Machining and positioning device for fin-reinforced heat exchange tube and machining and positioning method therefor

A technology of positioning device and heat exchange tube, which is used in precision positioning equipment, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of high price, low production efficiency and cannot meet mass production, etc. Accurate, responsive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

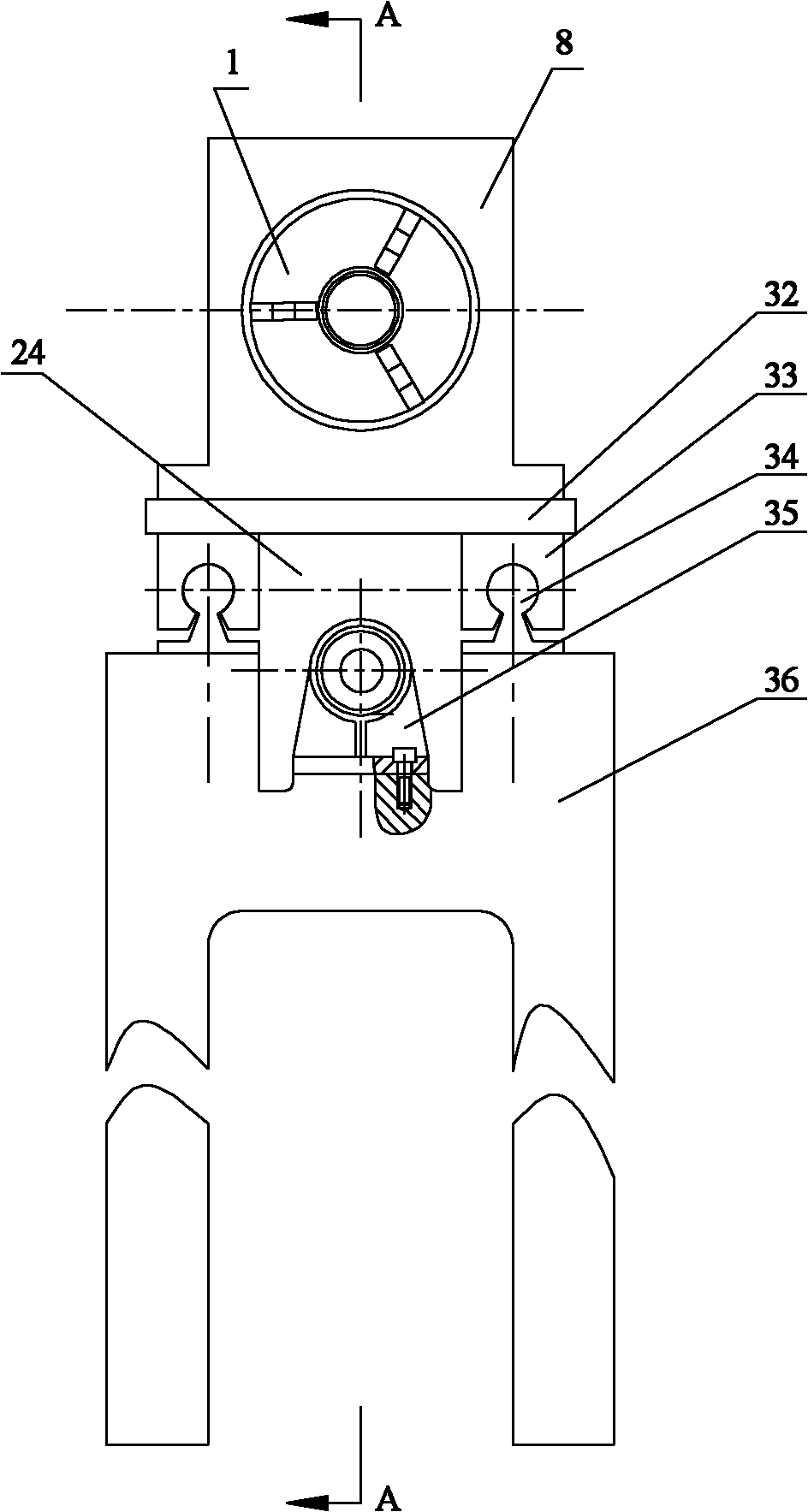

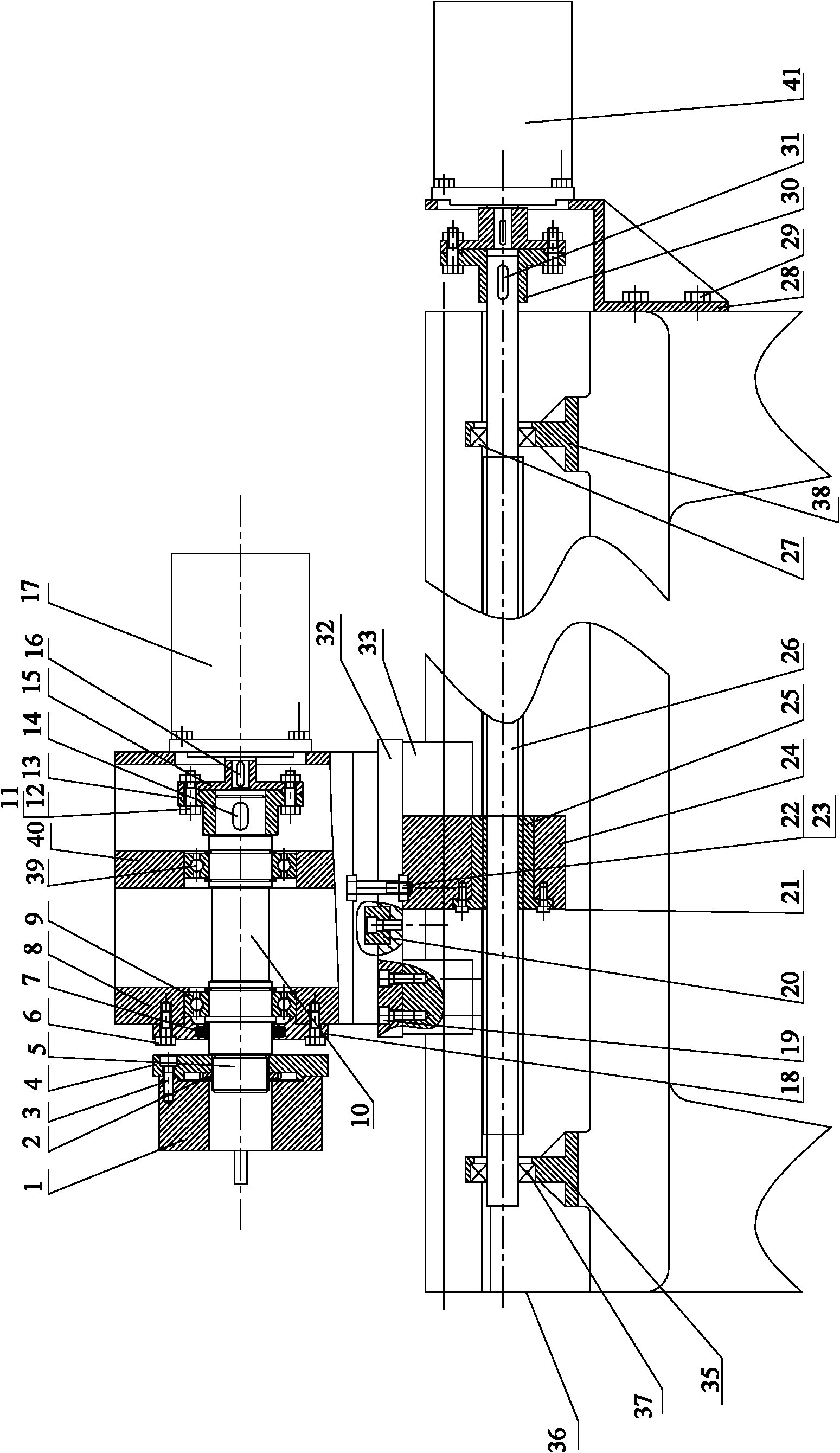

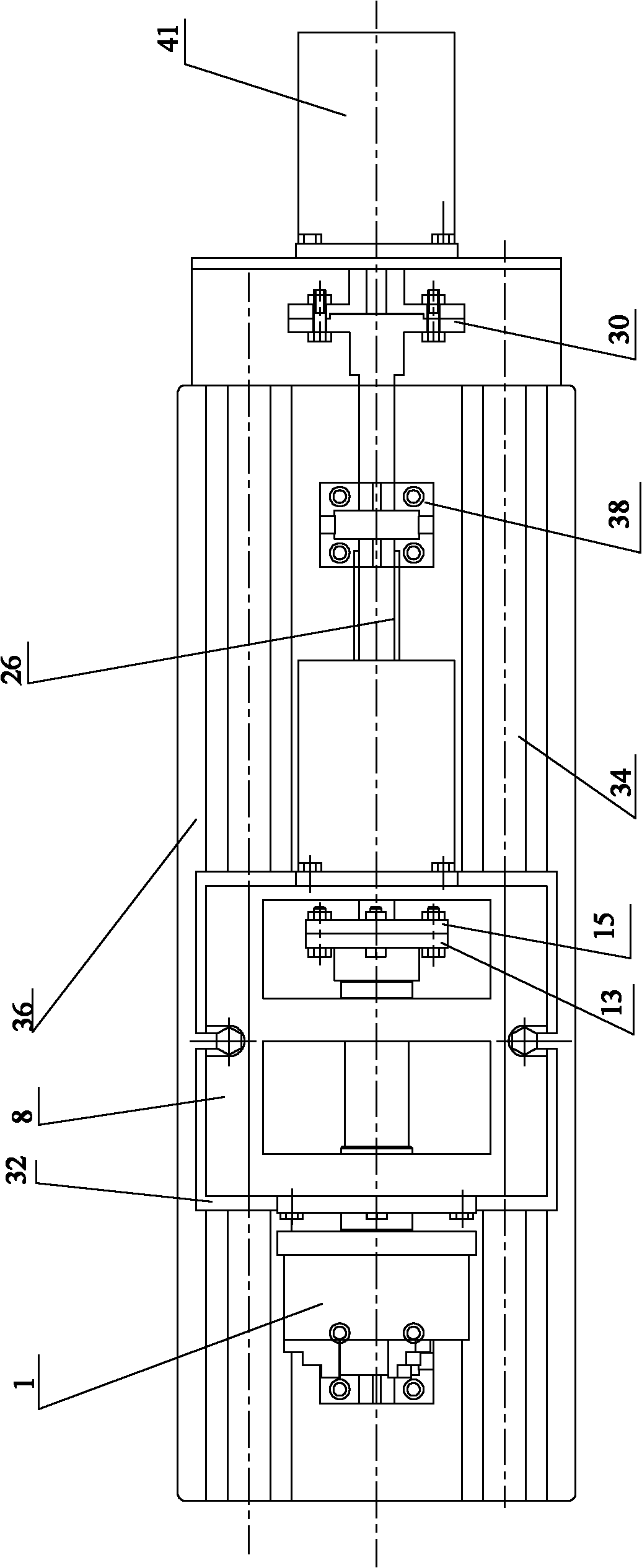

[0033] Figure 1 ~ Figure 3 Shows the specific structural schematic diagram of this embodiment, such as figure 1 As shown, the processing and positioning device for strengthening warped fin heat exchange tubes includes a box body 8, a rotating mechanism, a clamping mechanism, a distance fixing mechanism, a base plate 32 and a bed 36, such as figure 2 As shown, the bottom of the box body 8 is fixed on the base plate 32 by bolts 20, the clamping mechanism is placed at the front end of the box body 8, the rotating mechanism is placed in the box body 8, and extends out of the box body 8 to connect with the clamping mechanism ; The distance mechanism and the bed 36 are both arranged under the base plate 32, and the distance mechanism is connected with the distance mechanism and the bed 36 respectively.

[0034] Such as figure 2 As shown, the box body 8 is provided with a middle partition 40 that divides the box body into two cavities, and the front side wall of the box body 8 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com