CCD fixture for micro-structure cutting machine tool

A cutting machine tool and microstructure technology, which is applied in the field of CCD fixtures, can solve the problems of inability to adapt, small range of CCD movement, poor adjustment accuracy and ease of use, and achieve the effects of fast precision, high versatility, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

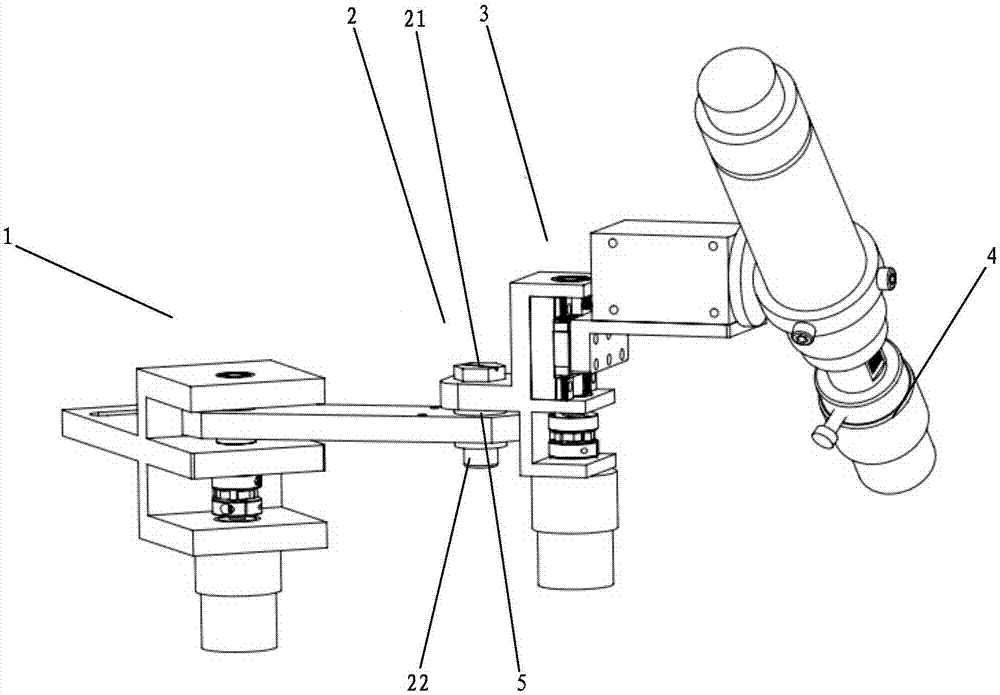

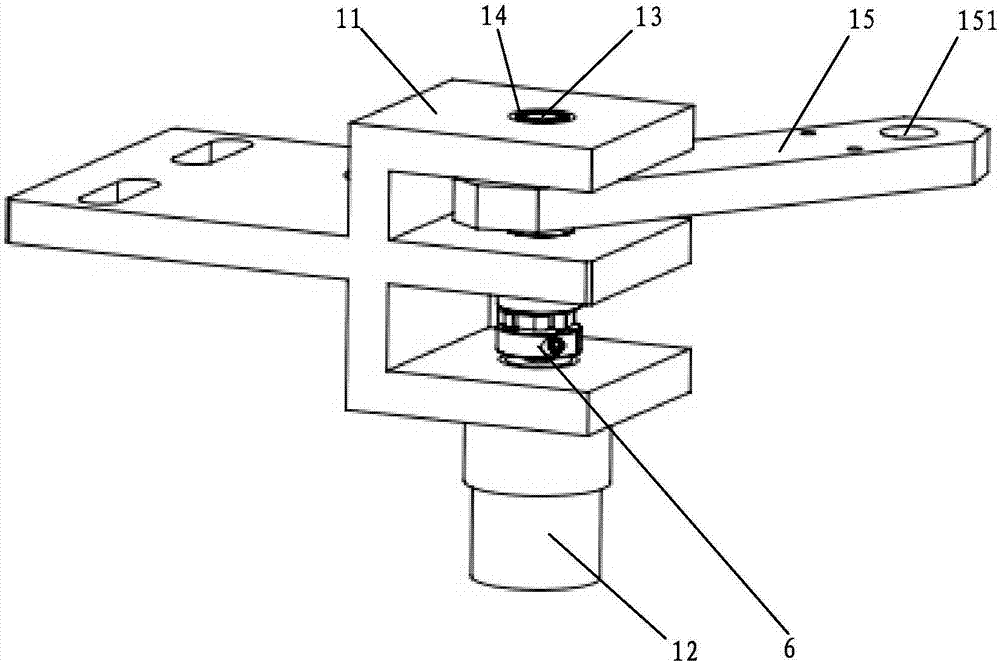

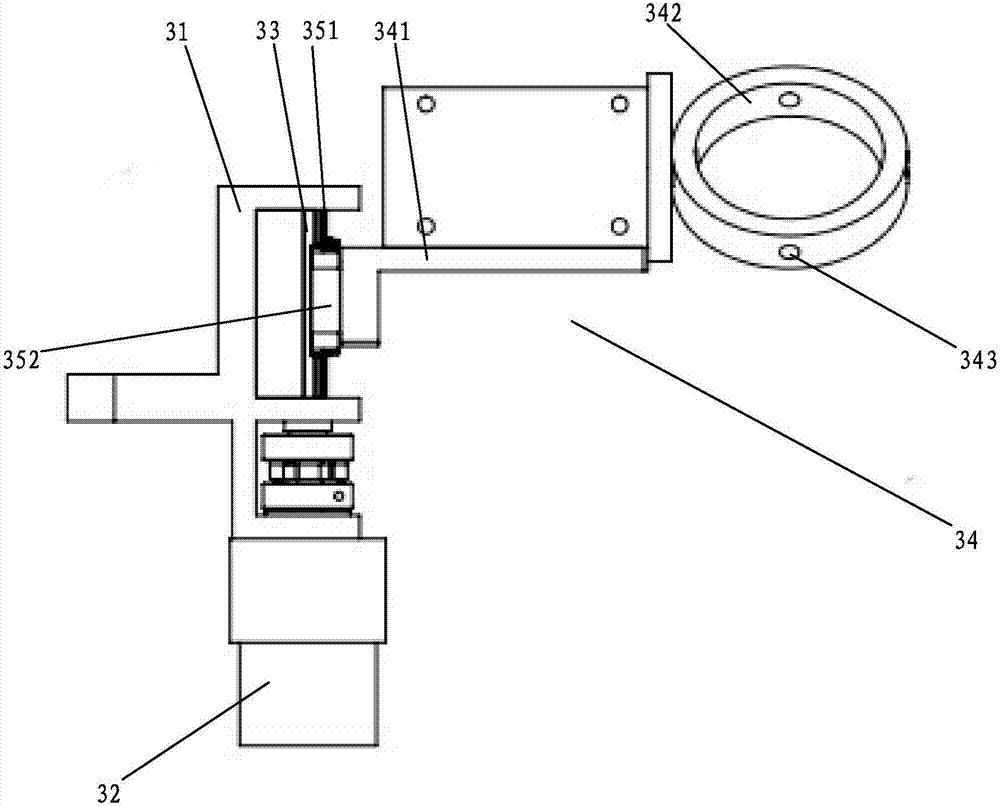

[0027] refer to figure 1 , the present embodiment relates to a fixture, including a horizontal adjustment device 1, a fine adjustment device 2 and a vertical adjustment device 3, the horizontal adjustment device 1 is connected with the vertical adjustment device 3 through the fine adjustment device 2; the horizontal adjustment device 1 drives the vertical adjustment device 3 to move on an arc; the micro-adjustment device 2 controls the radius value of the motion arc of the vertical adjustment device 3; a CCD camera 4 is installed on the vertical adjustment device 3; The straight adjusting device 3 drives the CCD camera 4 to move in the vertical direction.

[0028] The horizontal adjustment device 1 drives the vertical adjustment device 3 to move on the track of a semicircle through the micro adjustment device 2, so that the CCD camera 4 installed on the vertical adjustment device 3 can move to the corresponding position on the horizontal plane; After the CCD camera 4 is moved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com