High-precision positioning omnidirectional wheel

An omnidirectional wheel, high-precision technology, applied in the field of omnidirectional wheels, can solve the problem of low movement accuracy of omnidirectional wheels, achieve good printing effect, improve movement accuracy, and meet the effect of high-precision movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

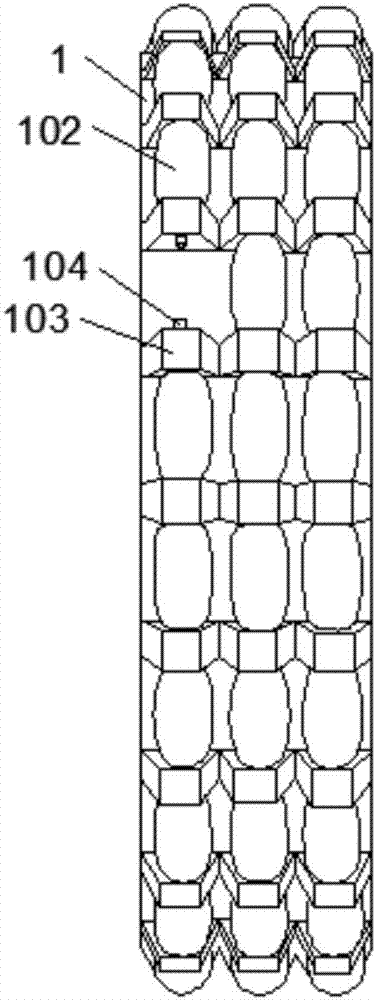

[0036] An omnidirectional wheel with high precision positioning, including a hub 101, a support frame 103 is arranged on the outer circumference of the hub 101, and the support frame 103 and the hub 101 are injection molded, using high-strength hard plastic;

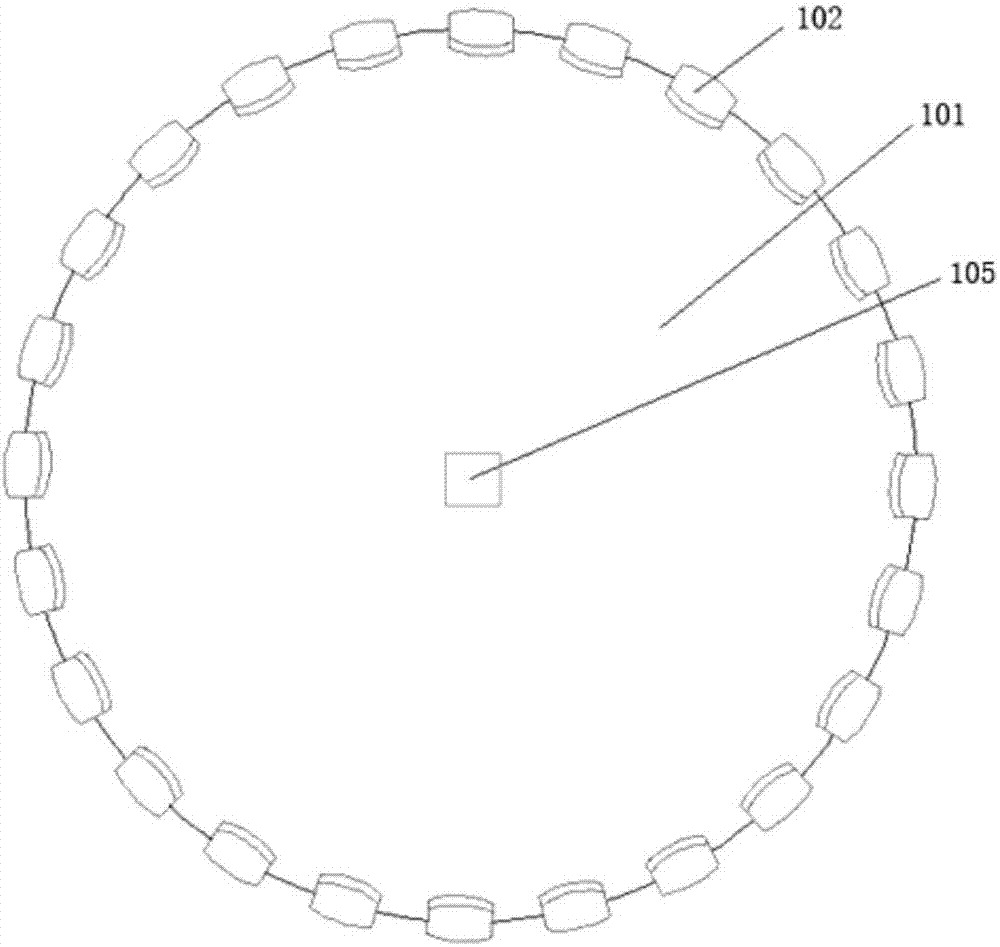

[0037] The supporting frame 103 is provided with a driven wheel 102, and the driven wheel 102 adopts high-strength elastic plastics to improve the frictional force of the driven wheel 102; 3 rows of driven wheels 102 are arranged on the outer circumference of the wheel hub 101; the radius of the wheel hub 101 The length of the driven wheel 102 is 8 mm, and the number of driven wheels 102 on each row of driven wheels is 24. The surface of the driven wheel 102 is provided with lines 106 along the moving direction of the driven wheel 102 .

specific Embodiment 2

[0038] Utilizing the high-precision positioning omni-directional wheels, a high-precision positioning omni-directional wheel set is further proposed, including two sets of omni-directional wheels, each set of omni-directional wheels includes 2 omni-directional wheels connected by axle 5, two sets of omni-directional wheels The steering wheel is installed in a "ten" structure;

[0039] The connection mode is as follows: comprise connecting nut 2, nut 4 and axle shaft 5, described connecting nut 2 junction is square, and junction is provided with threaded hole 3, and axle shaft 5 two ends are respectively provided with thread, and described thread and thread The hole 3 is matched, and the center of the hub 101 is provided with a square hole 105, and the square hole is matched with the joint of the connecting nut 2, and a nut 4 is arranged between the axle 5 and the hub 101 to fix the hub 101; adopt this structure , using the square hole 105 and the nut 4, the positioning and fix...

specific Embodiment 3

[0041]According to the specific embodiment 2, a high-precision omnidirectional wheel set is provided, and a high-precision mobile trolley is further provided. The mobile trolley includes a housing 6, and a high-precision cross-section is arranged under the housing 6 in the shape of a "cross". The omnidirectional wheel set A7 and the omnidirectional wheel set B8, the omnidirectional wheel set A7 and the omnidirectional wheel set B8 respectively include two identical omnidirectional wheels and the omnidirectional wheels are connected by the axle 5, the omnidirectional wheel set The wheel hubs 101 of A7 and omnidirectional wheel set B8 are different in size so that the two axles 5 are located on different horizontal planes. The omnidirectional wheel set A7 is driven by the drive motor A9, and the omnidirectional wheel set B8 is driven by the drive motor B10.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com