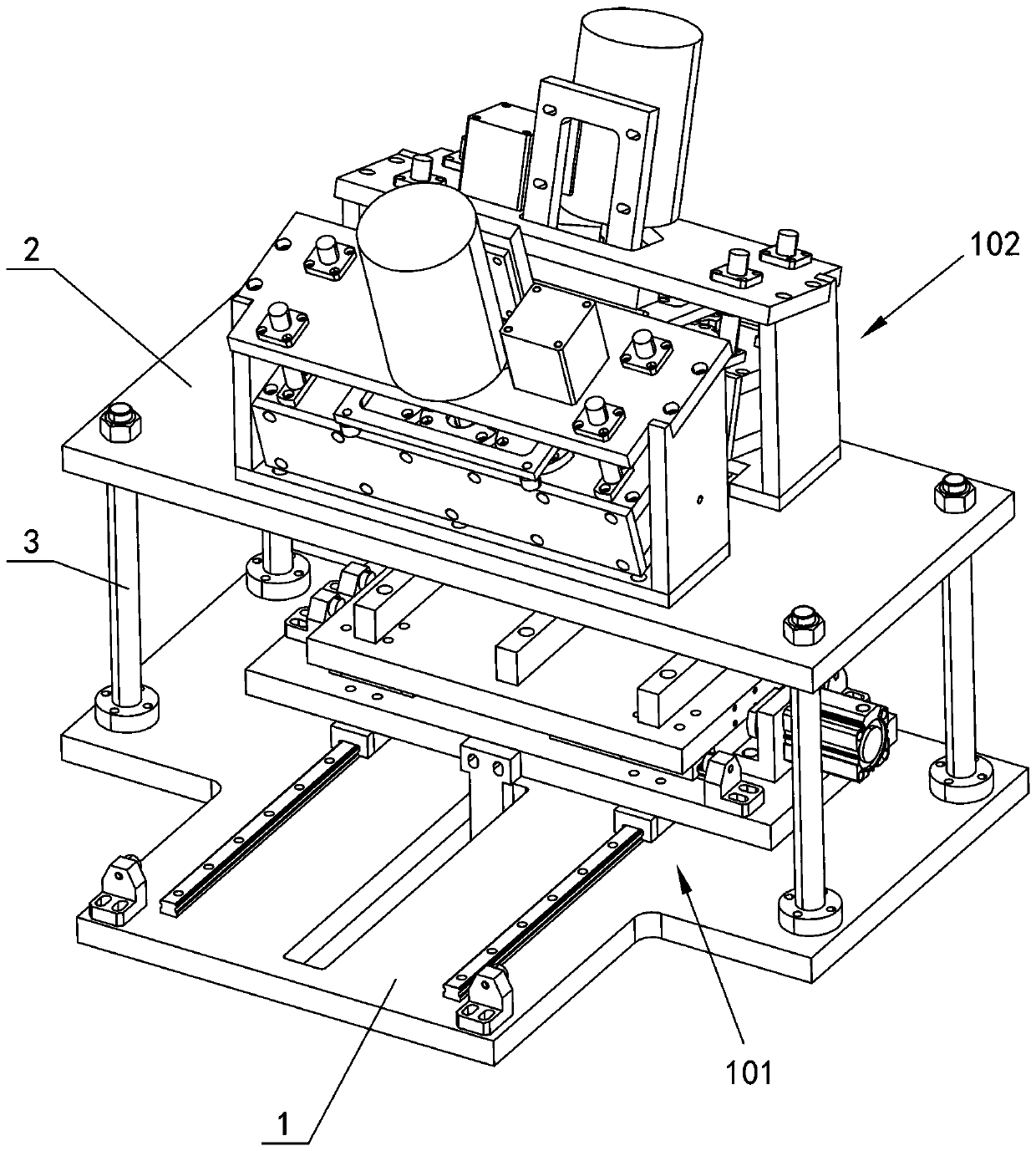

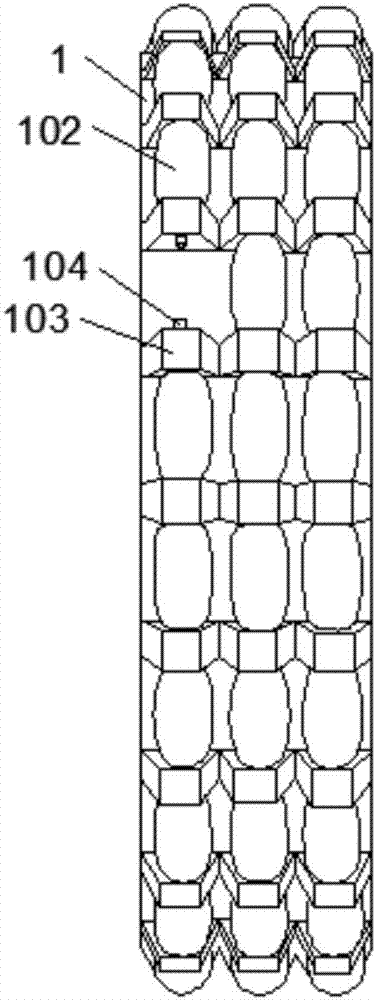

Anti-radiation medicine liquid injection robot with controllable liquid injection speed

PendingCN107050577APrecise Injection SpeedControllable injection speedAutomatic syringesIntravenous devicesMechanical componentsControl theory

The invention provides an anti-radiation medicine liquid injection robot with the controllable liquid injection speed. The anti-radiation medicine liquid injection robot is composed of two parts, including an intelligent controller and a mechanical component, wherein the mechanical component is characterized by being composed of the following parts: a base plate (1), a linear guide rail (2) fixed to the edge of the base plate, a slider (3) capable of sliding on the guide rail, a motor (4), a motor bracket (5) fixed to the base plate, a screw rod (6) with threads, a coupler (7) arranged between the screw rod and a motor shaft, a nut (8) matched with the screw rod, a bracket (9) fixed to the slider (3) and the nut (8), a push rod (10) fixed to the slider, a pressure sensor (11) at the front end of the push rod, a pushed end (12) of an injection pump piston, a horizontal semicylindrical injection pump limiting groove (13), arc-shaped limiting cover boards (14) provided with hinges and being capable of being turned over at the upper part of the injection pump, an injection pump (15), a motor rotation angle sensor (16), and an intelligent controller (17) positioned on the same straight line with the guide rail and the motor.

Owner:SHANGHAI UNIV OF MEDICINE & HEALTH SCI

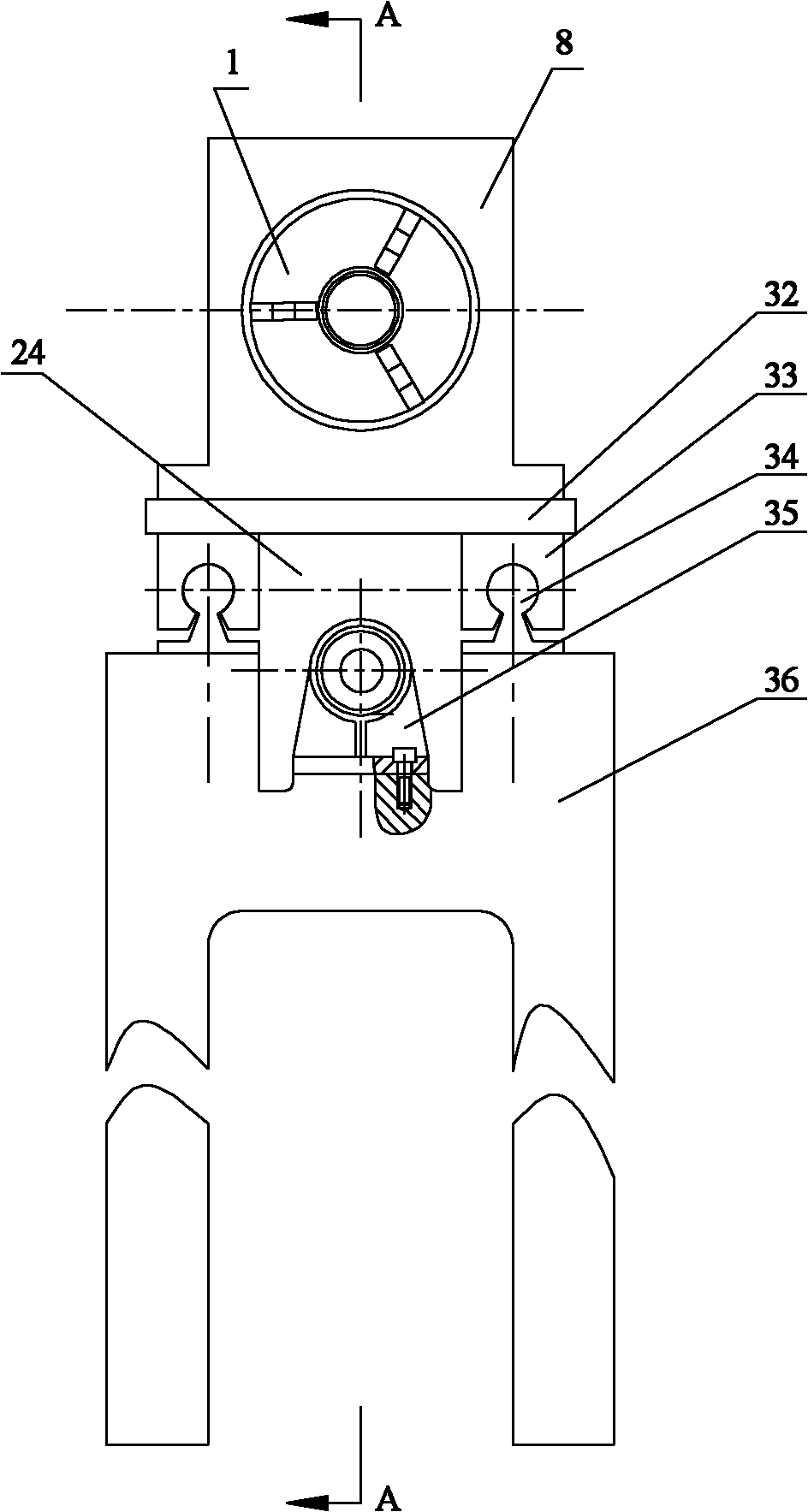

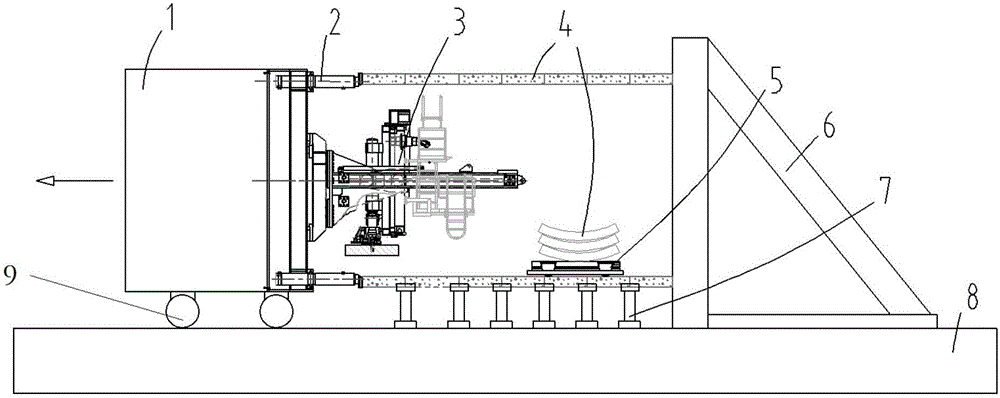

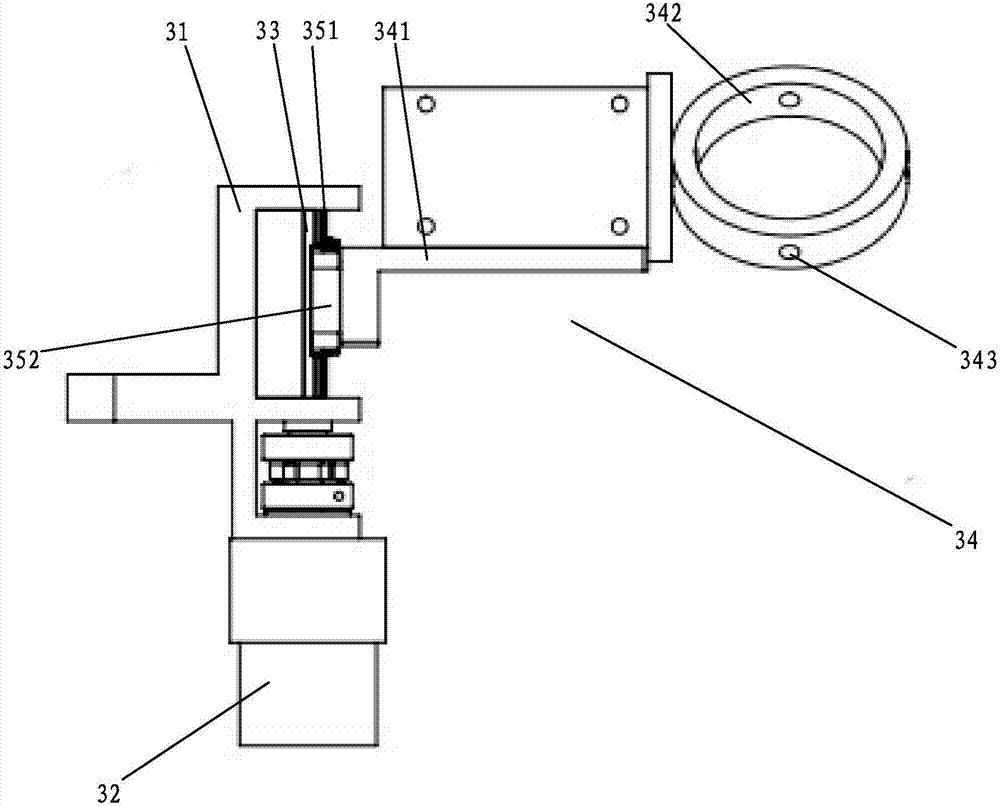

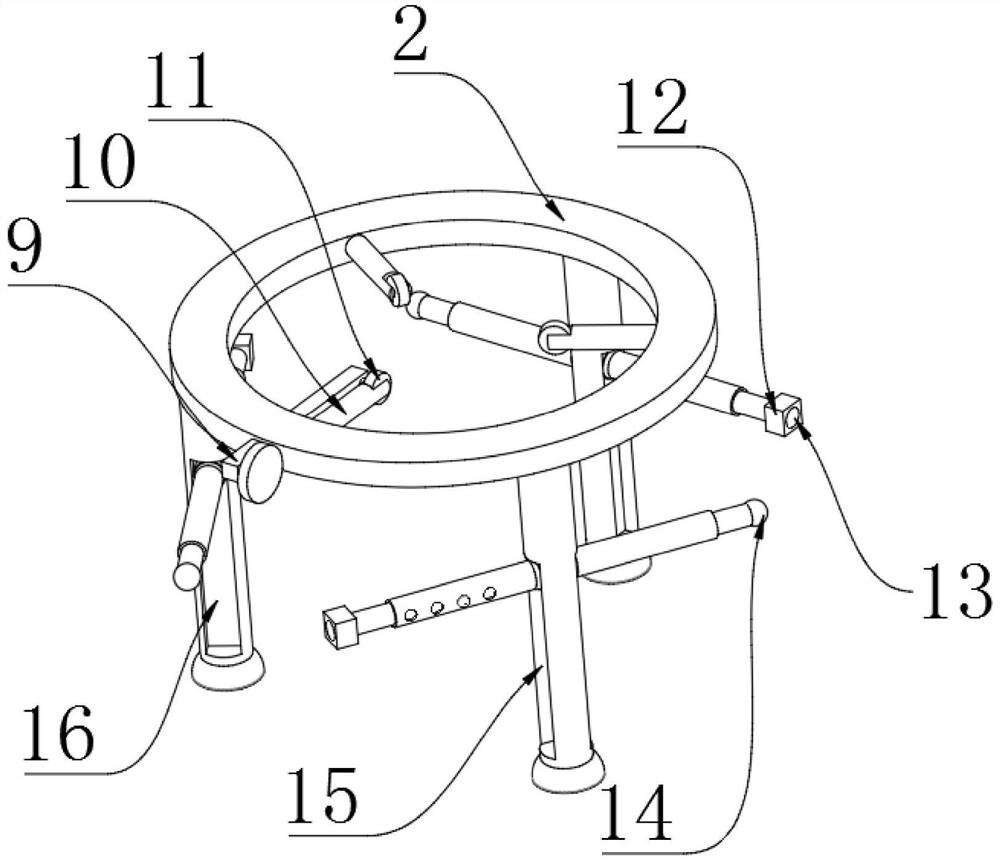

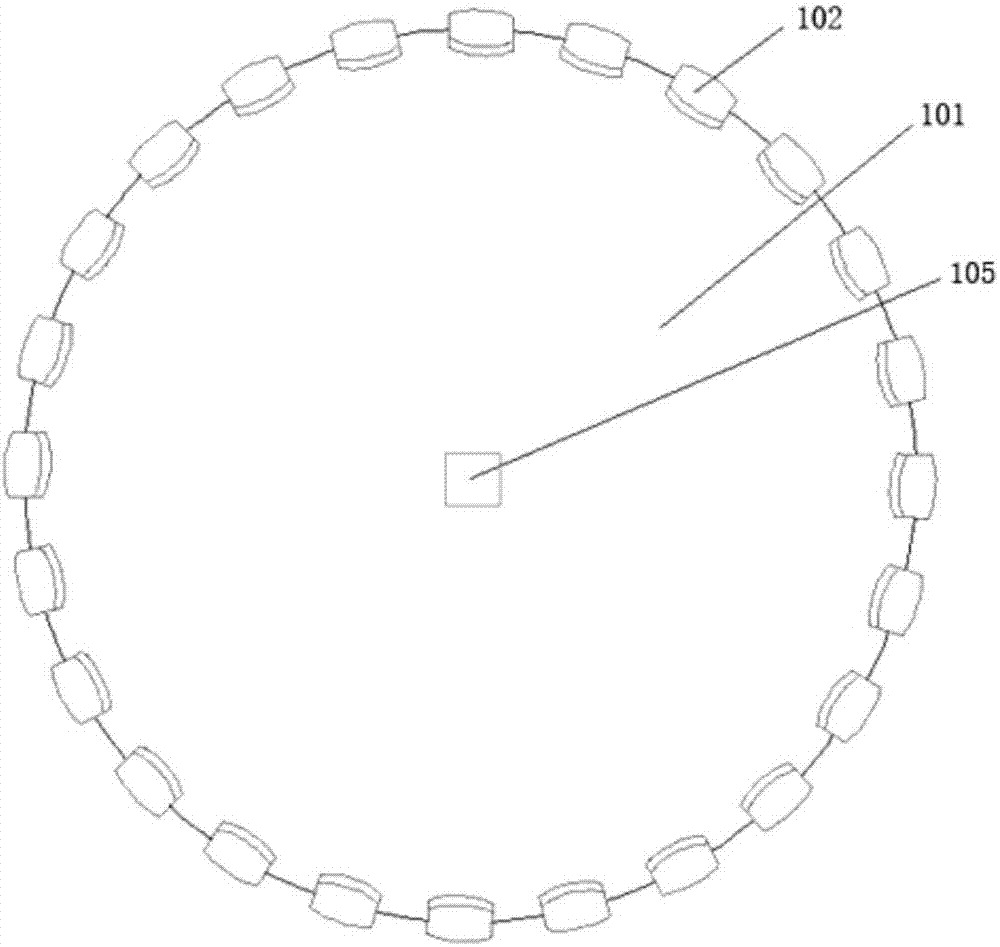

Duct piece assembly simulated experimental device

InactiveCN106522988AEasy to assembleAssembly precisionUnderground chambersTunnel liningPulp and paper industryAnnular duct

The invention discloses a duct piece assembly simulated experimental device, comprising a counterweight matter, a duct piece pushing counterforce bracket, a duct piece assembling machine, and a pushing cylinder; the duct piece assembling machine and the pushing cylinder are fixed at the same side of the counterweight matter, and the duct piece assembling machine is used for assembling the duct piece so as to form an annular tunnel; the pushing cylinder leans against the end part of the annular tunnel through own expansion, so as to push the counterweight matter to move. When one annular duct piece is assembled by the duct piece assembling machine, the pushing cylinder can make the duct piece assembling machine fixed on the counterweight matter to move through own expansion under the supporting of the end part of the annular tunnel and the duct piece pushing counterforce bracket; when the duct piece assembling machine is moved in place, the pushing cylinder can be contracted so as to assemble the next duct vat. The importance is that the simulated experimental device is good for constructors to understand and skillfully operate the duct vat assembly, and the assembling ability of constructor is further improved, the shield construction quality is improved, and working efficiency is promoted.

Owner:CENT SOUTH UNIV

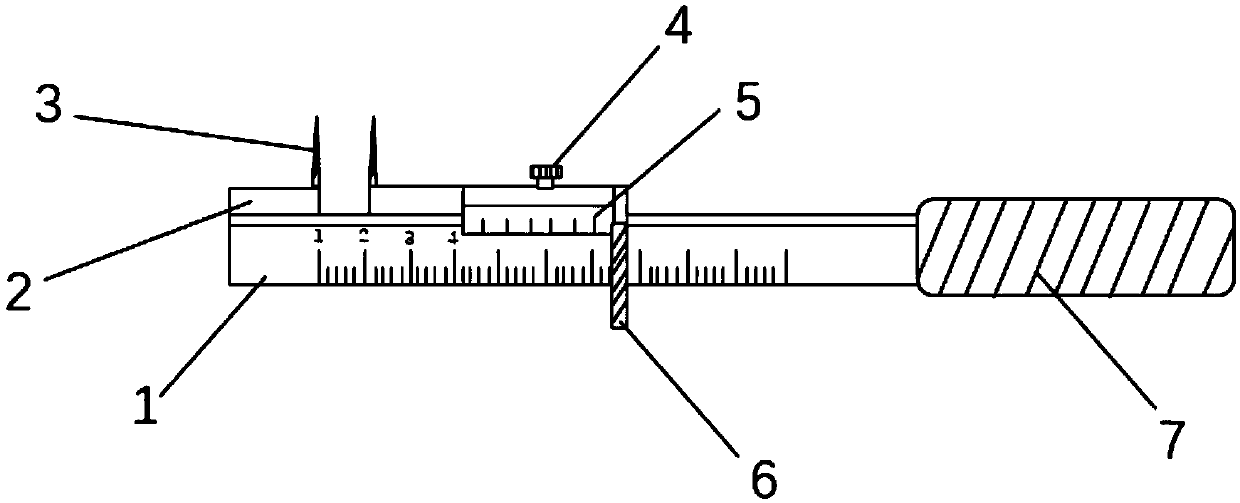

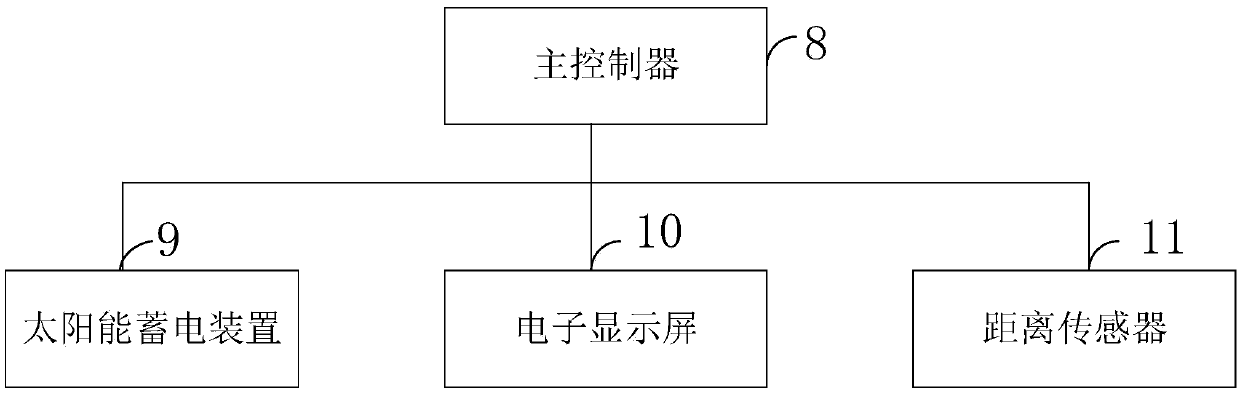

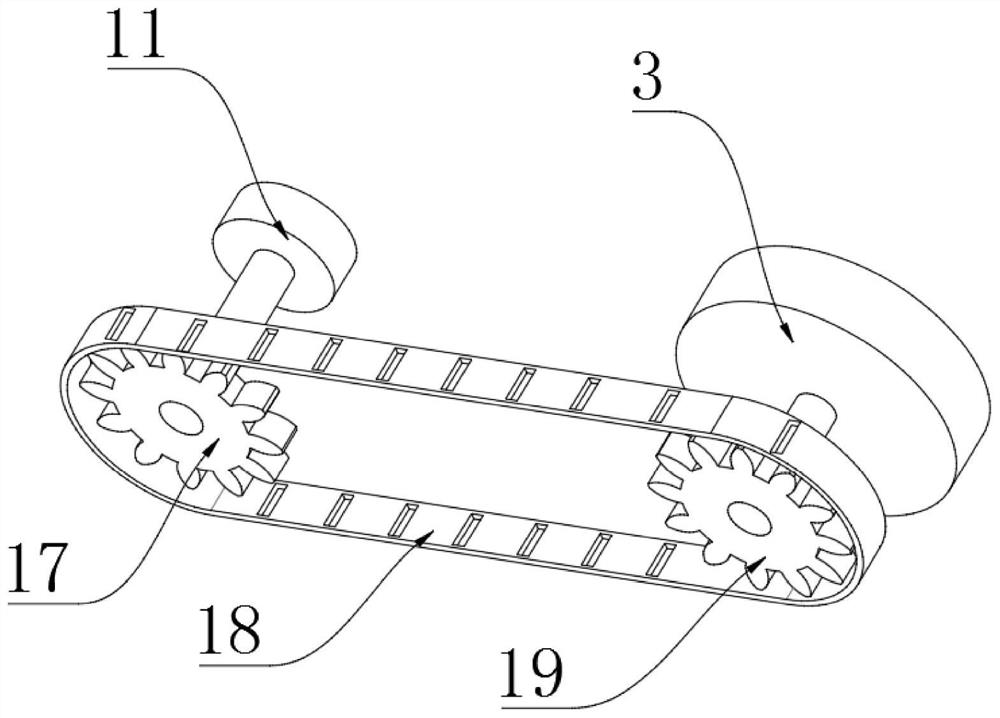

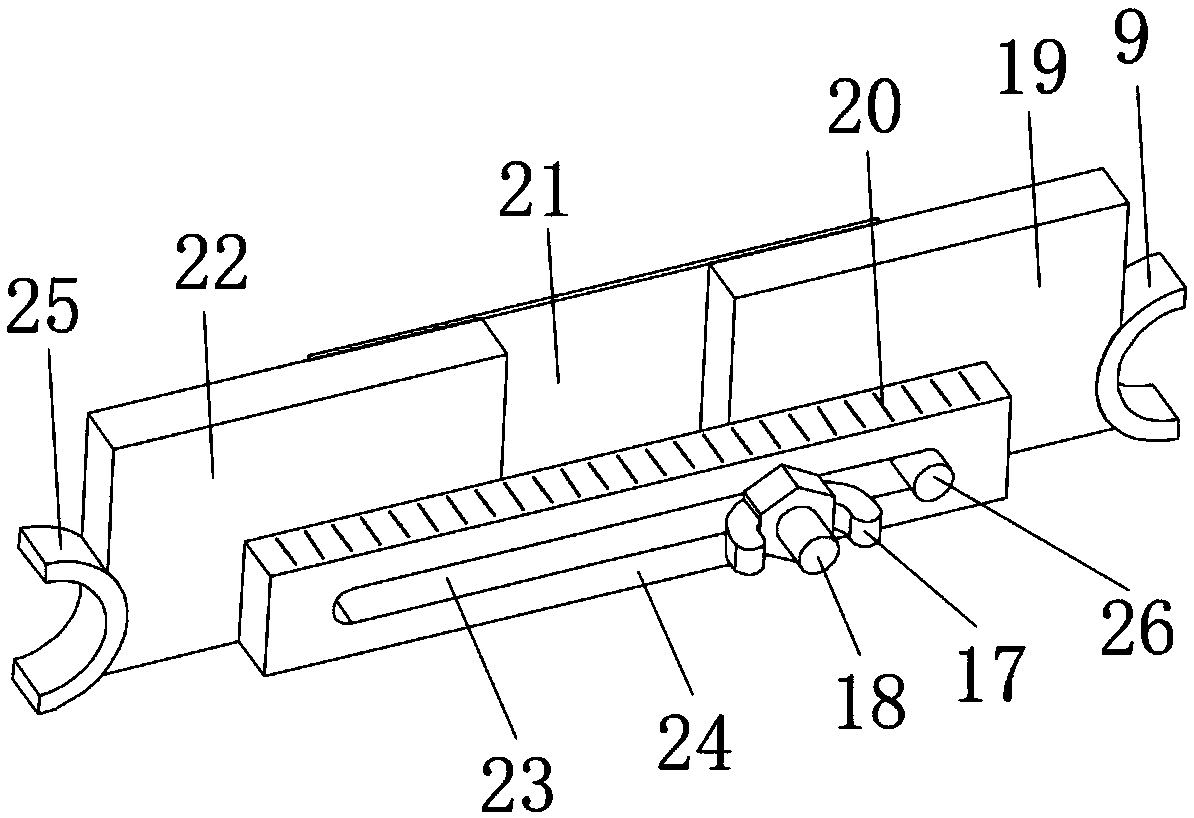

Knee joint tissue balance measuring device and method

InactiveCN108969153AEasy to holdEasy to recordMeasurement devicesJoint implantsPhysical medicine and rehabilitationKnee Joint

The invention belongs to the technical field of medical apparatus and instruments and discloses a knee joint tissue balance measuring device and method. The knee joint tissue balance measuring devicecomprises a ruler body and is characterized in that a slider sleeves the top of the ruler body and includes a left slider and a right slider, the left slider is fixed to the ruler body through a nut,the right slider is fixed to the ruler body through a fastening screw and can slide on the ruler body, a vernier scale is welded to the right side of the right slider, a push assisting rod is fixed tothe lower end of the vernier scale through a nut and sleeves the ruler body, the ruler body is welded to a handle, and a measuring jaw is welded to the top of the slider. By the knee joint tissue balance measuring device and method, the flexion-extension gap of knee joint soft tissue can be precisely measured, and whether the knee joint soft tissue is in a balance state or not can be determined from one aspect.

Owner:THE FIRST PEOPLES HOSPITAL OF NANTONG

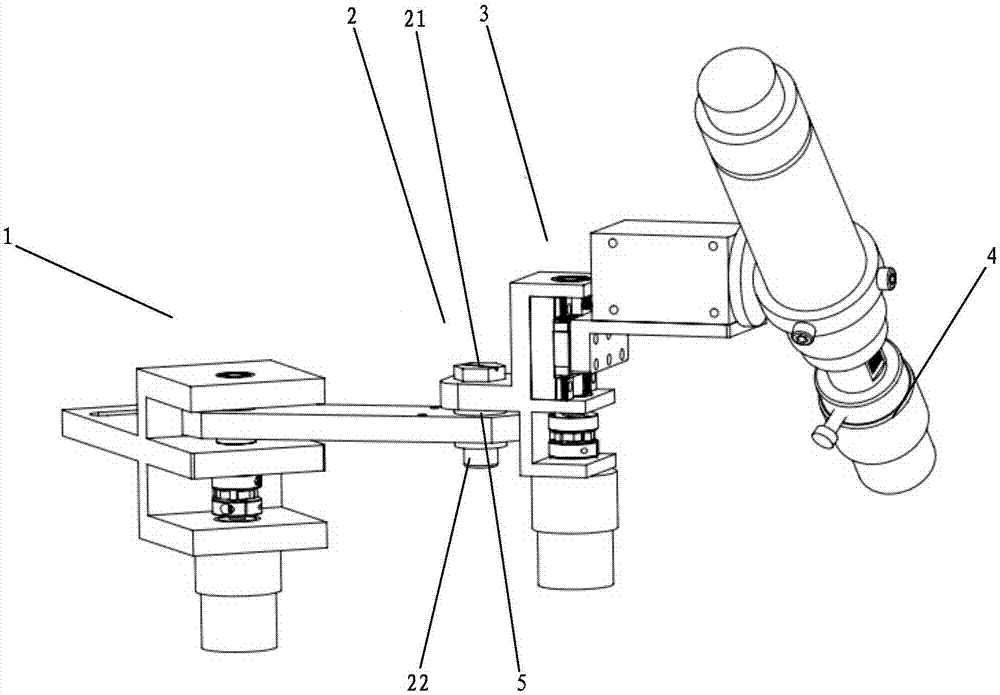

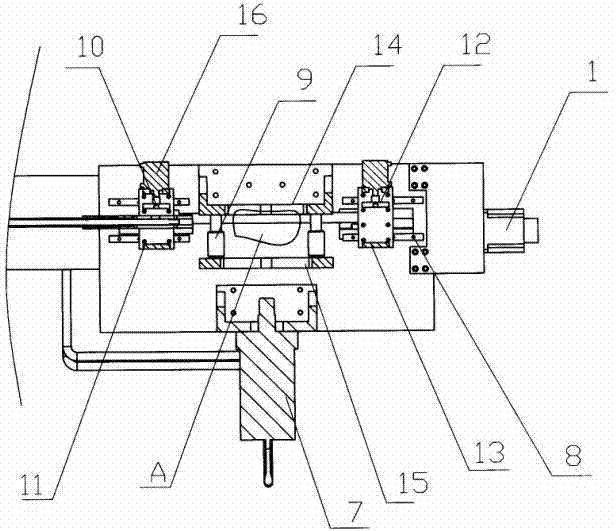

CCD fixture for micro-structure cutting machine tool

PendingCN107378644AEasy to adjustFlexible adjustmentMeasurement/indication equipmentsMicro structureEngineering

The invention discloses a CCD fixture for a micro-structure cutting machine tool. The CCD fixture comprises a horizontal adjusting device, a micro adjusting device and a vertical adjusting device. The horizontal adjusting device is connected with the vertical adjusting device through the micro adjusting device and drives the vertical adjusting device to move on a circular arc. The micro adjusting device controls the radius value of the movement circular arc of the vertical adjusting device. A CCD camera is installed on the vertical adjusting device. The vertical adjusting device drives the CCD camera to move in the vertical direction. According to the CCD fixture for the micro-structure cutting machine tool, the structure that rough adjusting is combined with fine adjusting, and rapid adjusting is combined with slow adjusting is adopted, thus, the CCD camera can be flexibly adjusted on the horizontal plane, adjusting is convenient and rapid, and the precision is high; the distance between the CCD camera and a shot object can be adjusted as required, so that the focal length of the CCD camera is adjusted; and the CCD fixture can be applied to working occasions with the requirements for long distance, so that the universality is high.

Owner:GUANGDONG UNIV OF TECH

Steel plate pre-bending device having disinfection function and used for clinical surgery of orthopedics department

The invention discloses a steel plate pre-bending device having a disinfection function and used for clinical surgery of the orthopedics department. The device comprises a right bottom plate, whereina first guide wheel and a second guide wheel are symmetrically mounted on front and back sides of the left end of the upper surface of the right bottom plate, a slide rail is arranged above the rightside of the upper surface of the right bottom plate in the front-and-back direction, front and back ends of the slide rail are fixedly connected with the right side of the upper surface of the right bottom plate through mounting supports, the slide rail is glidingly connected with a slide hole in a movable plate, a doctor can adjust the position of the movable plate on the slide rail and the leftward movement distance of a cylinder to bend a steel plate in specific position, and the operation is convenient. A liquid pump works to spray a disinfectant in a disinfectant box on the bent steel plate through a spray head, and the bent steel plate is convenient to disinfect. A waterproof vibrating motor works to drive a screen to drive the bent steel plate to shake up and down, the disinfectantattached to the bent steel plate is quickly separated, and the doctor is not required to wipe the steel plate, so that the workload of the doctor is reduced.

Owner:林雪琴

High-stability anesthesia injection device for leg surgery

InactiveCN112891681AAccurate movement distanceAvoid affecting the effect of anesthesiaAnaesthesiaInfusion syringesEngineeringLocal anesthesia

The invention discloses a high-stability anesthesia injection device for leg surgery, and relates to the technical field of local anesthesia injection. The problem that the injection depth is not accurate due to the fact that the injection depth of local anesthesia injection is subjectively judged by a medical worker is solved. The high-stability anesthesia injection device specifically comprises an injection needle tube and a bearing connecting ring, and sliding connecting grooves which are evenly distributed are formed in the outer wall of the periphery of the injection needle tube; uniformly-distributed driven connecting rods are fixedly connected to the inner wall of one side of the bearing connecting ring through screws; and driven rotating wheels are rotationally connected with the inner walls of one sides of the driven connecting rods. By arranging the driven connecting rods, the driven rotating wheels, driving connecting rods, driving rotating wheels and the sliding connecting grooves, the driven rotating wheels, the driving rotating wheels and the sliding connecting grooves in the injection needle tube rub to fix the injection needle tube, the moving distance of the injection needle tube is adjusted through rotation of the rotating wheels, so that the moving distance of the injection needle tube is more accurate, and the situation that the anesthesia effect is affected due to the fact that the anesthesia injection depth is poor due to subjective judgment of the medical worker is avoided.

Owner:景淑英

Full-automatic punching flanging device

The utility model relates to a fully automatic punching and flanging device, which relates to a compound device for punching and flanging a workpiece. The fully automatic punching and flanging device is composed of a console, a frame, a fuel tank, a front cylinder group, a rear cylinder group and a motor. It is characterized in that: the front cylinder group and the rear cylinder group are respectively installed at both ends of the Outside the frame, power is provided for the front oil cylinder group and the rear oil cylinder group respectively. The motor is installed on the outside of the end frame body of the front oil cylinder group, and the console is connected with the fuel tank and the motor respectively. The beneficial effects of the utility model are: the utility model designs the flanging punch to have a stepped or trapezoidal cross-section, which can complete the punching and flanging process at one time, with precise moving distance and high precision of the hole distance, and can continuously process the pipe. Punching and flanging, simple operation, high work efficiency and low production cost.

Owner:JIANGXI AVONFLOW HVAC TECH CO LTD

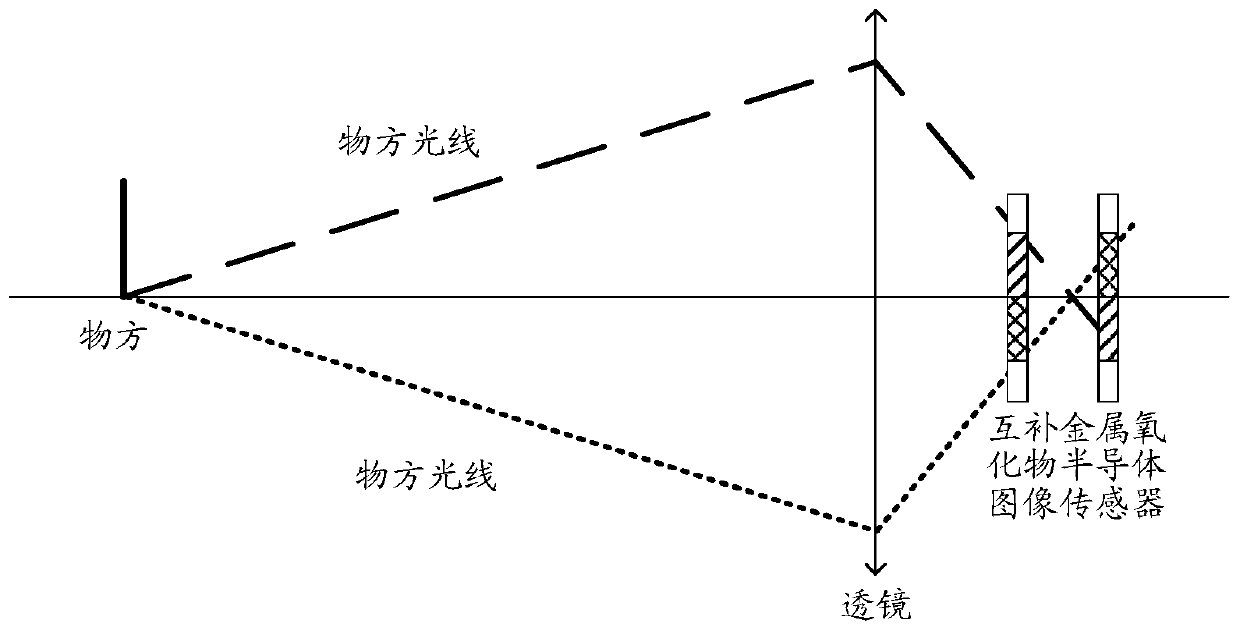

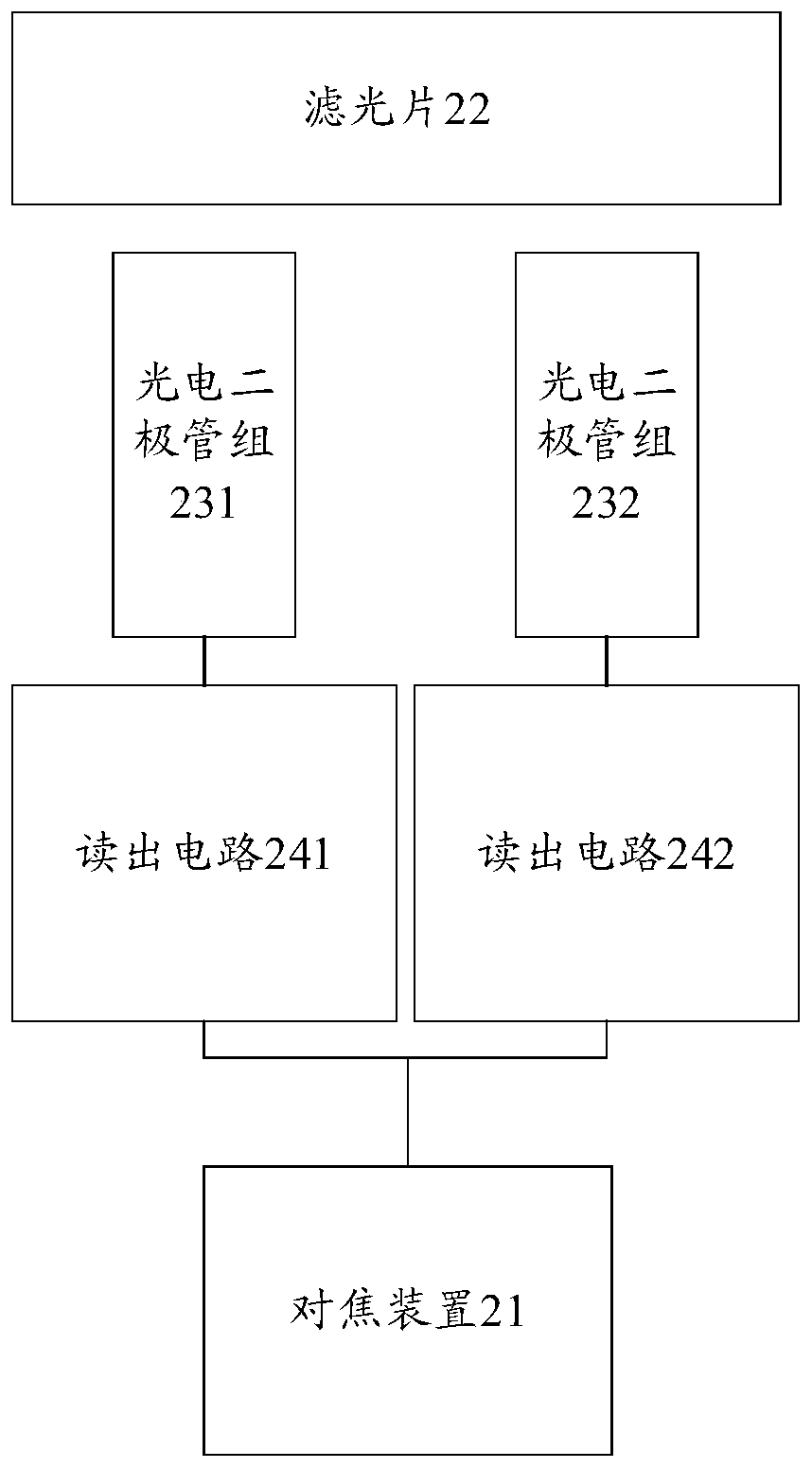

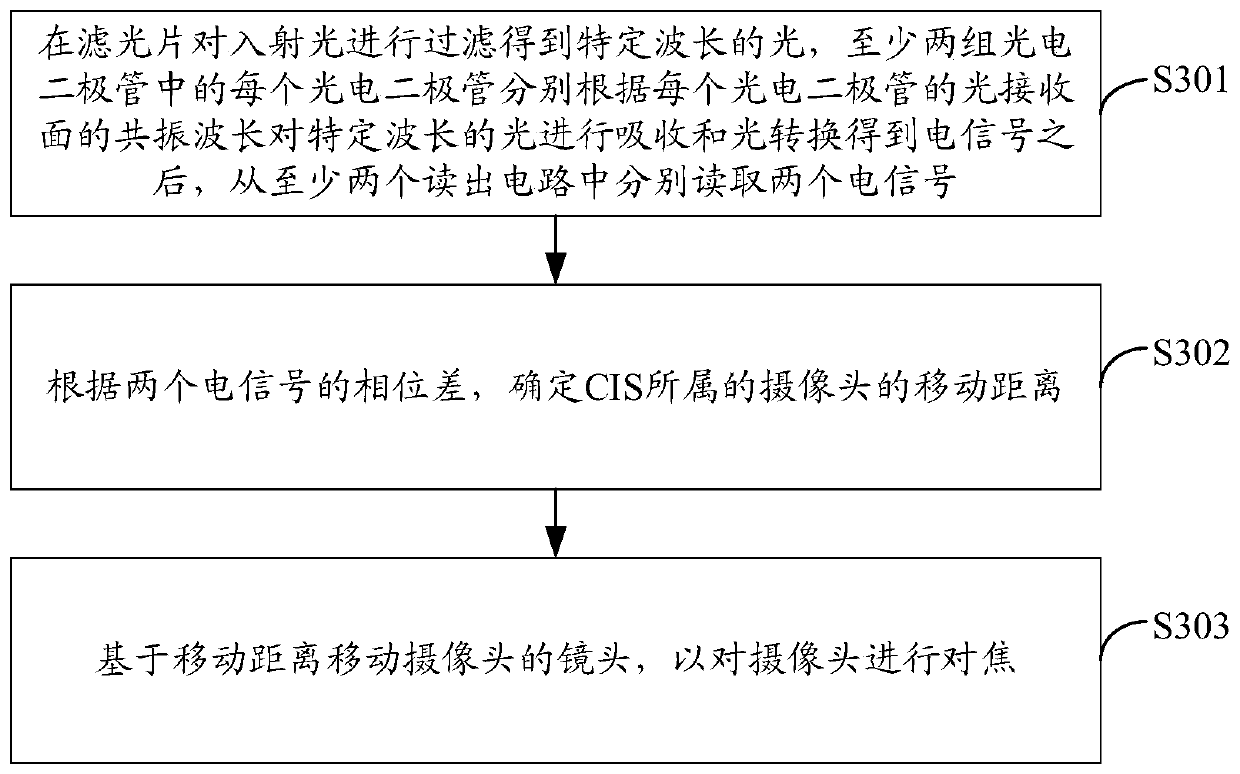

Focusing method and device, terminal and computer storage medium

ActiveCN110290328AImprove light absorptionImprove experienceTelevision system detailsColor television detailsCamera lensPhase difference

The embodiment of the invention discloses a focusing method. The method is applied to a focusing device, the focusing device is connected with a reading circuit of a pixel structure of a CIS, the pixel structure further comprises an optical filter and at least two sets of photodiodes, each set of photodiodes is correspondingly connected with one reading circuit, and an isolation region is arranged between each set of photodiodes; the method comprises the following steps of: oincident light is filtered by the optical filter to obtain light with a specific wavelength; each photodiode absorbs light with a specific wavelength and converts the light into an electric signal according to the resonant wavelength of the light receiving surface of each photodiode; two electric signals are read from the at least two reading circuits respectively, the moving distance of the camera to which the CIS belongs is determined according to the phase difference of the two electric signals, and the lens of the camera is moved based on the moving distance so as to focus the camera. The embodiment of the invention further provides a focusing device, a terminal and a computer storage medium.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Suspension type skimbar putting device

The invention relates to a suspension type skimbar putting device, which comprises a cantilever pole tilting device (10), a skimbar clamping device (13) and an energy medium system (3), wherein the energy medium system (3) is used for cooling the cantilever pole tilting device (10); the energy medium system (3) and a vehicle-mounted hydraulic station (5) are arranged on a rotating platform (15); the rotating platform (15) is arranged on a suspension platform (7) and is rotated relatively to the suspension platform (7); the suspension platform (7) is arranged on a walking platform (1); a walking driving device (2) is arranged on the walking platform (1); the suspension platform (7) is driven by the walking driving device (2) to move; and the vehicle-mounted hydraulic station (5) is used for driving the cantilever pole tilting device (10) and the skimbar clamping device (13) to operate. The suspension type skimbar putting device has a compact structure, is reliable to operate, and has high putting accuracy, and convenience in maintaining, overhauling and replacing easily damaged parts.

Owner:HUATIAN ENG & TECH CORP MCC

Adjustable cloth material playing and dyeing device

ActiveCN108978087APrevent rotationAvoid shakingTextile treatment carriersCotton materialComputer engineering

The invention discloses an adjustable cloth material playing and dyeing device. The device comprises a rectangular box body and a first fixing board. The left side surface and the right side surface in the interior of the box body are slidably connected with left and right ends of two support rods which are arranged on a same horizontal plane. The two support rods are arranged in parallel. The left side surface and the right side surface on the inner wall of the rectangular box body are equipped with limit grooves along forward-backward direction. The left and right ends of each support rod are fixed with sliding clamp blocks. The sliding clamp blocks are slidably connected with the limit grooves on the inner wall of the rectangular box body. Right ends on the outer side surfaces of the two support rods are fixedly connected with lower ends of two vertical rods. The distances between the two support rods and positions of the two support rods are convenient to adjust. Therefore, the device is more applicable. Dyeing effect of cloth material is ensured. By means of support columns, sliding blocks and limit sliding rods, stability during movement of the support columns is ensured. Thepossibility of cloth material sliding and falling down from the support rods is lowered.

Owner:永春县产品质量检验所福建省香产品质量检验中心国家燃香类产品质量监督检验中心福建

Automatic feeding device for preassembled movable vanes

InactiveCN107127549AAccurate movement distanceAvoid feeding errorsMetal working apparatusEngineeringPush out

Owner:UNIV OF SHANGHAI FOR SCI & TECH

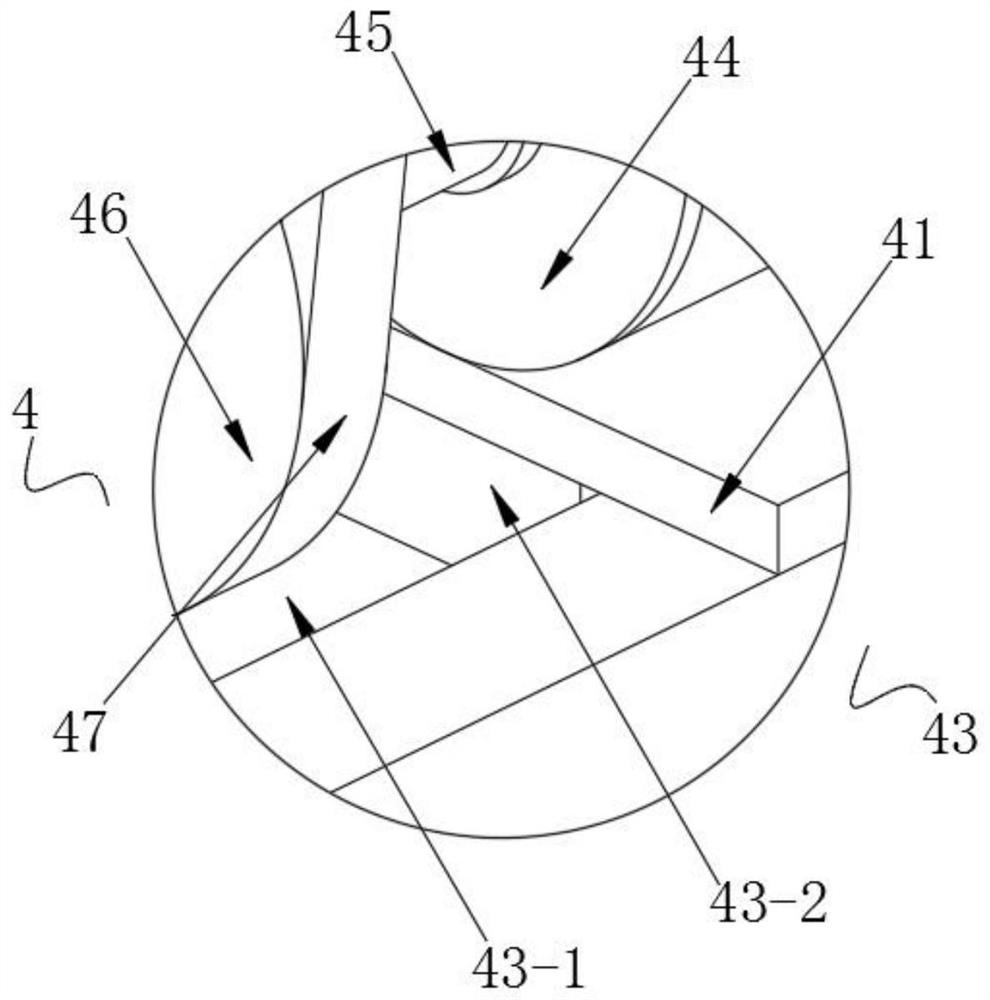

Cylinder cover valve seat ring valve wire grinding and flapping machine

PendingCN110640466APlay a guiding roleAccurate movement distanceOther manufacturing equipments/toolsGrinding feedersGear wheelElectric machinery

The invention provides a cylinder cover valve seat ring valve wire grinding and flapping machine. The cylinder cover valve seat ring valve wire grinding and flapping machine comprises a lower fixed plate and an upper fixed plate; supporting rods are connected between the upper fixed plate and the lower fixed plate; a cylinder cover locating movable device is arranged on the lower fixed plate; twogroups of rotary lifting devices in a front and back manner are arranged on the upper fixed plate; the rotary lifting devices comprise brackets; mounting plates are arranged on the brackets; reciprocating air cylinders are arranged on the mounting plates; the reciprocating air cylinders are connected with gear boxes; fixed frames are arranged on the gear boxes; motors are arranged on the fixed frames; driving gears and synchronizing gears are arranged in the gear boxes; synchronizing gears are connected with rotating shafts; the lower ends of the rotating shafts penetrate through the gear boxes; outer sleeves sleeve the lower ends of the rotating shafts; bases are arranged at the lower parts of the outer sleeves; oblique bumps are arranged on the bases; oblique guide surfaces and straightsurfaces are arranged on the oblique bumps; slots and limiting grooves are formed in the lower ends of the rotating shafts; rotating rods are arranged in the slots; limiting pins and sliding pins arearranged on the outer walls of the rotating rods; springs are arranged at the parts, located at the upper parts of the limiting pins, of the outer walls of the rotating rods; the sliding pins of the rotating rods are in fit with the oblique guide surfaces of the oblique bumps; sucking discs are arranged at the lower ends of the rotating rods; and the lower ends of the sucking discs and valve rodsare sucked.

Owner:ZHEJIANG NUOKEN MASCH TECH CO LTD

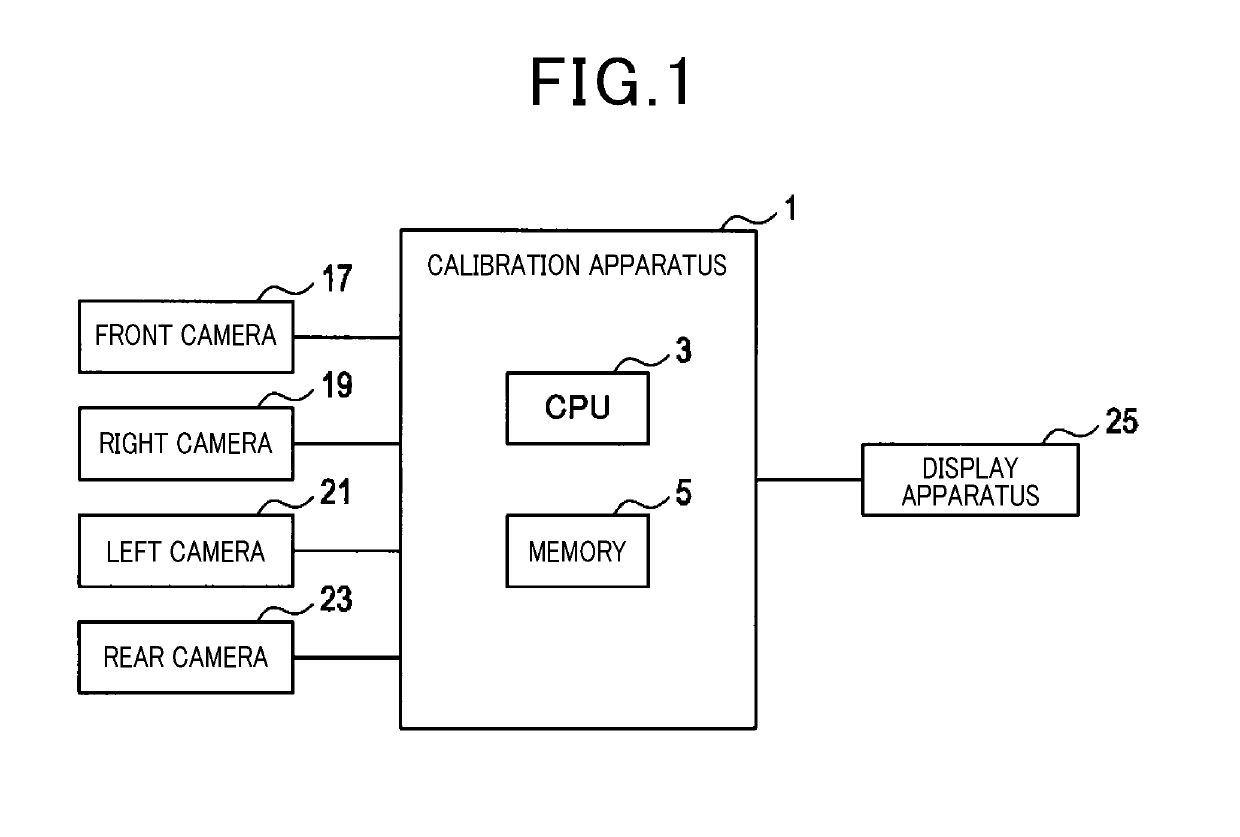

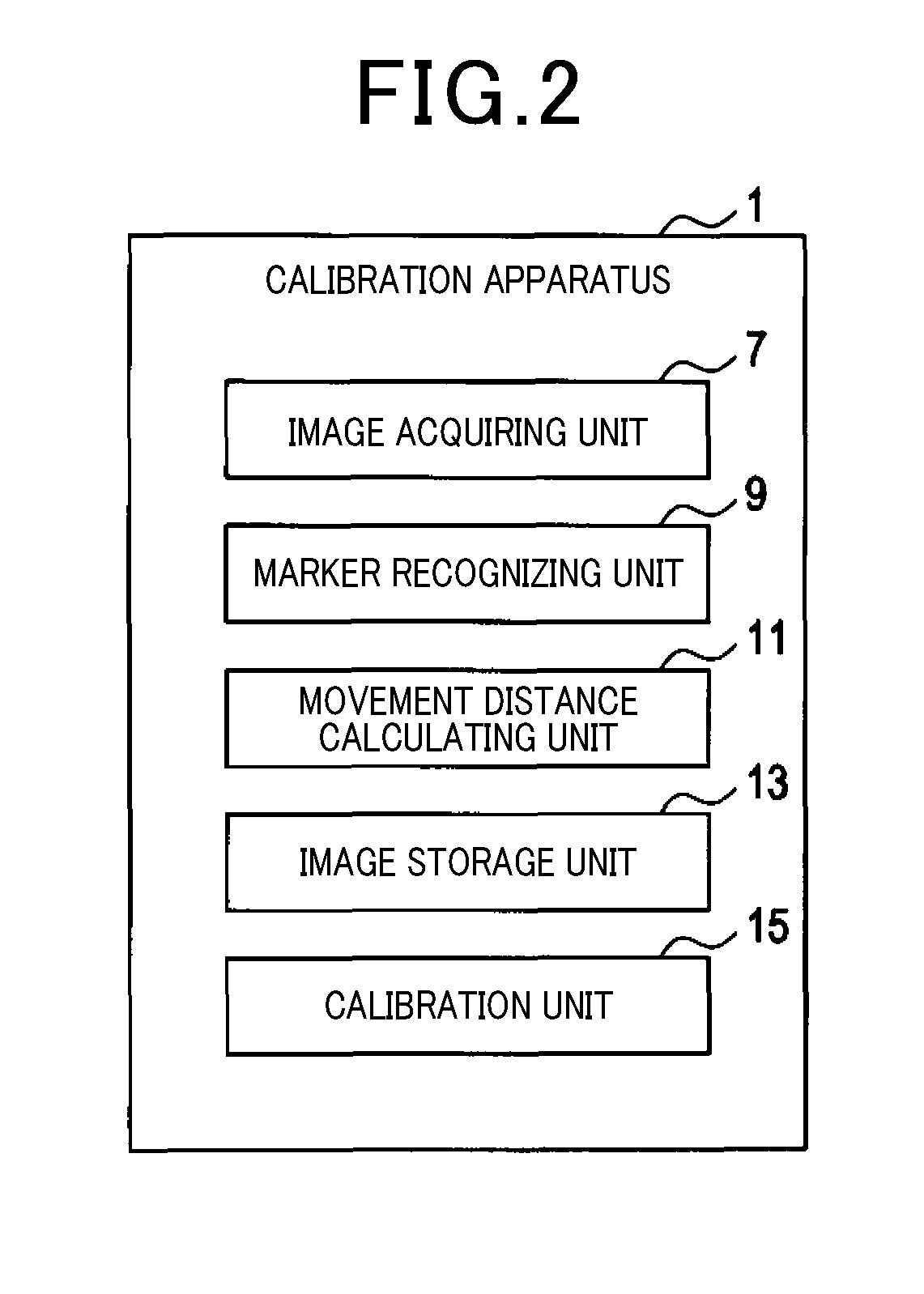

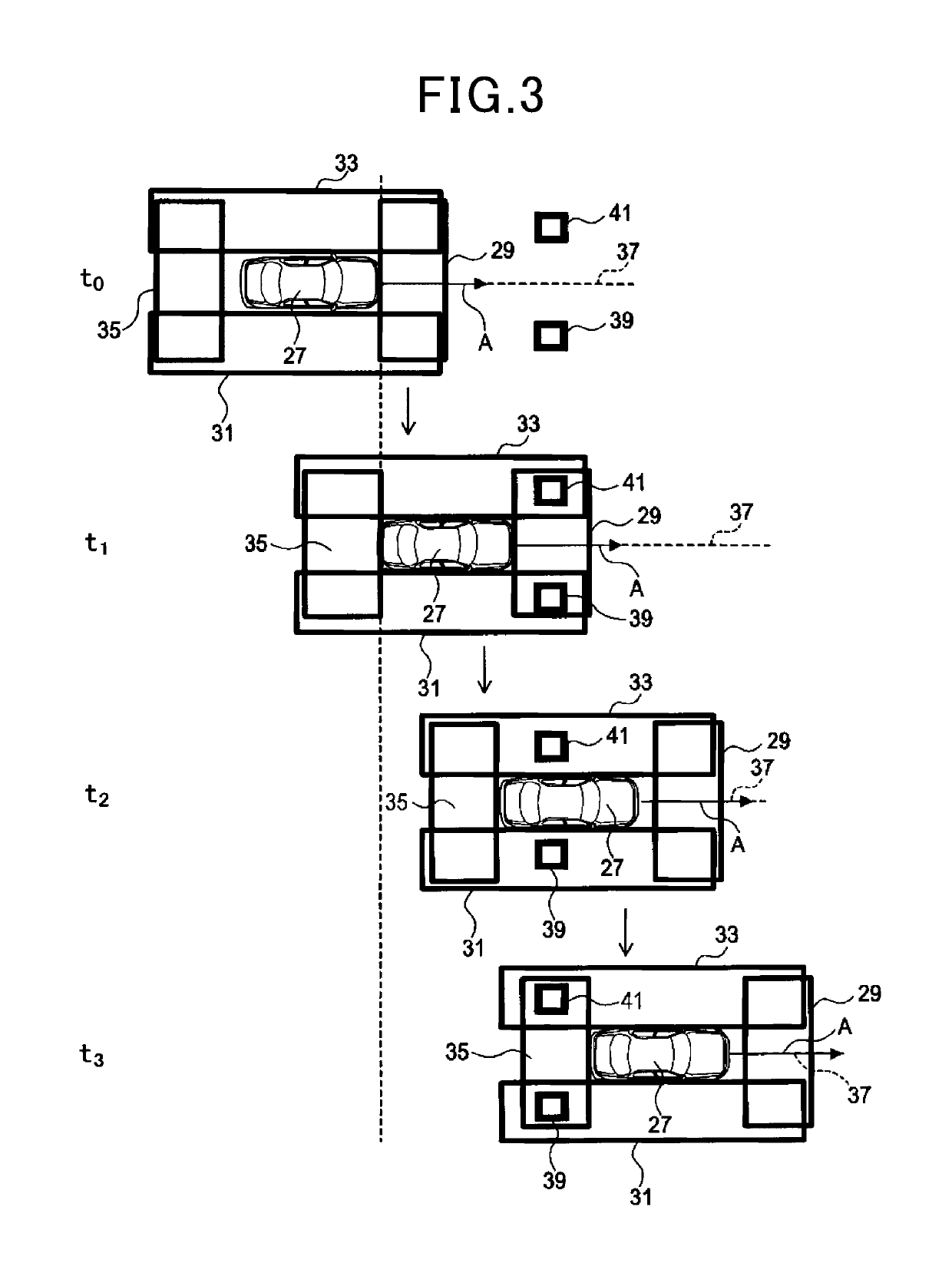

Calibration apparatus for onboard camera and calibration method for onboard camera

ActiveUS20190259180A1Reduce in quantityReduce the numberTelevision system detailsImage enhancementComputer graphics (images)In vehicle

A calibration apparatus for an onboard camera includes an image acquiring unit, a marker recognizing unit, a movement distance calculating unit, an image storage unit, and a calibration unit. The movement distance calculating unit calculates a movement distance of a vehicle based on a number of times that a process in which a first feature portion in a marker moves to a position overlapping a second feature position in the marker in the image is repeated. The image storage unit stores a specific image that includes the marker. The calibration unit calibrates the onboard camera using the specific image. The image storage unit stores, as the specific image, (a) the image in which the marker is recognized, and (b) the image acquired when the movement distance from a position of the vehicle when the specific image has been acquired in the past reaches a predetermined distance.

Owner:DENSO CORP

Numerical control relief grinding machine

PendingCN110948054AChange distanceControl the moving distanceLarge fixed membersNumerical controlElectric machinery

The invention relates to the technical field of machining, and discloses a numerical control relief grinding machine. The numerical control relief grinding machine comprises a base, a stand column, arelieving mechanism, a first guide mechanism, a first power mechanism, a workbench, a second guide mechanism and a second power mechanism, wherein the relieving mechanism comprises a backed-off cutterand is connected to the stand column through the first guide mechanism, the guide direction of the first guide mechanism is the same as the height direction of the stand column, the first power mechanism comprises a first motor and a first transmission piece, the first transmission piece is connected with the relieving mechanism to drive the relieving mechanism to move, the guide direction of thesecond guide mechanism is the same as the length direction of the base, the workbench is connected to the base through the second guide mechanism, the second power mechanism comprises a second motorand a second transmission piece connected with the second motor, and the second transmission piece is connected with the relieving mechanism to drive the relieving mechanism to move. According to themachine, the problems that in the prior art, the relief grinding machine is driven by the hydraulic driving, so that positioning precision is poor, the temperature is influenced, the safety is not high and the like are solved.

Owner:东莞微航实业有限公司

High-precision positioning omnidirectional wheel

PendingCN107984967AHigh precisionExtended service lifeNon-metallic wheel bodyMotion directionDrive wheel

Owner:NEIJIANG NORMAL UNIV

Lead screw nut mechanism

InactiveCN113551108AEasy to useAvoid weightGearingGear lubrication/coolingTransmission beltElectric machinery

The invention discloses a lead screw nut mechanism. The lead screw nut mechanism comprises a supporting plate, wherein fixed plates are fixedly connected to the two ends of one side of the supporting plate; a lead screw is fixedly connected between the opposite sides of the two fixed plates; a transmission mechanism is arranged on the outer surface of the lead screw; a lubricating mechanism and a clamping mechanism are arranged in the transmission mechanism; the transmission mechanism comprises a movable plate and a movable block; and one side of the movable plate is in sliding connection with the supporting plate through a sliding piece. The invention relates to the technical field of lead screw nuts. According to the lead screw nut mechanism, the transmission mechanism is arranged, a motor is used for driving a rotating shaft to rotate, and transmission of a first transmission wheel, transmission of a transmission belt and transmission of a second transmission wheel are matched, so that the lead screw rotates; and through sliding supporting of a sliding groove and a sliding block, the lead screw nut mechanism is prevented from completely bearing the weight of machining equipment in the using process, long-term use of the lead screw can be kept, and the moving distance of the machining equipment can be better and accurately adjusted.

Owner:襄阳海斌机电有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com